Direct formic acid fuel cell with vanadium sulfate oxide homogeneous assisted catalysis

A formic acid fuel cell and co-catalyst technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problem of reducing the loading of the main catalyst, and achieve the effect of avoiding the dehydration reaction of formic acid and avoiding CO poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

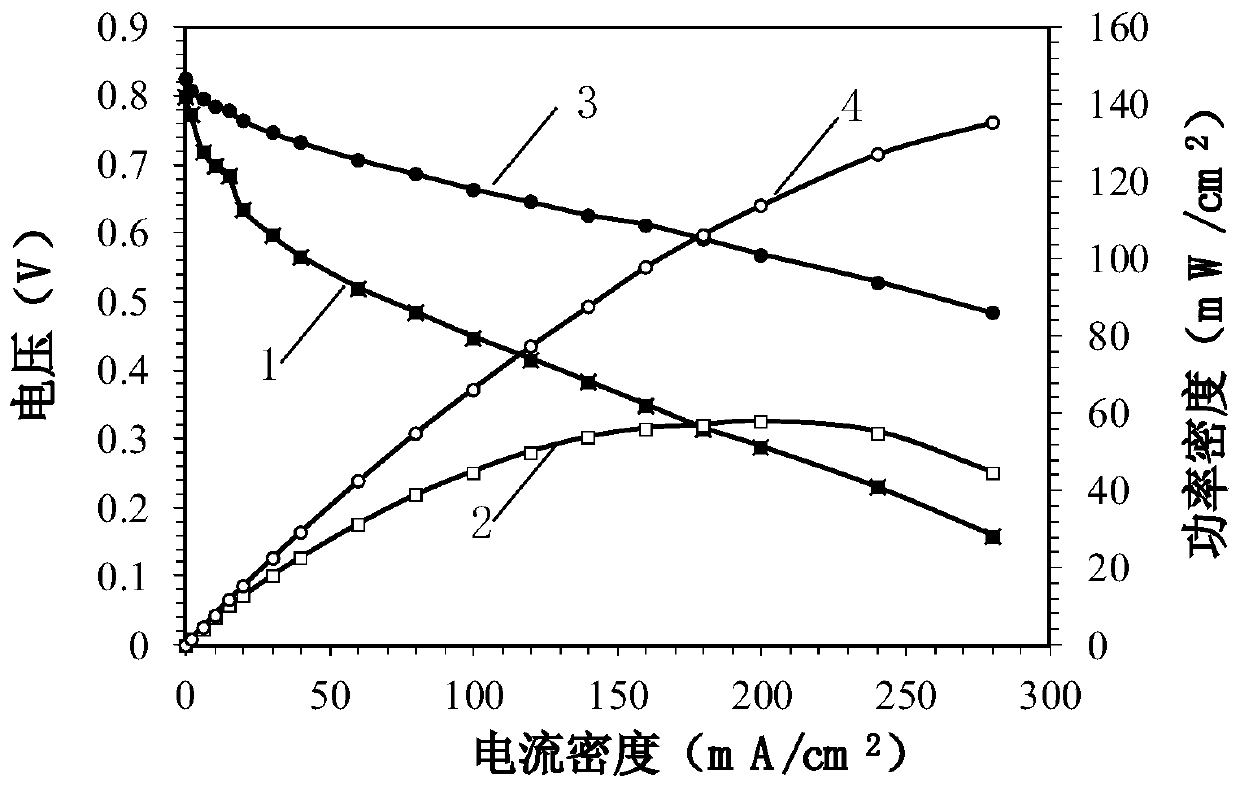

Image

Examples

Embodiment 1

[0054] Example 1: Preparation of carbon-supported Pd catalyst

[0055] 10g glucose monohydrate and 10g urea (glucose to urea mass ratio 1:1) were dissolved in 20mL deionized water to obtain glucose urea solution; ) was dissolved in 443.4mL deionized water, then added to the glucose urea solution, and 10wt% hydrochloric acid was added dropwise to keep the pH value at a constant value; placed in a water bath at 85°C, and fully stirred. After 45 minutes of polymerization reaction, a commercially available carbon carrier XC-72 was added at a mass ratio of carbon carrier to palladium chloride of 90:10, stirred for 1 hour to form a suspension, and spray-dried to obtain a precursor. The precursor was placed in a tube furnace under N 2 Under the protection of the atmosphere, at 10°C min -1 Raise the temperature to 160°C for 2 hours at the same rate to fully polymerize the prepolymer, and then raise the temperature to 900°C for 2 hours at the same rate to complete the carbonization p...

Embodiment 2

[0056] Embodiment two: anion exchange resin treatment

[0057] Commercially available anion exchange resins are usually ion exchange resins containing chloride ions, Amberlite IRA402 was acid-boiled in 10wt% formic acid solution for 2 hours to realize ion exchange and obtain Amberlite containing formate ions IRA402, an anion exchange resin for direct formic acid fuel cell anode preparation obtained by washing with deionized water and drying: anion exchange resin treated with formic acid.

Embodiment 3

[0058] Embodiment three: anion exchange resin suspension preparation

[0059] 5g PBI is dissolved in 90g NMP, adds the formic acid treatment anion exchange resin that obtains in 5g embodiment two, in ZrO 2 Mill in a ball mill tank for 2 hours to obtain an anion exchange resin suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com