Etchant solution for Al-4.5Mg-Zr-Si-Ce alloy

An al-4.5mg-zr-si-ce, corrosion solution technology, applied in the field of corrosion solutions, can solve the problems of time-consuming and increase production costs, and achieve the effects of clear display, cost saving, and short corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] A kind of Al-4.5Mg-Zr-Si-Ce alloy corrosion solution, take mixed acid as raw material, adopt conventional solution preparation method to prepare, in 90ml of distilled water, successively add 2.6ml of nitric acid, 4.4ml of hydrochloric acid and 3ml of hydrofluoric acid, and then stir evenly with a glass rod.

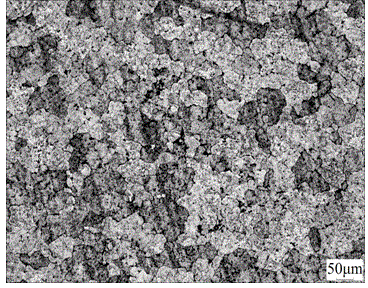

[0015] The corrosion solution prepared by the above steps is used to corrode the Al-4.5Mg-Zr-Si-Ce alloy, the specific effect is shown in figure 1 , it can be seen that the effect of the Al-4.5Mg-Zr-Si-Ce alloy corrosion solution of the present invention is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com