Cylinder type lithium ion battery cell and making method thereof

A technology for lithium-ion batteries and manufacturing methods, which is applied in the field of batteries and cylindrical lithium-ion battery cells, can solve the problems of poor safety, leakage rate and high production scrap rate, and achieve low leakage rate, low production scrap rate, high energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

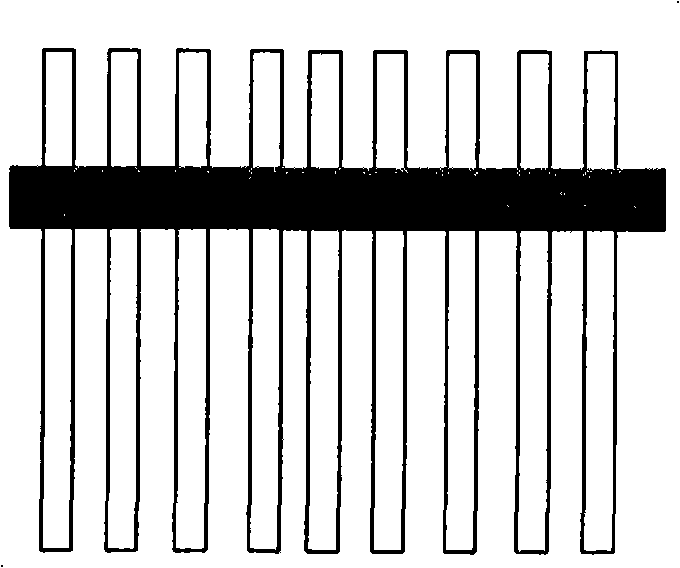

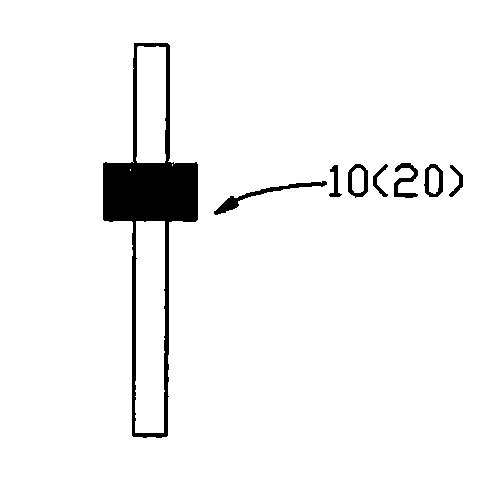

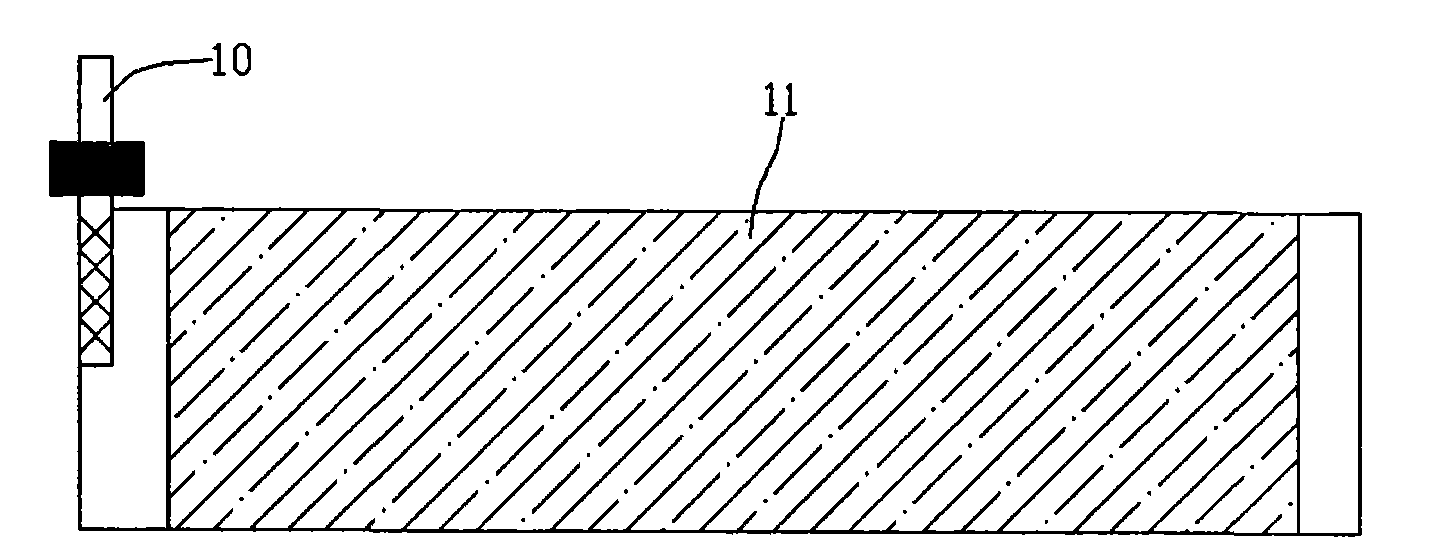

[0032] The battery cell of the present invention includes a casing, a positive pole piece and a negative pole piece, wherein the positive pole piece is composed of a positive electrode base welded with an aluminum tab, and the negative pole piece is composed of a negative pole base welded with a nickel tab, and the aluminum tab and the nickel tab are respectively It is an aluminum sheet and a nickel sheet compounded with ear glue on both sides; the positive electrode sheet, the negative electrode sheet and the diaphragm are wound together to form a core, and the outer shell is an aluminum-plastic composite film with double arc grooves, and the core is located on the double circle. inside the arc groove.

[0033] In the following, a cylindrical lithium-ion battery cell with a diameter of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com