Square lithium ion battery

A lithium-ion battery, square technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of waste of winding core space, decreased energy density, large thickness of a single winding core, etc., to improve the quality of energy Density, improved space utilization, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] This embodiment provides a prismatic lithium-ion battery, wherein:

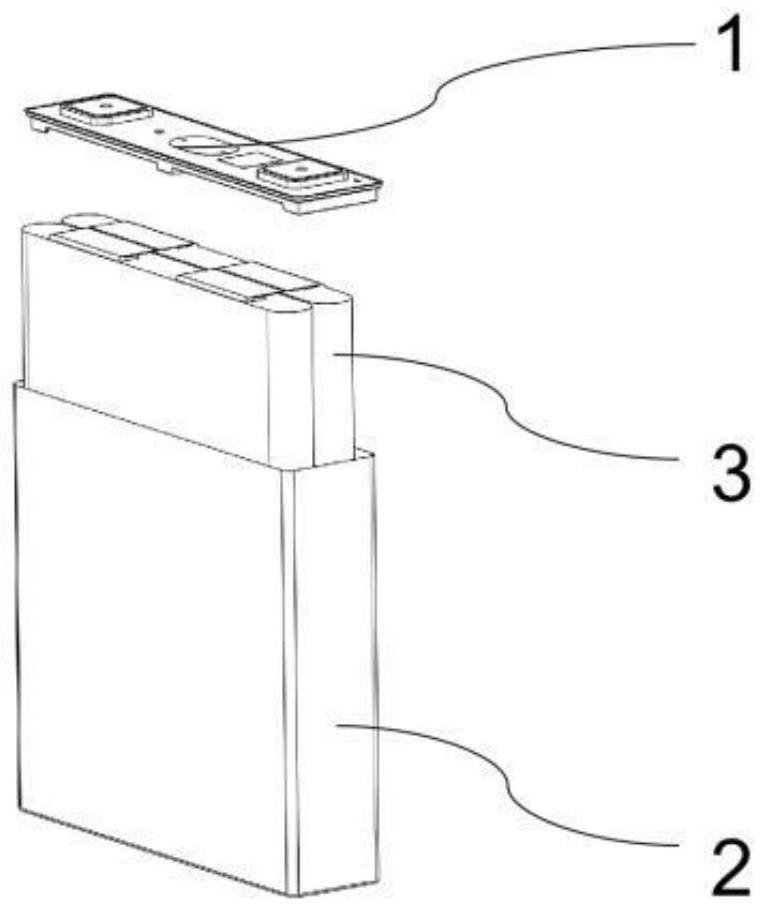

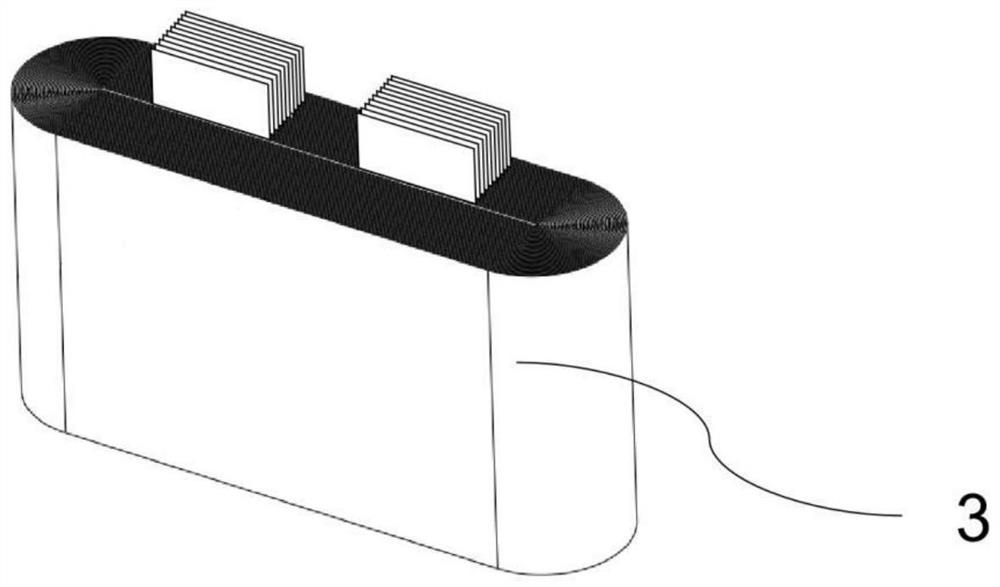

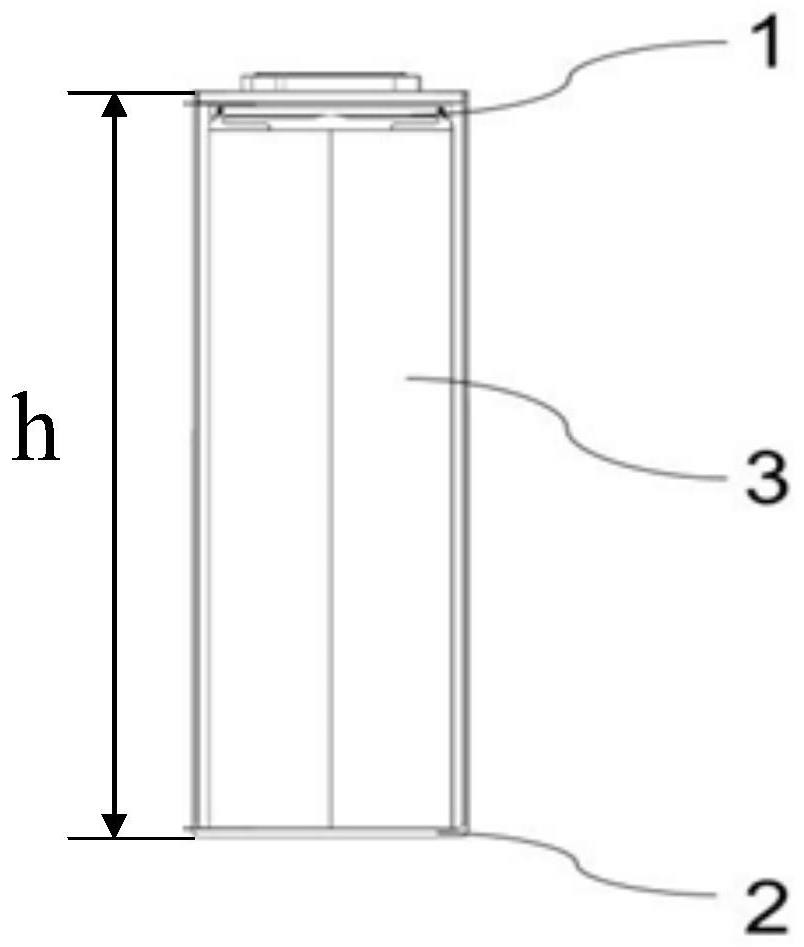

[0086] The square lithium-ion battery comprises a square casing 2 and a cover plate 1. At least one winding core 3 is arranged in the square casing 2. The winding core 3 includes a positive electrode sheet 4 and a negative electrode sheet 7 arranged on both sides of the separator. The positive electrode sheet 4 includes a positive electrode Active material coating area 5 and positive electrode uncoated area 6, negative electrode sheet 7 includes negative electrode active material coating area 8 and negative electrode uncoated area 9;

[0087] The shell size of the selected square lithium-ion battery is: 66mm*220mm*102mm, the battery size is V=1.48L; the width of the short side of the cover plate is T=66mm; the number of winding cores is n=4; single-sided positive electrodes in a single winding core The area of active material coating area 5 is 0.75m 2 , the area Sc of the positive electrode active m...

Embodiment 2

[0091] This embodiment provides a prismatic lithium-ion battery, wherein:

[0092] The square lithium-ion battery comprises a square casing 2 and a cover plate 1. At least one winding core 3 is arranged in the square casing 2. The winding core 3 includes a positive electrode sheet 4 and a negative electrode sheet 7 arranged on both sides of the separator. The positive electrode sheet 4 includes a positive electrode Active material coating area 5 and positive electrode uncoated area 6, negative electrode sheet 7 includes negative electrode active material coating area 8 and negative electrode uncoated area 9;

[0093] The shell size of the selected square lithium-ion battery is: 66mm*220mm*102mm, the battery size is V=1.48L; the width of the short side of the cover plate is T=66mm; the number of winding cores is n=4; single-sided positive electrodes in a single winding core The area of active material coating area 5 is 0.9m 2 , the area Sc of the positive electrode active ma...

Embodiment 3

[0097] This embodiment provides a prismatic lithium-ion battery, wherein:

[0098] The square lithium-ion battery comprises a square casing 2 and a cover plate 1. At least one winding core 3 is arranged in the square casing 2. The winding core 3 includes a positive electrode sheet 4 and a negative electrode sheet 7 arranged on both sides of the separator. The positive electrode sheet 4 includes a positive electrode Active material coating area 5 and positive electrode uncoated area 6, negative electrode sheet 7 includes negative electrode active material coating area 8 and negative electrode uncoated area 9;

[0099] The shell size of the selected square lithium-ion battery is: 66mm*220mm*102mm, the battery size is V=1.48L; the width of the short side of the cover plate is T=66mm; the number of winding cores is n=4; single-sided positive electrodes in a single winding core The area of active material coating area 5 is 1.0m 2 , the area Sc of the positive electrode active ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com