Sharpening system having multiple abrasive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

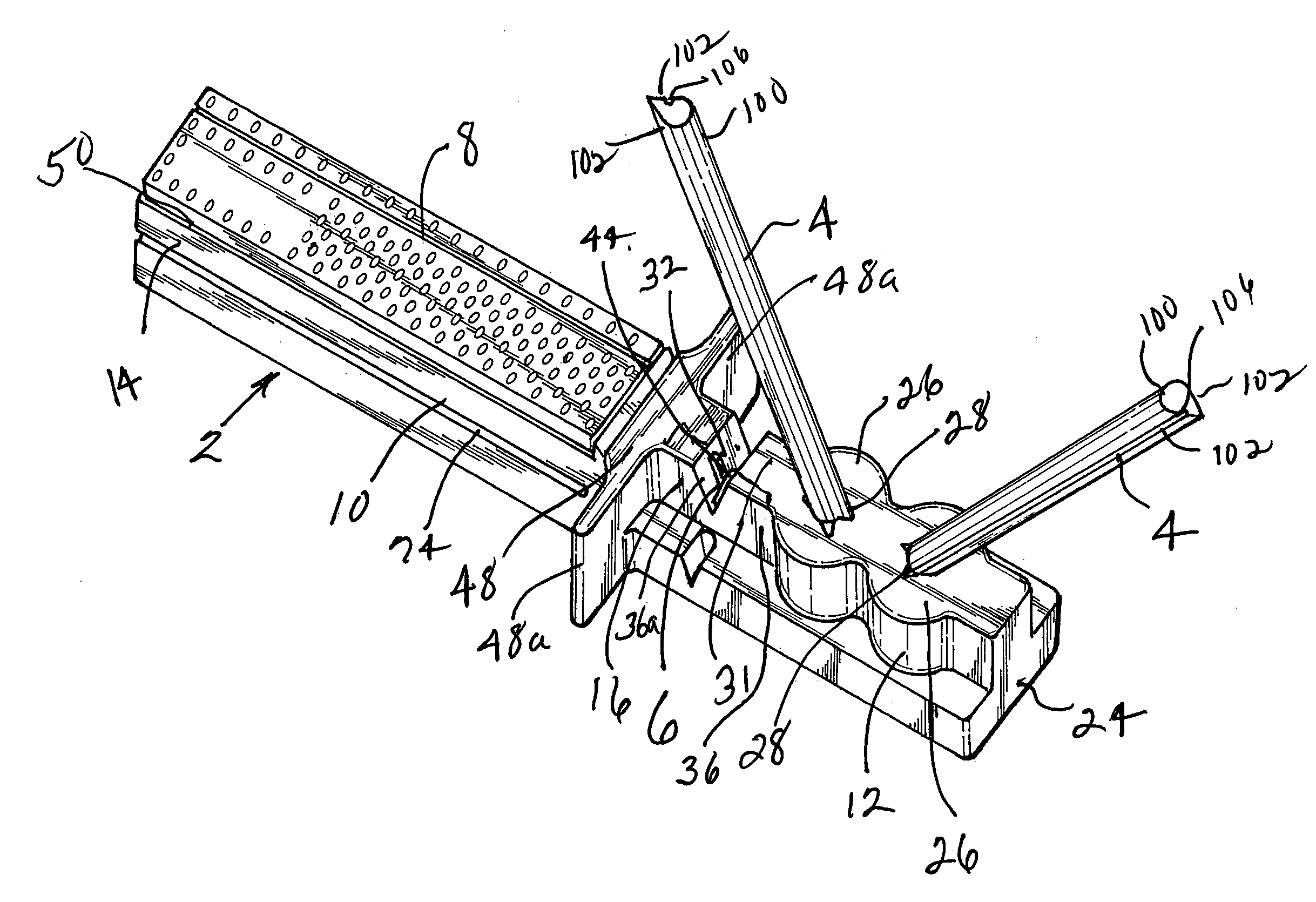

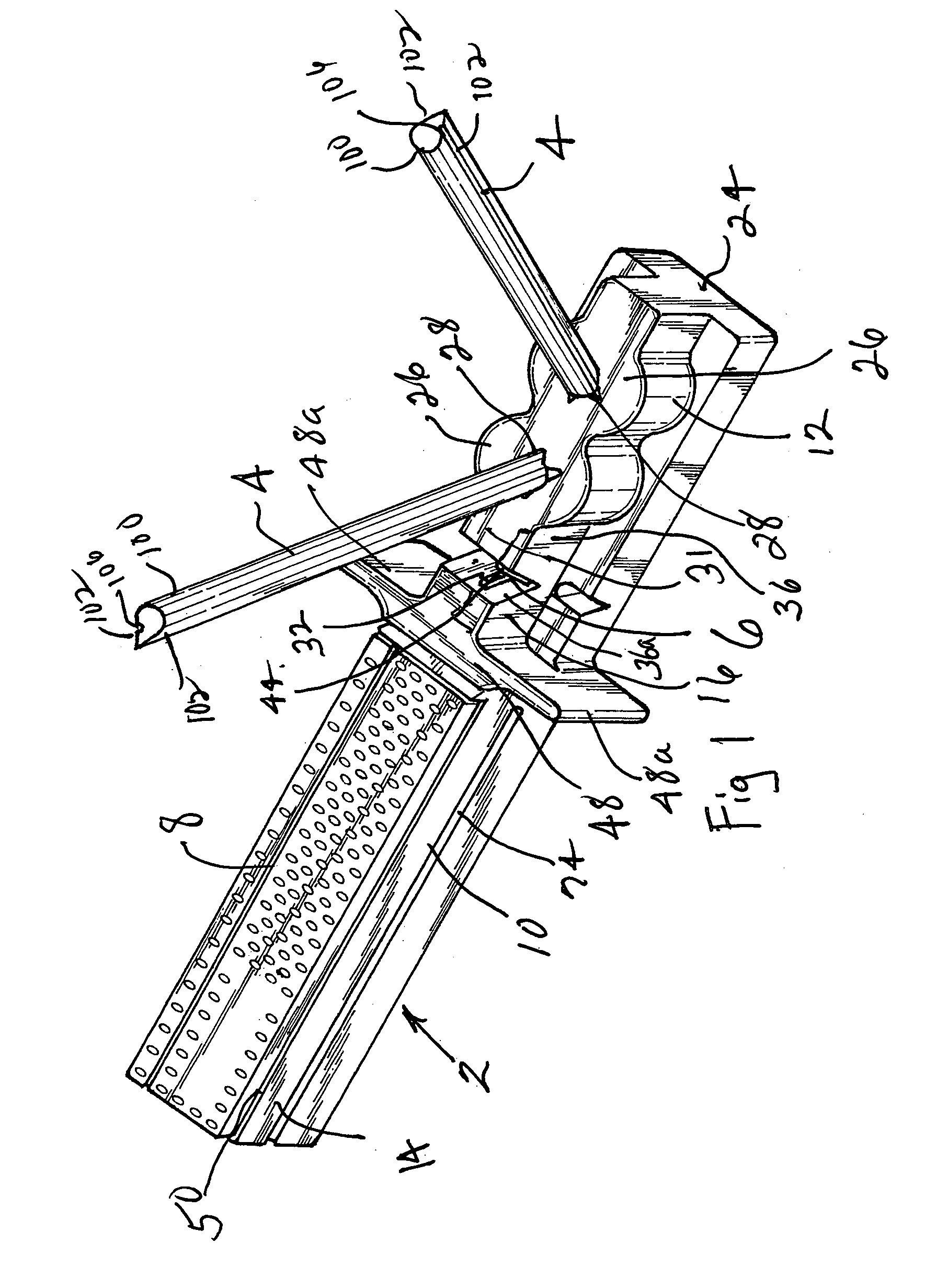

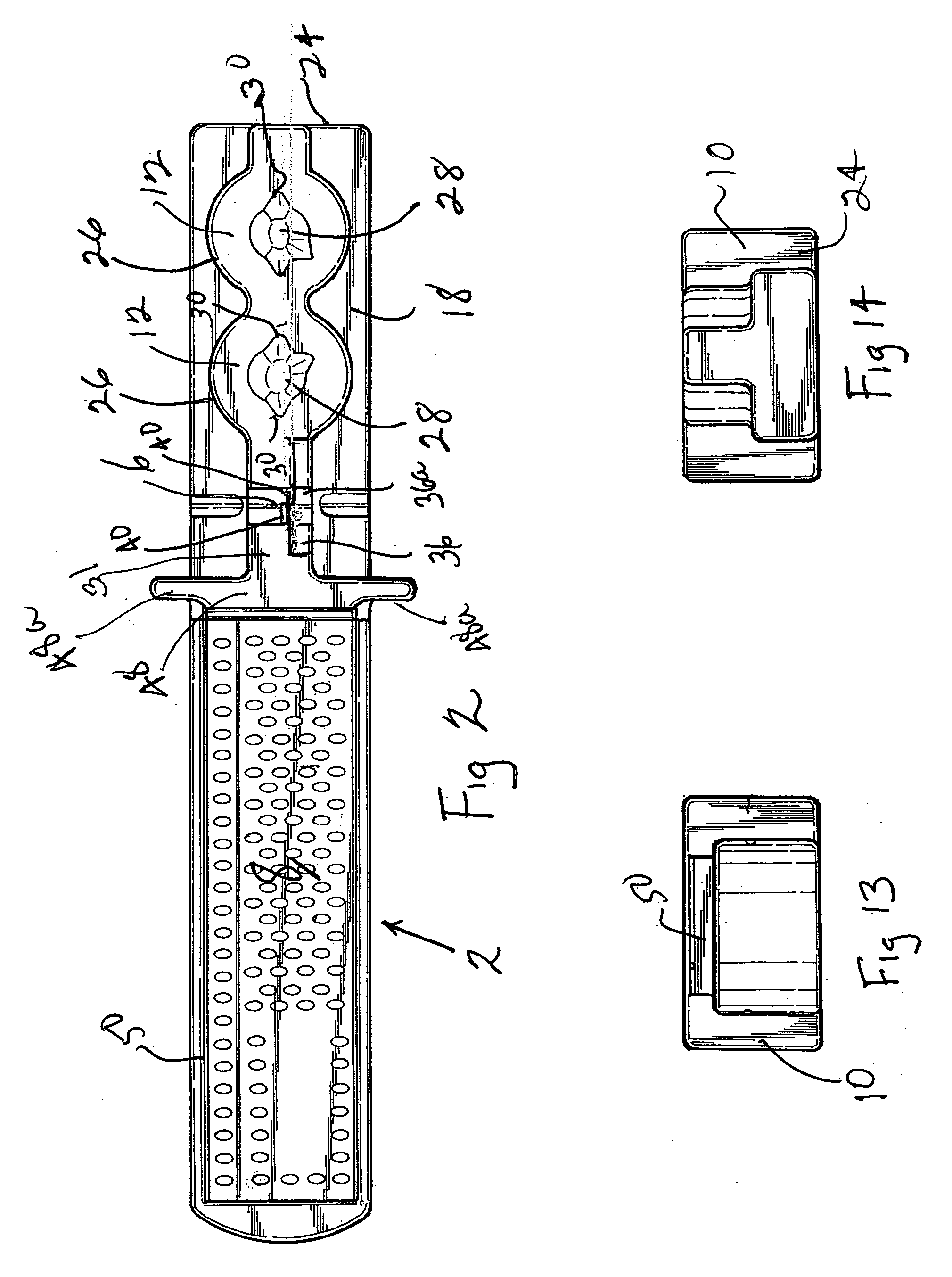

[0023] Referring now to FIGS. 1 there is illustrated the abrasive sharpening system of the invention, generally designated by reference numeral 2. In FIG. 1 sharpening system 2 includes three sharpening stations formed by a pair of angularly oriented upright rods 4, a carbide sharpener station 6, and a flat abrasive stone 8, all of which will be described in detail later. Each of the rods 4, carbide sharpening station 6, and flat stone 8 are supported on a base 10 which is formed of a durable plastic material and the like.

[0024] Referring to FIGS. 1-3 and 13, base 10 possesses an upper rod support portion 12 for supporting abrasive rods 4 and an opposite upper portion 14FIGS. 1 and 3) for supporting and storing flat abrasive stone 8. The carbide sharpener 6 is positioned in a narrowed upper portion 16 of base 10 intermediate of upper portions 12 and 14. Both support portion 12 and upper portion 16 are carried on the top of a lower base section 18 having a rectangular configuration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com