Additive used for metal-air cell, room temperature liquid oxygen ion conductor electrolyte, and metal-air cell

A metal-air battery, metal-air technology, applied in the field of electrochemical energy storage, can solve the problems of electrode passivation hindering reaction, limited number of active reaction sites, and limiting the application of metal-air batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Unless otherwise specified, the reagents in the examples of the present invention can be purchased through commercial channels.

[0073] Analysis method is as follows in the embodiment of the present invention:

[0074] The battery discharge test was performed using Neware battery testing system (Neware Co., China).

Embodiment approach

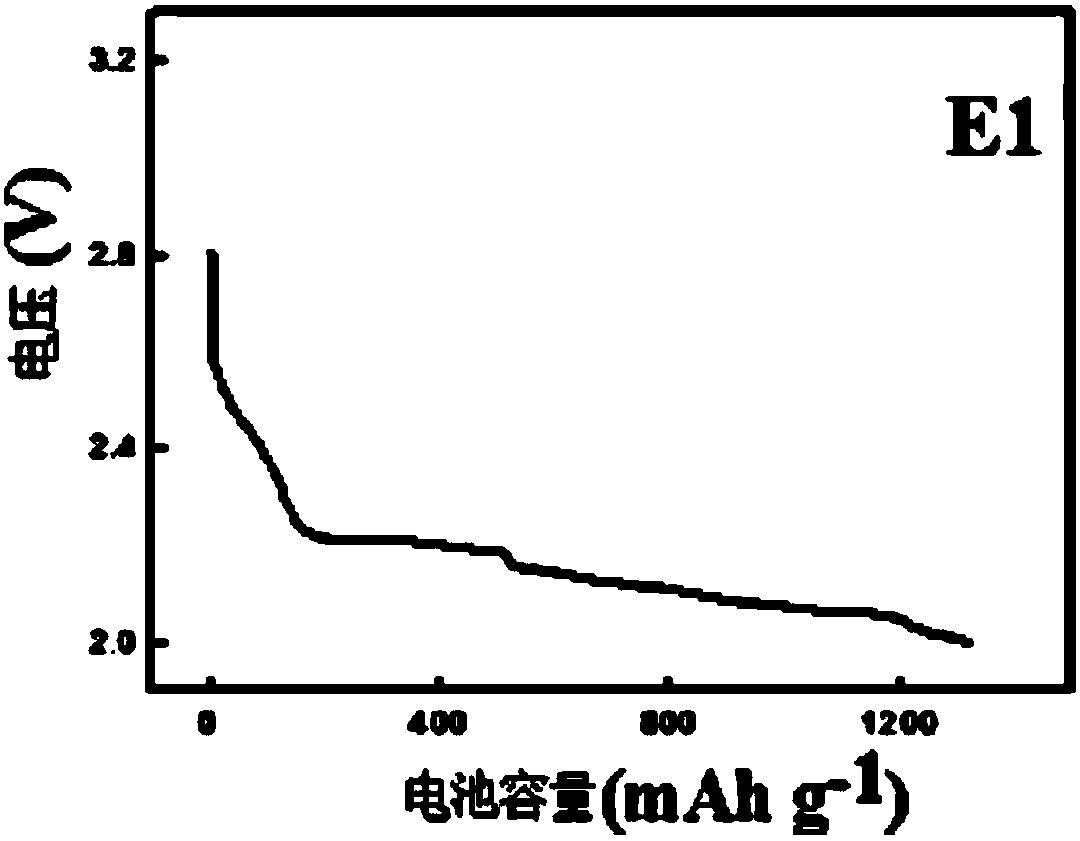

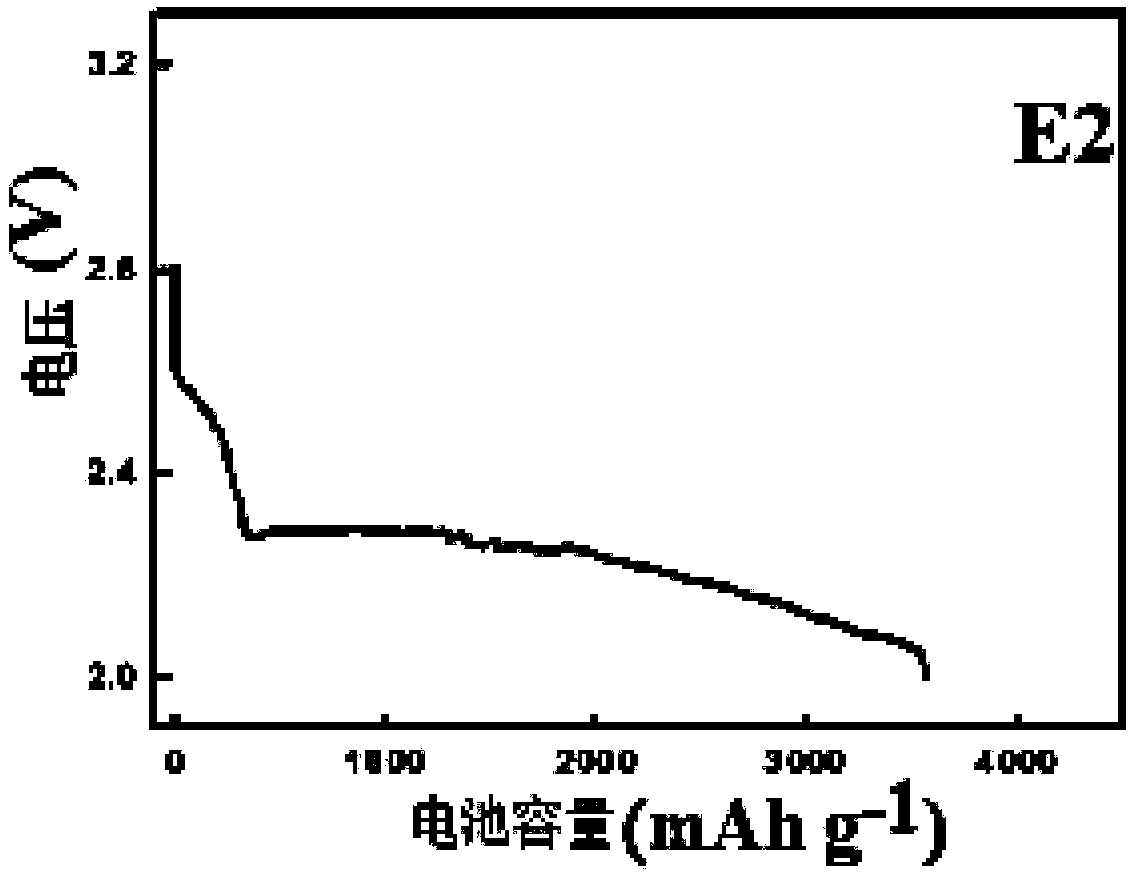

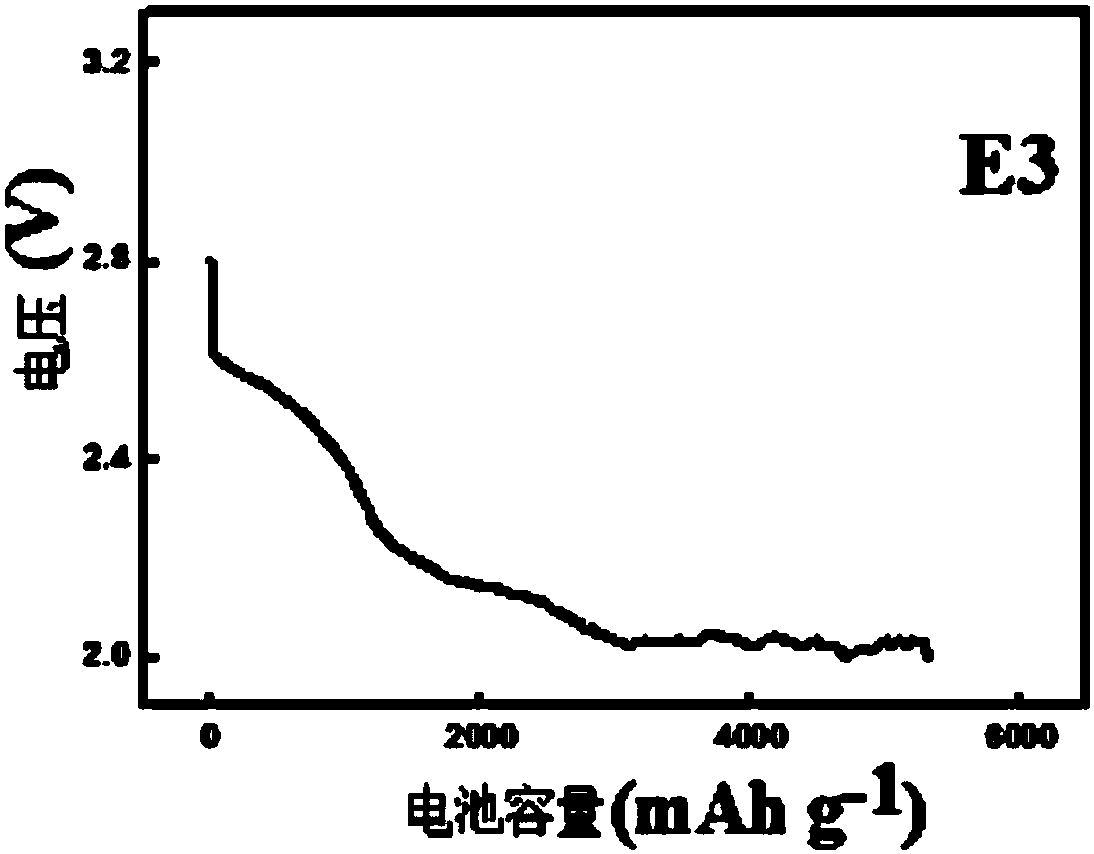

[0075] According to one embodiment of the present invention, the battery discharge test includes the following steps: standing still for 8 hours, performing a constant current discharge test with 2V as the discharge cut-off voltage and a current density of 100 mA / g (calculated based on the positive carbon load).

[0076] According to one embodiment of the present invention, a method for preparing a metal-air battery:

[0077] Gained electrolytic solution is dripped in the Whatman GF / D glass fiber diaphragm by the amount of 140 microliters, and pack CR2032 type button cell case together with air positive pole piece and a pair of metal negative pole pieces, put into protective atmosphere (N 2 -O 2 , 78:22, v / v) were assembled in a glove box, and a metal-air battery was obtained after standing for 8 hours.

Embodiment 1

[0078] Example 1 Lithium-air battery containing room temperature liquid oxygen ion conductor electrolyte 1

[0079] Under a dry atmosphere, use 1,2-(1,1,2,2-tetrafluoroethoxy)ethane as an ether solvent, and use N-methyl, propylpiperidine bistrifluoromethanesulfonimide Salt (PP13TFSI) is used as an ionic liquid salt, which is dissolved in an ether solvent to prepare an additive for a metal-air battery with an ionic liquid salt concentration of 0.1mol / L, as a liquid oxygen ion conductor electrolyte at room temperature.

[0080]The Ketjen black carbon loaded with nickel foam at 0.1 mg / cm2 is the air positive pole piece; the metal negative pole is lithium. A lithium-air battery 1 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com