Current collector and application thereof

A current collector and conductive layer technology, applied in the direction of electrode carrier/current collector, structural parts, final product manufacturing, etc., can solve problems such as limiting applications, affecting the electrical performance of lithium-ion batteries, and dropping active layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The lithium ion battery of the present embodiment is obtained by the following steps:

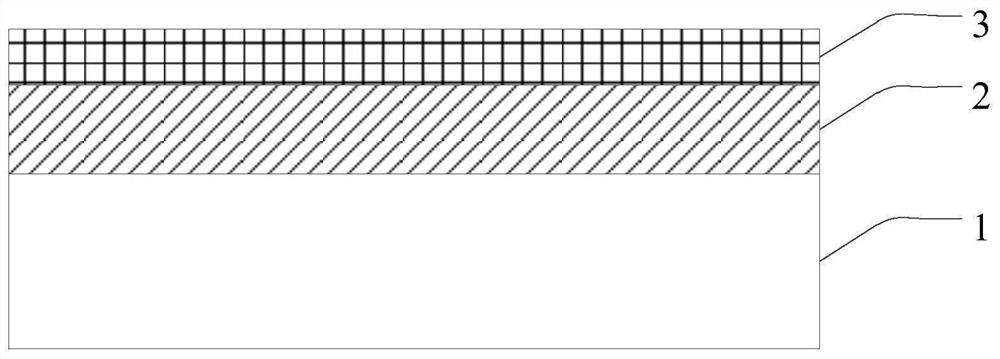

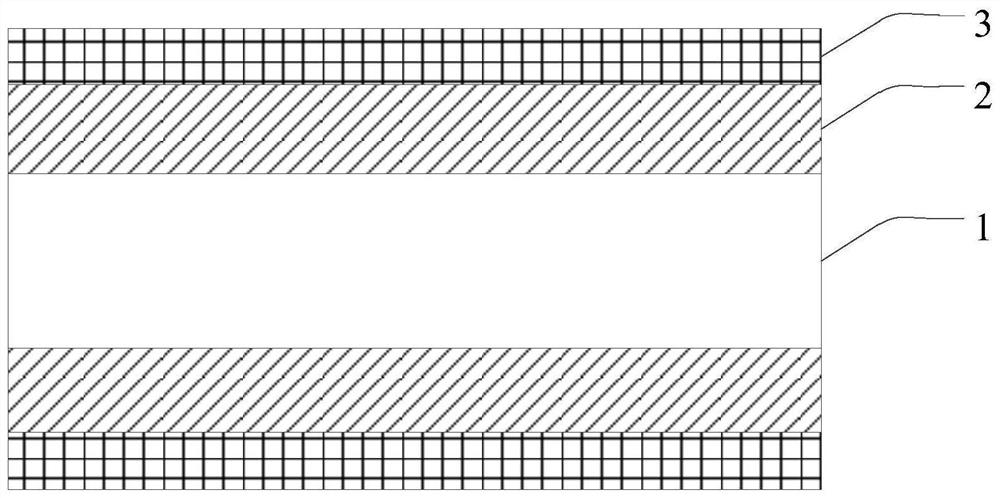

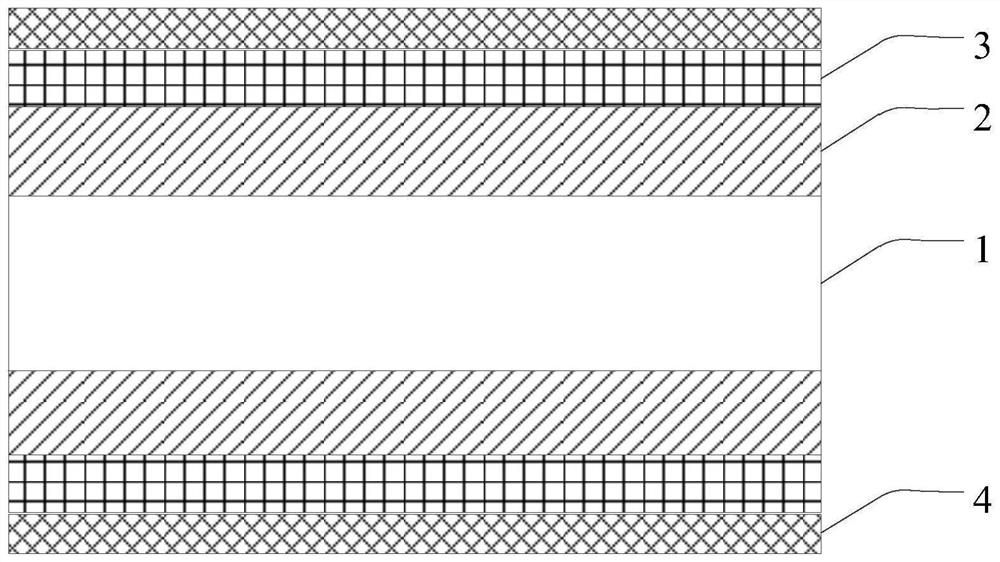

[0085] 1) Preparation of the positive electrode fluid

[0086] First in the vacuum is 2 * 10 -4 The temperature of 30 ° C is deposited in the two functional surfaces of the insulating layer under the conditions of PA, followed by a vacuum of 2 * 10. -2 The surface deposition of the second conductive layer at a temperature of 120 ° C in the condition of PA is deposited in the surface deposition of the second conductive layer in the surface of the first conductive layer.

[0087] Wherein the material of the insulating layer is polyethylene terephthalate (PET), the thickness is 6 μm, the material of the first conductive layer is aluminum, the first conductive layer has a density of 90%, and the thickness of the first conductive layer. The material of 800 nm and the second conductive layer is aluminum, and the surface roughness of the second conductive layer is 200 nm, and the thickness of t...

Embodiment 2

[0098] The preparation method of the lithium ion battery of the present embodiment is basically the same as that of Example 1, and the only difference is:

[0099] In step 2), the positive electrode active slurry is applied to the entire surface of the second conductive layer. After 6 hours of 90-130 ° C, after the roller roller pressure, the positive electrode active layer is obtained, and the partial positive electrode active layer is removed. The surface of the dielectric layer is welded to the surface of the exposed second conductive layer to obtain a positive electrode sheet.

[0100] In step 3), the negative electrode active slurry is applied to the entire surface of the negative electrode concentration fluid. After 6 hours of 90 to 130 ° C, the roller roller is pressed, and the negative electrode active layer is obtained, and the negative electrode active layer is removed. The surface of the fluid is welded to the surface of the exposed negative electrode fluid to obtain a ...

Embodiment 3

[0103] The preparation method of the lithium ion battery of the present embodiment is basically the same as that of Example 1, and the only difference is:

[0104] In step 2), the positive electrode active slurry is uniformly applied to both surfaces of the second conductive layer of the positive electrode concentration fluid, and the partial region does not apply a positive active slurry in the width direction of the second conductive layer. The region of the positive active slurry does not apply the extreme ear, and then welded to the outer ear, resulting in a positive electrode sheet.

[0105] In step 3), the negative electrode active slurry is uniformly applied to both surfaces of the copper foil, and the negative electrode active slurry is not applied in the width direction of the copper foil, and the negative electrode active slurry is not applied. Regional die cuts the ears, and then welded to the outer ear, resulting in a negative electrode.

[0106] Figure 8 A schematic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com