Negative pressure formation method and battery

A chemical formation method and negative pressure technology, which are applied in the field of negative pressure chemical formation methods and batteries to achieve the effects of reducing liquid loss, reducing formation time, and accelerating formation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

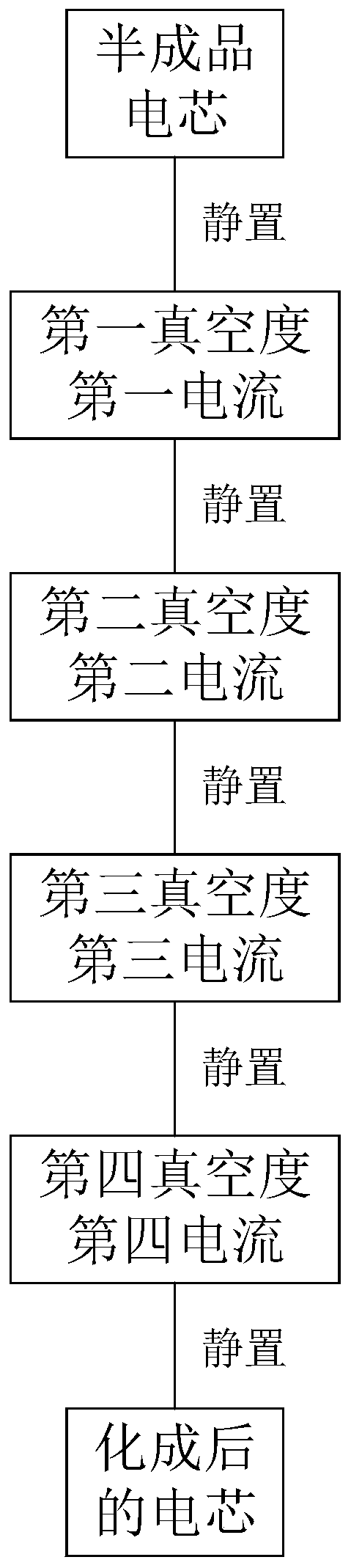

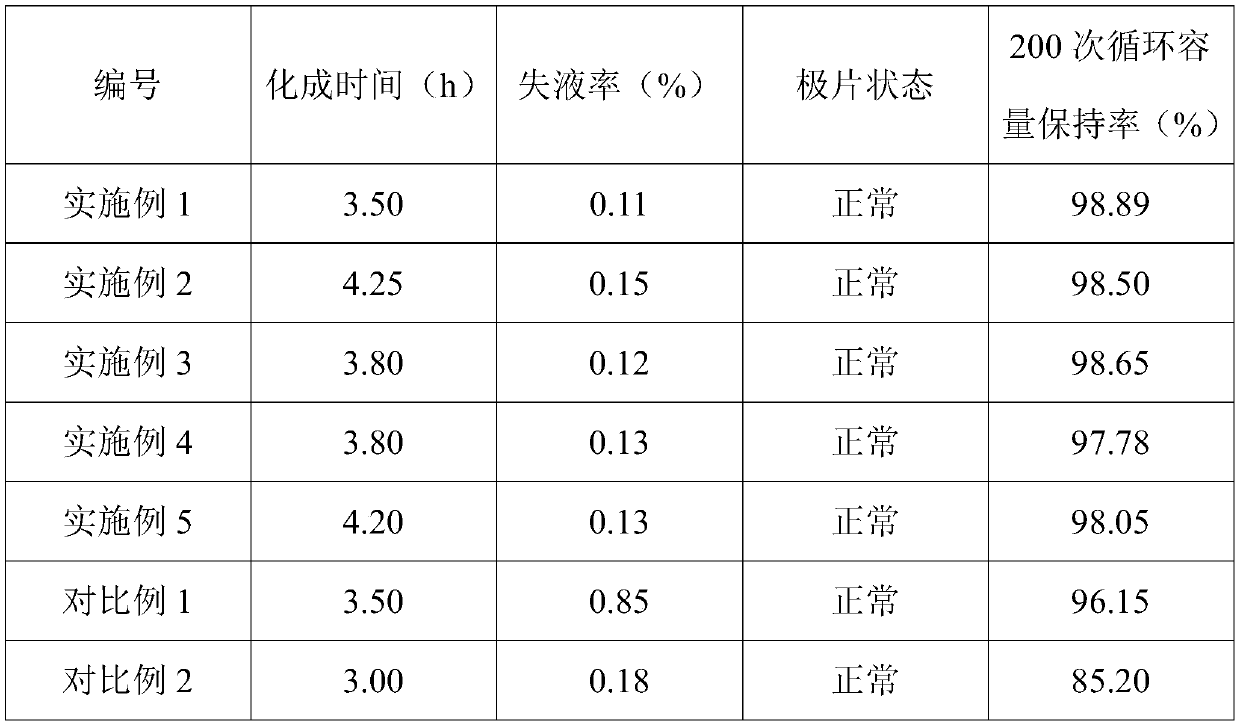

[0075] The present embodiment carries out negative pressure formation according to the following method:

[0076] (1) At the formation temperature of 45°C, let the semi-finished cell stand for 15 minutes, vacuumize the semi-finished cell to a vacuum of -90KPa, keep the vacuum constant, and charge it to 3V with a constant current of 0.05C ;

[0077] (2) Stand still for 15 minutes and reduce the vacuum degree to -70KPa, keep the vacuum degree constant, and charge it to 3.4V with a constant current of 0.1C;

[0078] (3) Stand still for 15 minutes and reduce the vacuum degree to -50KPa, keep the vacuum degree constant, and charge it to 3.8V with a constant current of 0.3C;

[0079] (4) Stand still for 15 minutes and reduce the vacuum degree to -25KPa, keep the vacuum degree constant, charge with a constant current of 0.5C to 4V, and then change to charge with a constant voltage of 4V until the current reaches the cut-off current of 0.05C, Stop charging, let it stand for 15 minut...

Embodiment 2

[0084] The present embodiment carries out negative pressure formation according to the following method:

[0085] (1) At the formation temperature of 90°C, let the semi-finished cell stand for 1 min, vacuumize the semi-finished cell to a vacuum degree of -80KPa, keep the vacuum constant, and charge it with a constant current of 0.03C to 2.8 V;

[0086] (2) Stand for 1min and reduce the vacuum degree to -60KPa, keep the vacuum degree constant, and charge to 3.0V with a constant current of 0.1C;

[0087] (3) Stand still for 1min and reduce the vacuum degree to -40KPa, keep the vacuum degree constant, and charge to 3.5V with a constant current of 0.2C;

[0088] (4) Stand still for 1min and reduce the vacuum degree to -10KPa, keep the vacuum degree constant, charge with a constant current of 0.3C to 3.7V, and then change to constant voltage charge with this voltage until the current reaches the cut-off current of 0.04 C, stop charging, let it stand for 1min, and get the battery ...

Embodiment 3

[0092] The present embodiment carries out negative pressure formation according to the following method:

[0093] (1) At the formation temperature of 40°C, let the semi-finished cell stand for 30 minutes, vacuumize the semi-finished cell to a vacuum degree of -100KPa, keep the vacuum constant, and charge it with a constant current of 0.07C to 3.2 V;

[0094](2) Stand still for 30 minutes and reduce the vacuum degree to -80KPa, keep the vacuum degree constant, and charge it to 3.7V with a constant current of 0.3C;

[0095] (3) Stand still for 30 minutes and reduce the vacuum degree to -60KPa, keep the vacuum degree constant, and charge it with a constant current of 0.5C to 4.0V;

[0096] (4) Stand still for 30 minutes and reduce the vacuum degree to -40KPa, keep the vacuum degree constant, charge with a constant current of 1.0C to 4.3V, and then change to constant voltage charge with this voltage until the current reaches a cut-off current of 0.06 C, stop charging, let it sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com