Automatic cleaning device for ink scraping blade of gravure printing machine and cleaning method thereof

An automatic cleaning and gravure printing machine technology, which is applied to gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve problems such as uneven force, damage by cleaning people, and trailing printed matter, so as to improve work efficiency and reduce labor Strength and yield improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment, further illustrate the present invention.

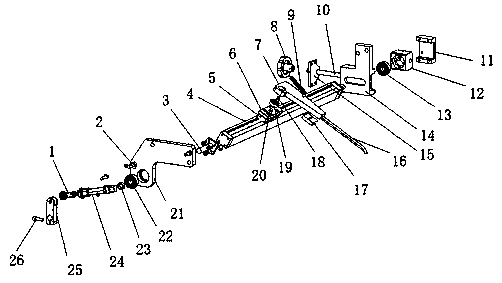

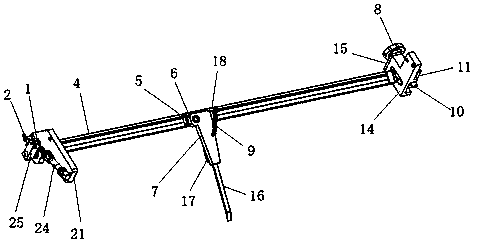

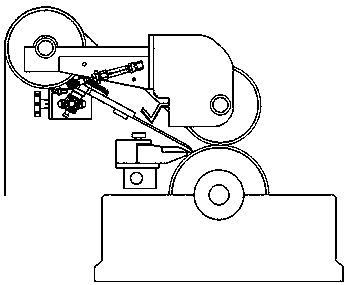

[0052] see figure 1 , figure 2 , image 3 It can be seen that a kind of gravure printing machine squeegee edge automatic cleaning device of the present invention is made up of cylinder block 4, cylinder slider 5, strip 16 and shaft end cylinder 24; The block 5 moves along the horizontal direction of the cylinder block 4, and the cylinder slider 5 is connected with a fixed pick strip 16, which is obliquely arranged above the scraper device, and one end of the root of the pick strip 16 is connected with the cylinder slider 5, and the other end of the pick strip 16 It is the rejecting end, and the rejecting end is positioned at the top of the knife edge of the scraper of printing roller; The right end of cylinder block 4 is connected with cylinder shaft seat 12 by bearing 13, and the left end of cylinder block 4 is provided with cylinder rotating shaft 3, and cylinder rotating shaft 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com