Pole piece and preparation method thereof, battery cell and battery

A pole piece and cell technology, which is applied in the field of pole piece and its preparation, battery cell and battery, can solve the problems of micro-short circuit of positive and negative pole pieces, increase mass energy density, avoid internal short circuit, and reduce specific gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] 2. Preparation method of pole piece

[0045] A second aspect of the present invention provides a method for preparing a pole piece, comprising the following steps:

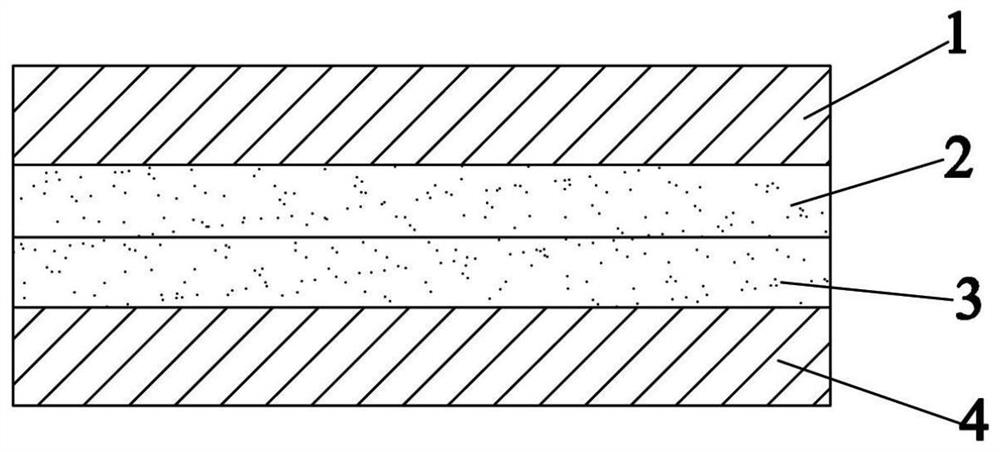

[0046] preparing a first self-supporting layer and a second self-supporting layer;

[0047] Depositing a first conductive metal layer on one side of the first self-supporting layer, and depositing a second conductive metal layer on one side of the second self-supporting layer;

[0048] The first metal conductive layer and the second metal conductive layer are pasted together and rolled to form pole pieces.

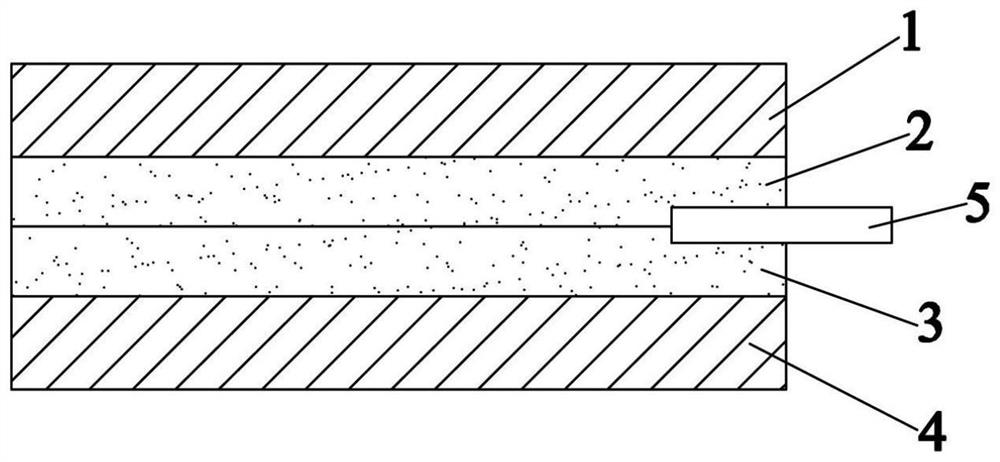

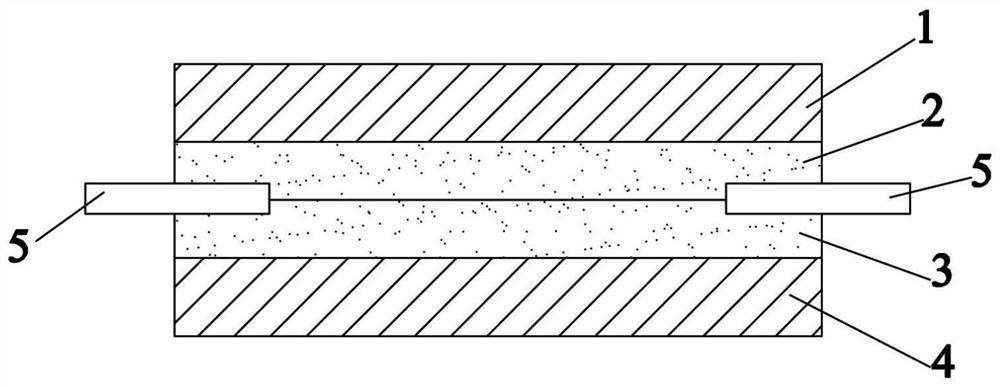

[0049] In some embodiments, before the first metal conductive layer and the second metal conductive layer are laminated, a metal foil strip is placed between the two, so that at least a part of the metal foil strip is exposed to the first metal conductive layer and / or The second metal conductive layer is rolled to form a pole piece. The metal foil strip can be arranged on one edge of the first metal ...

Embodiment 1

[0059] Preparation of positive electrode sheet:

[0060] Mix NCM523 powder, SP conductive carbon black, VGCF carbon nanofibers and PTFE in a ratio of 92:3:3:2, then stir and mix evenly at 350°C under inert gas protection to form a block, and place the block in Press on a heating plate at 350°C to a thickness of 55 μm to make the first self-supporting layer of the positive electrode and the second self-supporting layer of the positive electrode, with a weight per unit area of 17.8 mg / cm 2 ;

[0061] On one side of the first self-supporting layer of the positive electrode, the first metal conductive layer (metal aluminum layer) with a thickness of 1 μm is vacuum evaporated, and the second metal conductive layer (metal aluminum layer) with a thickness of 1 μm is vacuum evaporated on one side of the second self-supporting layer of the positive electrode. aluminum layer);

[0062] A metal foil strip (aluminum foil) is set between the first metal conductive layer and the second ...

Embodiment 2

[0068] The difference with embodiment 1 is:

[0069] Preparation of positive electrode sheet:

[0070] Mix NCM523 powder, SP conductive carbon black, VGCF carbon nanofiber and PTFE at a ratio of 92:3:3:2, dissolve in a solvent and stir evenly to form a slurry, and coat the slurry on a positive electrode current collector with a thickness of 12 μm On the aluminum foil, dry and roll to form a pole piece with a thickness of 120μm, wherein the coating amount of the slurry per unit area is 17.8mg / cm 2 .

[0071] Preparation of negative electrode sheet:

[0072] Mix artificial graphite powder, SP conductive carbon black, VGCF carbon nanofiber and PTFE in a ratio of 95:1:2:2, then stir and mix evenly at 350°C under inert gas protection conditions to form a block, and put the block Press on a heating plate at 350°C to a thickness of 51 μm to make the first self-supporting layer of the negative electrode and the second self-supporting layer of the negative electrode, with a weight p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com