Gluing structure battery cell with embedded tab, fabrication method of gluing structure battery cell and lithium battery

A built-in, tab technology, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrode manufacturing, etc., can solve the problems of stack-type batteries prone to dislocation, low battery mass energy density, limiting battery power, etc. The effect of improving hardness and overall anti-vibration ability, reducing safety hazards and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention discloses a method for preparing an adhesive structure electric core with embedded tabs, which comprises the following preparation steps:

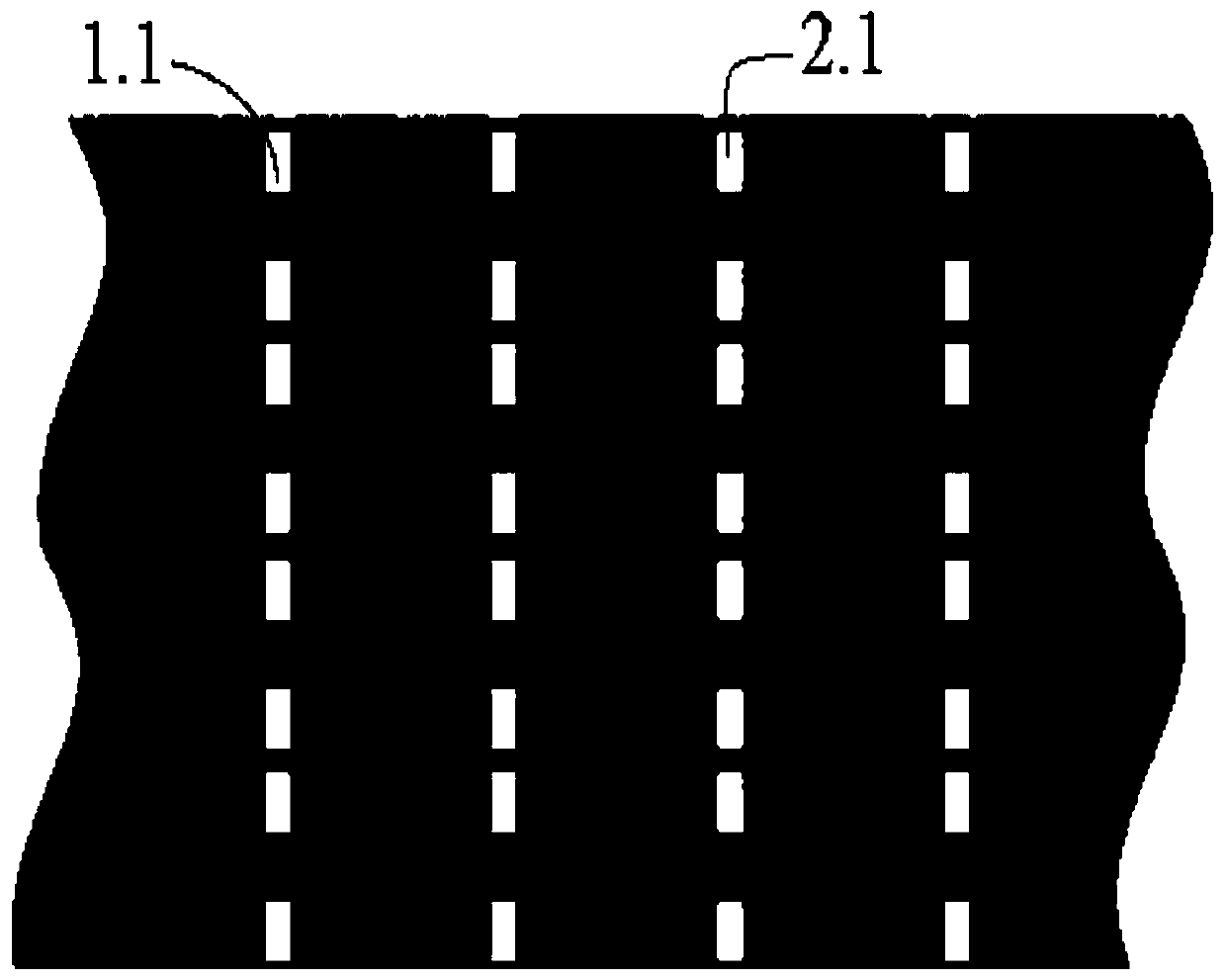

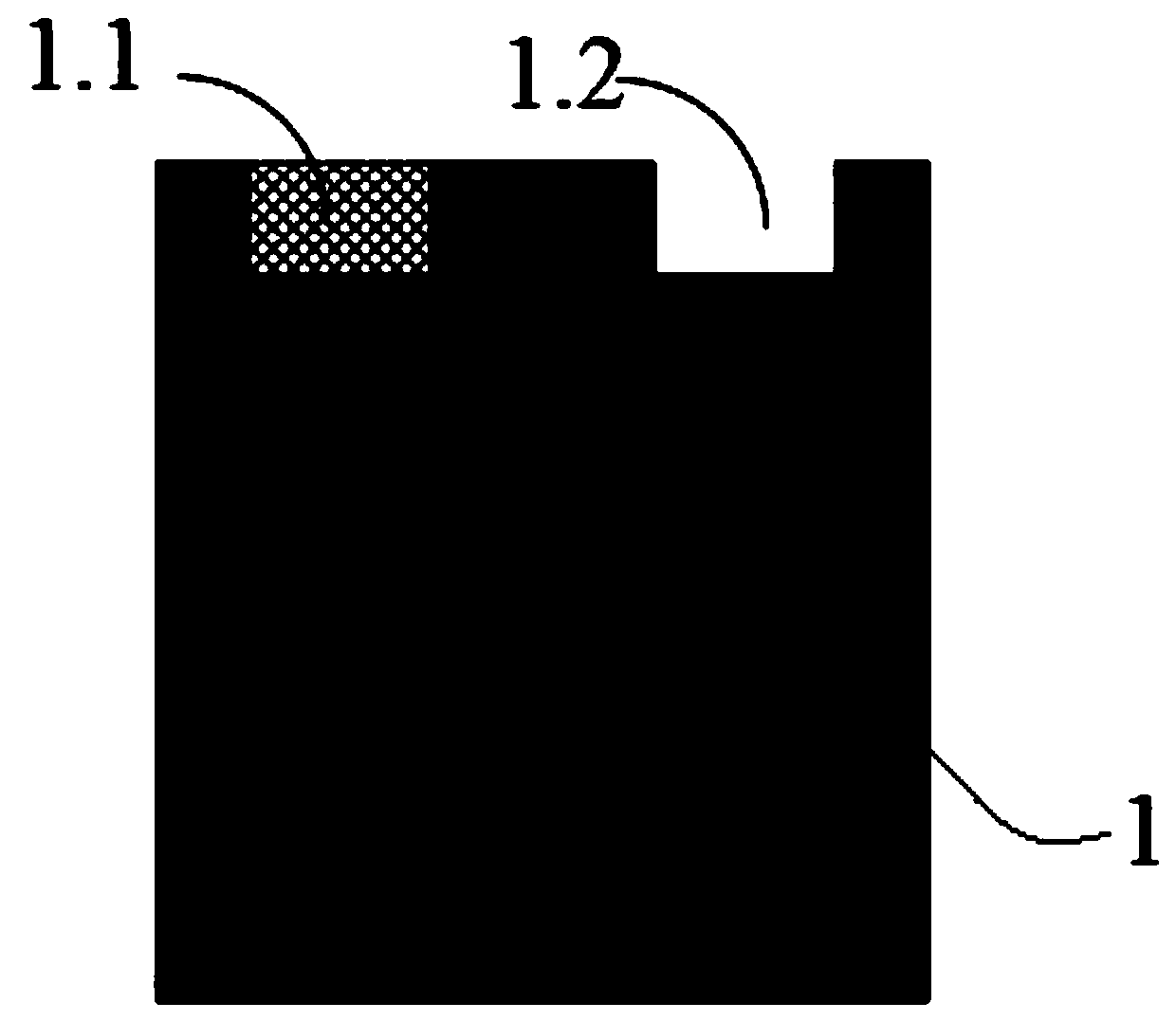

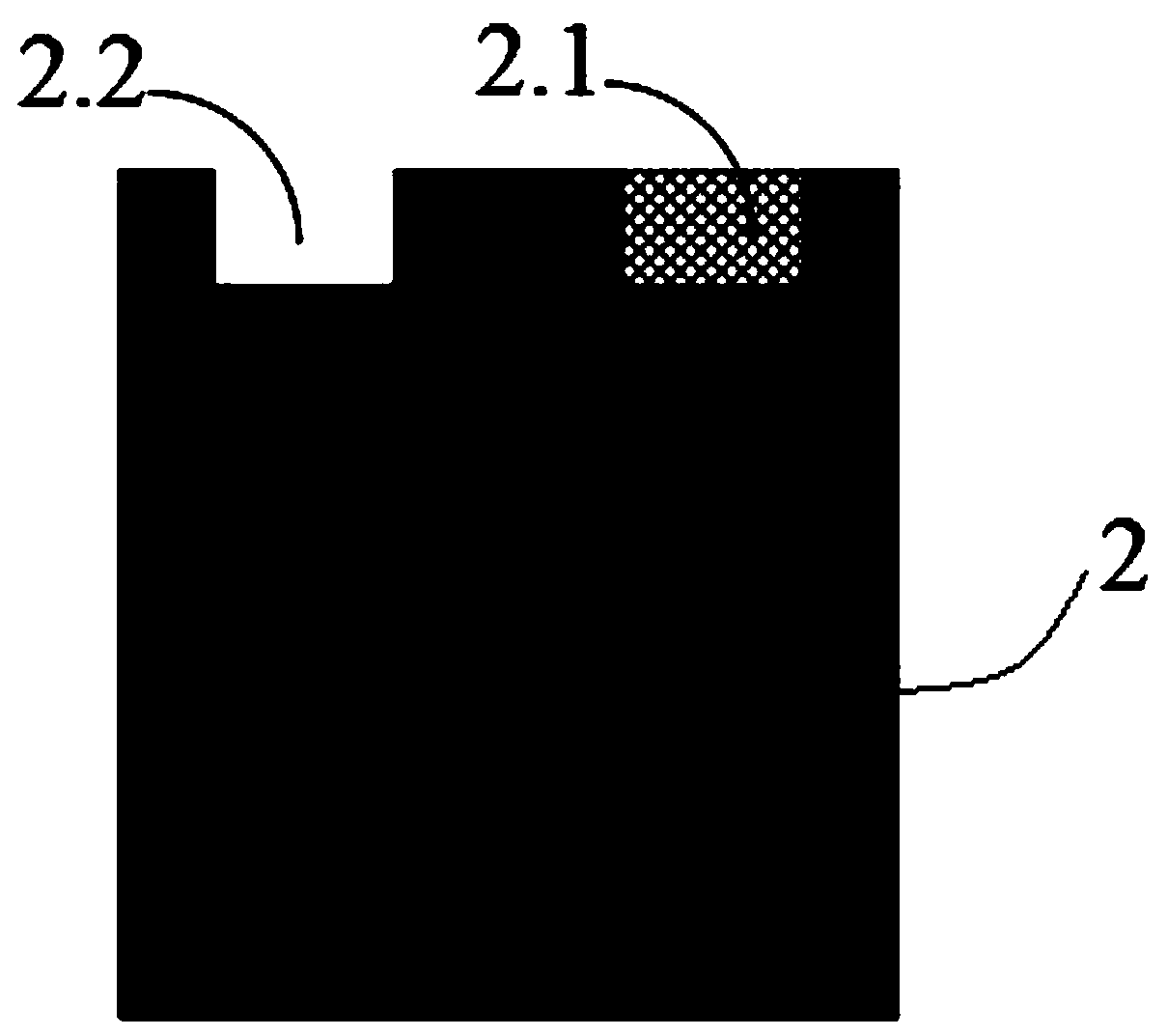

[0053] 1) Metal foil surface coating: coat the metal foil surface and reserve a blank area as the positive electrode tab 1.1 or the negative electrode tab 2.1; the specific coating method is as follows figure 1 As shown, the uncoated blank area in the figure is used as the positive electrode tab 1.1 or the negative electrode tab 2.1. In this application, the current collector is almost completely coated, and only the tabs are reserved in the middle without coating. It is beneficial to reduce the waste of raw materials and reduce production costs; at the same time, different from the way in which the positive pole or negative pole protrudes out of the pole piece in the prior art, this application chooses this embedded method, which is conducive to ensuring the battery cell The mass energy density is higher.

[0054] 2)...

Embodiment 1

[0062] According to the above preparation method, a laminated battery is prepared, wherein the size of the positive pole piece 1 and the negative pole piece 2 is length×width=180mm×169mm, and the size of the positive pole tab 1.1 and the negative pole tab 2.1 is length×width=40mm× 25mm, the material of the adhesive layer is acrylic, and the material of the metal conductive adhesive is a mixture of epoxy resin and metal nickel.

Embodiment 2

[0064] The material selected in this embodiment, the size of the pole pieces, and the size of the tabs are exactly the same as those in Comparative Document 1, but the wound lithium-ion batteries are prepared, such as Figure 10 As shown, after the process of hot-pressed cell, tab welding, mylar film coating, cell insertion into the shell, shell cover sealing welding, baking, liquid injection, and chemical formation, the wound-type ternary lithium battery is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com