Patents

Literature

69 results about "Battery sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

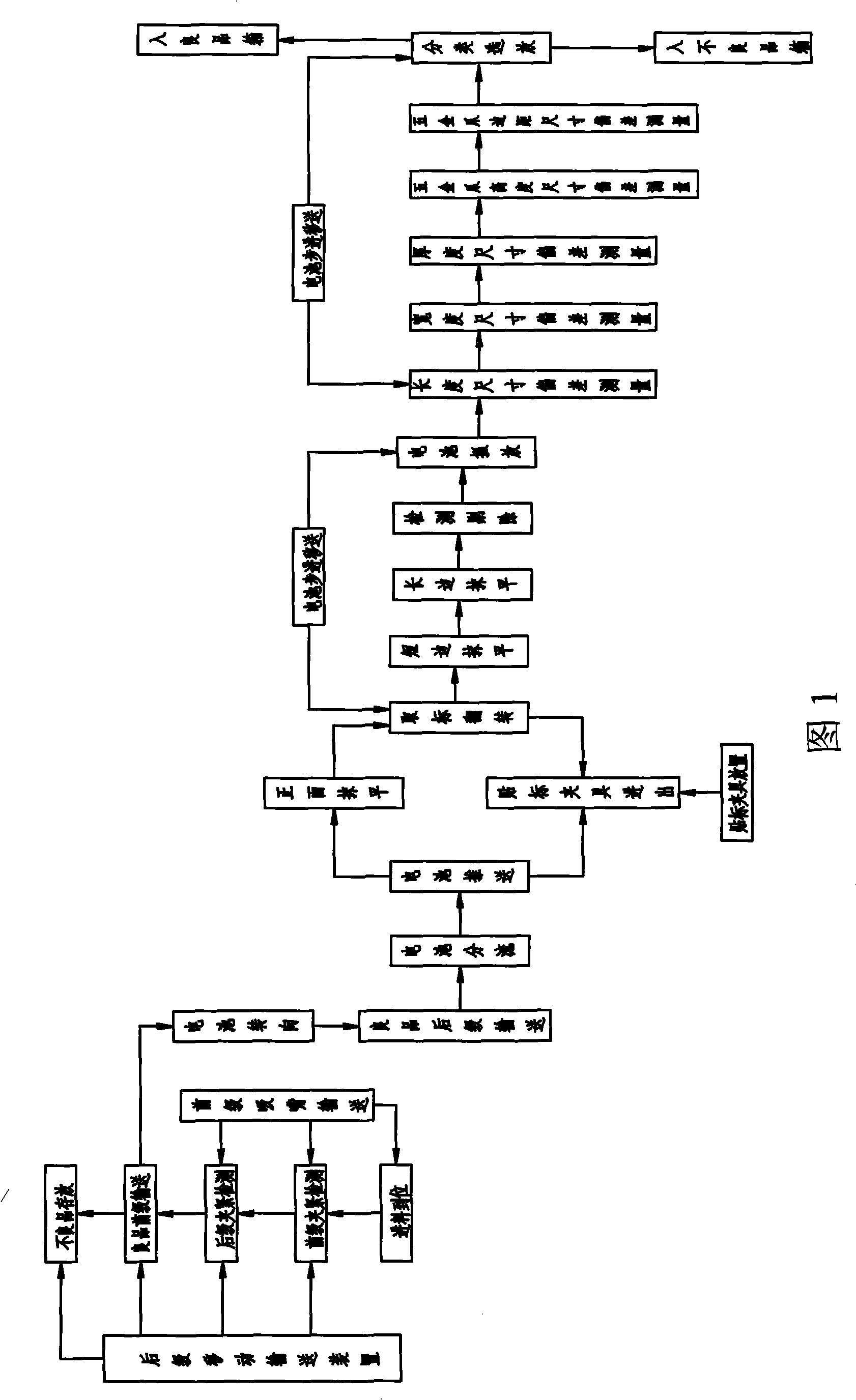

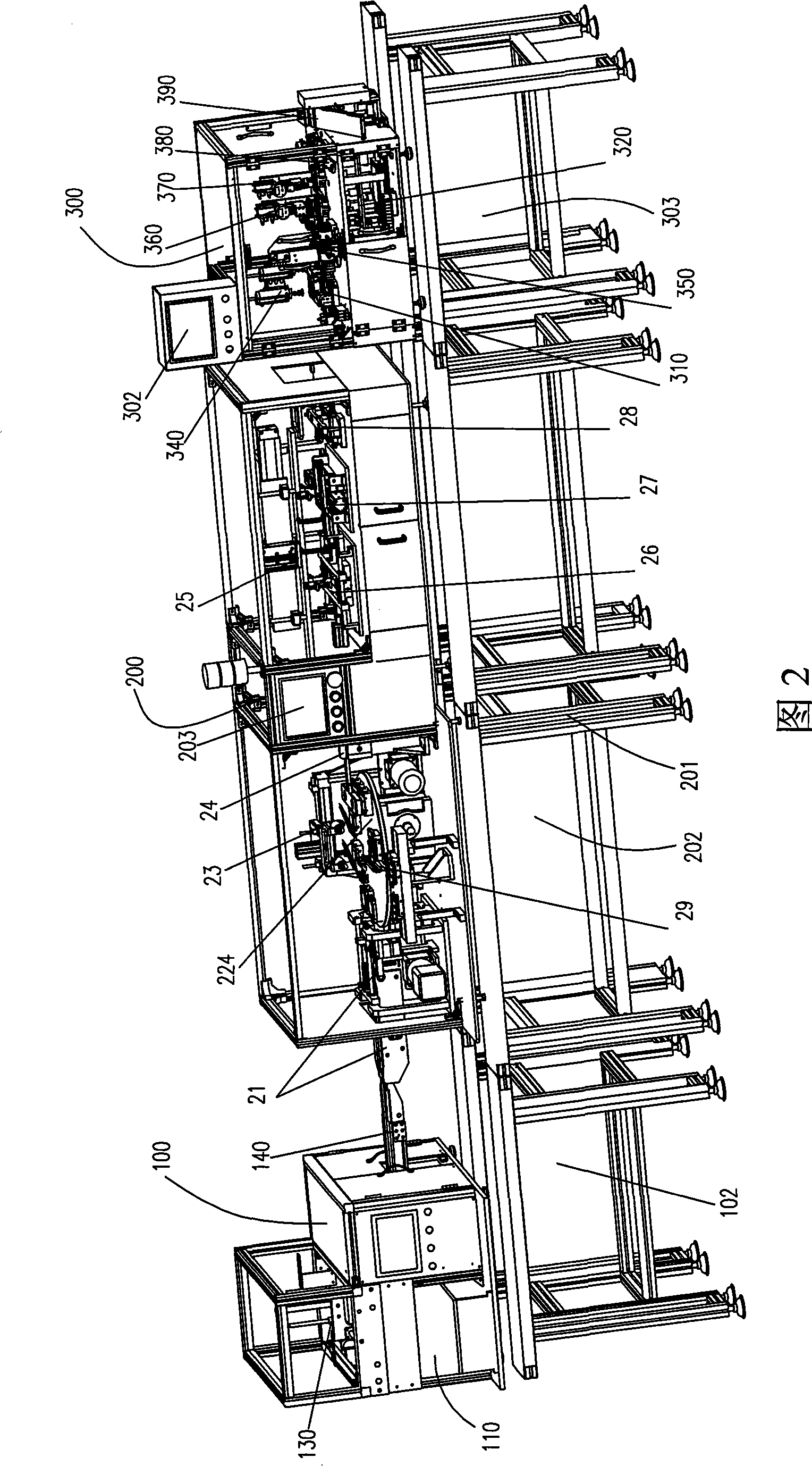

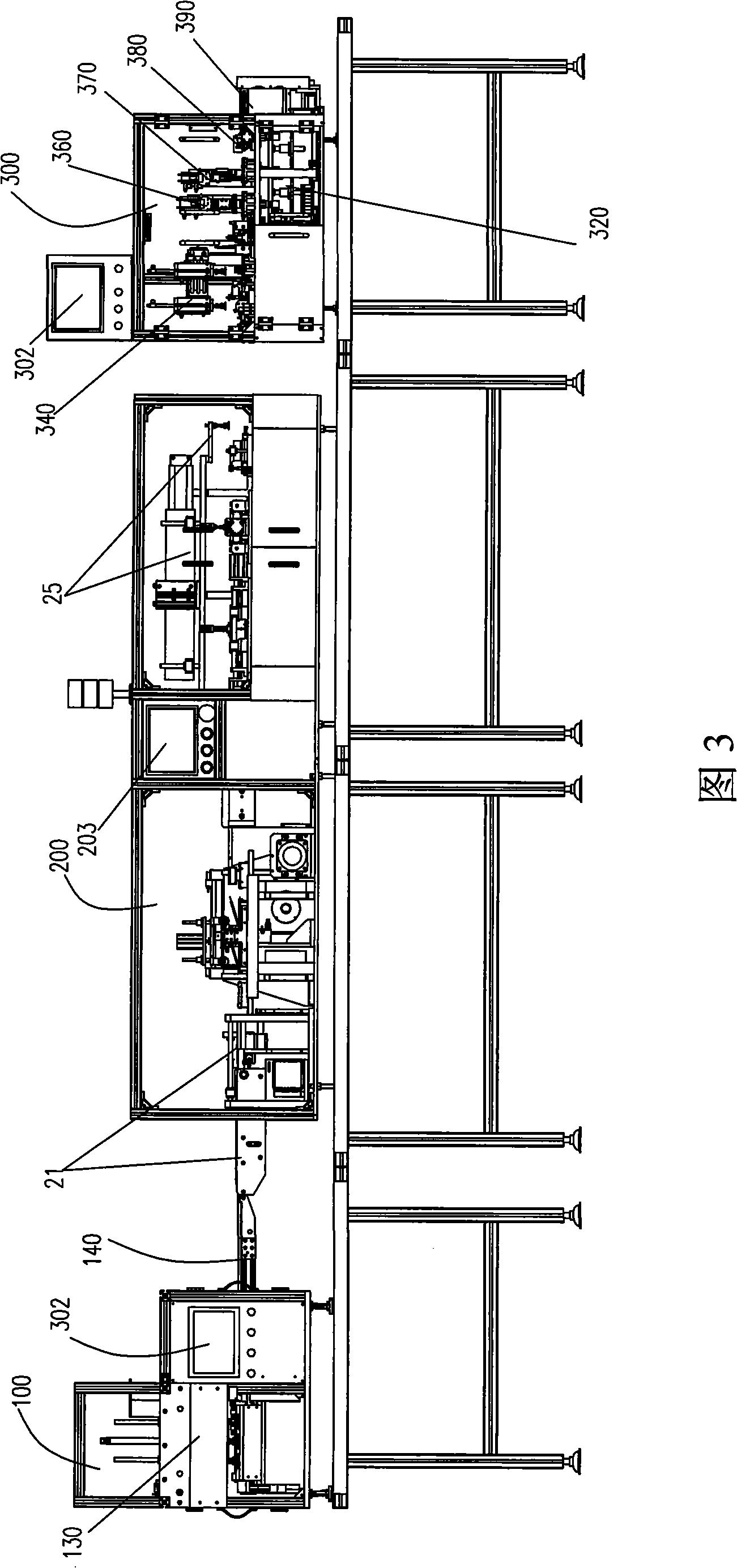

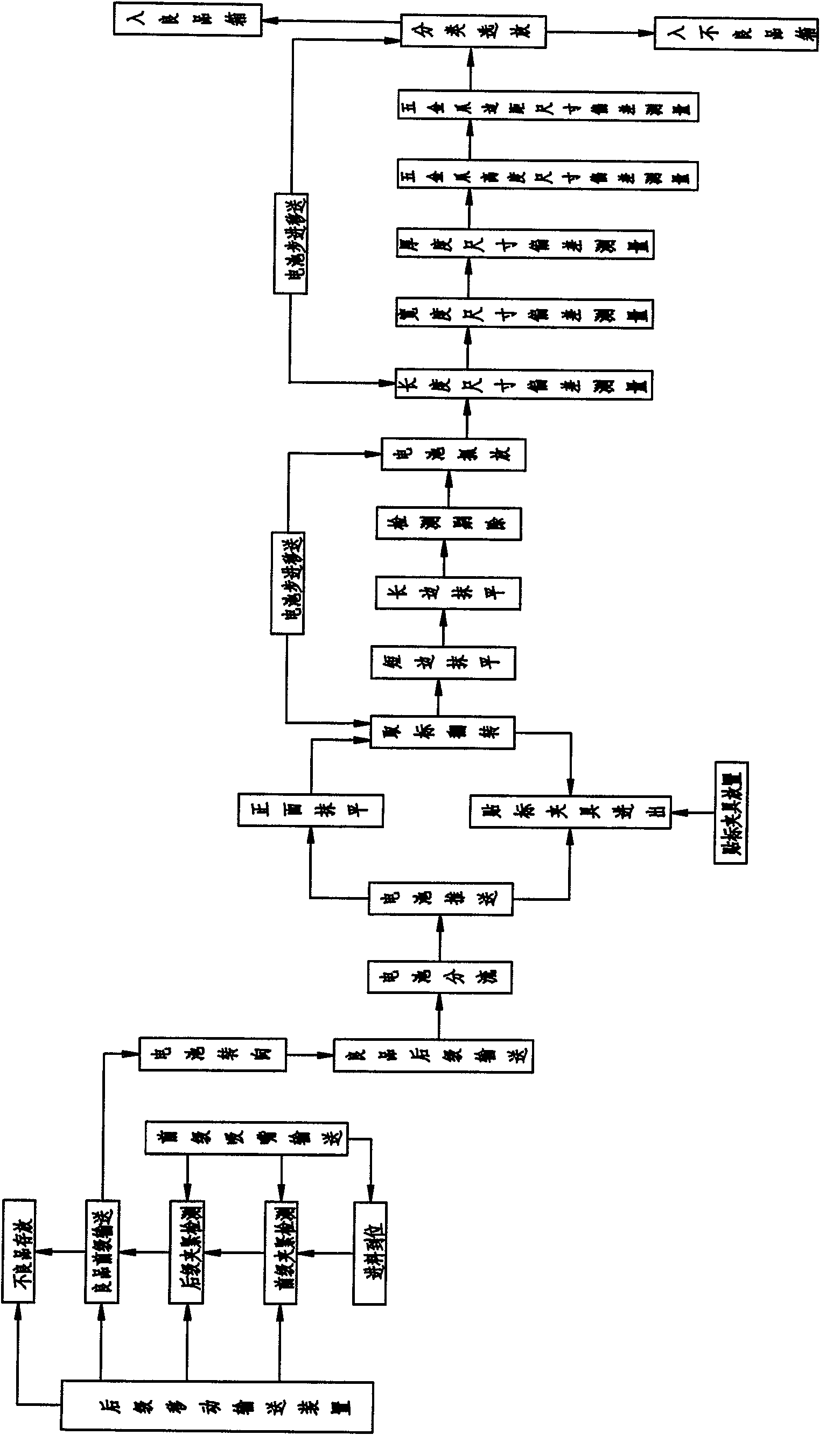

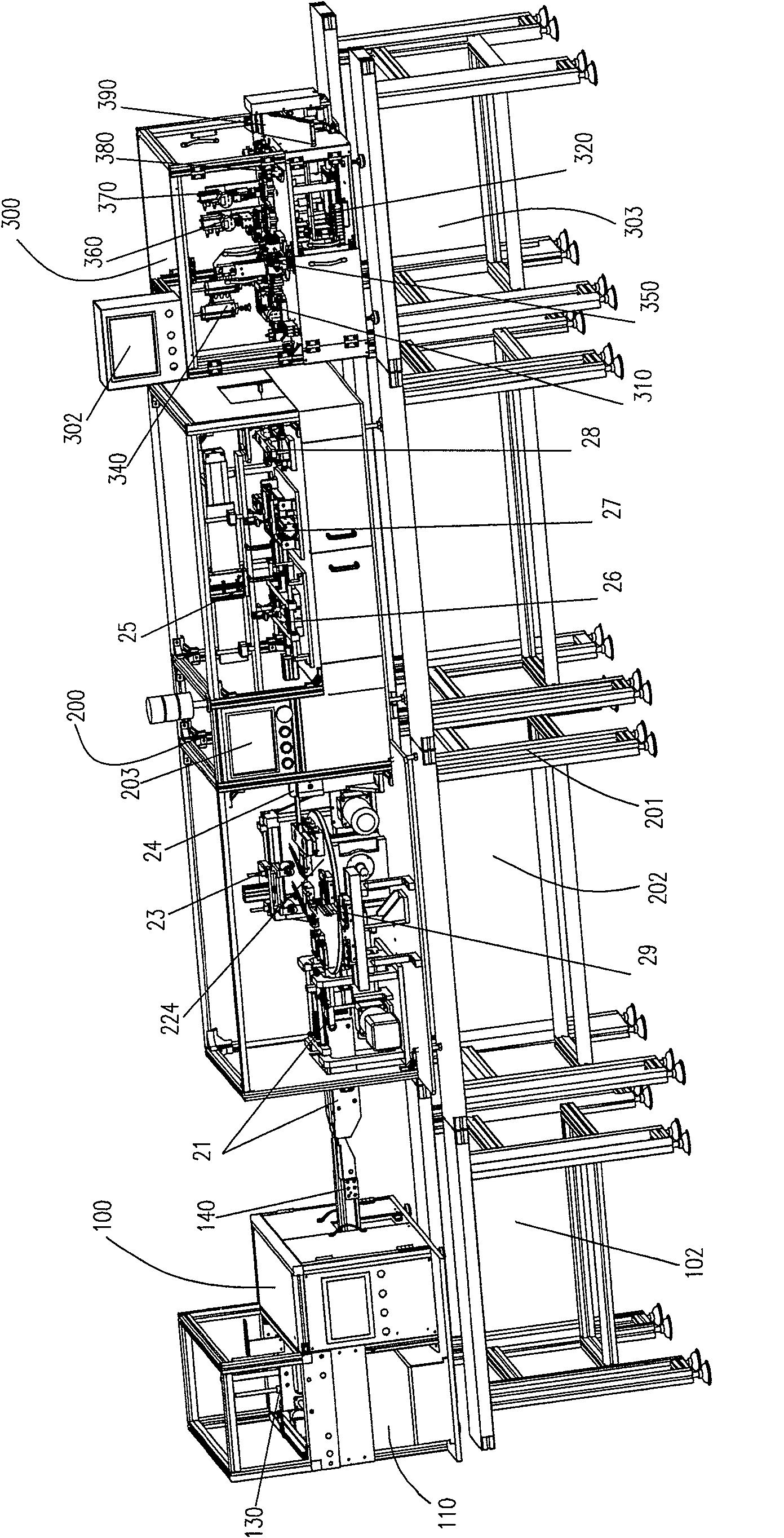

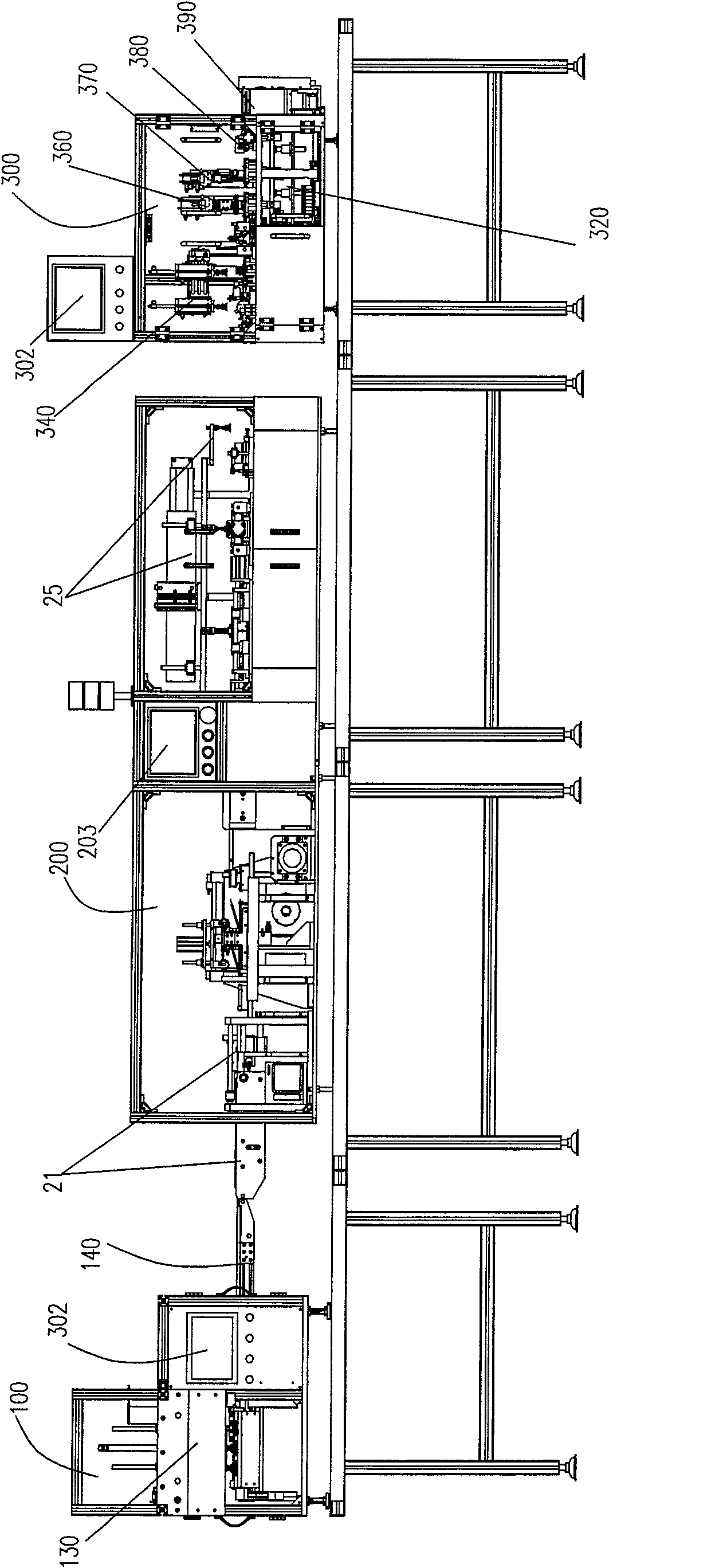

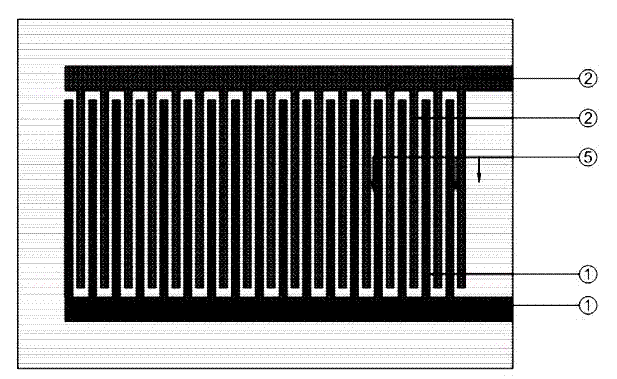

Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

InactiveCN101276929AReduce labor intensityImprove the wrapping effectFinal product manufacturePrimary cellsEngineeringAutonomation

The invention relates to a mobile phone detecting, mark wrapping, measuring automatic product line and technical flow. The product line comprises an orderly arranged mobile phone inside parameter automatic detector, a mobile phone automatic mark wrapper and a mobile phone cell size difference automatic measurer. A discharge port end of the mobile phone inside parameter automatic detector is connected with an inlet point end of the mobile phone automatic mark wrapper. A discharge port end of the mobile phone automatic mark wrapper is connected with an inlet point end of the mobile phone cell size difference automatic measurer that is connected electrically. In the invention, the cell feed in, position, clamp detection, mark wrapping and difference measurement after the mark wrapping are completed automatically. The mark wrapping effect is good, stable, and strongly reliable. The invention is simple in operation, high in efficiency and automatic level, which reduces the product manufacturing cost greatly and improves product quality and manufacturing speed, work efficiency as well as lightens labor intensity of the workers and improves labor capacity.

Owner:GRAND TECH SHENZHEN

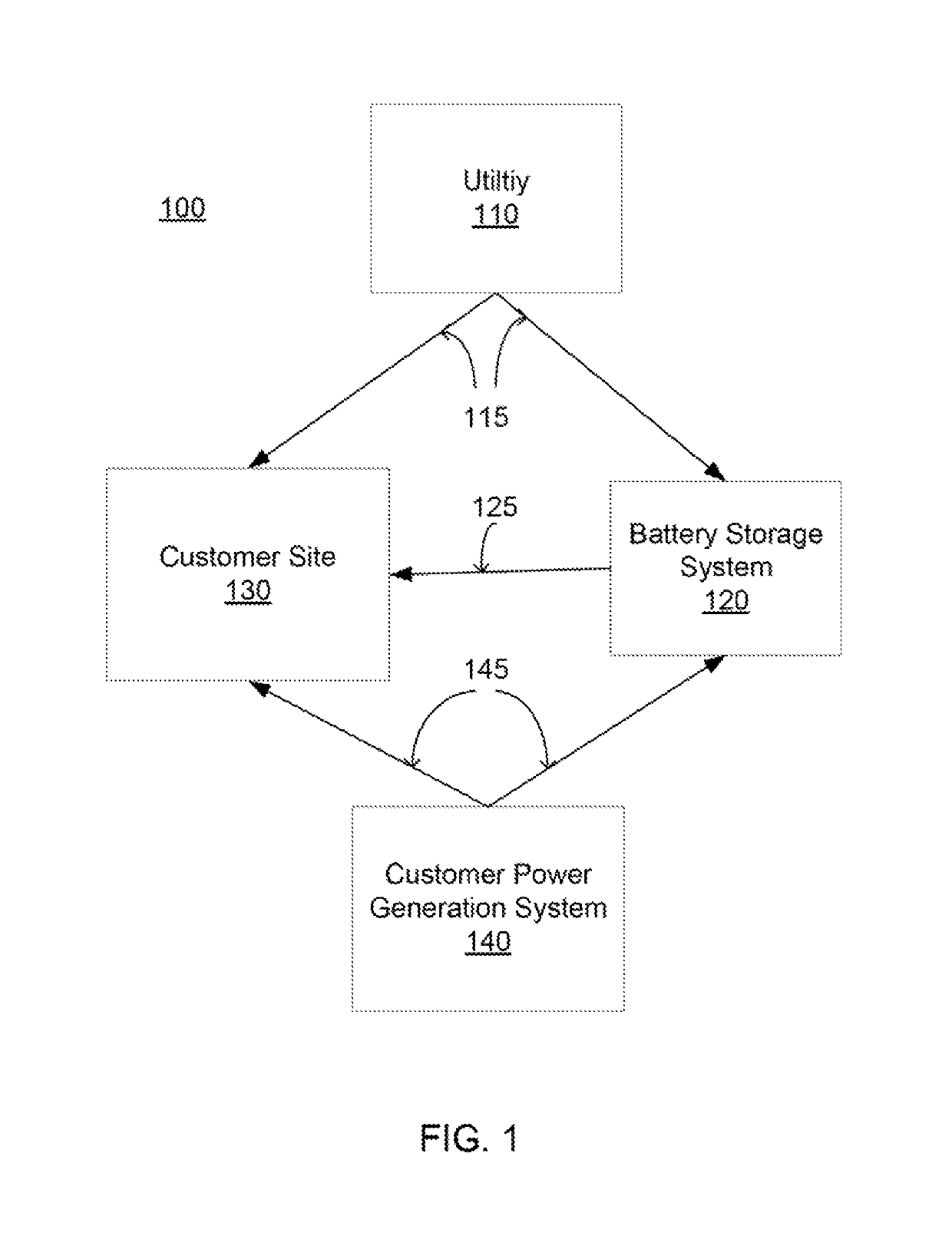

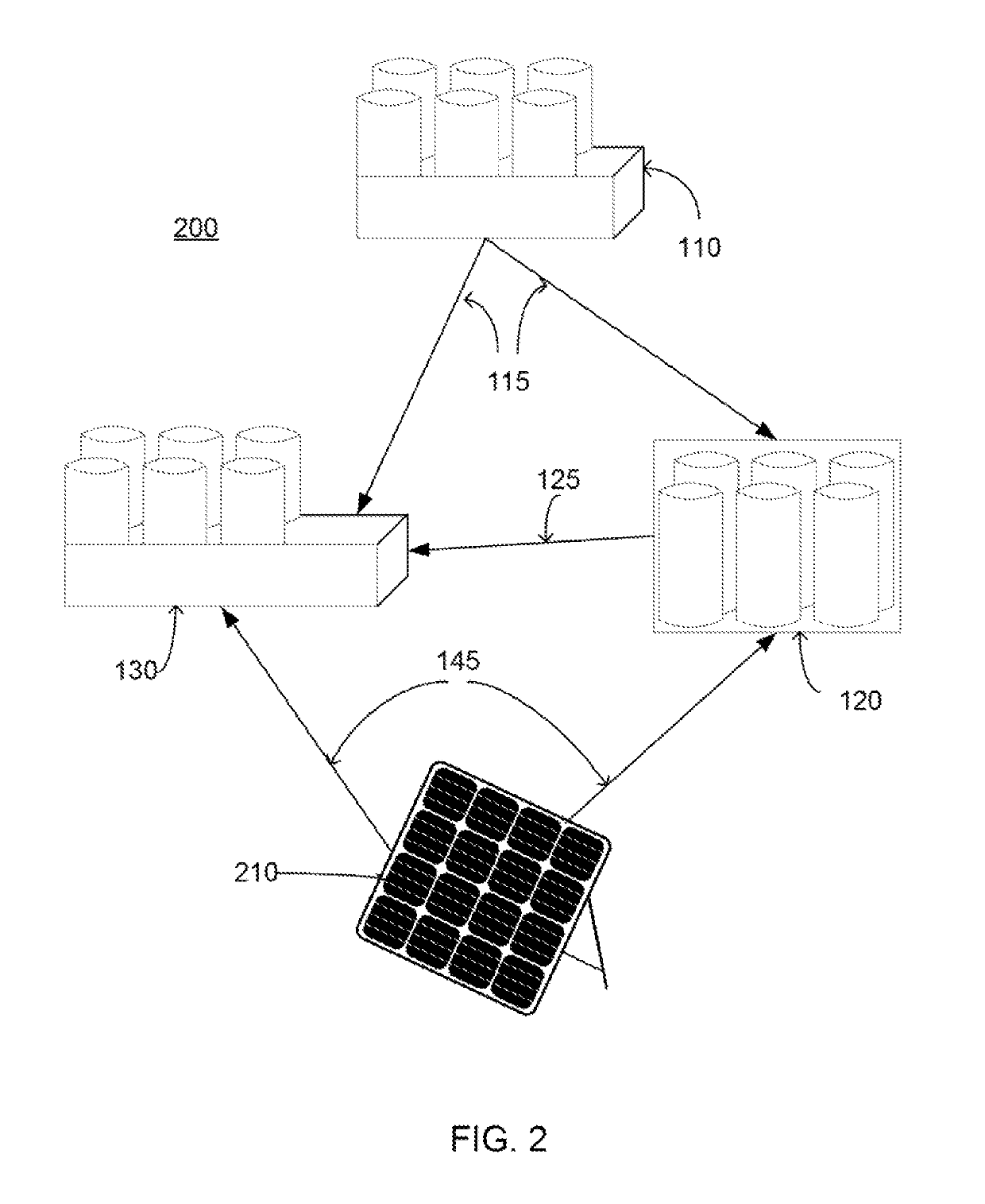

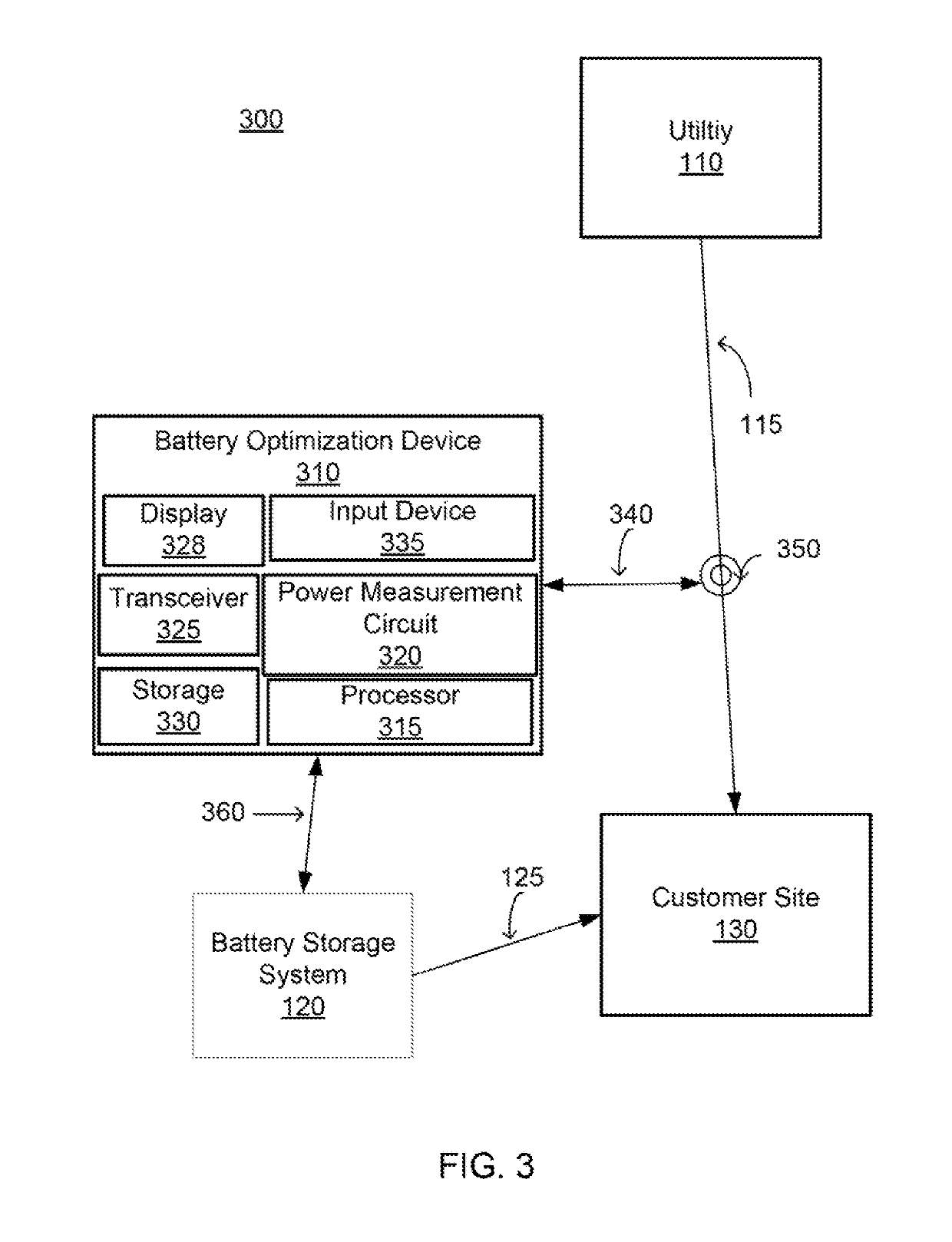

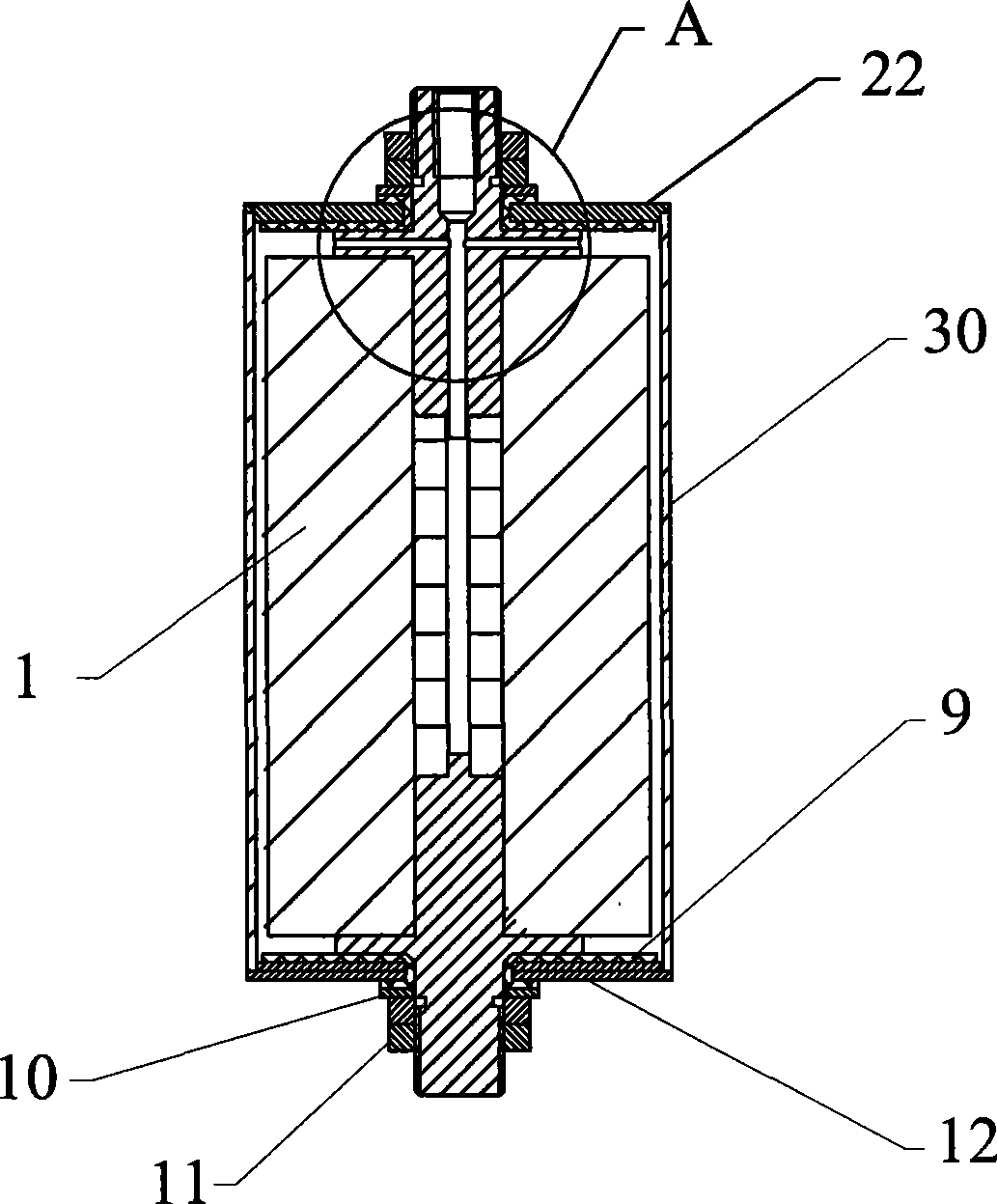

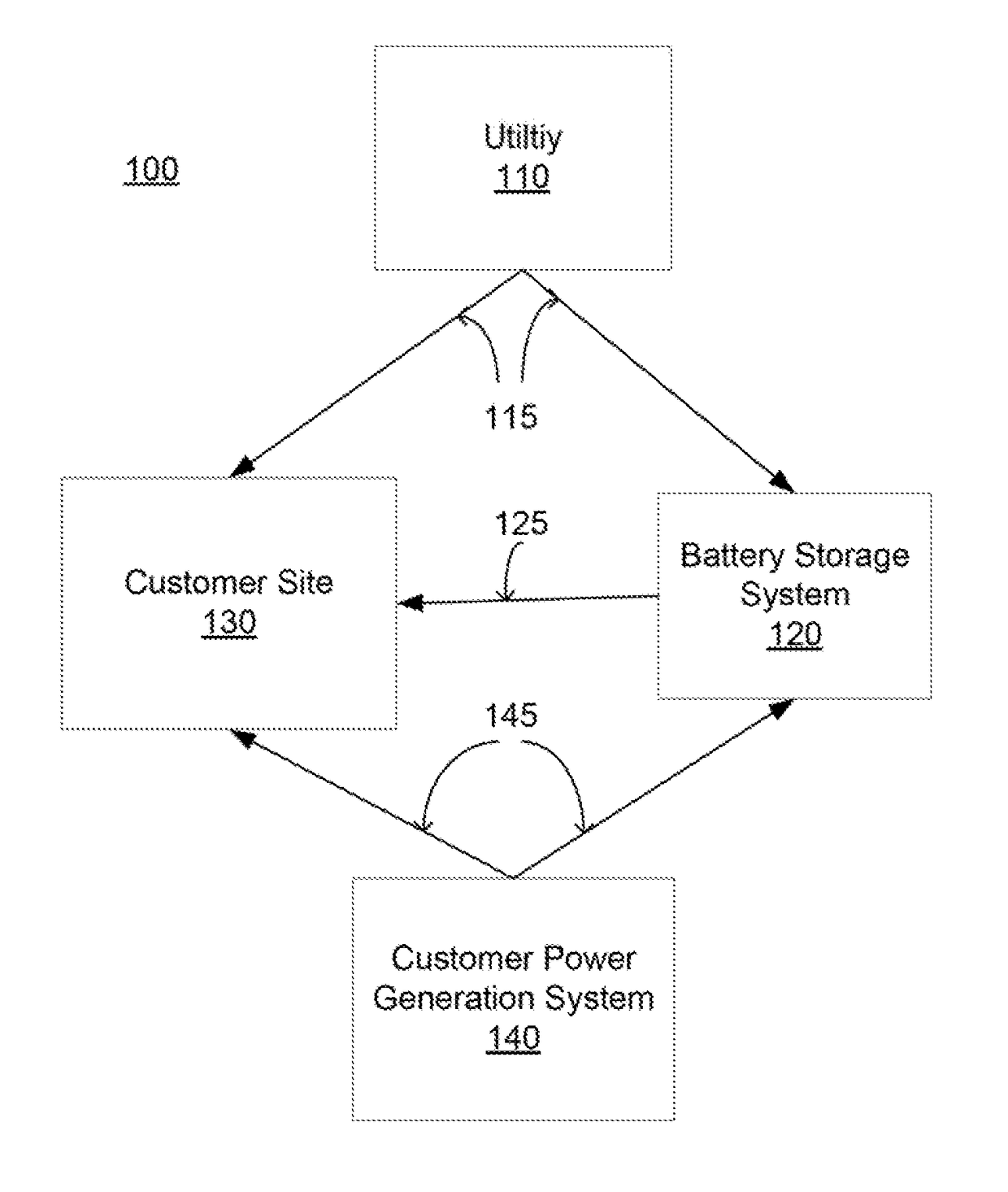

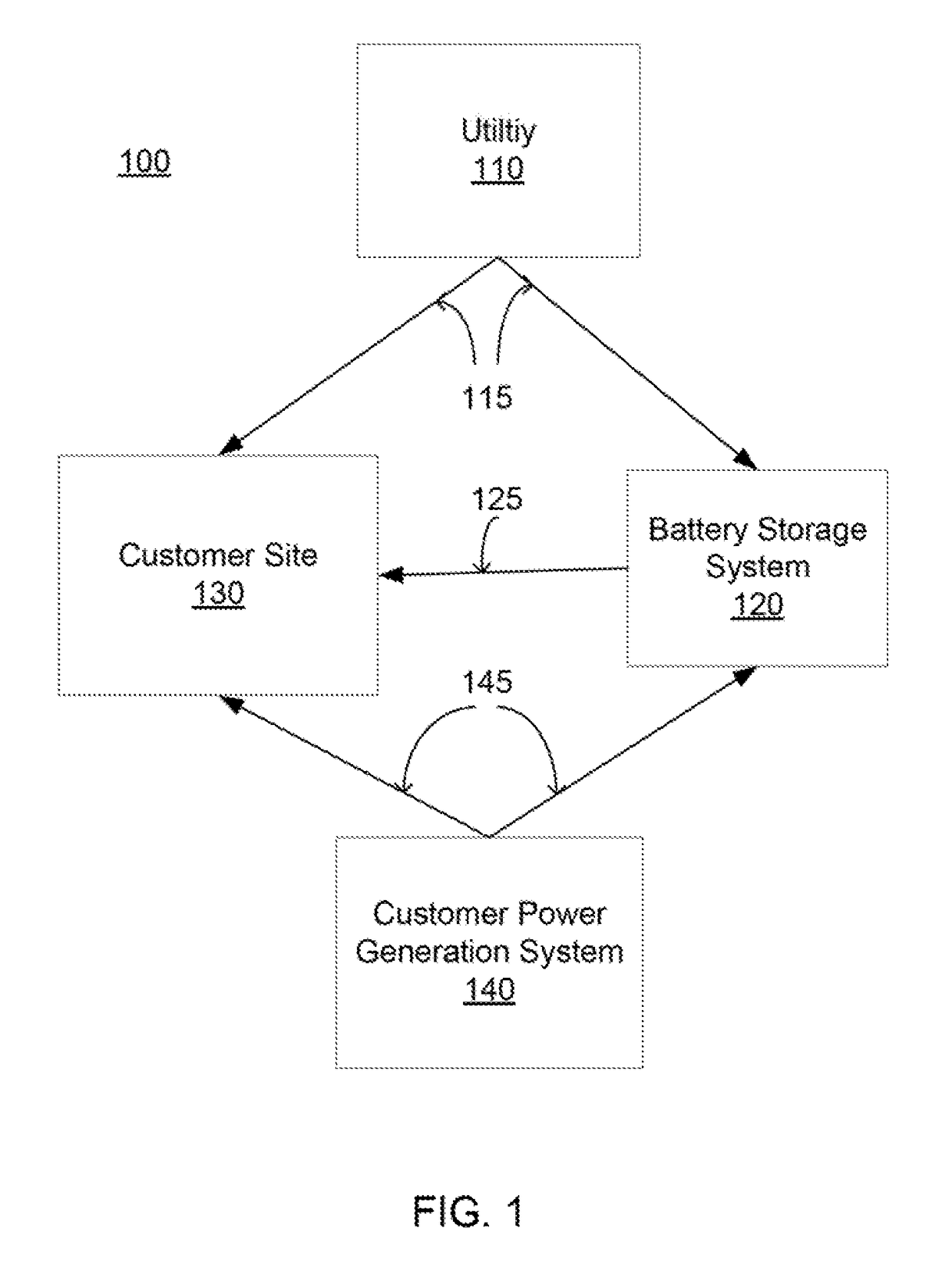

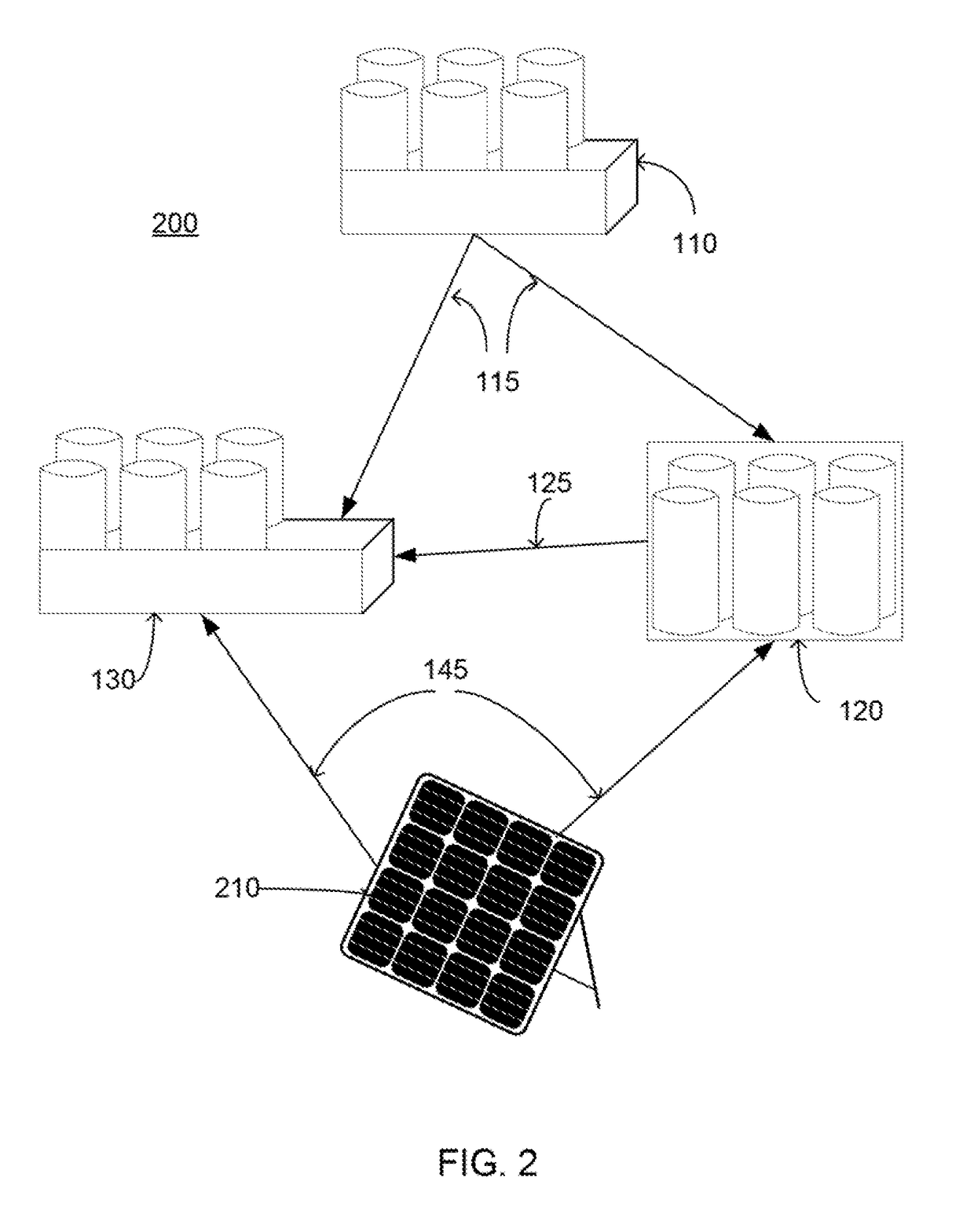

Optimal battery sizing for behind-the-meter applications considering participation in demand response programs and demand charge reduction

ActiveUS10497072B2Low costLarge capacityData processing applicationsComputer controlPower usageObject function

A system and method are provided. The system includes a processor. The processor is configured to receive power related data relating to power usage of power consuming devices at a customer site from a plurality of sources. The processor is further configured to generate object function inputs from the power related data. The processor is additionally configured to apply the generated object function inputs to an objective function to determine an optimal capacity for a battery storage system powering the power consuming devices at the customer site while minimizing a daily operational power cost for the power consuming devices at the customer site. The processor is also configured to initiate an act to control use of one or more batteries of the battery storage system in accordance with the optimal capacity for the battery storage system.

Owner:NEC CORP

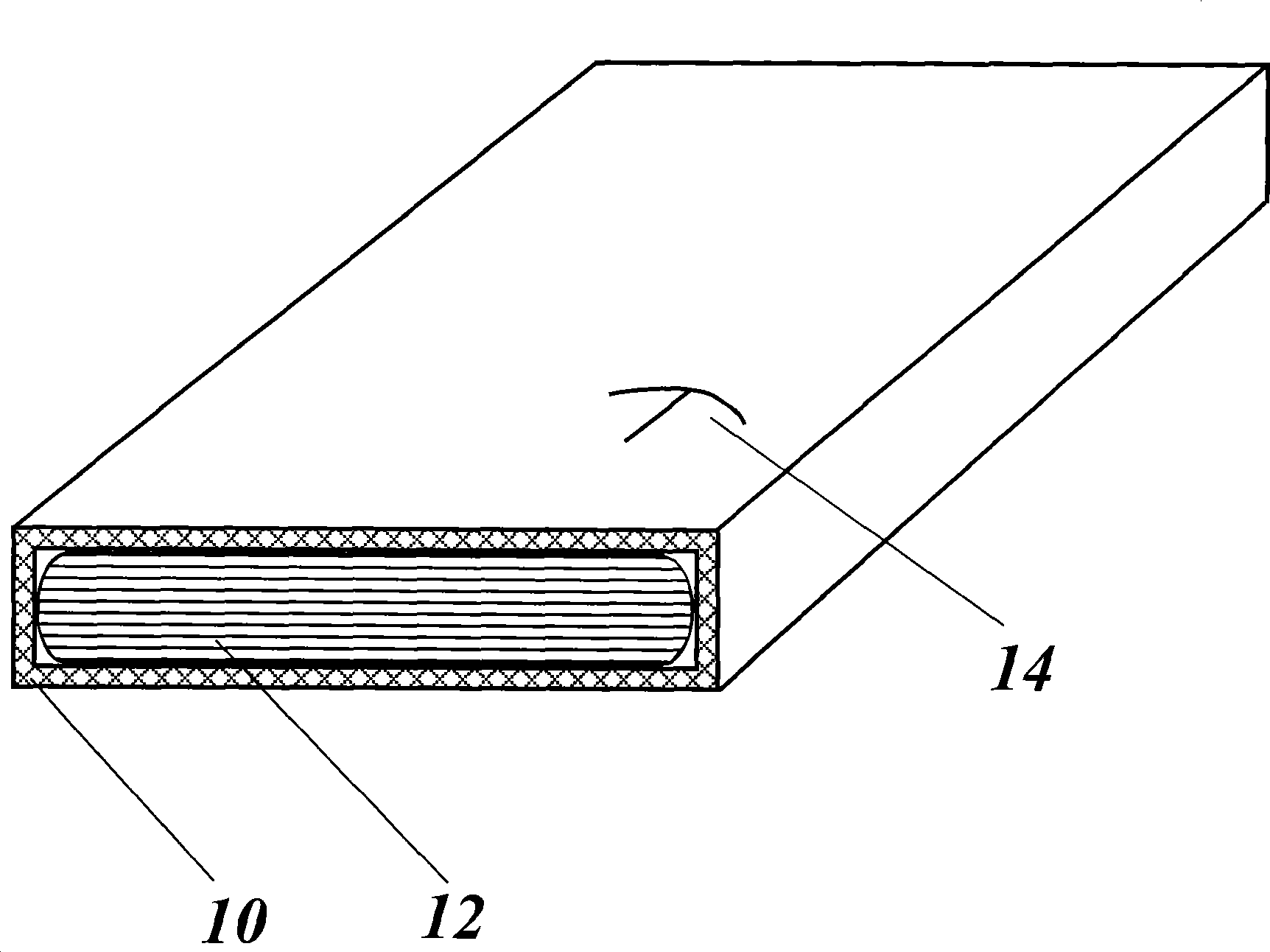

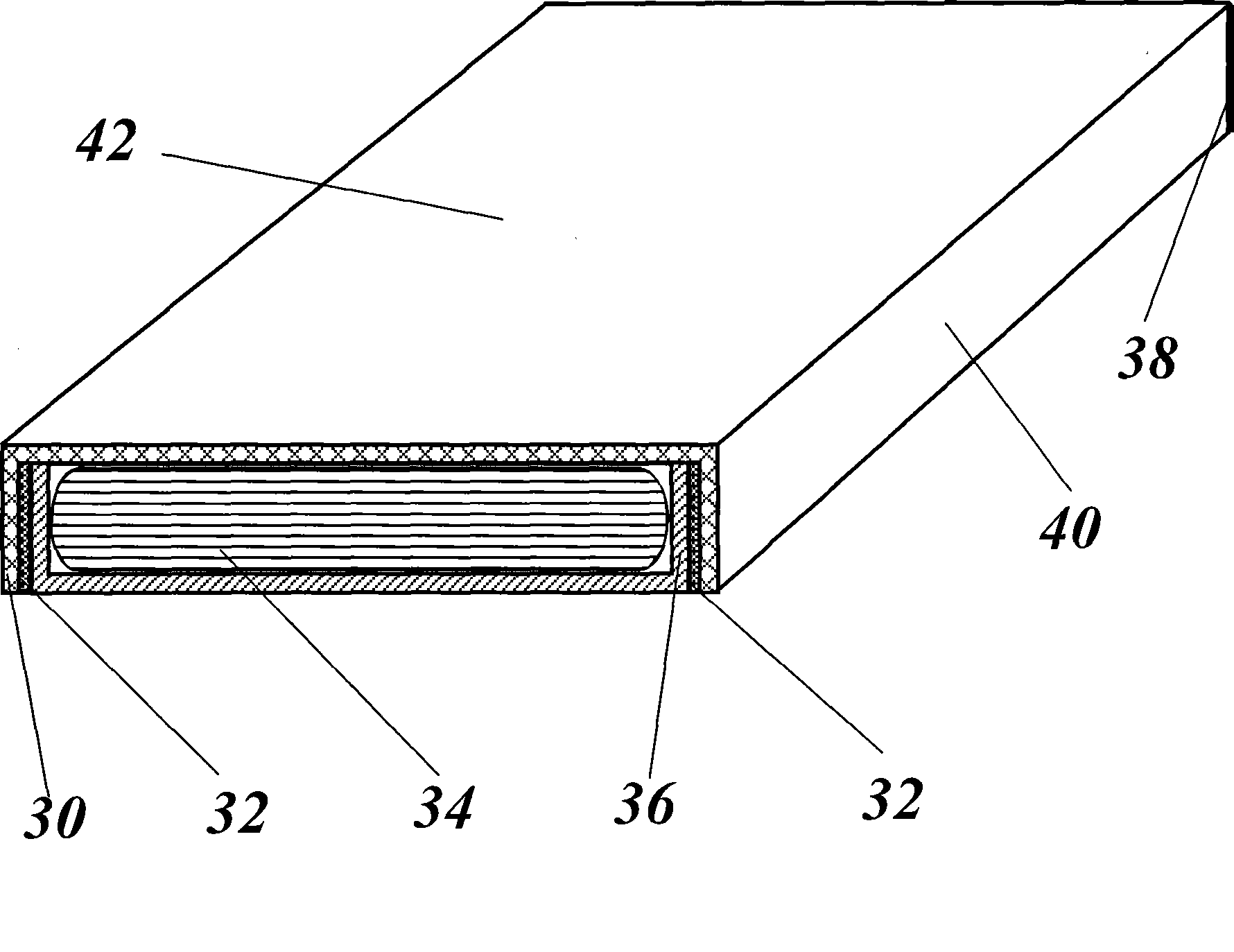

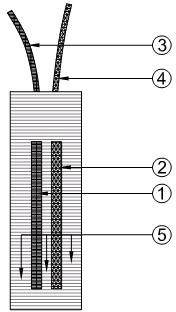

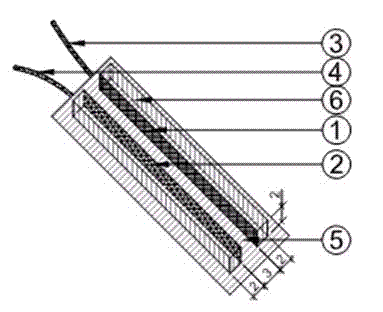

Safe high-energy folding case lithium ion battery and its production technology

The invention relates to a joggled shell lithium ion battery that forms a composite battery shell with metal chaff and temperature-sensitive macromolecule. Five temperature and pressure safety valves are equipped on a metal / macromolecule composite joggled shell, which overcomes problem of present liquid state lithium ion battery and defects of polymer soft package batteries, and improves battery reliability. Compared with present liquid state metal shell lithium ion battery, the joggled shell lithium ion battery of the invention has volume improved 10% to 30%; compared with present polymer soft package batteries, the battery of the invention has volume improved 3% to 10% with tympanites and liquid leakage rate less than 0.1ppm. In addition, there is a little of joggled plate material, manufacturing device and mould being simple. Consumption of the materials and energy loss in process is less, which reduces cost, manufactures the battery adequately, meets need of the customers for various battery sizes and fills blank of super thin lithium ion battery field below 3.0mm.

Owner:黄穗阳

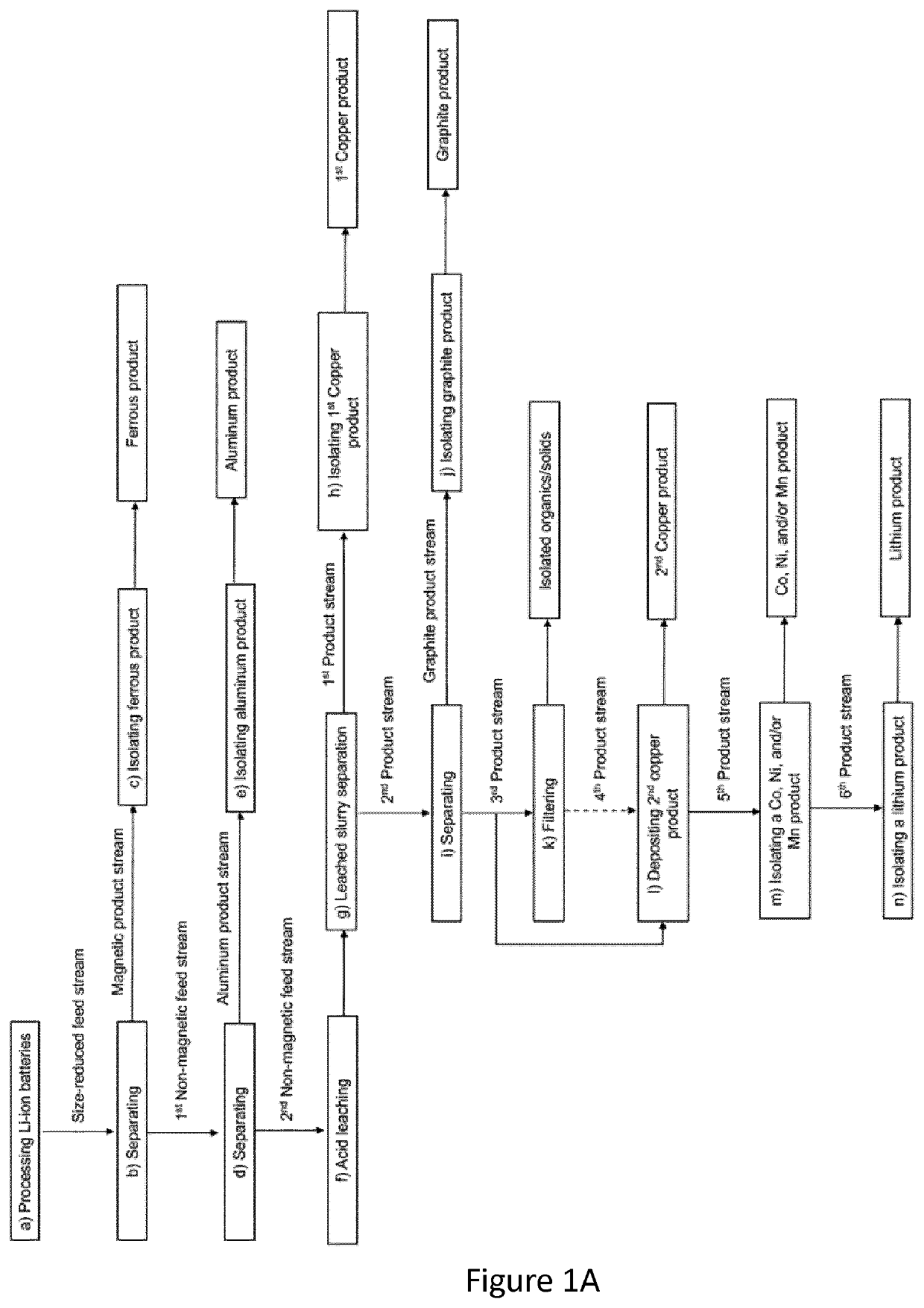

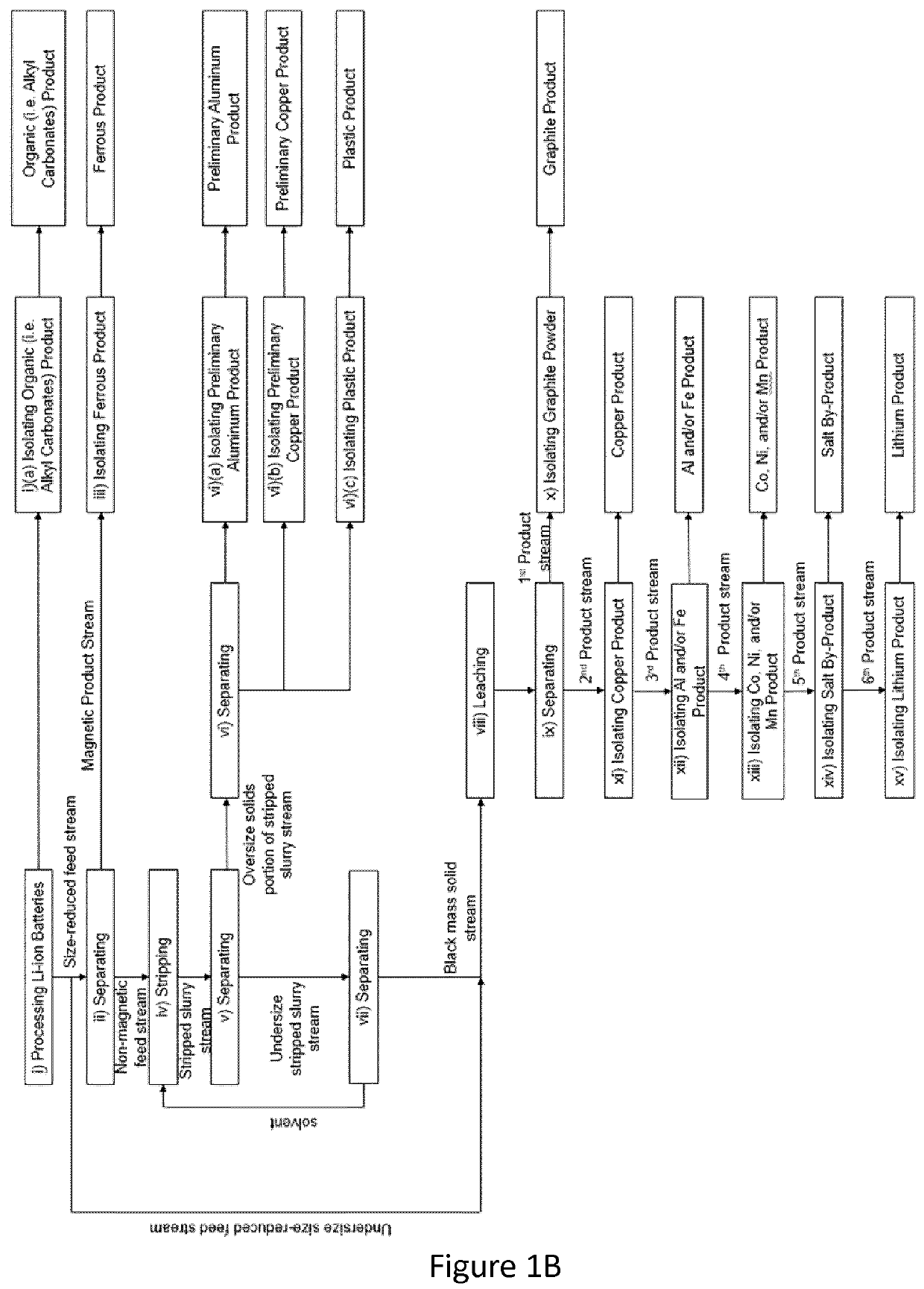

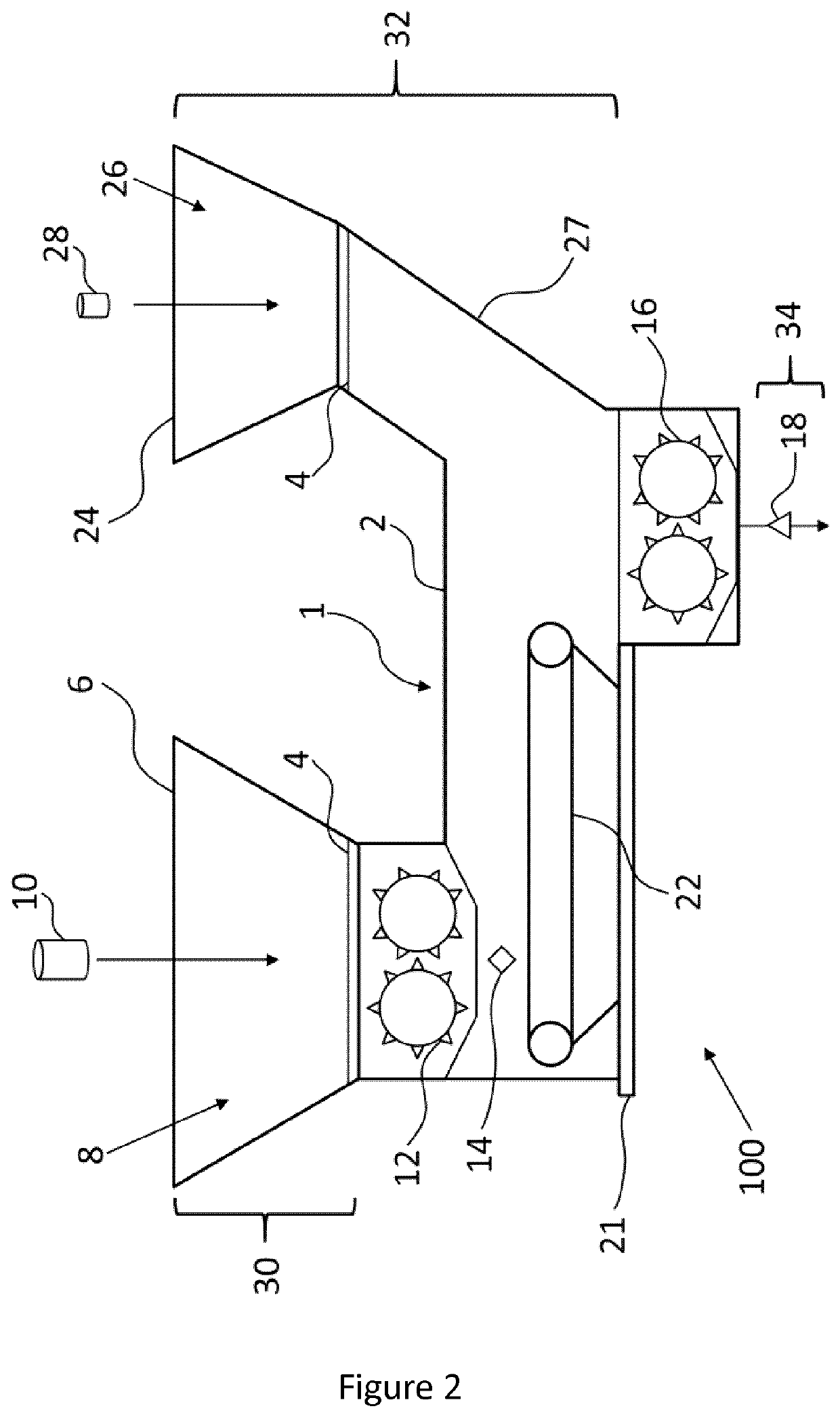

Process, apparatus, and system for recovering materials from batteries

ActiveUS20200078796A1Small sizeWaste accumulators reclaimingFlotationAluminium preparationsProcess engineering

The present application provides a process to recover materials from rechargeable lithium-ion batteries, thus recycling them. The process involves processing the batteries into a size-reduced feed stream; and then, via a series of separation, isolation, and / or leaching steps, allows for recovery of a copper product, cobalt, nickel, and / or manganese product, and a lithium product; and, optional recovery of a ferrous product, aluminum product, graphite product, etc An apparatus and system for carrying out size reduction of batteries under immersion conditions is also provided.

Owner:LI CYCLE CORP

Tungstic oxide semiconductor battery and preparation method therefor

InactiveCN102148267AHigh currentPhotovoltaic energy generationSemiconductor devicesElectrical batteryMetal foil

The invention relates to a tungstic oxide semiconductor battery and a preparation method therefor. The preparation method comprises the following steps: taking tungstic oxide as a raw material, adding a conductive agent, an activating agent, an addition agent and an organic polymer film-forming agent to the raw material so as to prepare tungstic oxide semiconductor battery sizing, taking two metal foils with different work functions as a positive electrode and a negative electrode, pasting the positive electrode and the negative electrode in the same horizontal plane of a plastic substrate, then pouring the tungstic oxide semiconductor battery sizing into the surface of the electrodes, and drying and packaging the electrodes. The tungstic oxide semiconductor battery has the effects of (1) semiconductor chemical effect, electron transportation is carried out between the two metal electrodes with different work functions; (2) photoelectric effect, the electric current of the battery obviously increases when the battery is irradiated under the sun; and (3) thermoelectric effect, the electric current increases along with the rising of temperature when the battery is in a certain temperature range (5-100 DEG C).

Owner:NANCHANG UNIV

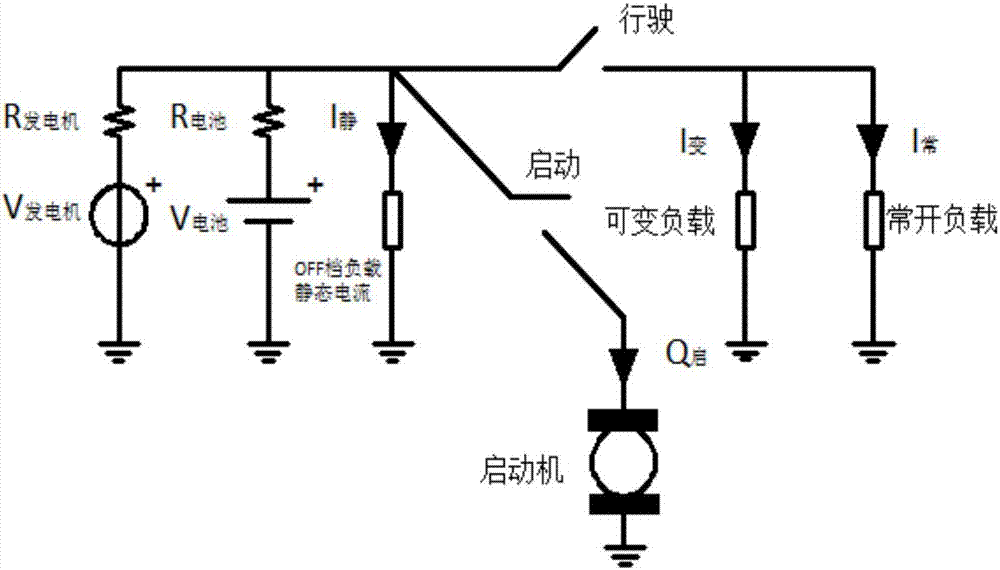

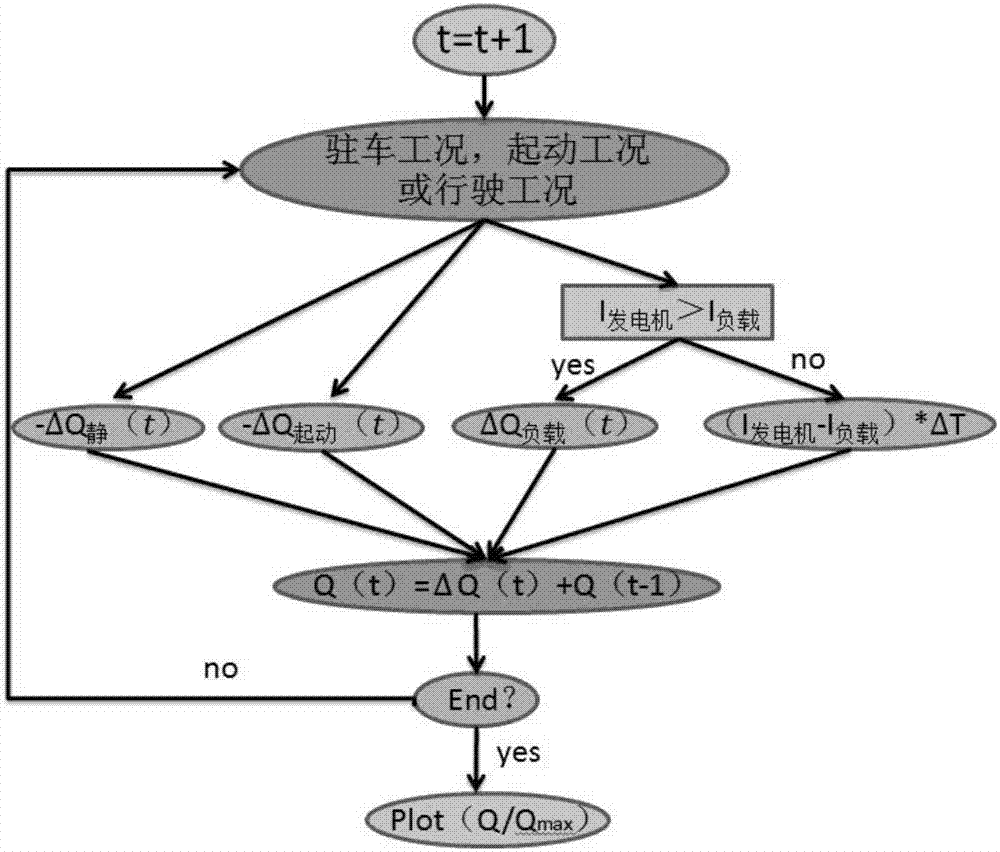

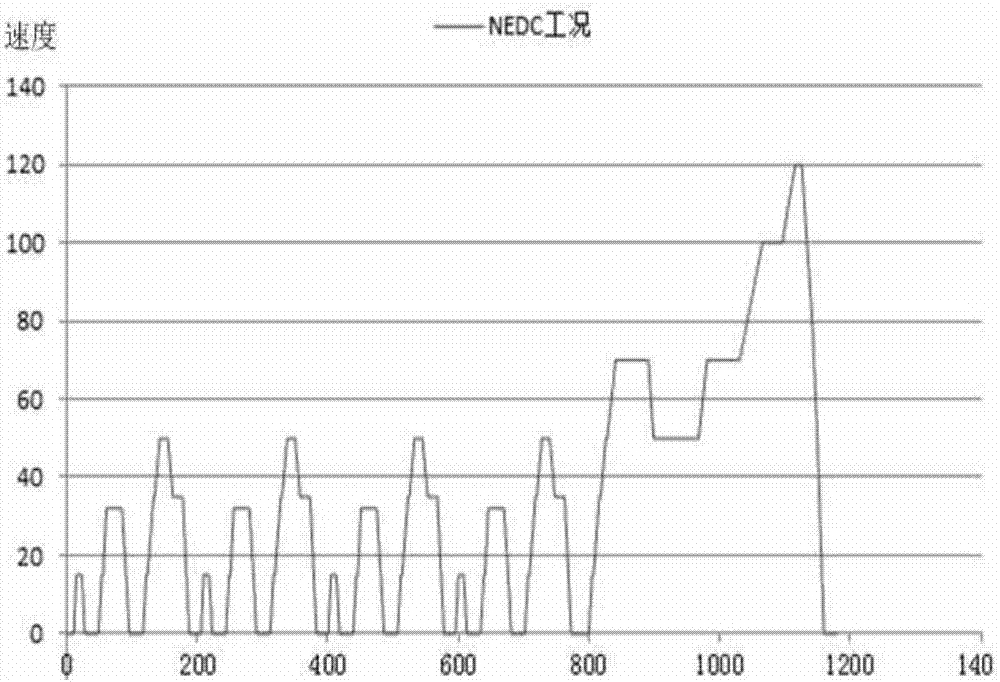

Analog simulation method for automobile storage battery sizing

ActiveCN106980725ASolve frequent power lossSolve the difficulty of starting the vehicleElectrical testingDesign optimisation/simulationElectrical batteryCharge discharge

The invention relates to an analog simulation method for automobile storage battery sizing. The method comprises the steps of (1) dividing a driving cycle into three working conditions including a parking working condition, a starting working condition and a driving working condition, and calculating charge-discharge situations and electricity demand situations of a storage battery under different working conditions; (2) inputting a rated capacity and an initial charge state of the selected battery, and simulating under NEDC (New European Driving Cycle) working conditions through a MATLAB (matrix laboratory); and (3) carrying out multiple cycles to obtain the capacity of the storage battery after one and a half years. According to the analog simulation method, all electricity demand working conditions, including the starting working condition, the driving working condition and the parking working condition of an automobile in the use process are fully considered; meanwhile, the influence of environmental factors is also considered, starting in the low temperature environment is added into simulation calculation so that a calculation result is accurate; in addition, a simulation process simulates the use condition of the storage battery in the whole life cycle, and one-sidedness caused by only consideration of a new battery is avoided. Meanwhile, the problems of frequent lack of electricity and difficult starting of the automobile and shortened life of the storage battery caused by improper storage battery sizing and cost waste caused by excessive battery capacity selection can be solved from the technical angle.

Owner:CHERY AUTOMOBILE CO LTD

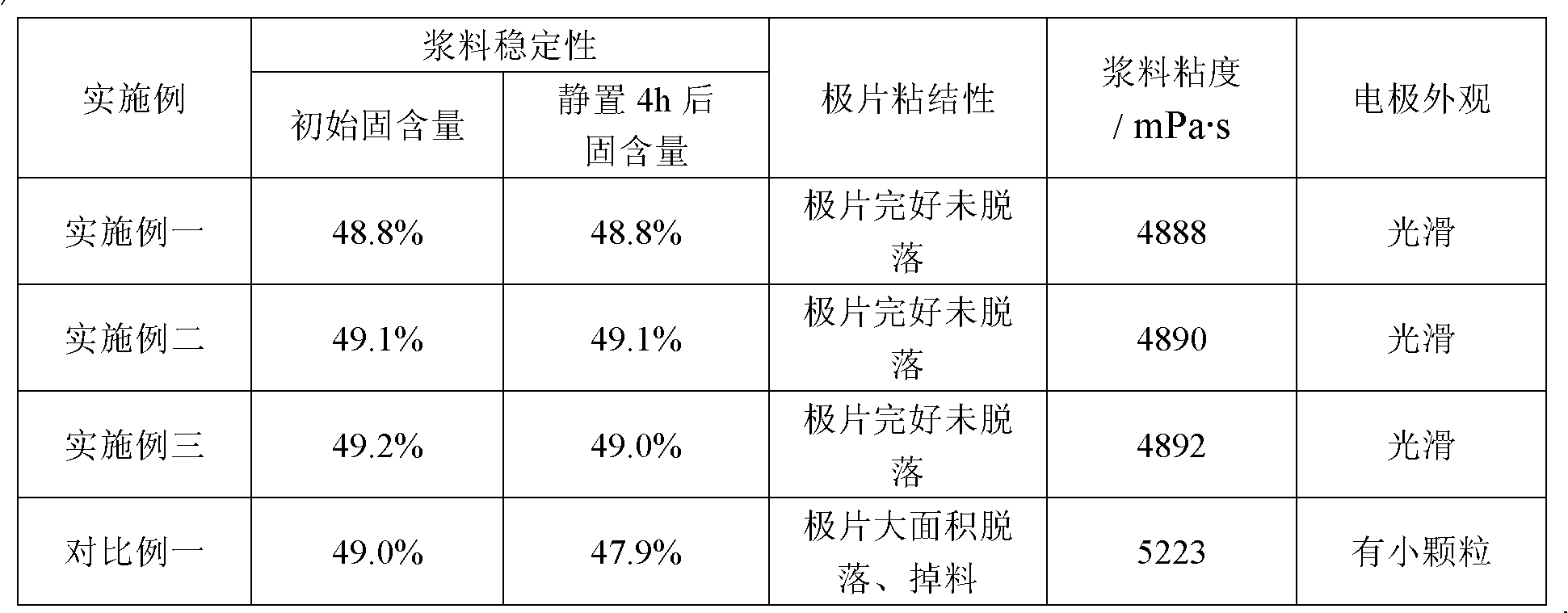

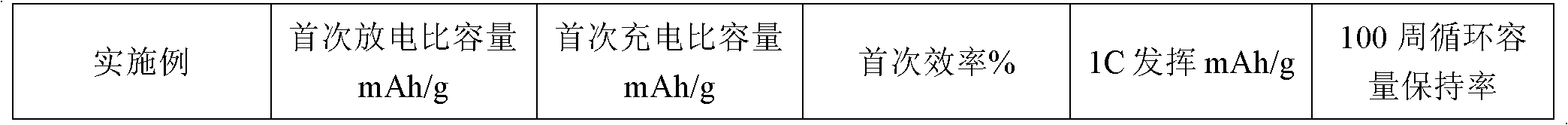

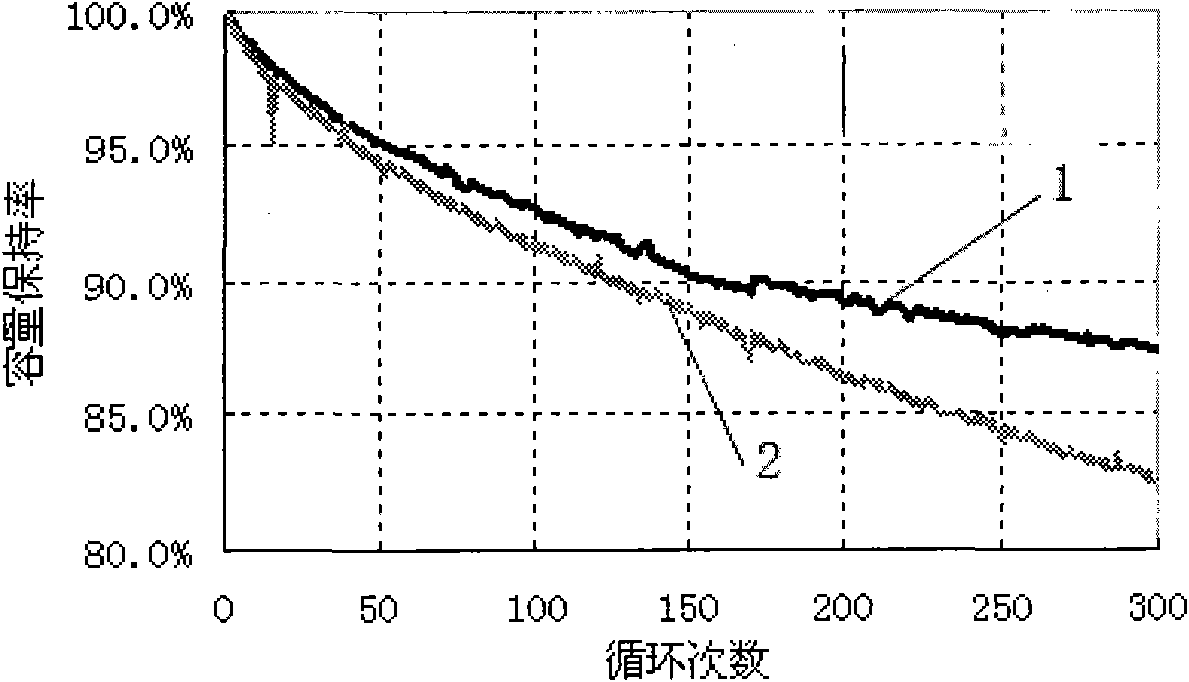

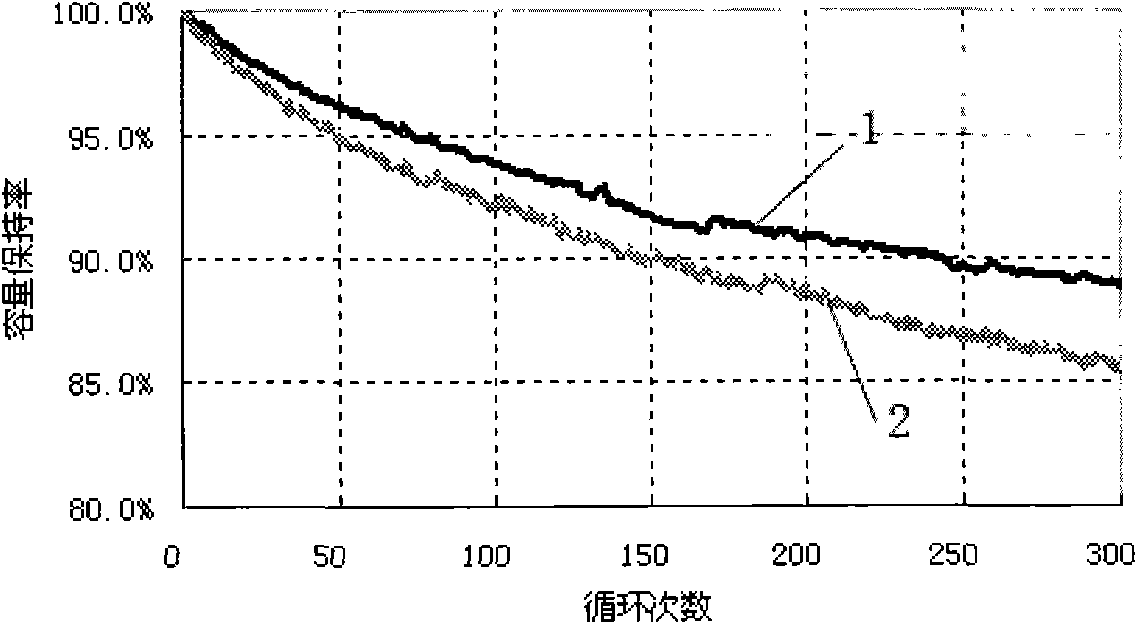

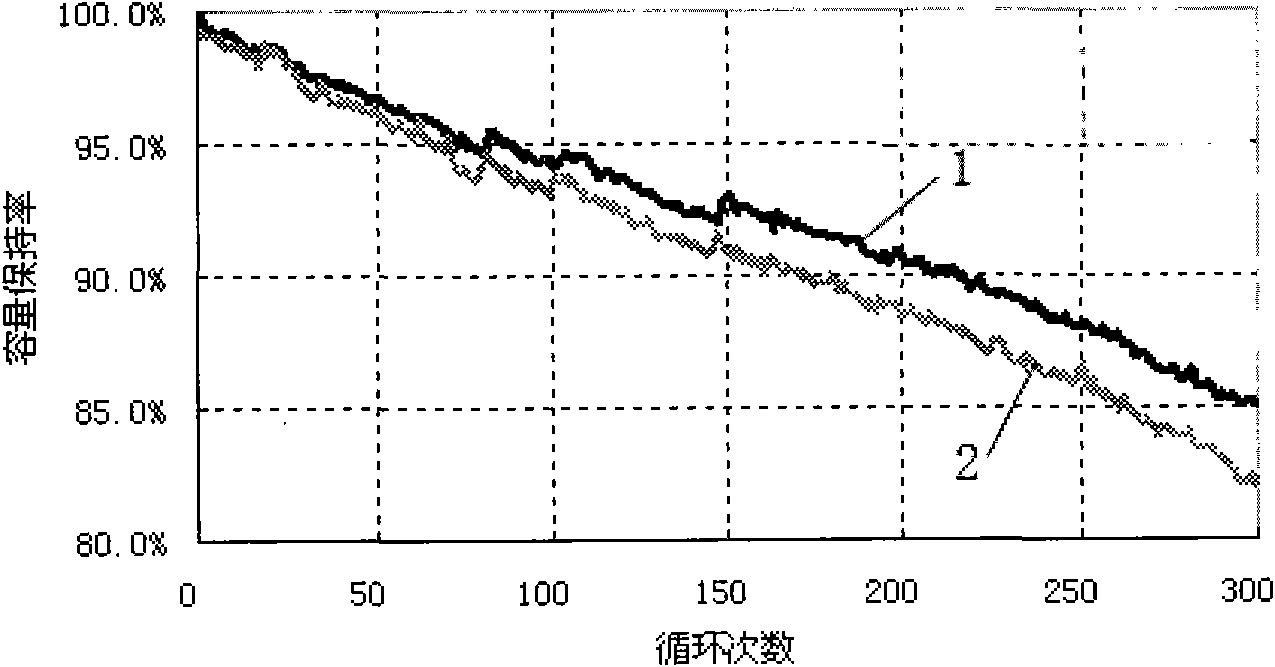

Method for dispersing micro-scale and nano-scale electrode materials

The invention discloses a method for dispersing micro-scale and nano-scale electrode materials, which is suitable for a battery sizing agent consisting of micro-scale and nano-scale active substances, a conductive agent, an adhesive and a solvent. The method comprises the following step of: adding an organic acid additive decomposed at the temperature of 150 DEG C into the battery sizing agent in an amount of 0.1-8 percent of the total weight of the micro-scale and nano-scale active substances, the conductive agent and the adhesive. The method for dispersing the micro-scale and nano-scale electrode materials by taking the organic acid additive as a surfactant is adopted, so that micro-scale and nano-scale active substances can be dispersed more uniformly and stably, and the sizing agent is prevented from settling and can be decomposed into carbon dioxide and water at the temperature of about 150 DEG C for volatilizing, and therefore the battery capacity is increased effectively, the primary efficiency of the battery is improved and the cycle life of the battery is prolonged; the surface tension of the active substances can be reduced, the using amount of the solvent is reduced under the same sizing agent viscosity condition, and the cost is saved; and the adhesive properties of a coated electrode and a current collector can be enhanced, and the cycle life of the battery is prolonged.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

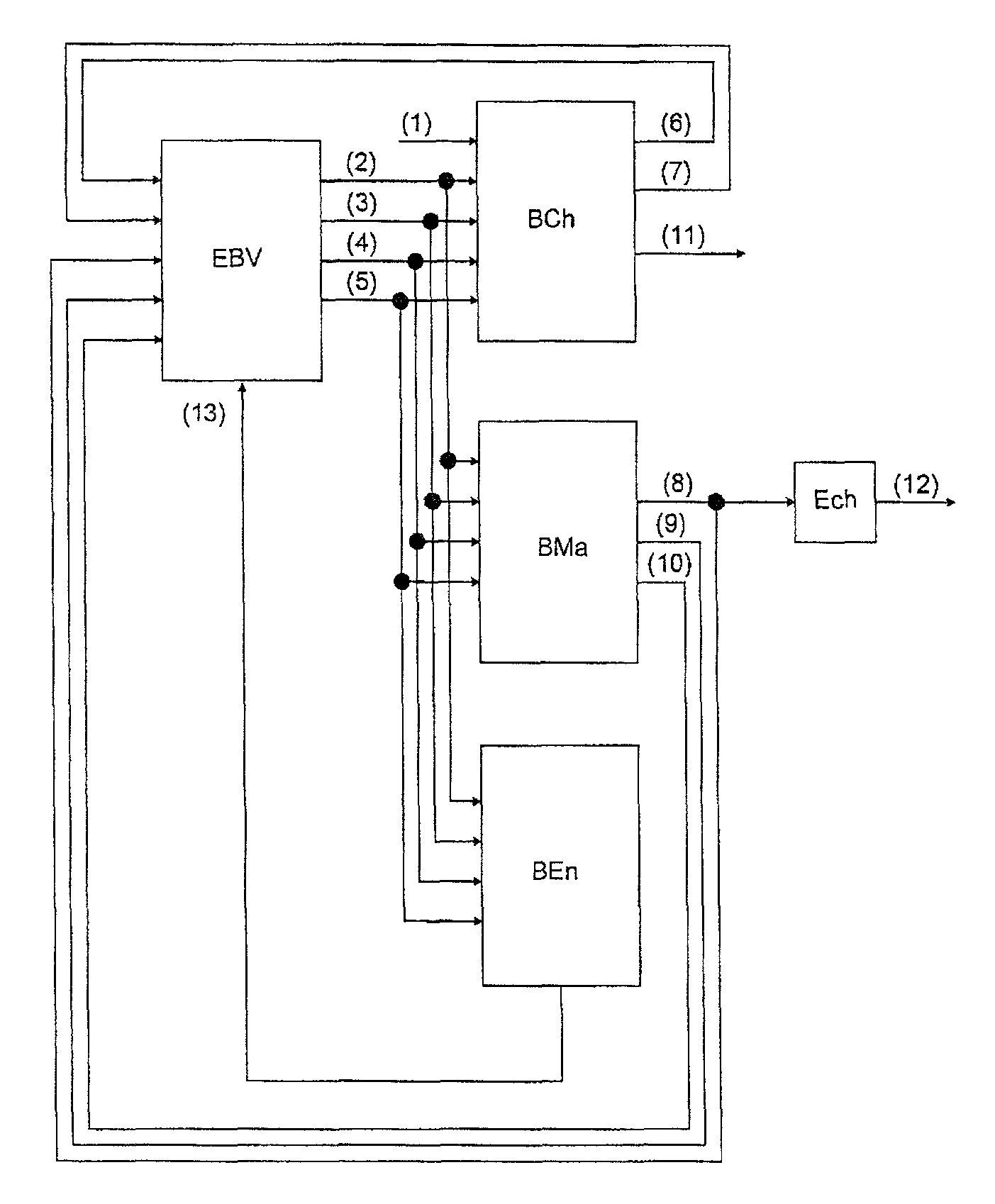

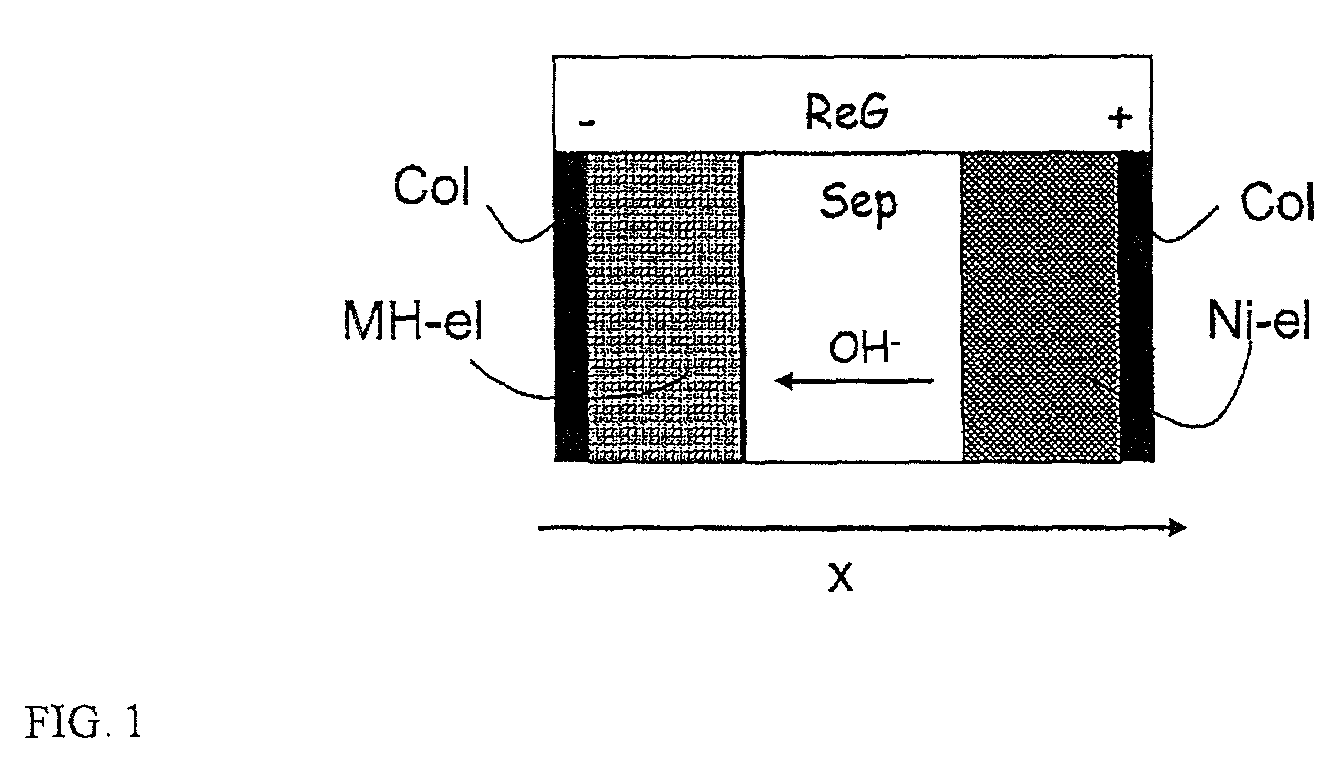

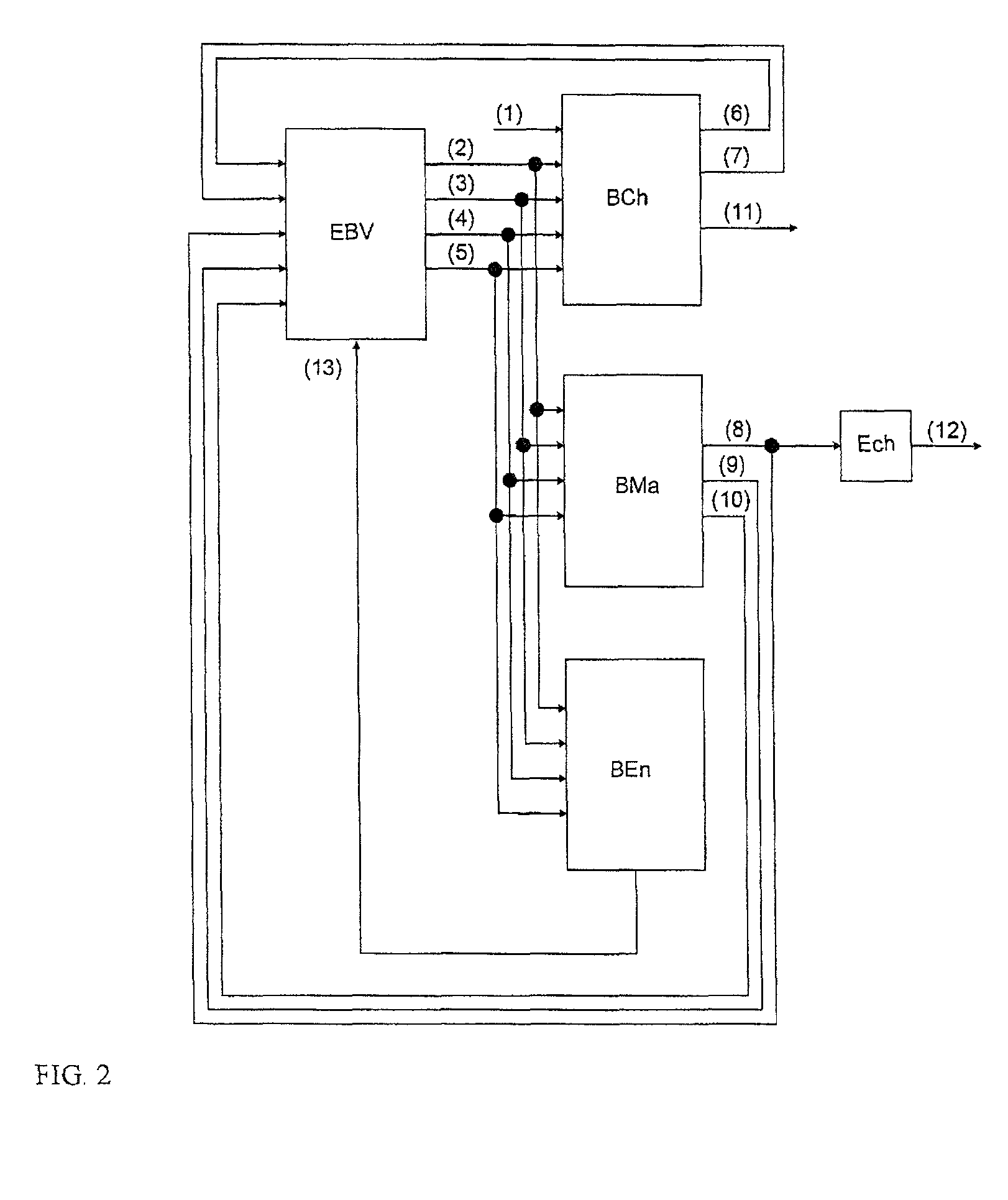

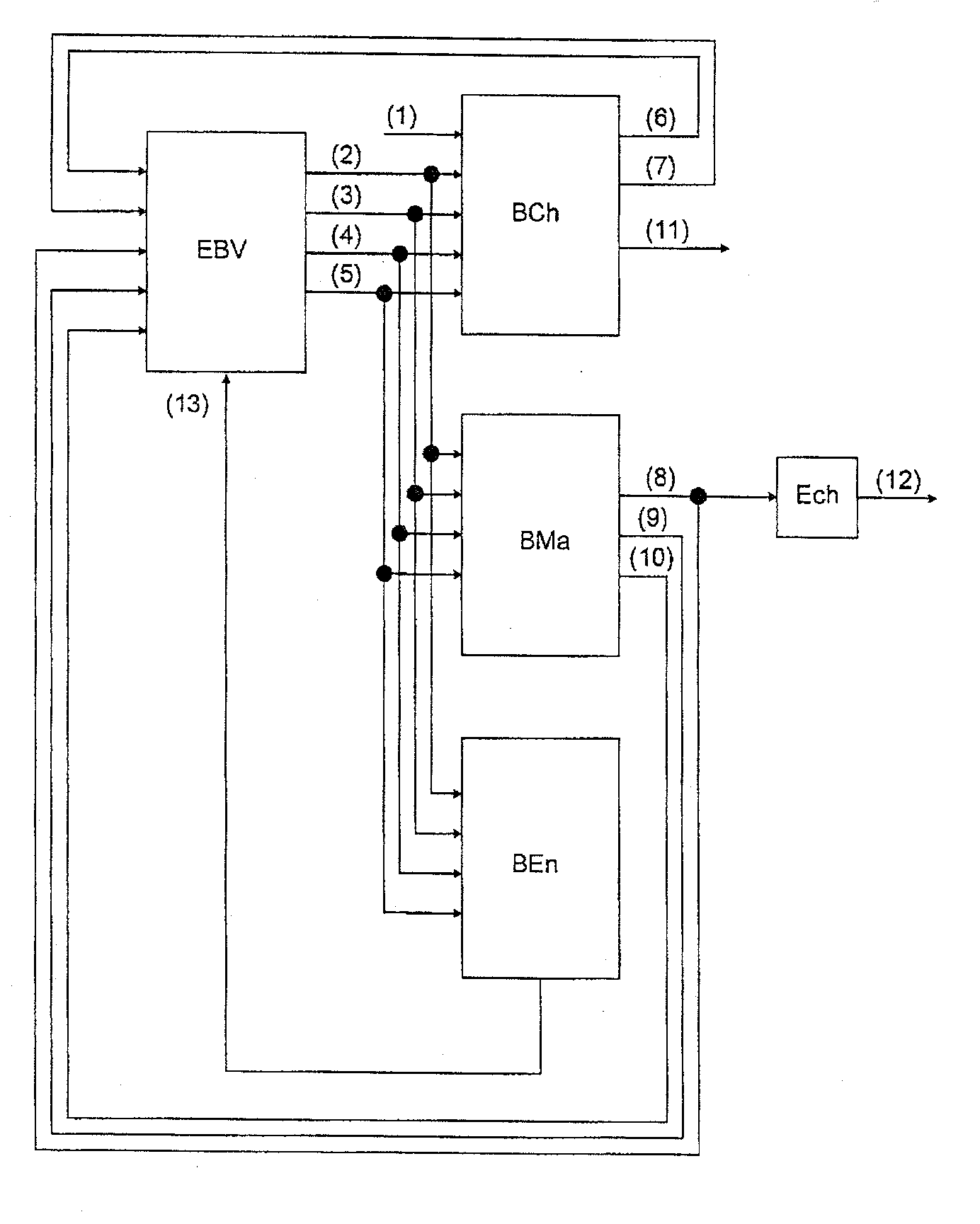

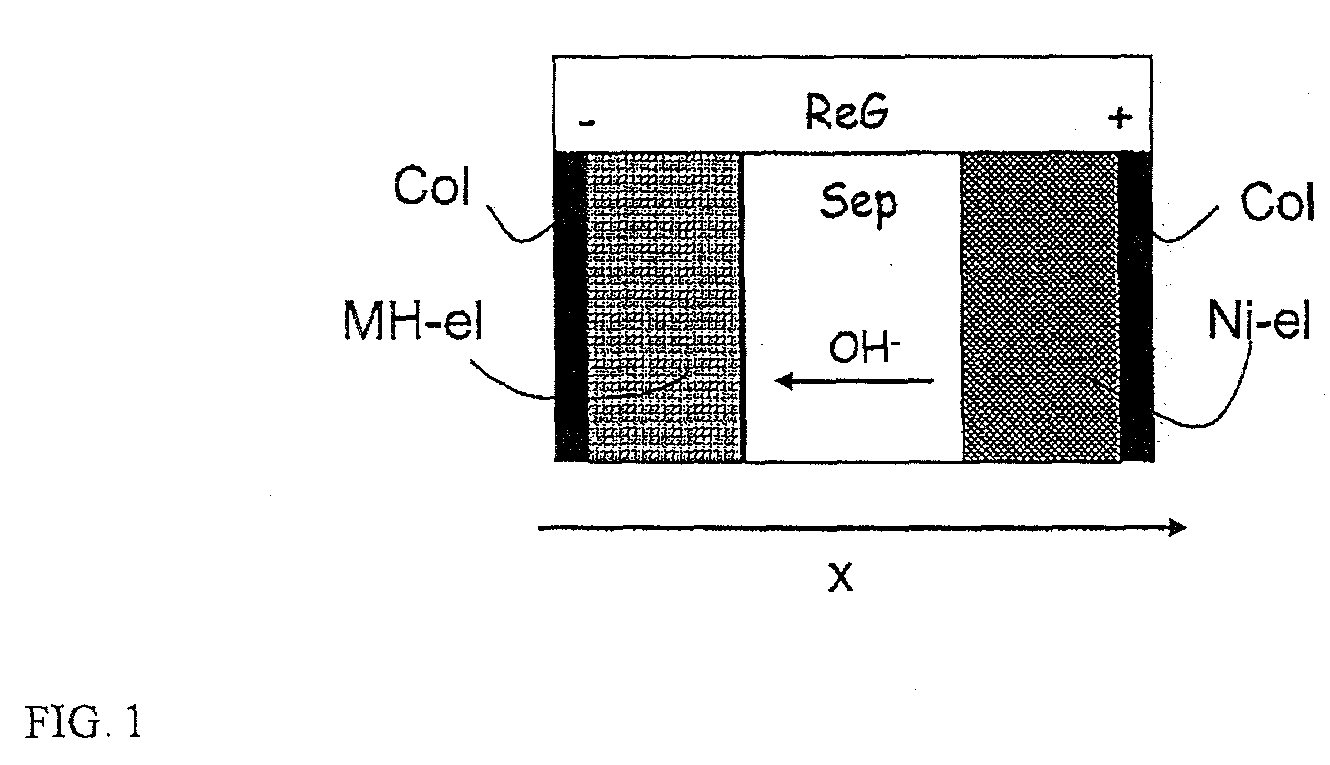

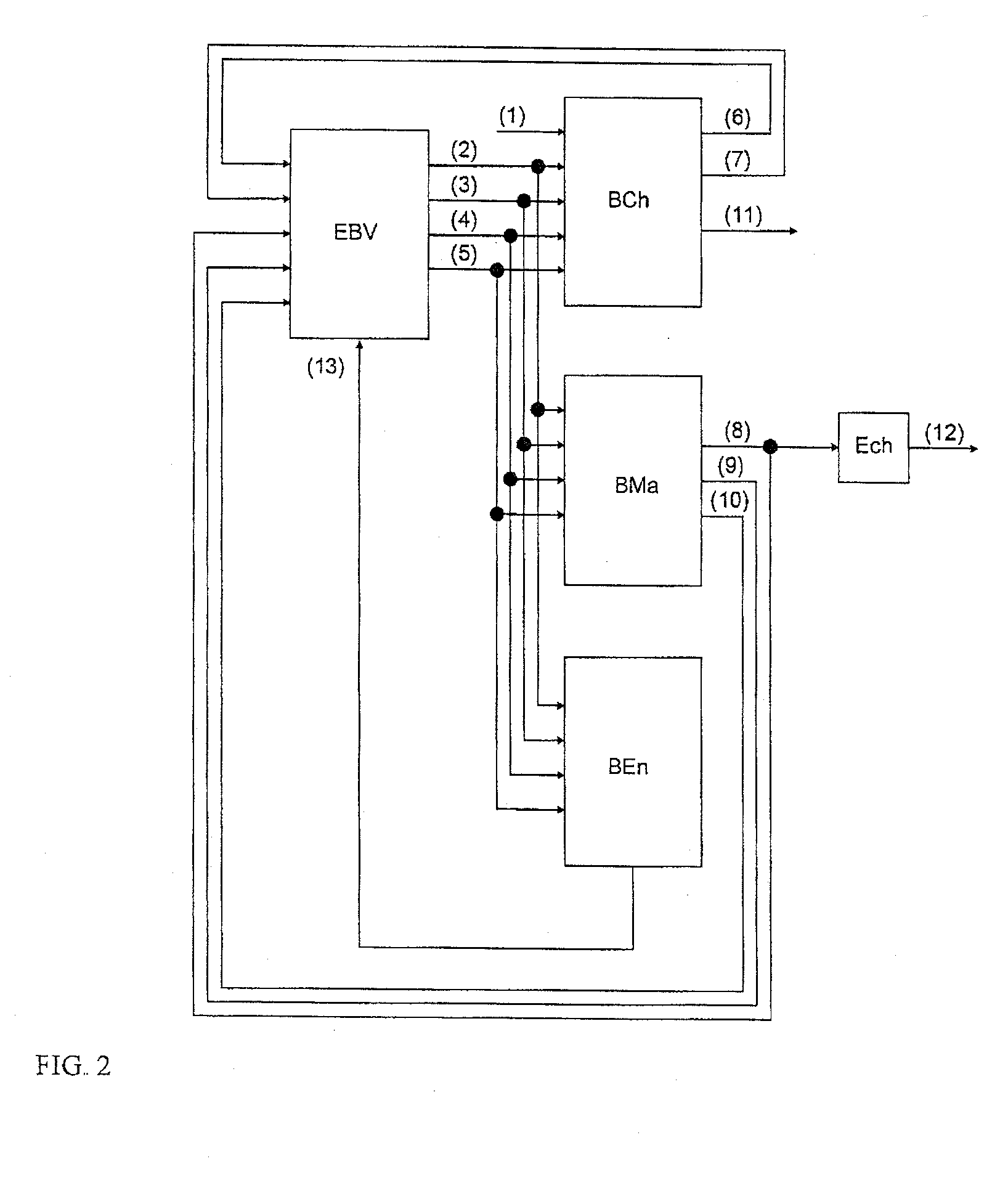

Method of estimating the non-measurable characteristics of an electrochemical system

The present invention relates to a method of estimating the internal state of an electrochemical system using mathematical models which allow management of an electrochemical battery during operation, and notably estimation of the characteristics of the battery that are not directly measurable. For applications relating to hybrid and electric vehicles, the most significant internal characteristics are the state of charge (SoC), the state of health (SoH) and the thermal state. Reconstruction of the internal characteristics is achieved using mathematical models of the battery. The method can be used synchronously with the operation of the battery itself (real time) with a reduced or off-line mathematical model, for calibration, optimization or validation of management and estimation strategies. The method is useful for battery sizing, which has to be optimized according to the energy and thermal management strategies.

Owner:INST FR DU PETROLE

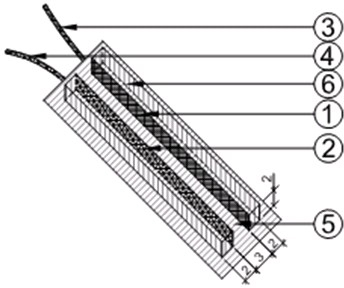

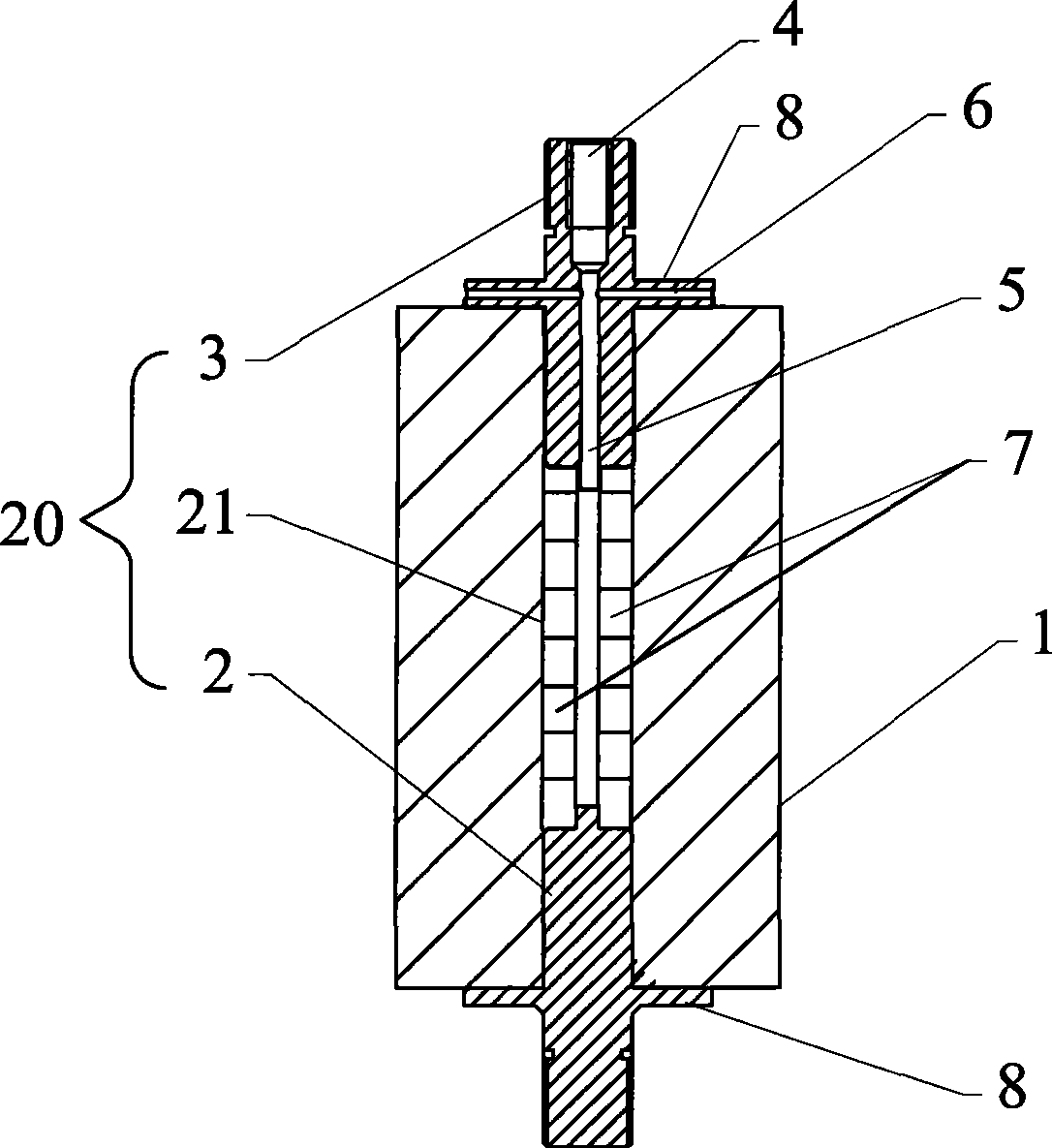

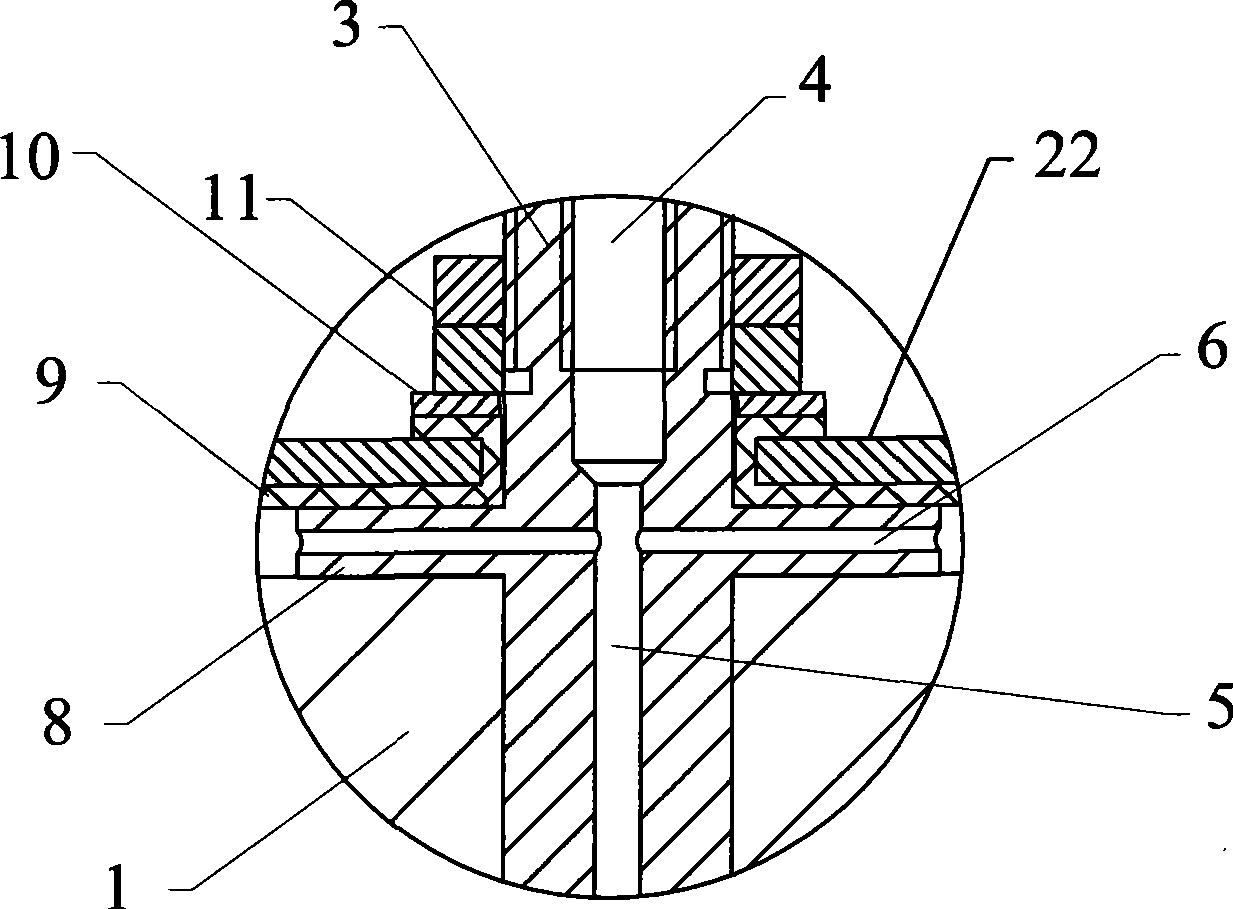

Core of cylindrical battery and method for assembling the core into the battery case

InactiveCN101393995AFirmly connectedReasonable structureFinal product manufacturePrimary cellsPower batteryPole piece

The invention provides an electric core of a cylindrical battery. The electric core comprises a roll core and a core axis penetrating the roll core. Positive and negative pole pieces and a diaphragm are wound on the core axis, and the two ends of the core axis are exposed out of the two end surfaces of the roll core. The invention further provides a method for mounting the electric core into the housing of the battery. By adopting the electric core of the cylindrical battery and the method for mounting the electric core into the housing of the battery, the core axis is fixed on the end cover or at the bottom part of the housing when being assembled; the relative fixing among the end cover, the housing, the core axis and the roll core provides the possibility of forming reliable connection between the positive pole piece and the negative pole piece and the positive electrode and the negative electrode of the battery; the center of gravity of the whole roll core is on the core axis; the core axis is sleeved on the end cover or in the center of the bottom part of the housing of the battery, the center of gravity of the battery is positioned in the geometric center of the outline thereof, and the structure is reasonable. The electric core of the cylindrical battery and the method for mounting the electric core into the housing of the battery are especially suitable for batteries with larger sizes or with heavier roll cores such as power batteries.

Owner:SHENZHEN BAK BATTERY CO LTD

Optimal battery sizing for behind-the-meter applications considering participation in demand response programs and demand charge reduction

ActiveUS20170256004A1Save power costLarge capacityData processing applicationsComputer controlPower usageObject function

A system and method are provided. The system includes a processor. The processor is configured to receive power related data relating to power usage of power consuming devices at a customer site from a plurality of sources. The processor is further configured to generate object function inputs from the power related data. The processor is additionally configured to apply the generated object function inputs to an objective function to determine an optimal capacity for a battery storage system powering the power consuming devices at the customer site while minimizing a daily operational power cost for the power consuming devices at the customer site. The processor is also configured to initiate an act to control use of one or more batteries of the battery storage system in accordance with the optimal capacity for the battery storage system.

Owner:NEC CORP

Method for manufacturing lithium-ion batteries

InactiveCN101673848AImprove capacity playImprove cycle performanceFinal product manufactureSecondary cellsPole pieceEngineering

The invention discloses a method for manufacturing lithium-ion batteries, which comprises a battery-precharging process. The method is characterized in that the battery-precharging process is realizedin the following way: using a precharging device to precharge a battery and using a vacuumizing device to vacuumize the inside of the battery at the same time, wherein the pressure in the vacuumizingprocess is set to be between 0.03 and 0.08 MPa; the precharging capacity is set to be 0.15 to 1 times of nominal capacity; and the precharging current is set to be between 0.05 and 1 C. The method adopting vacuum precharging can quickly and thoroughly discharge gas produced in the precharging process inside the battery and eliminate insulation region produced by the gas, thereby improving the capacity exerting-cycling performance of the battery, effectively eliminating or reducing lithium-separation situation of pole pieces, guaranteeing the qualified size of the battery and shortening precharging time. In addition, relative to the prior method, the method can leave out the processes of plugging cotton and covering rubber plugs.

Owner:SHENZHEN BAK BATTERY CO LTD

Method of estimating the non-measurable characteristics of an electrochemical system

The present invention relates to a method of estimating the internal state of an electrochemical system using mathematical models which allow management of an electrochemical battery during operation, and notably estimation of the characteristics of the battery that are not directly measurable. For applications relating to hybrid and electric vehicles, the most significant internal characteristics are the state of charge (SoC), the state of health (SoH) and the thermal state. Reconstruction of the internal characteristics is achieved using mathematical models of the battery. The method can be used synchronously with the operation of the battery itself (real time) with a reduced or off-line mathematical model, for calibration, optimization or validation of management and estimation strategies. The method is useful for battery sizing, which has to be optimized according to the energy and thermal management strategies.

Owner:INST FR DU PETROLE

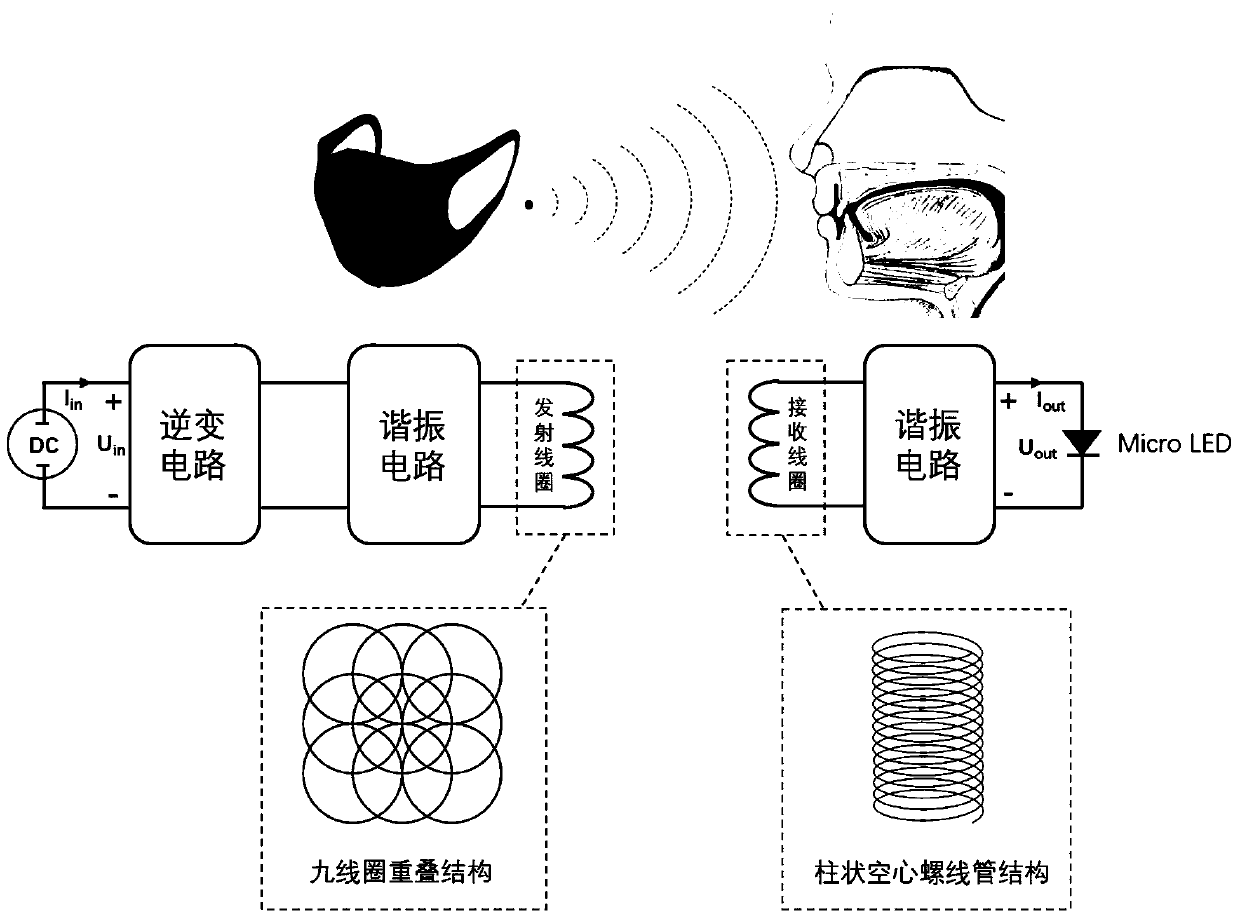

Oral implantable wireless power supply light-emitting micro device capable of promoting dental tissue repair

The invention discloses an oral implantable wireless power supply light-emitting micro device capable of promoting dental tissue repair. According to the invention, a resonance coil system is adoptedfor supplying power, so problems of wire abrasion, wire exposure and poor contact and potential safety hazards easily caused by a traditional wire connection power supply manner or the problems of limited battery size, limited service life, troublesome replacement and the like for a traditional battery power supply manner are solved, and more convenience and safety are achieved; and energy transmission is realized under the action of a high-frequency alternating magnetic field through the electromagnetic induction effect of an in-vitro transmitting coil and an in-vivo receiving coil, so continuous power supply can be provided for an LED phototherapy lamp implanted into an oral cavity in the treatment process, and a reliable optimal scheme is provided for long-term electric energy supply ofan implanted device.

Owner:SUN YAT SEN UNIV

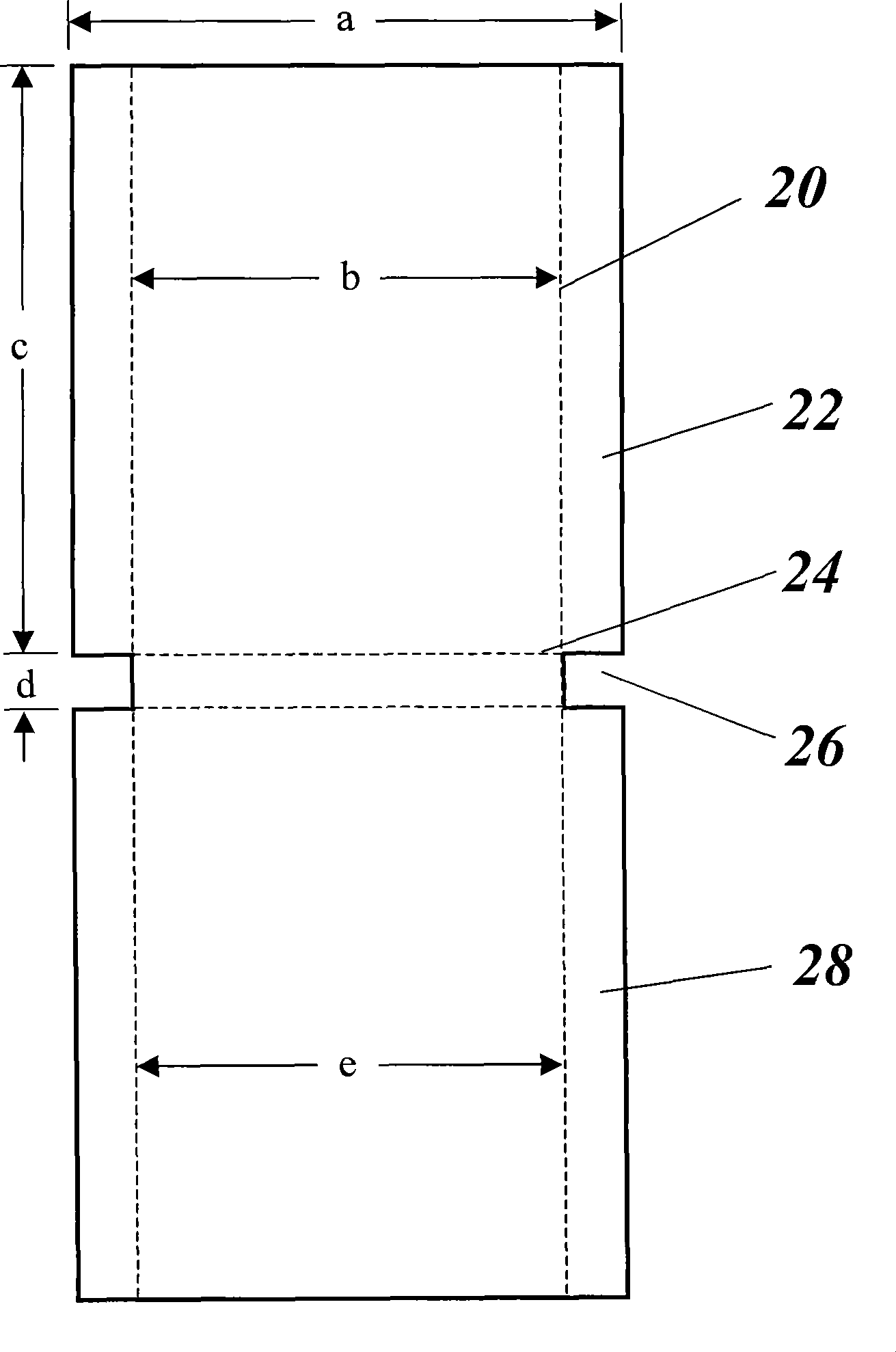

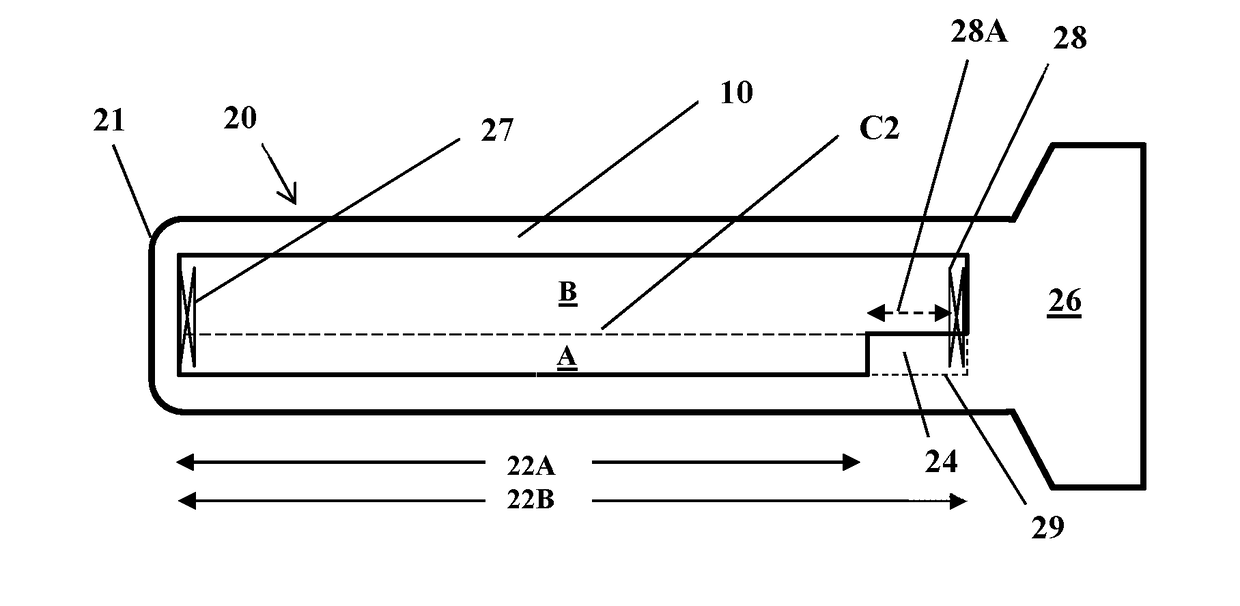

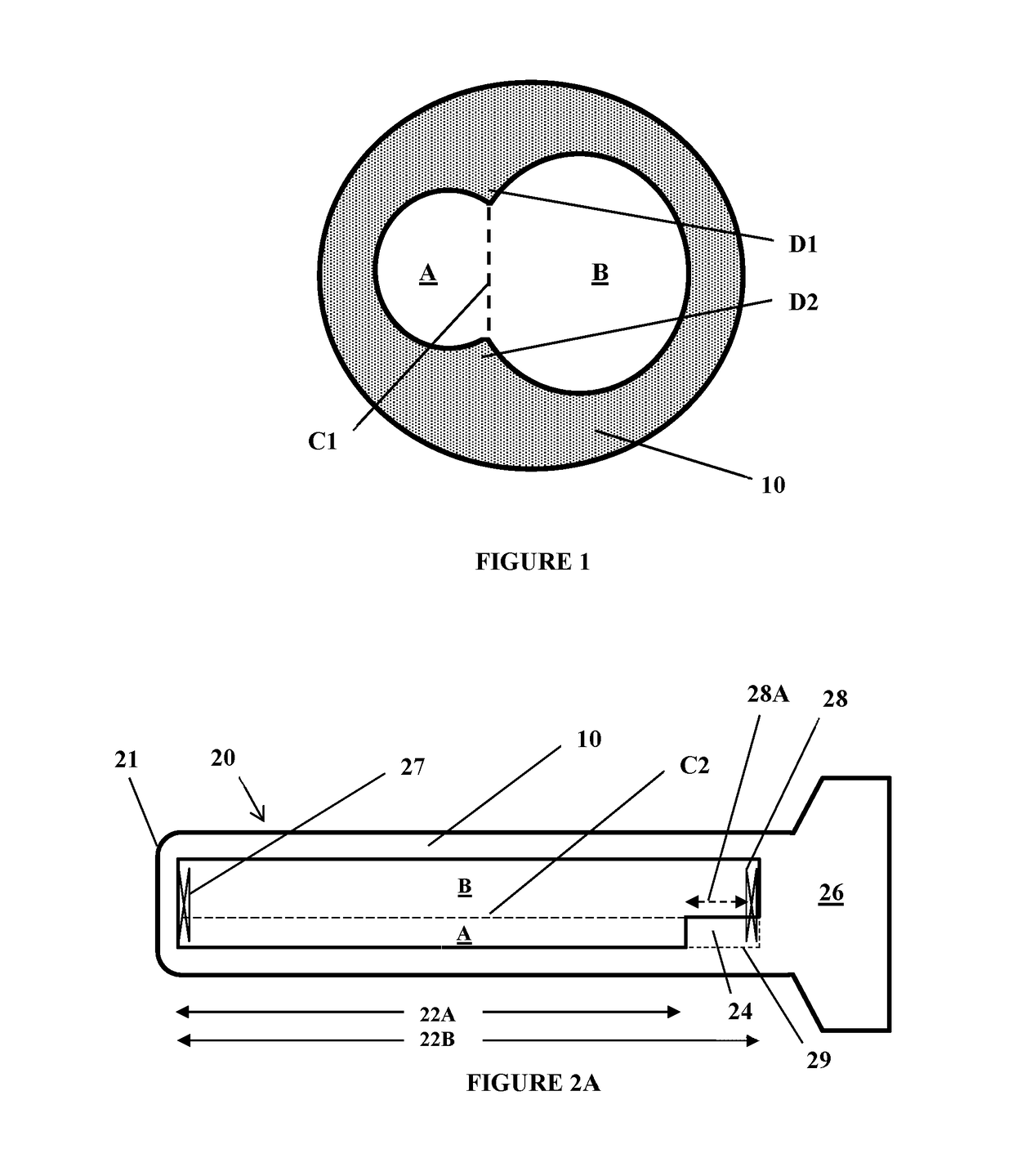

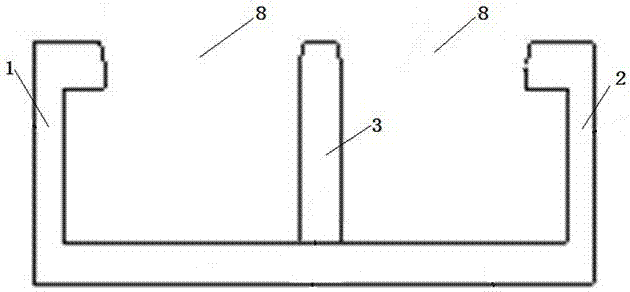

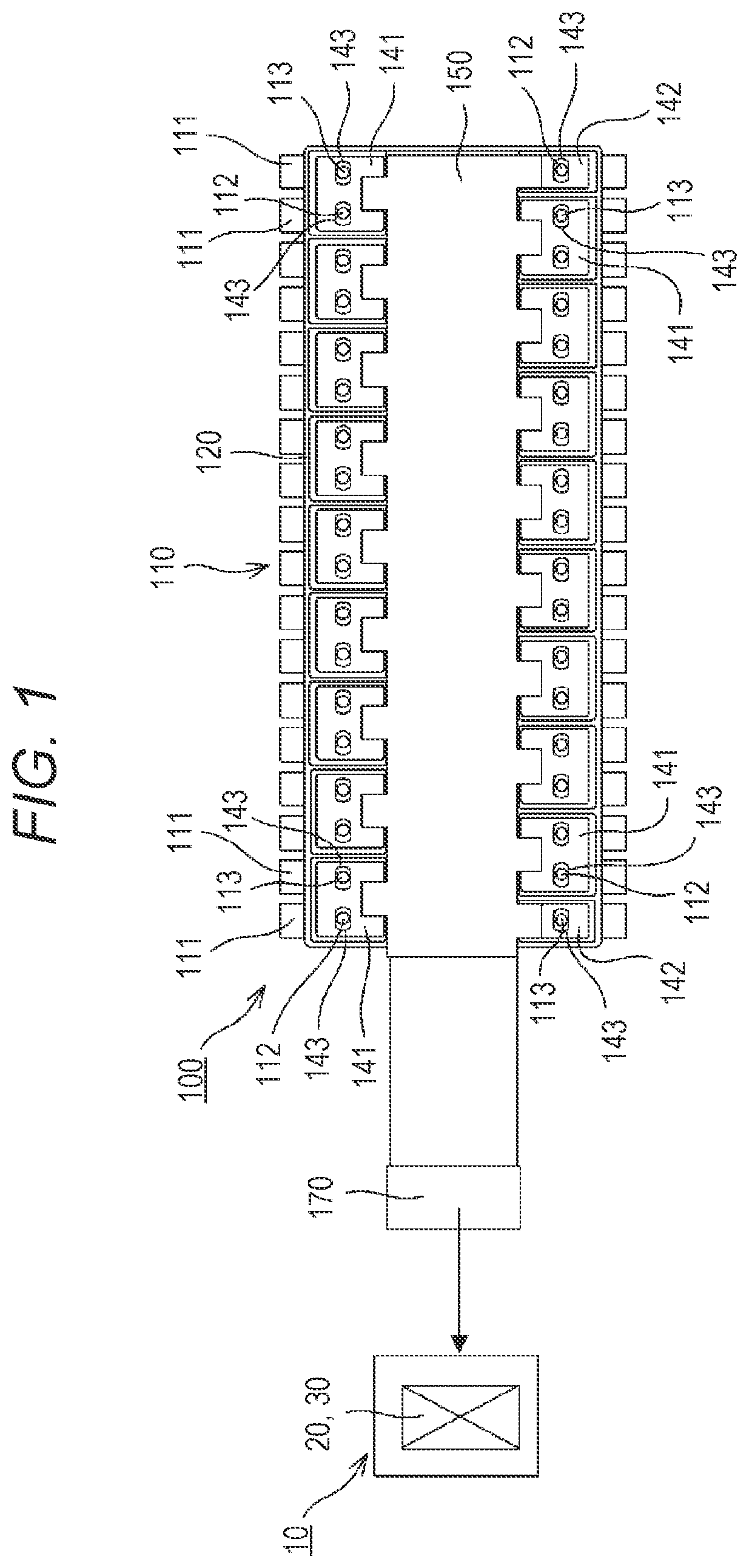

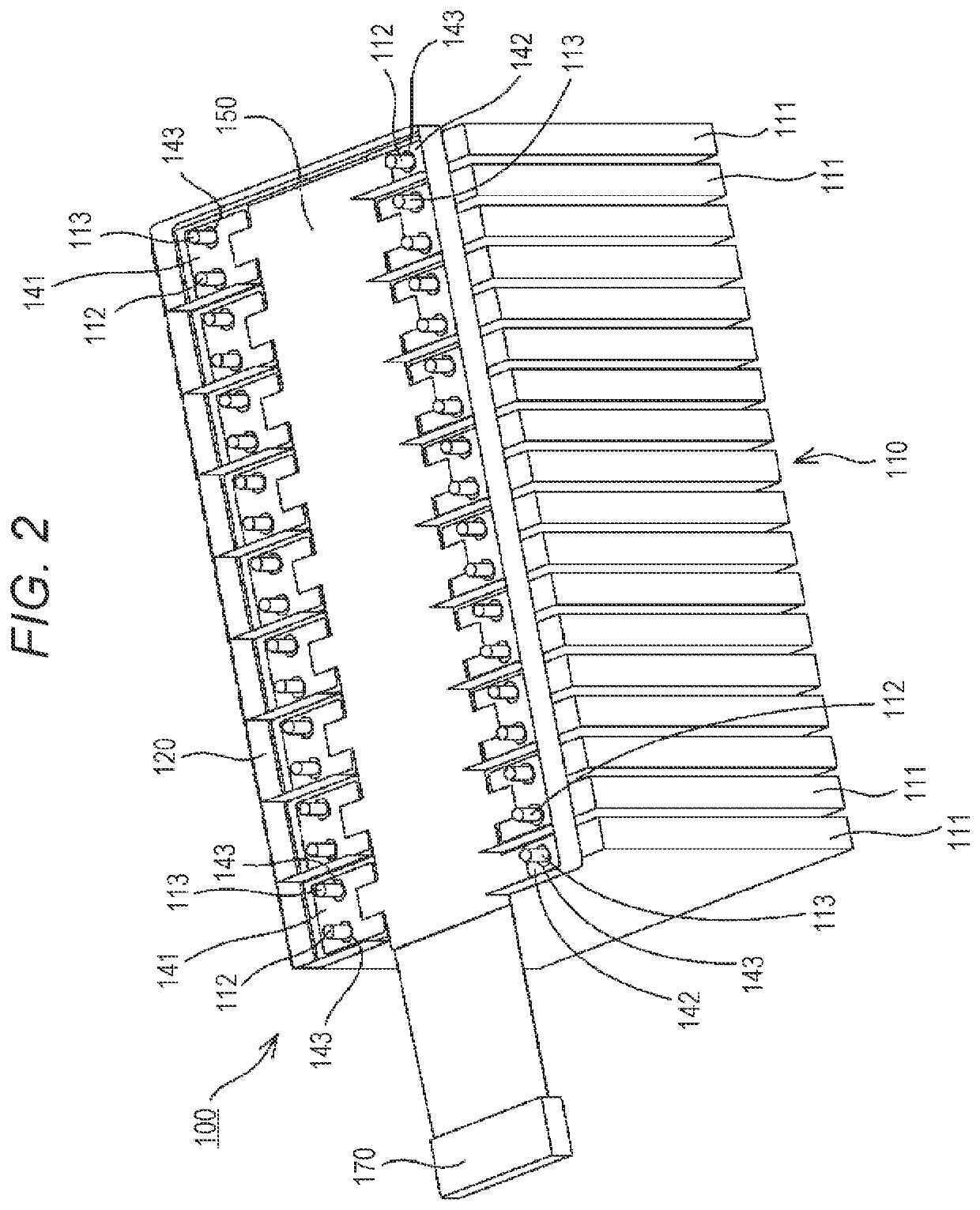

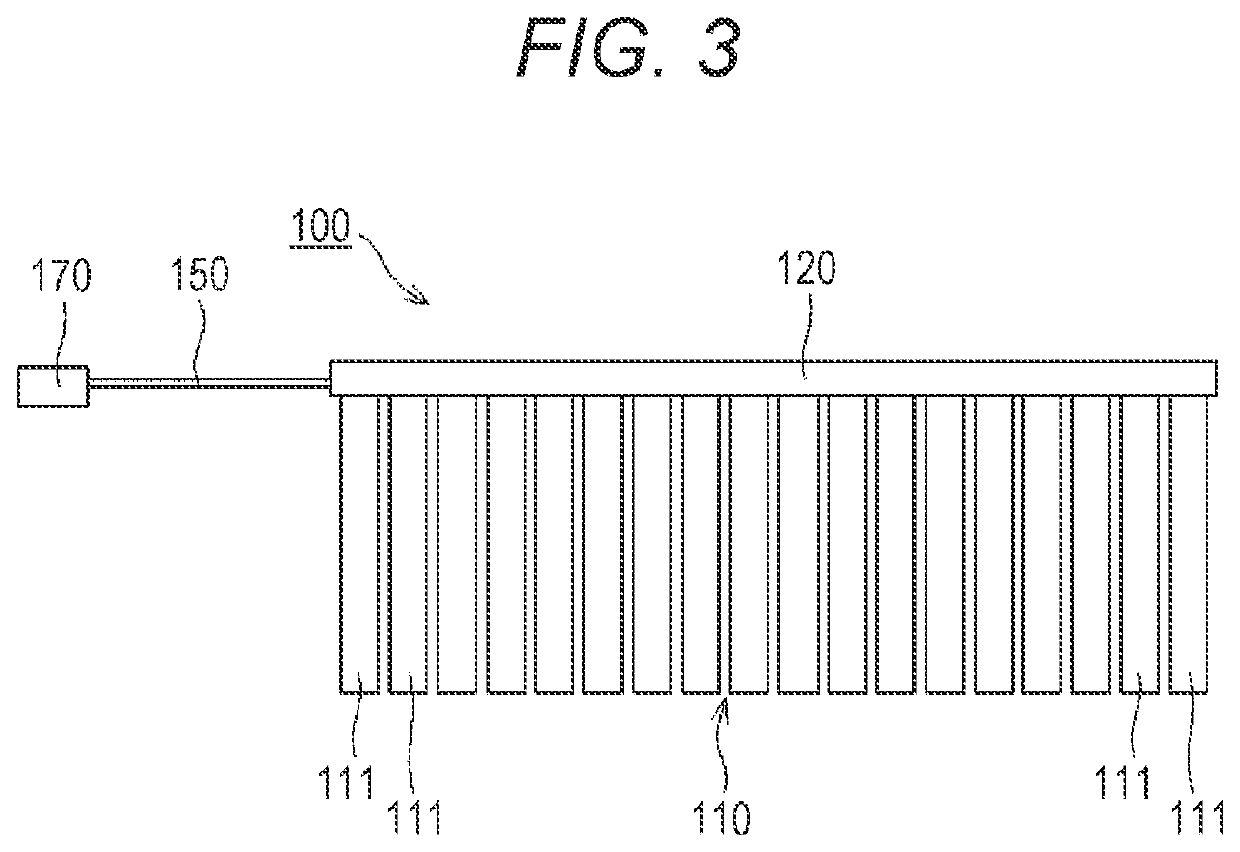

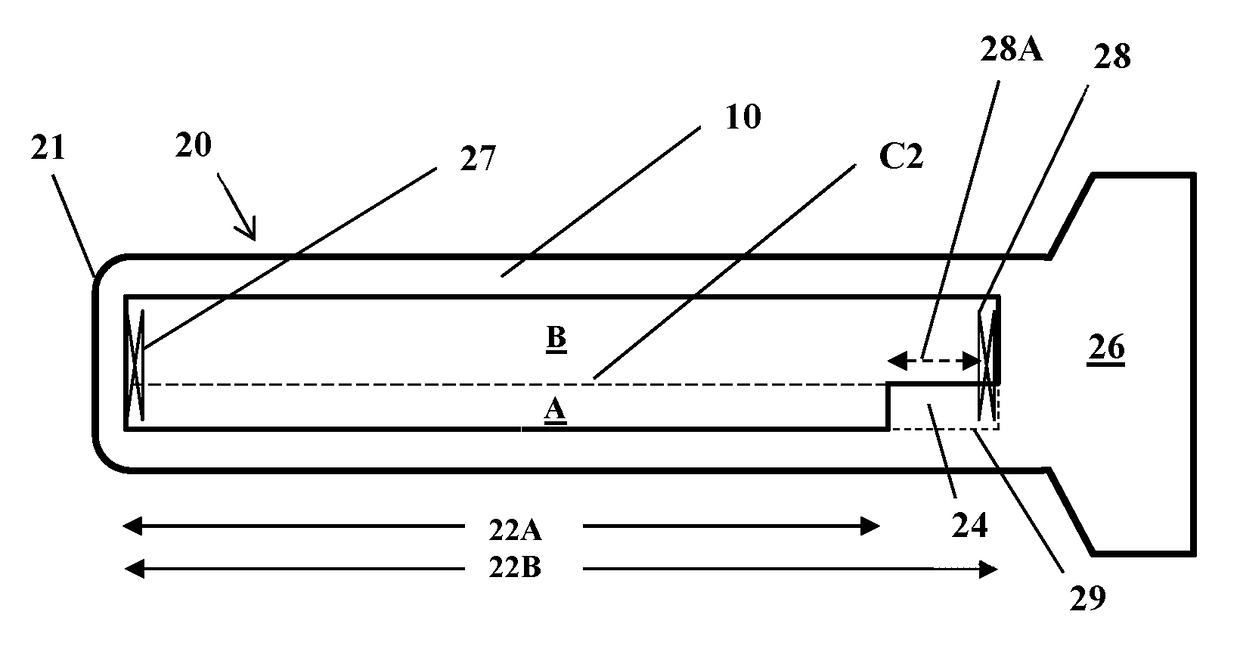

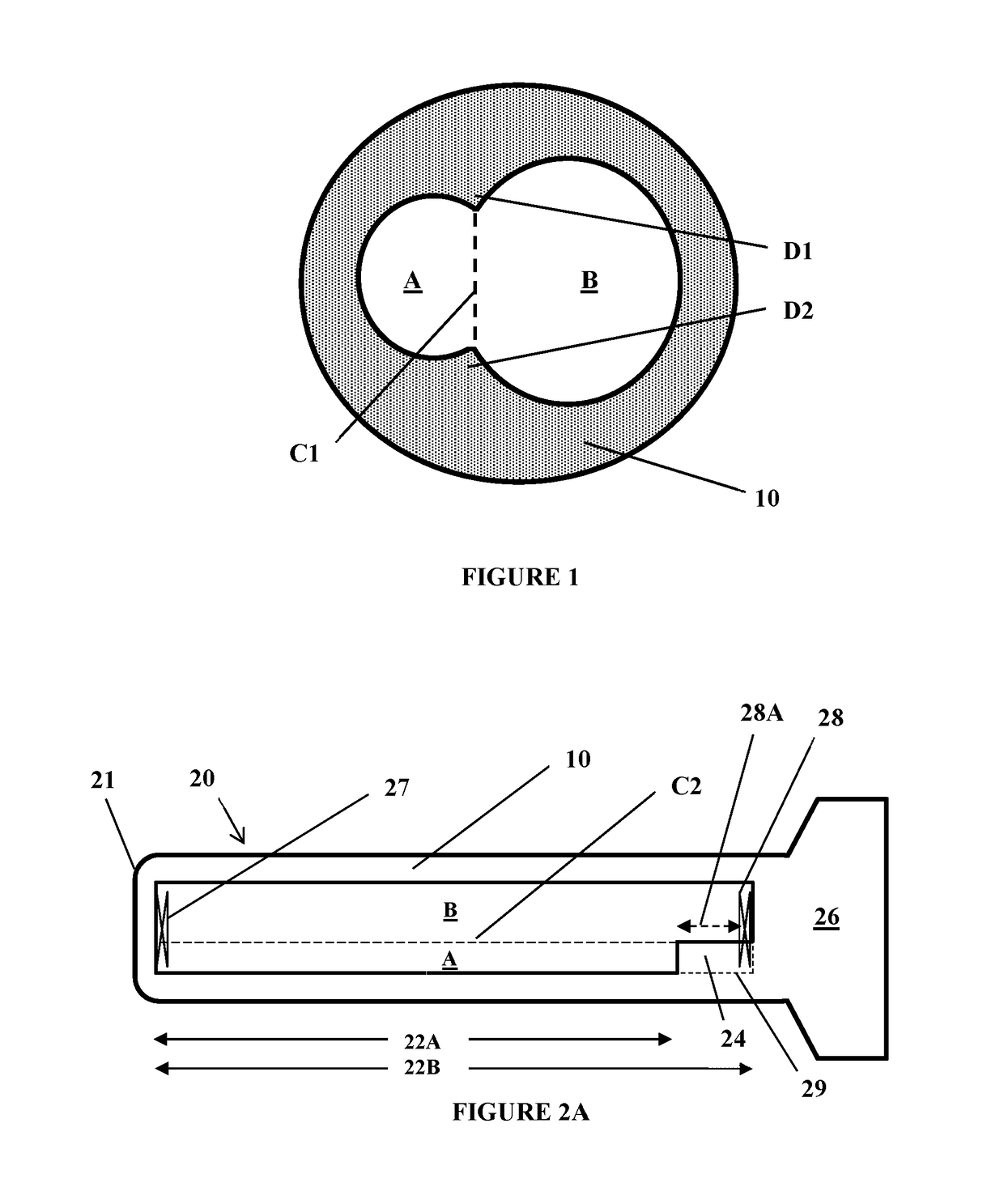

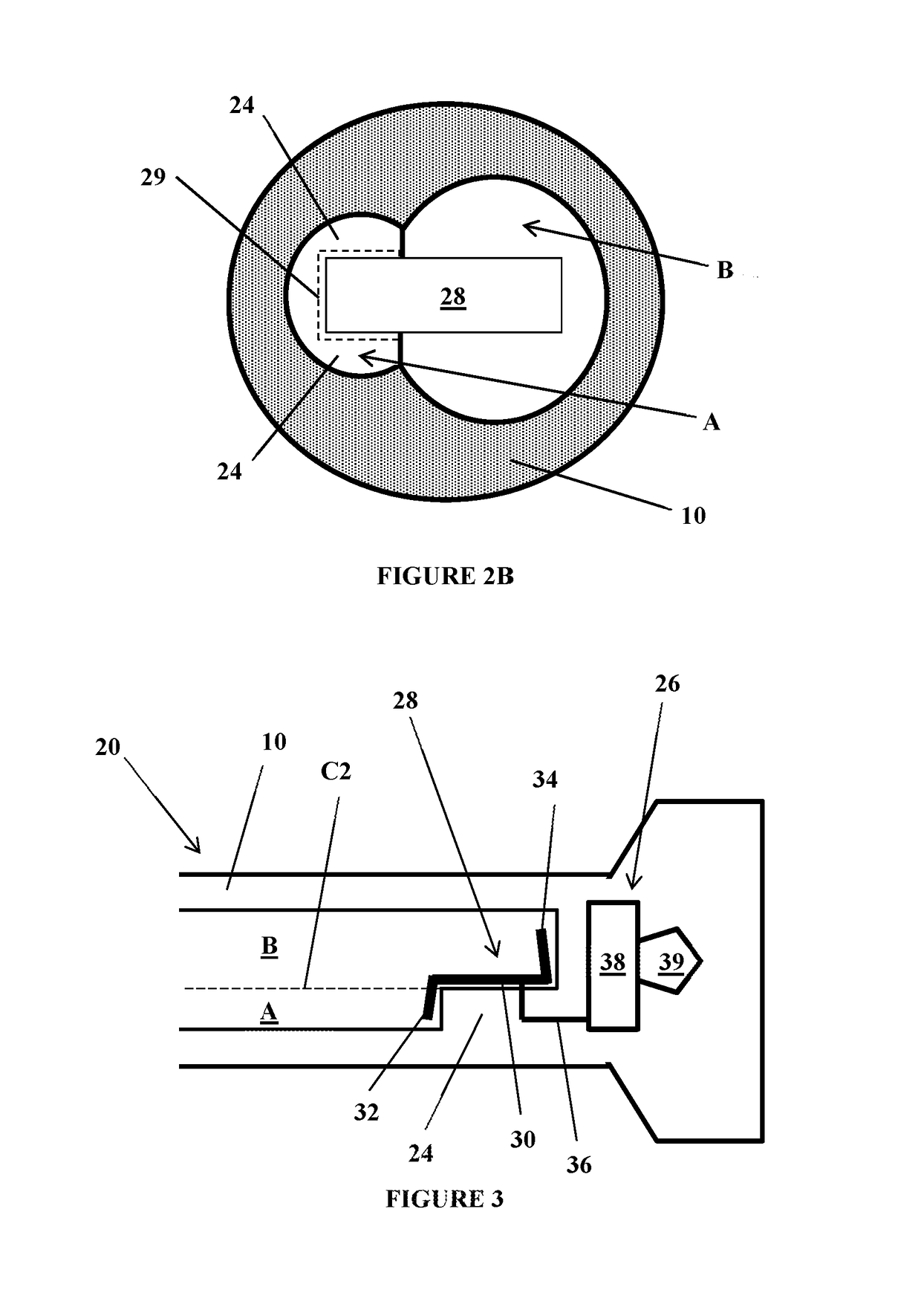

Slotted battery cavity for multiple cell sizes

A battery compartment for a device has a single cavity that is segmented into discrete slots, each slot associated with projections that secure and immobilize any batteries inserted into the compartment. Each slot is sized to receive a different size of battery, and the slots are positioned relative to one another to prevent batteries of different sizes from being inserted into the compartment. A shelf may be integrated within the slot(s), and the shelf may include a channel or a multi-planar yet unitary contact member to establish a single point of electrical connection between the battery compartment and the device.

Owner:ENERGIZER BRANDS

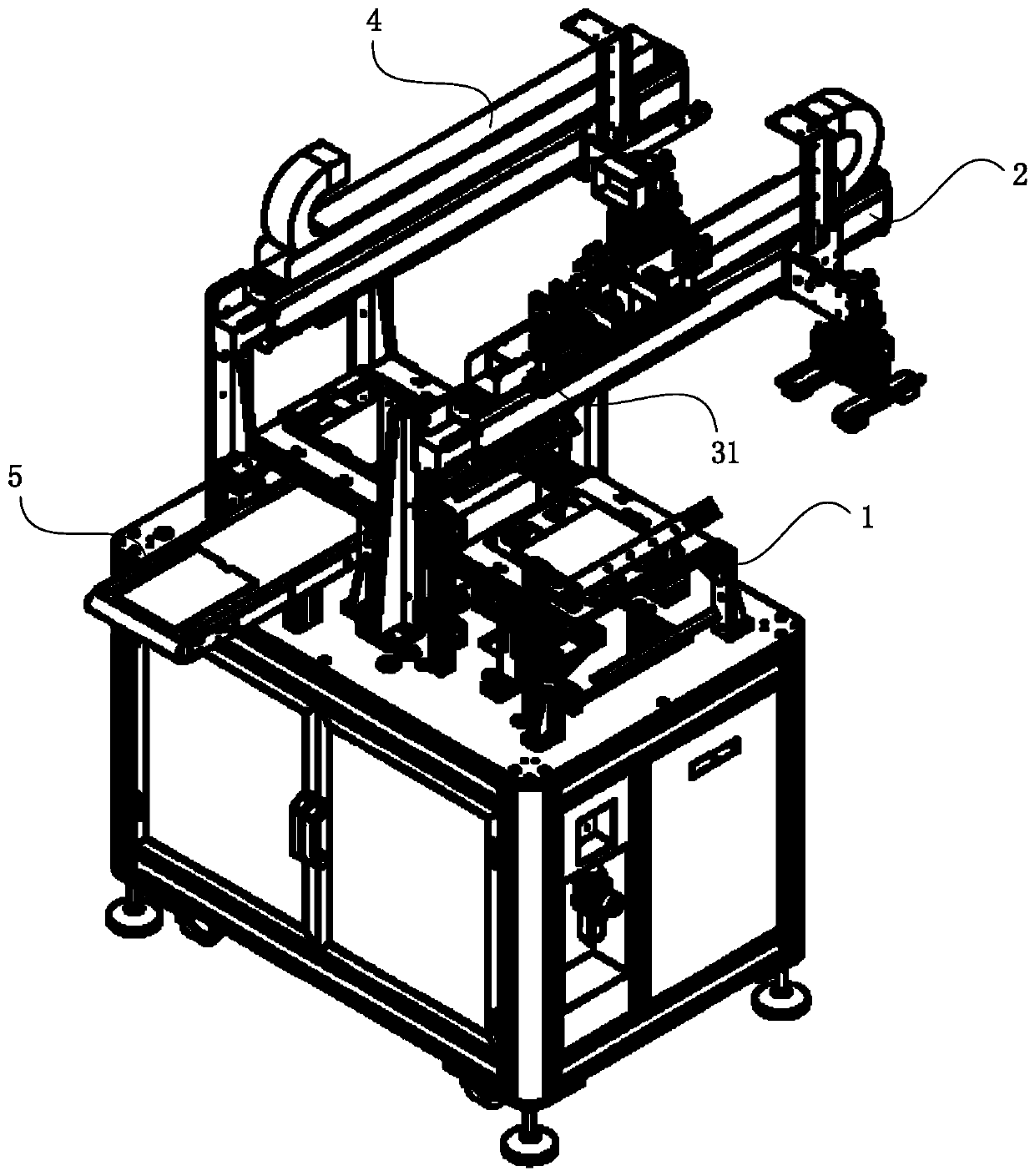

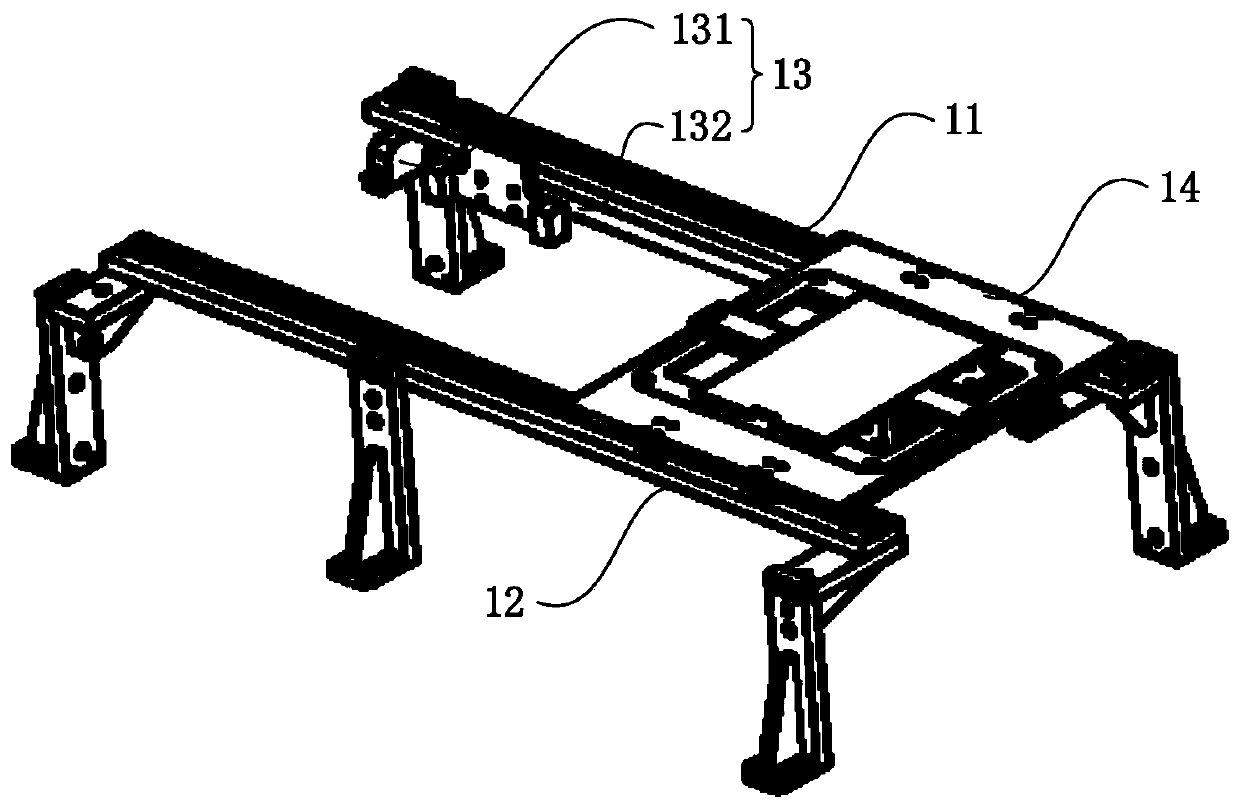

NG unloading sorting mechanism

InactiveCN111589726AReduce labor intensityImprove processing efficiencySortingRobot handInternal resistance

The invention provides a NG unloading sorting mechanism. The NG unloading sorting mechanism comprises a transfer mechanical hand, a NG unloading sorting mechanical hand as well as a battery thicknessNG unloading pull belt, a battery tab reshaping bad unloading pull belt, a batter dimension bad unloading pull belt, a battery voltage bad unloading pull belt, an OK discharge pull belt, a battery heat conduction coefficient NG unloading pull belt, a battery internal resistance NG unloading pull belt and a battery shell voltage bad unloading pull belt, which are sequentially arranged below the transfer mechanical hand from left to right, wherein the transfer mechanical hand is arranged at the front side below the NG unloading sorting mechanical hand; and the NG unloading sorting mechanical hand can sort and unload batteries on the transfer mechanical hand. The NG unloading sorting mechanism does not need manual operation, so that labor intensity of a worker is greatly reduced, and processing efficiency is improved.

Owner:ALLEGRO TECH

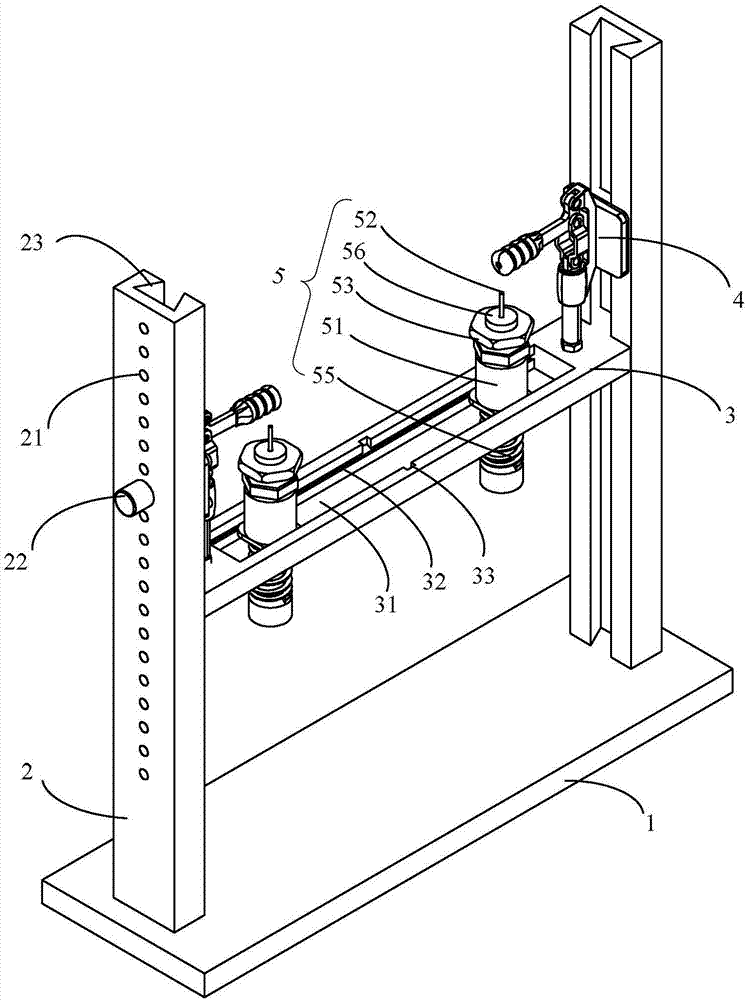

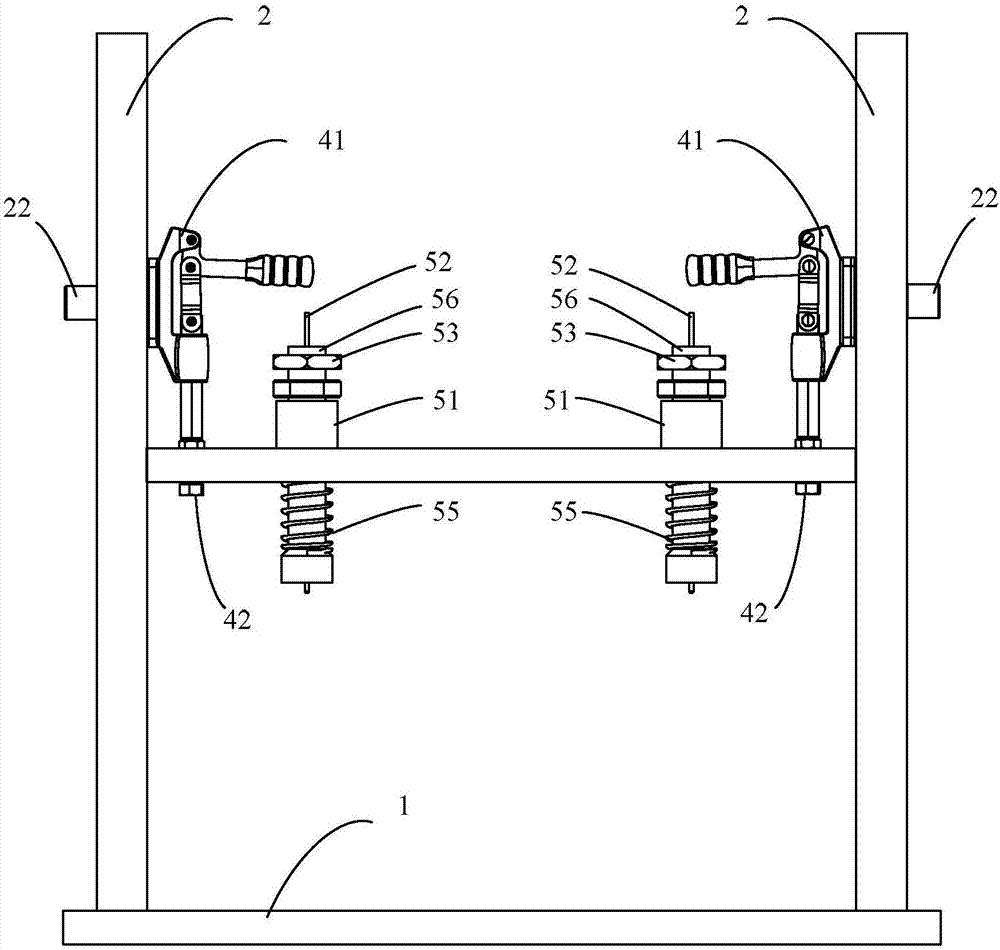

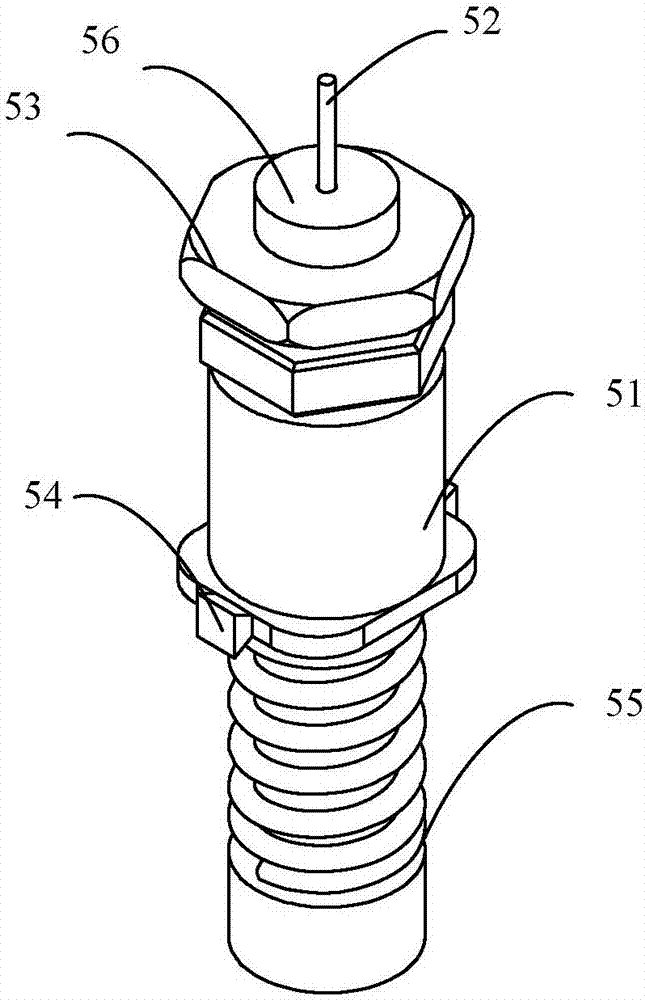

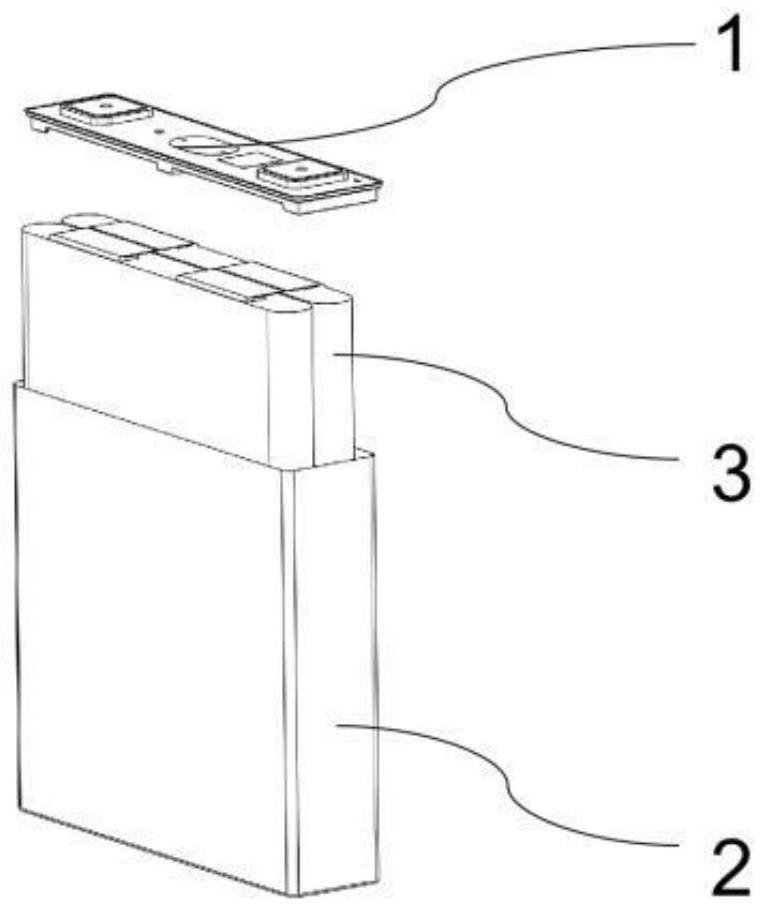

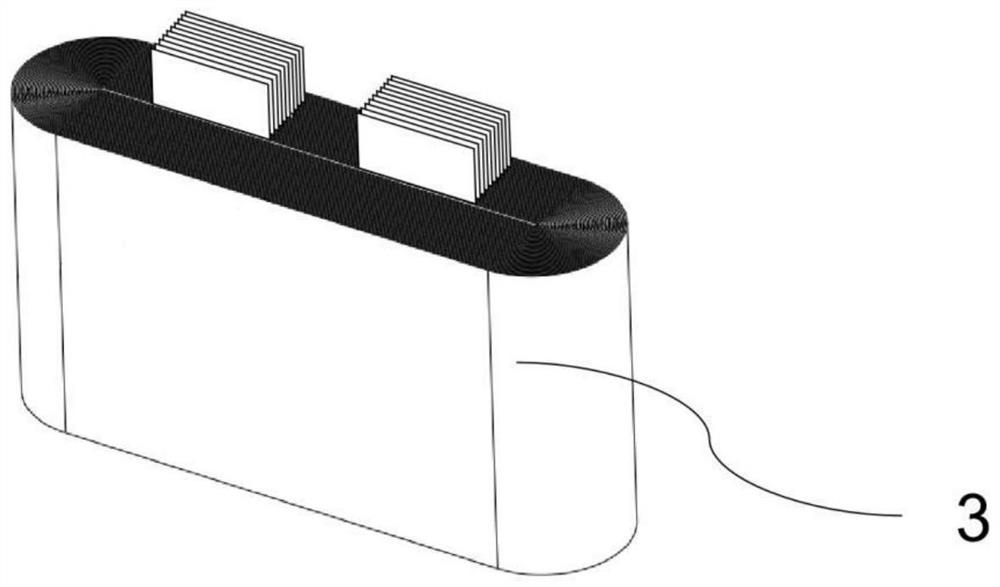

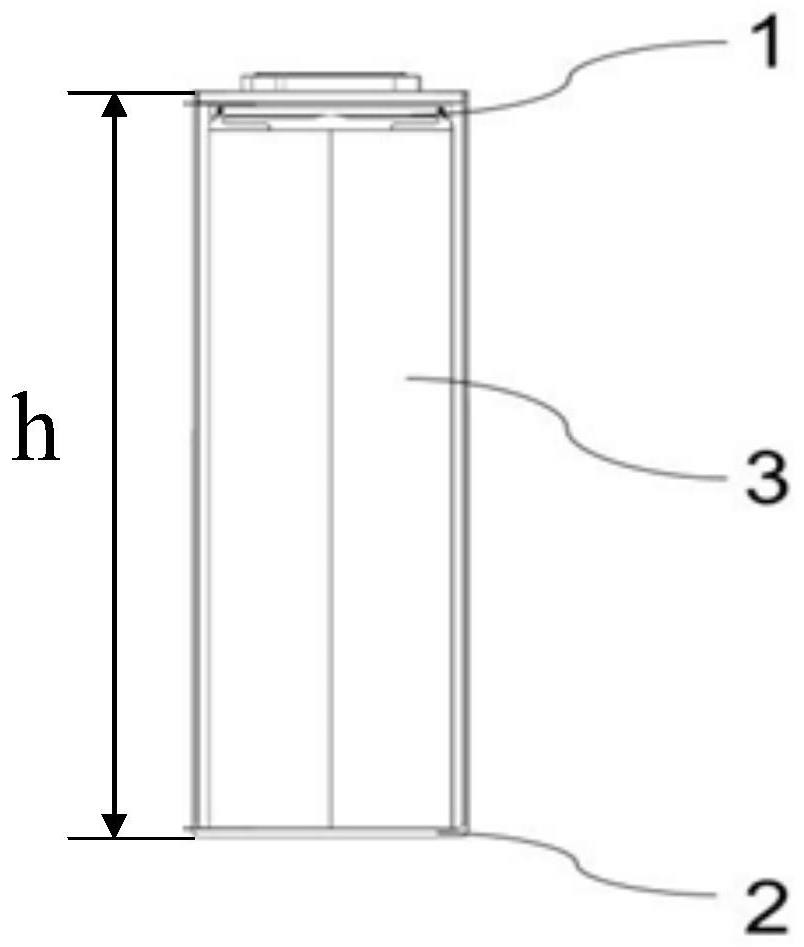

Battery testing fixture

PendingCN107515318AClosely connectedAvoid collection effectsMeasurement instrument housingElectrical batteryStructural engineering

Disclosed is a battery testing fixture. The battery testing fixture comprises a bottom plate, a stand column fixed onto the bottom plate, and a fixing assembly, wherein the fixing assembly can move up and down relative to the stand column and be fixed onto the stand column through a connector for pressing a battery on the bottom plate and being electrically connected with the battery. By means of the fixing assembly which can slide relative to the stand column and can be fixed onto the stand column, the battery testing fixture is applicable to batteries in various sizes, thereby being flexible in application.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

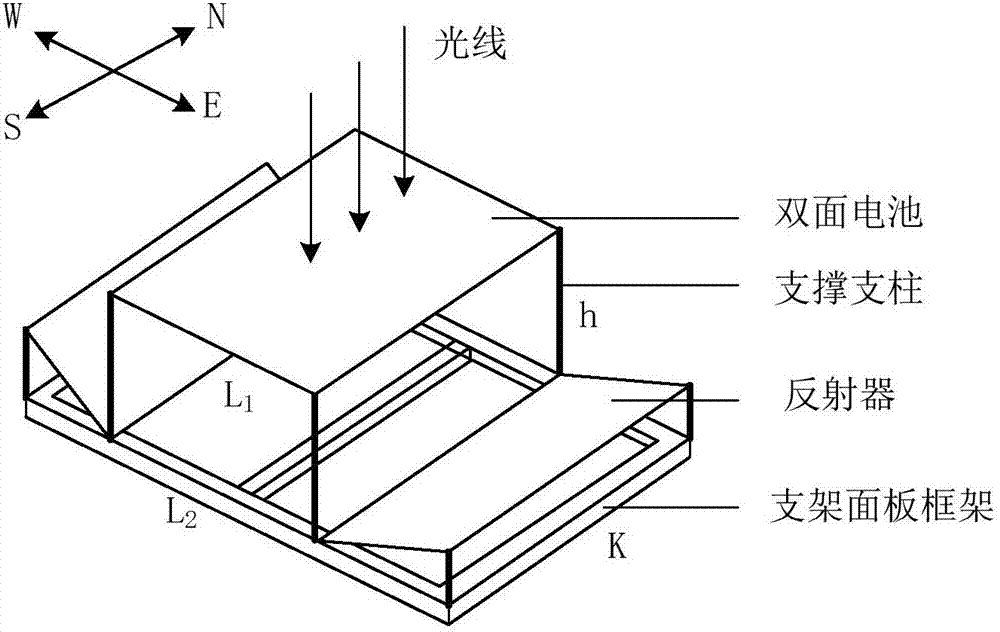

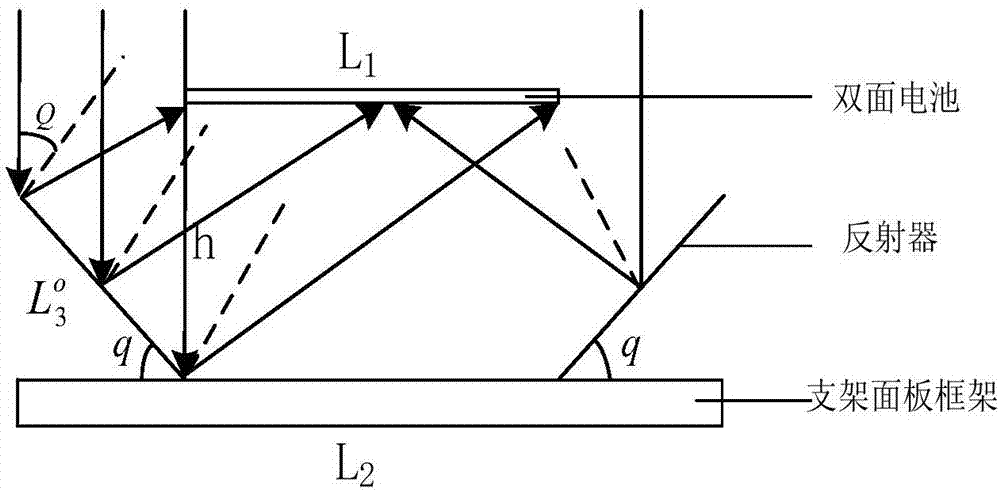

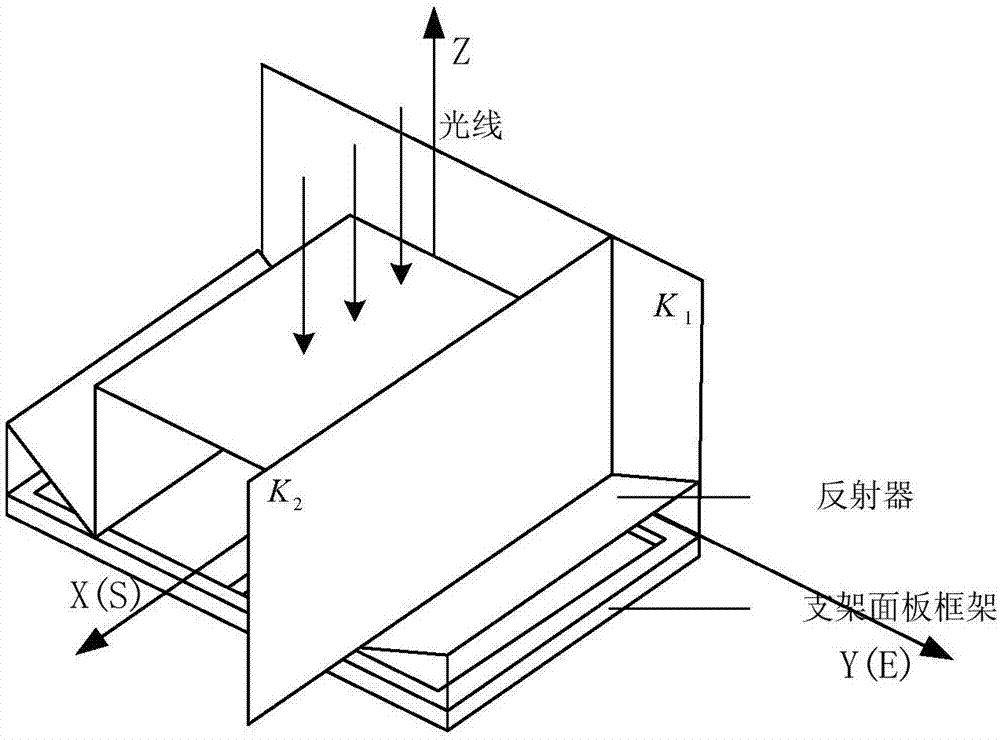

Design method of panel structure of double-sided solar battery tracking bracket

InactiveCN108011574AIncrease the amount of solar radiationIncrease radiation dosePhotovoltaic supportsEngineeringSolar battery

The invention discloses a design method of a double-sided solar battery bracket panel which is applied to a tracking bracket and is added with reflector structures. Based on the power generation performance of front and back sides of a double-sided solar battery and the optical principle, the invention provides a design method of a panel structure of a double-sided solar battery tracking bracket.The method comprises the steps of (1) analyzing a general structure of a designed bracket panel and local latitude and longitude, sunshine and climate conditions, (2) determining the size data of thedouble-sided battery and the distance between bracket panel frames, and designing initial sizes and inclination angles of two reflectors at left and right sides of the double-sided solar battery, and(3) designing certain size margins for the two reflectors with the consideration of the change of the angle between direct sunlight and the double-sided battery to improve the amount of radiation received by the battery, and finally determining the size data of the whole bracket panel. According to the method, the overall structure of the bracket panel can be flexibly designed according to a localenvironment, the size of the double-sided battery and the like, and the amount of radiation received by the double-sided battery can be significantly increased.

Owner:STATE GRID HUBEI ELECTRIC POWER COMPANY +3

Waste battery sorting method

The invention discloses a waste battery sorting method which comprises the following steps: (1) primary selection of waste batteries: conveying metal garbage subjected to magnetic separation and a battery mixture into a battery sorting trough through a first conveying belt, wherein metal substances with sizes less than sizes of batteries fall into a second conveying belt from an outlet of the battery sorting trough; (2) detection of the batteries: judging the metal garbage and the barriers in the battery mixture on the second conveying belt according to the fact that the batteries have the electricity output characteristics; and (3) grabbing of the waste batteries: grabbing the batteries, confirmed in the step (2), through a battery grabbing manipulator, and putting the batteries into a waste battery collection box. According to the waste battery sorting method, workers can be replaced for sorting the waste batteries in household garbage subjected to the magnetic separation, so that pollution to the environment due to the waste batteries is prevented; and the waste battery sorting method is high in automation degree, time-saving and labor-saving.

Owner:HENAN INST OF ENG

Square lithium ion battery

ActiveCN114243092AImprove mass energy densityImprove space utilizationFinal product manufactureSecondary cellsEngineeringPositive current

The invention provides a square lithium ion battery, the square lithium ion battery comprises a square shell and a cover plate, the square shell is internally provided with at least one roll core, the roll core comprises a positive plate and a negative plate which are arranged at two sides of a diaphragm, the positive plate comprises a positive current collector, and the negative plate comprises a negative current collector. The positive plate comprises a positive current collector and a positive active material coating area at least partially covering one surface of the positive current collector, and the negative plate comprises a negative current collector and a negative active material coating area at least partially covering one surface of the negative current collector; the square lithium ion battery meets the following conditions: (T / (30 * n)) 0.5 / V * Sc is greater than or equal to 3.0 and less than or equal to 5.0; according to the square lithium ion battery provided by the invention, the number of the roll cores and the coating area of the positive and negative active materials can be flexibly designed, the selection of the number of the roll cores and the coating area of the positive active materials and the size of the battery are limited, and the space utilization rate of the roll cores is improved, so that the mass energy density of the battery is improved; design is reasonable, operability is high, and popularization is facilitated.

Owner:SHANGHAI RUIPU ENERGY CO LTD

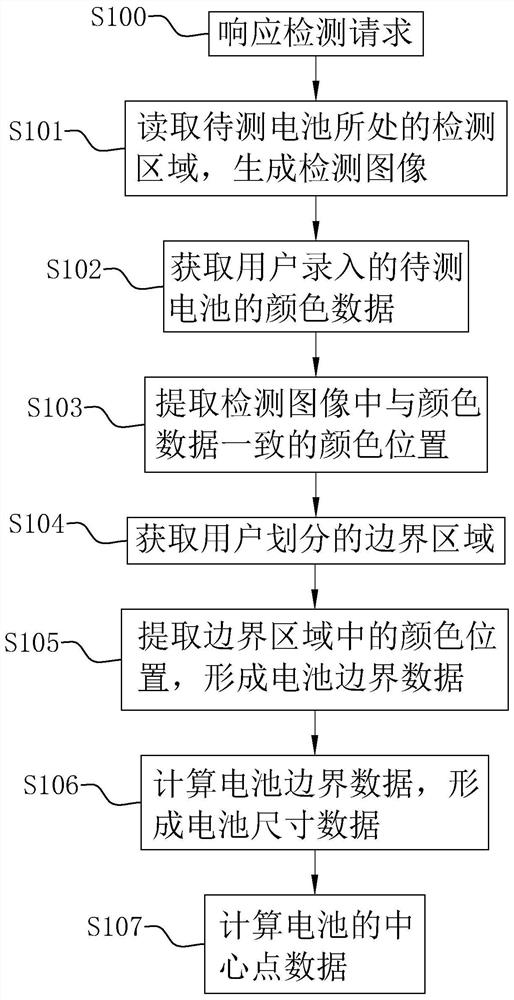

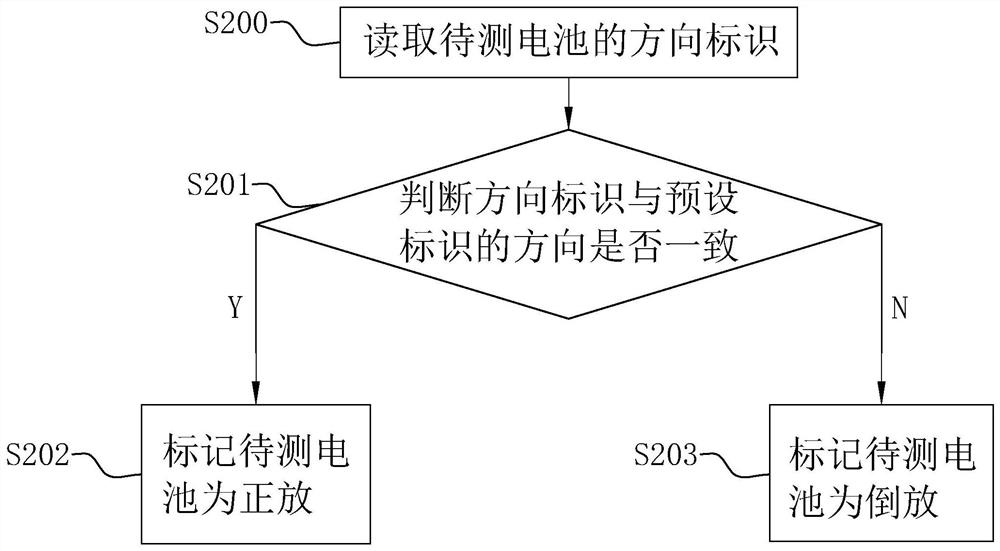

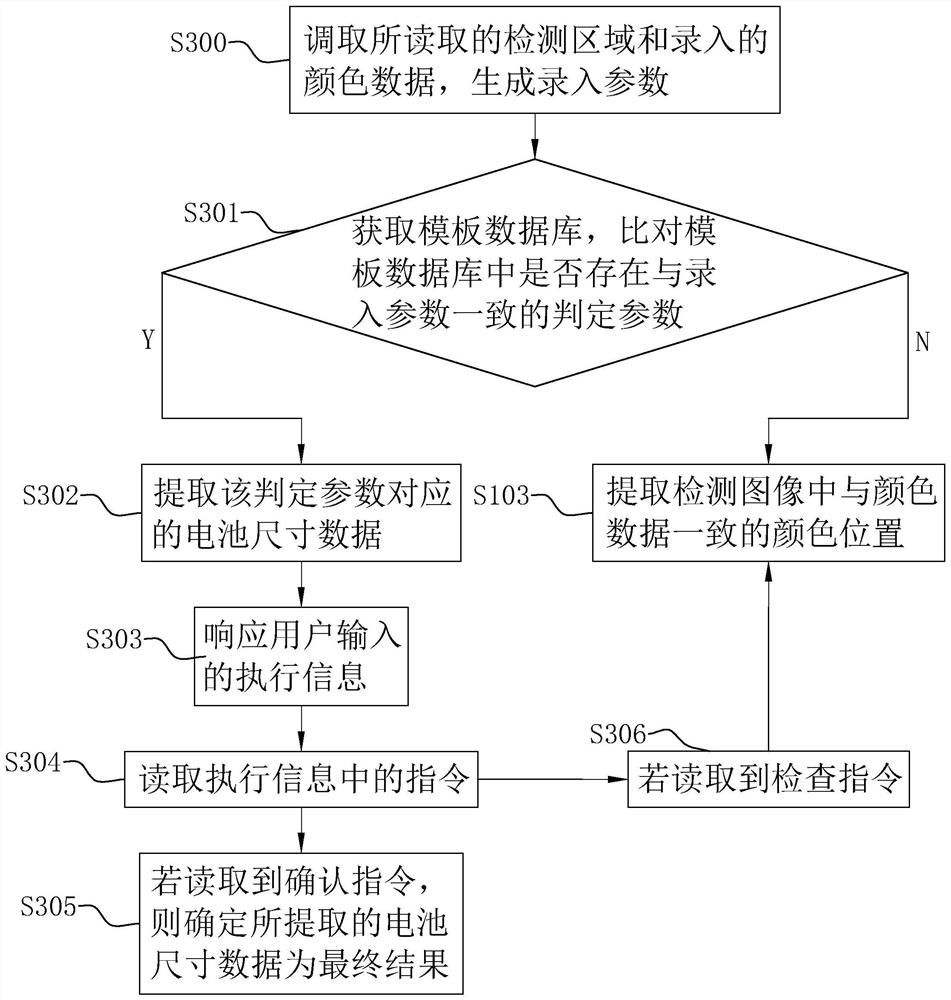

Battery size detection method, system and device and storage medium

PendingCN114140375AFully automatedGuaranteed stabilityImage enhancementImage analysisComputer hardwareEngineering

The invention relates to a battery size detection method, system and device and a storage medium, and relates to the technical field of battery detection.The method comprises the steps that a detection request is responded, and the detection request carries a detection instruction used for generating a detection image; according to the detection instruction, a detection area where the to-be-detected battery is located is read, and a detection image is generated; acquiring color data of the to-be-detected battery input by a user; extracting a color position consistent with the color data in the detection image; according to the color position, obtaining a boundary area divided by the user; extracting a color position in the boundary area to form battery boundary data; and calculating battery boundary data to form battery size data. The battery dimension detection device has the effect of automatically and finely detecting the battery dimension.

Owner:深圳市长荣科机电设备有限公司

Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

InactiveCN100585934CReduce labor intensityImprove the wrapping effectFinal product manufacturePrimary cellsProduction lineEngineering

The invention relates to a mobile phone detecting, mark wrapping, measuring automatic product line and technical flow. The product line comprises an orderly arranged mobile phone inside parameter automatic detector, a mobile phone automatic mark wrapper and a mobile phone cell size difference automatic measurer. A discharge port end of the mobile phone inside parameter automatic detector is connected with an inlet point end of the mobile phone automatic mark wrapper. A discharge port end of the mobile phone automatic mark wrapper is connected with an inlet point end of the mobile phone cell size difference automatic measurer that is connected electrically. In the invention, the cell feed in, position, clamp detection, mark wrapping and difference measurement after the mark wrapping are completed automatically. The mark wrapping effect is good, stable, and strongly reliable. The invention is simple in operation, high in efficiency and automatic level, which reduces the product manufacturing cost greatly and improves product quality and manufacturing speed, work efficiency as well as lightens labor intensity of the workers and improves labor capacity.

Owner:GRAND TECH SHENZHEN

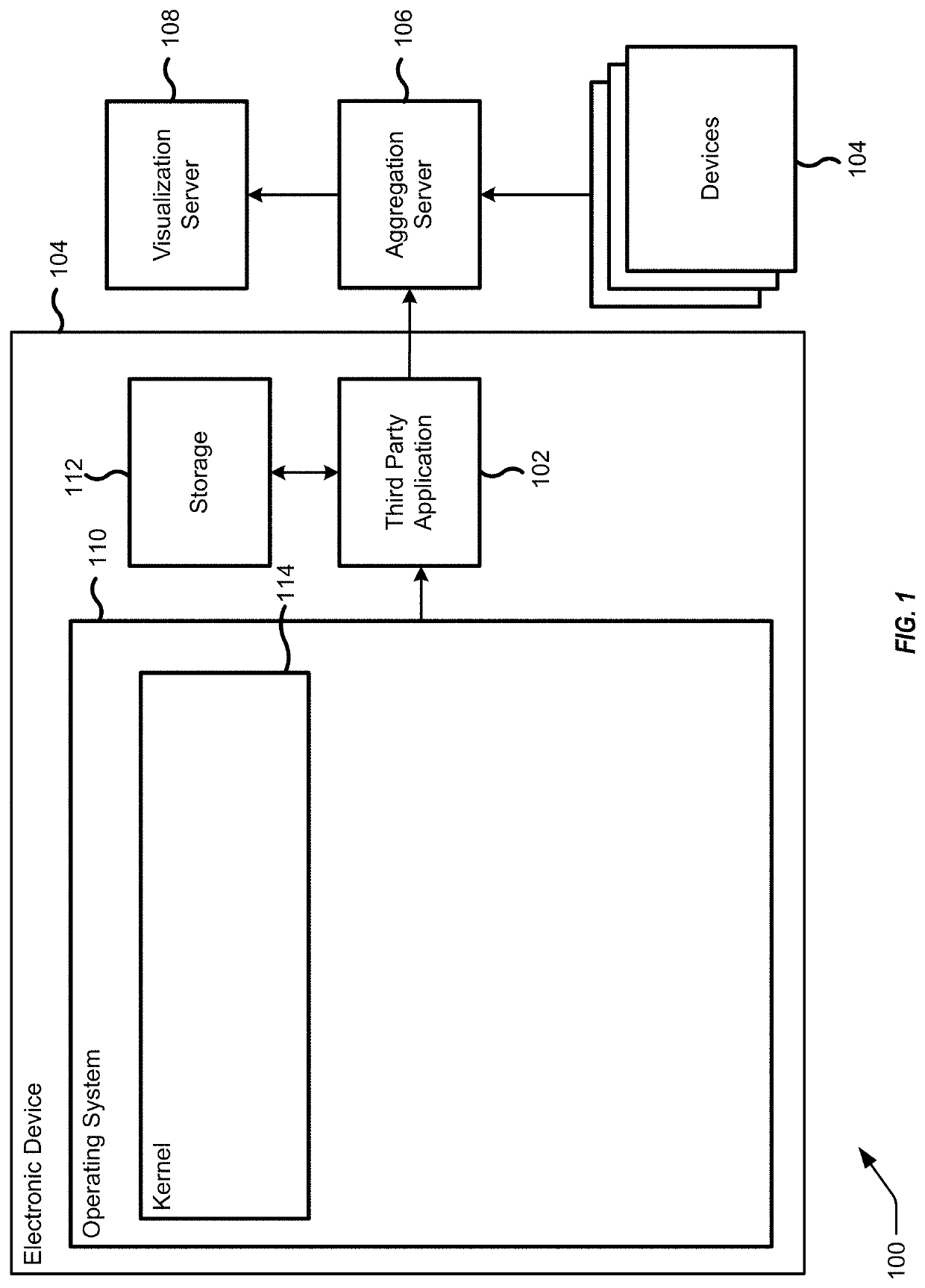

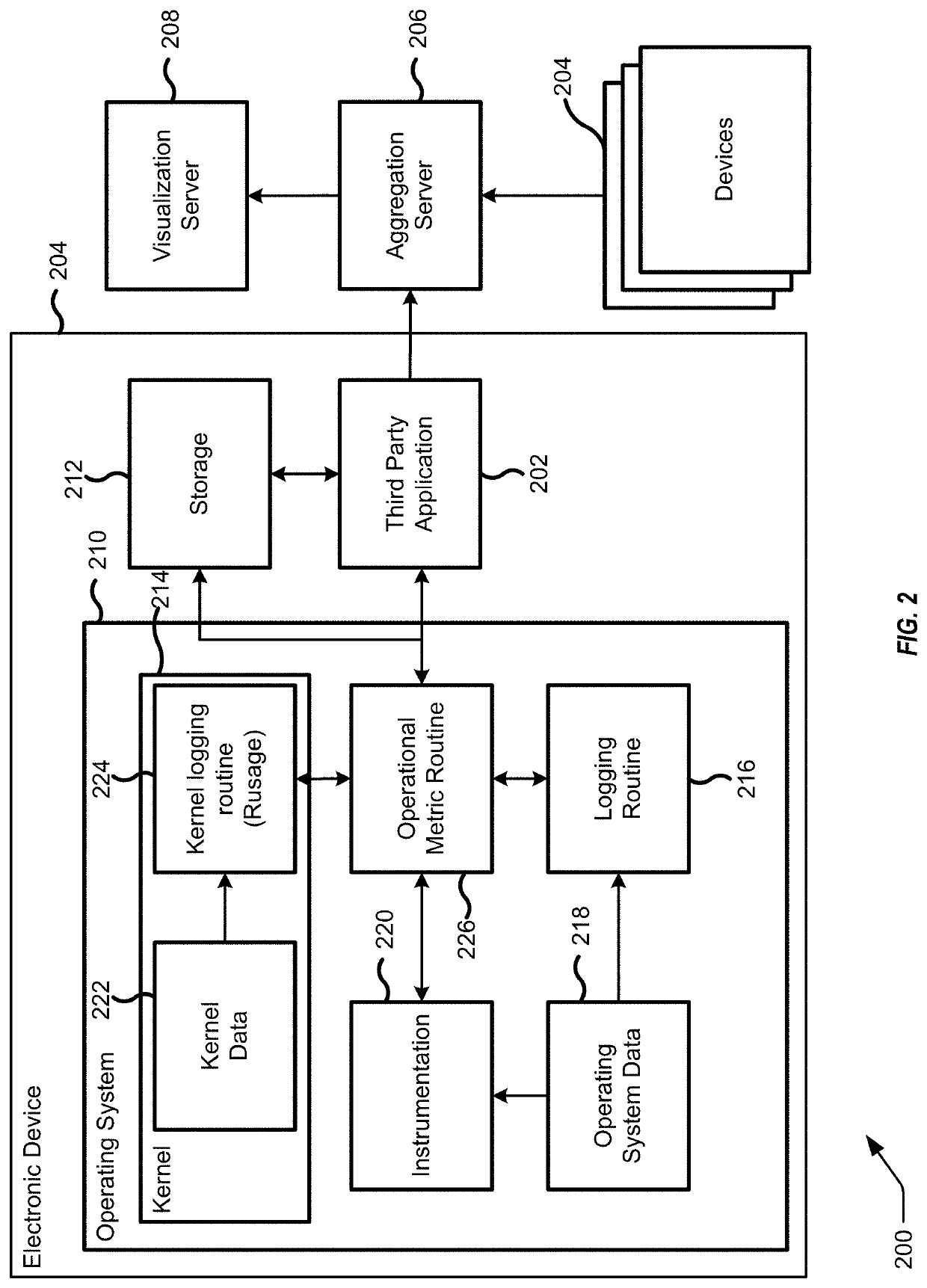

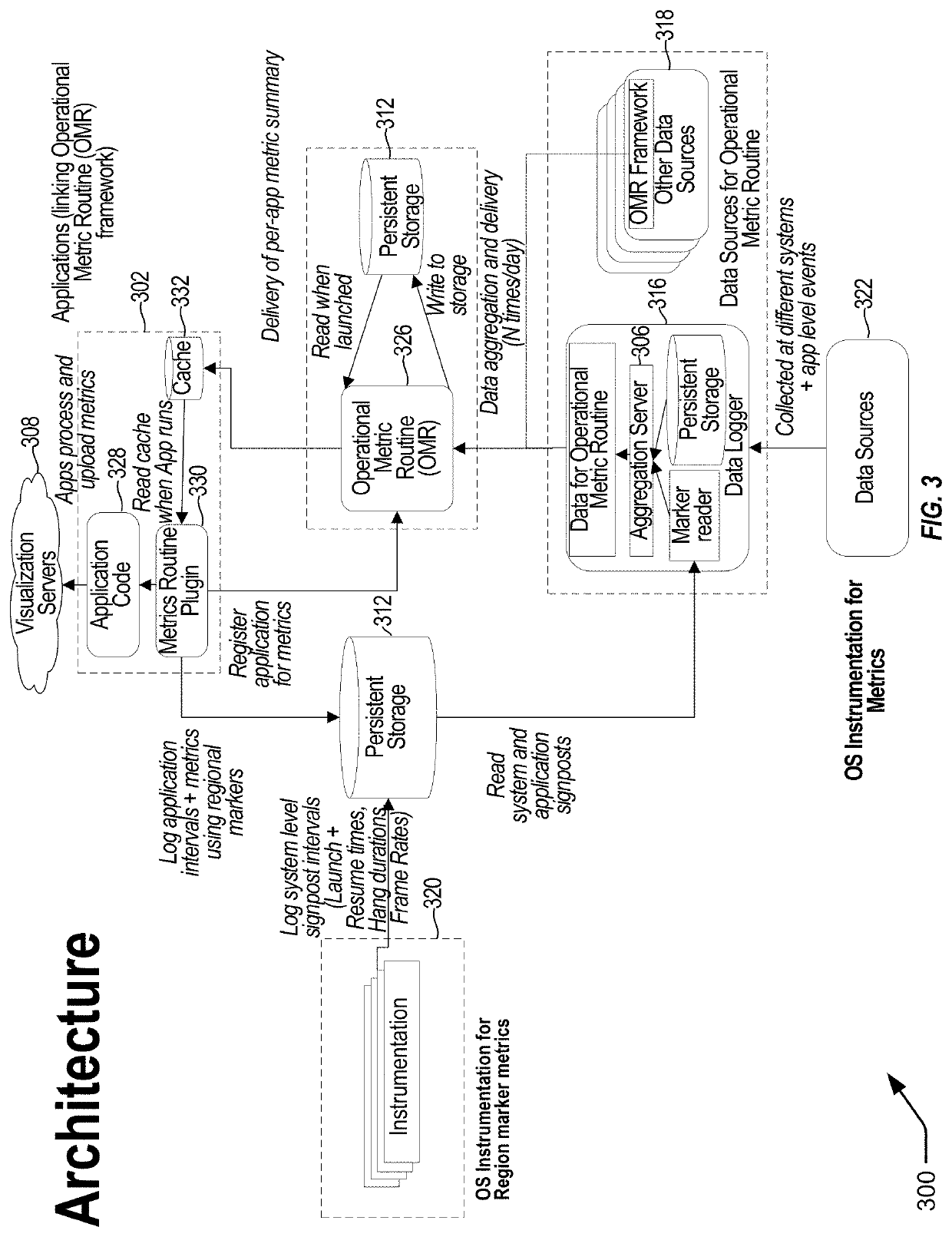

Logging techniques for third party application data

Embodiments of the present disclosure present devices, methods, and computer readable medium for techniques for measuring operational performance metrics, and presenting these metrics through an application programming interface (API) for developers to access for optimizing their applications. Exemplary metrics can include central processing unit or graphics processing unit time, foreground / background time, networking bytes (per application), location activity, display average picture luminance, cellular networking condition, peak memory, number of logical writes, launch and resume time, frame rates, and hang time. Regional markers can also be used to measure specific metrics for in application tasks. The techniques provide multiple user interfaces to help developers recognize the important metrics to optimize the performance of their applications. The data can be normalized over various different devices having different battery size, screen size, and processing requirements. The user interfaces can provide an intelligent method for visualizing performance changes for significant changes in application versions.

Owner:APPLE INC

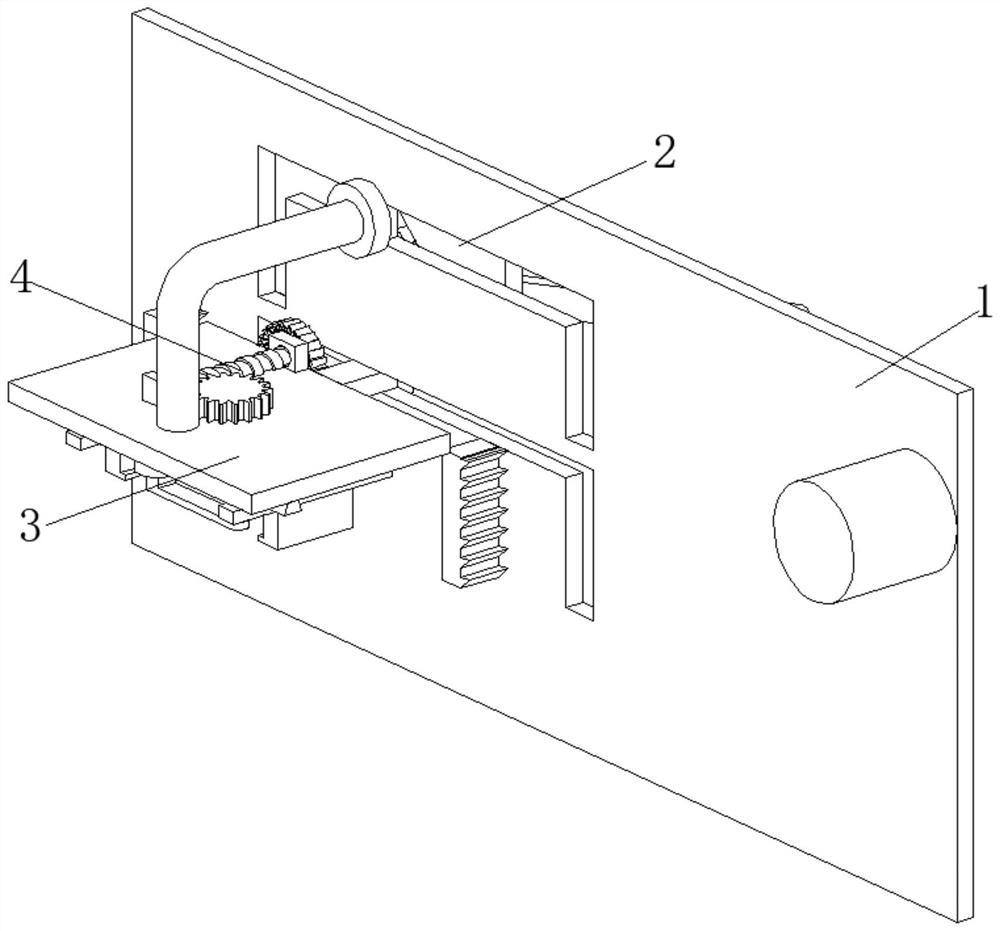

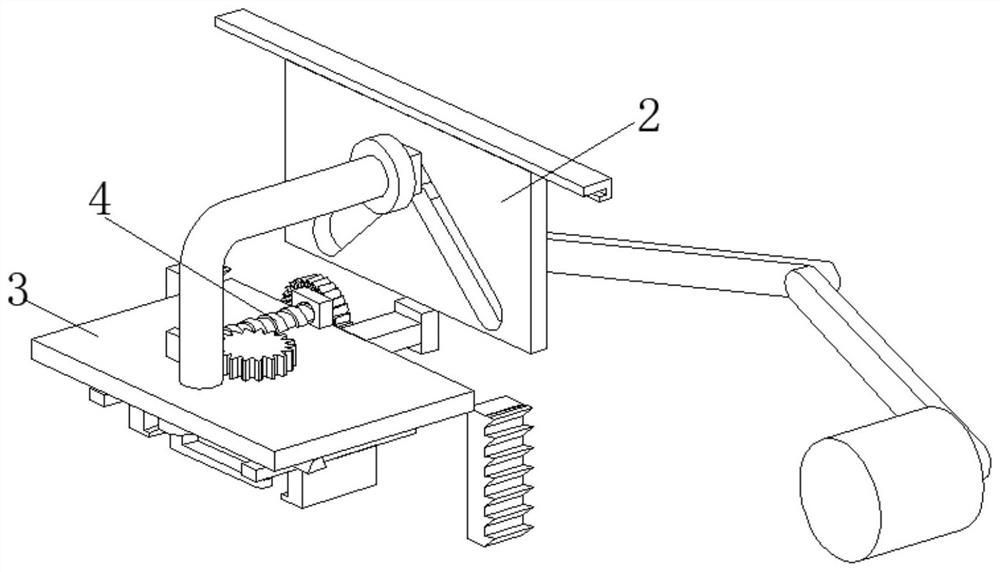

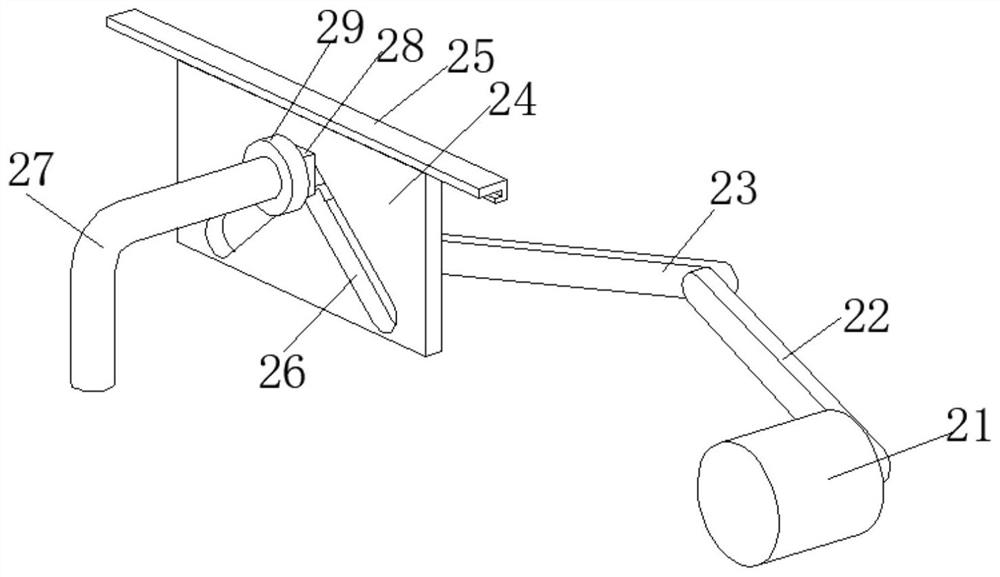

Rapid taking and placing device for power battery module

InactiveCN113370832APrevent fallingAvoid damageCharging stationsVehicular energy storagePower batteryElectrical battery

The invention relates to the technical field of power batteries, and discloses a rapid taking and placing device for a power battery module. The device comprises a mounting plate, a working mechanism is arranged on the rear portion of the mounting plate, a limiting mechanism is arranged on the front portion of the mounting plate, and an adjusting mechanism is arranged on the surface of the limiting mechanism. According to the rapid taking and placing device for the power battery module, through cooperative use of the working mechanism, the limiting mechanism and the adjusting mechanism, a battery can be straightened while the device clamps the battery, so the battery can be conveniently clamped subsequently, and the situation that the battery is damaged due to the fact that the battery deviates and then falls off after being clamped is prevented; through a supporting spring between an inner plate and an outer plate in the limiting mechanism, the device can adapt to batteries of different sizes when clamping the batteries, when the sizes of the batteries are large, the device can clamp the batteries excessively, but the inner plate and the outer plate can displace, the batteries are prevented from being damaged by clamping, and the application range of the device is greatly widened.

Owner:重庆新知创科技有限公司

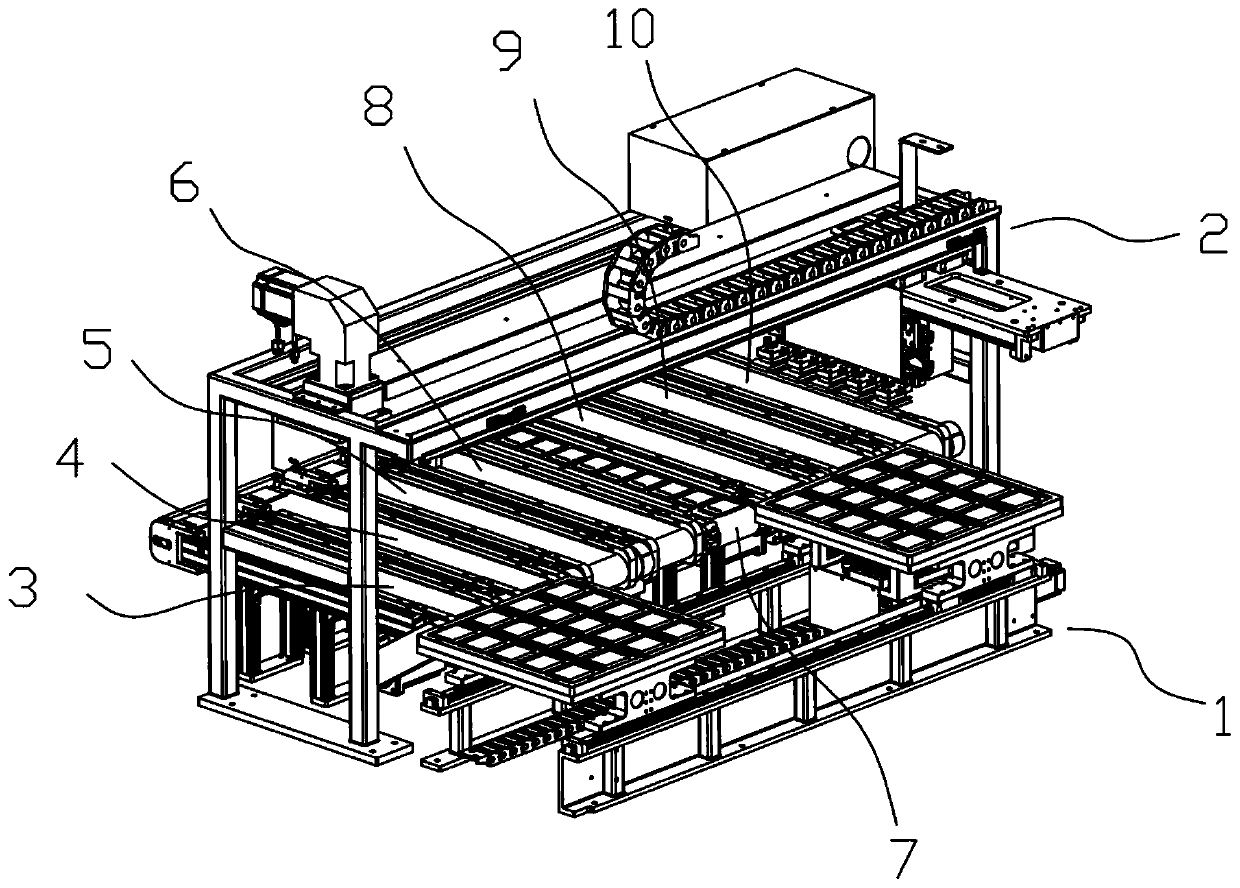

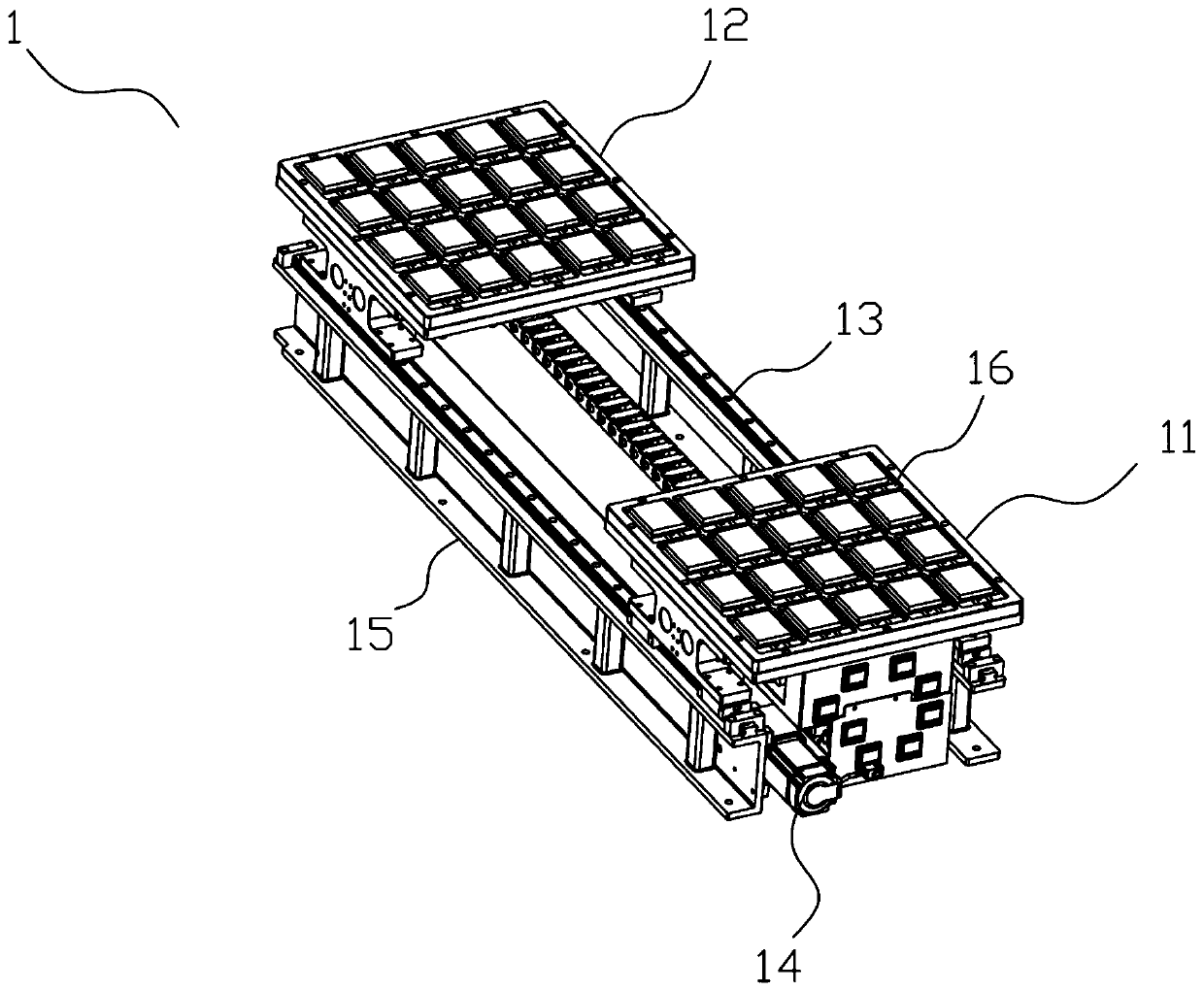

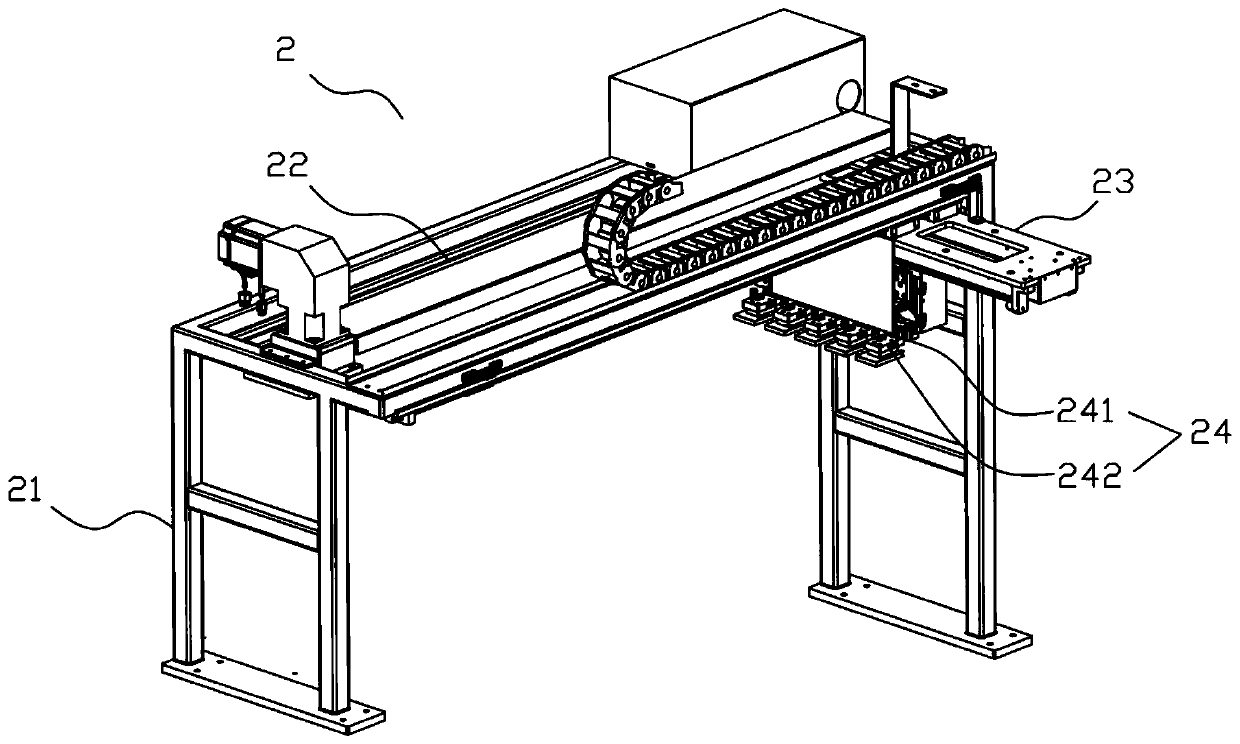

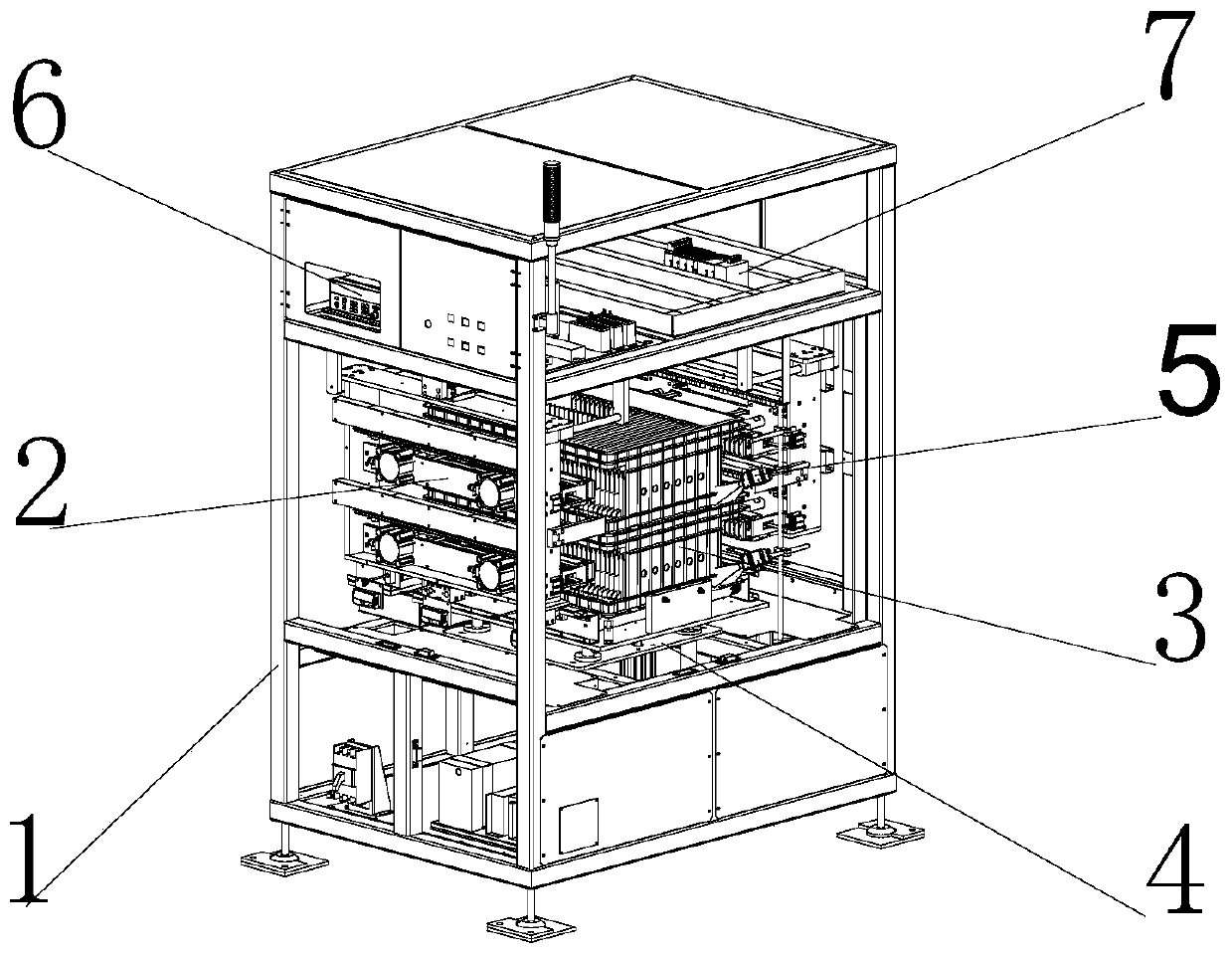

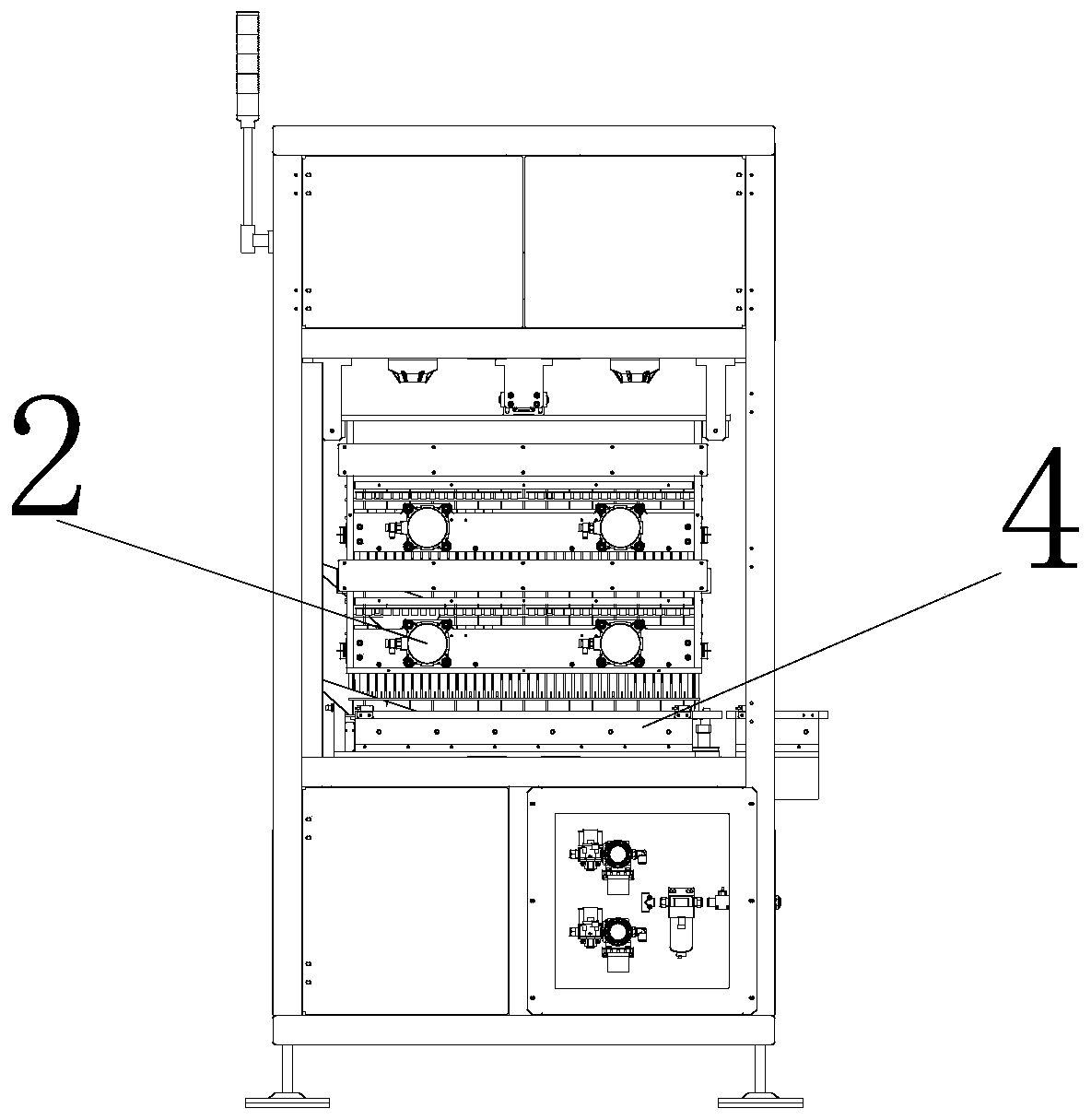

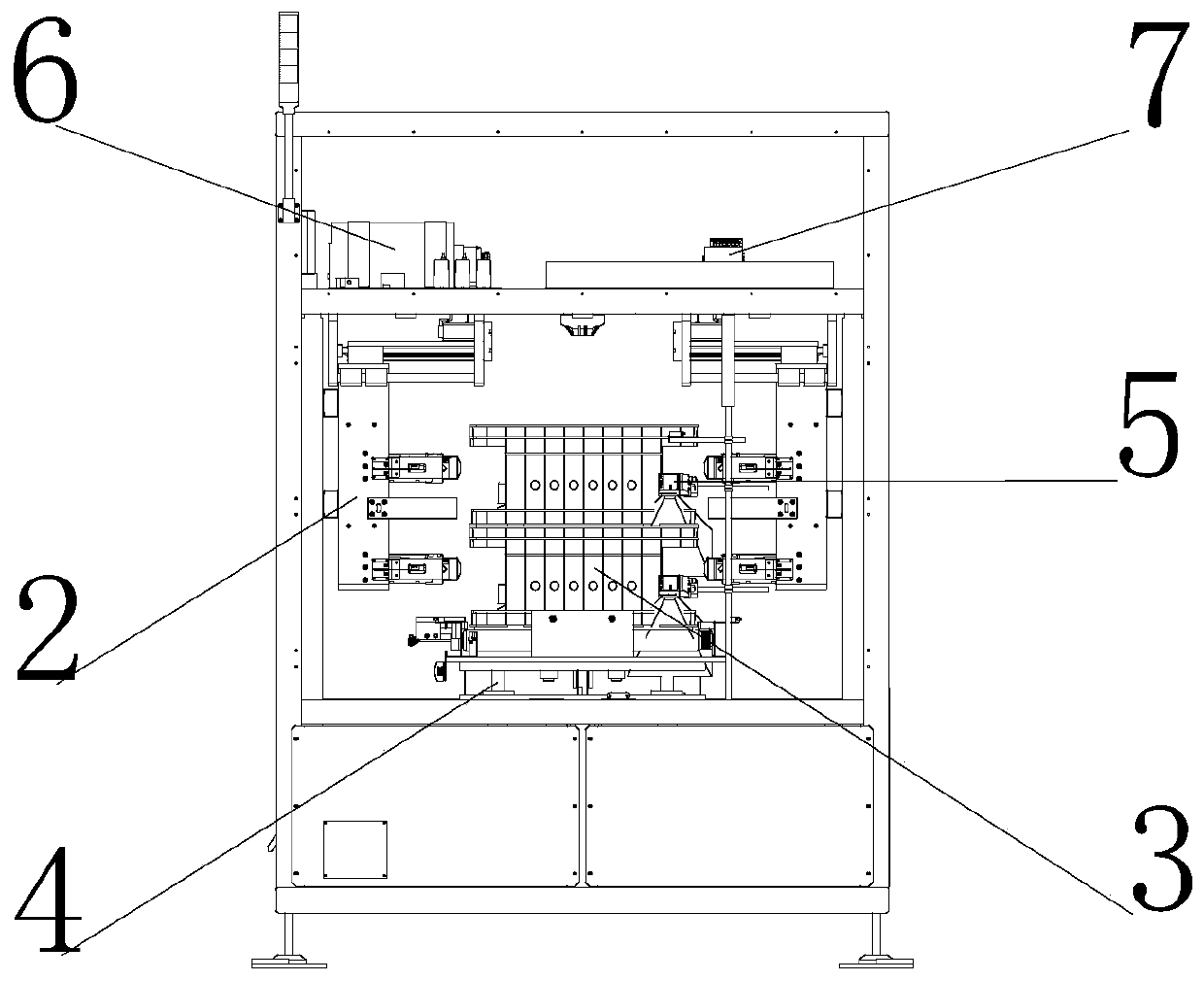

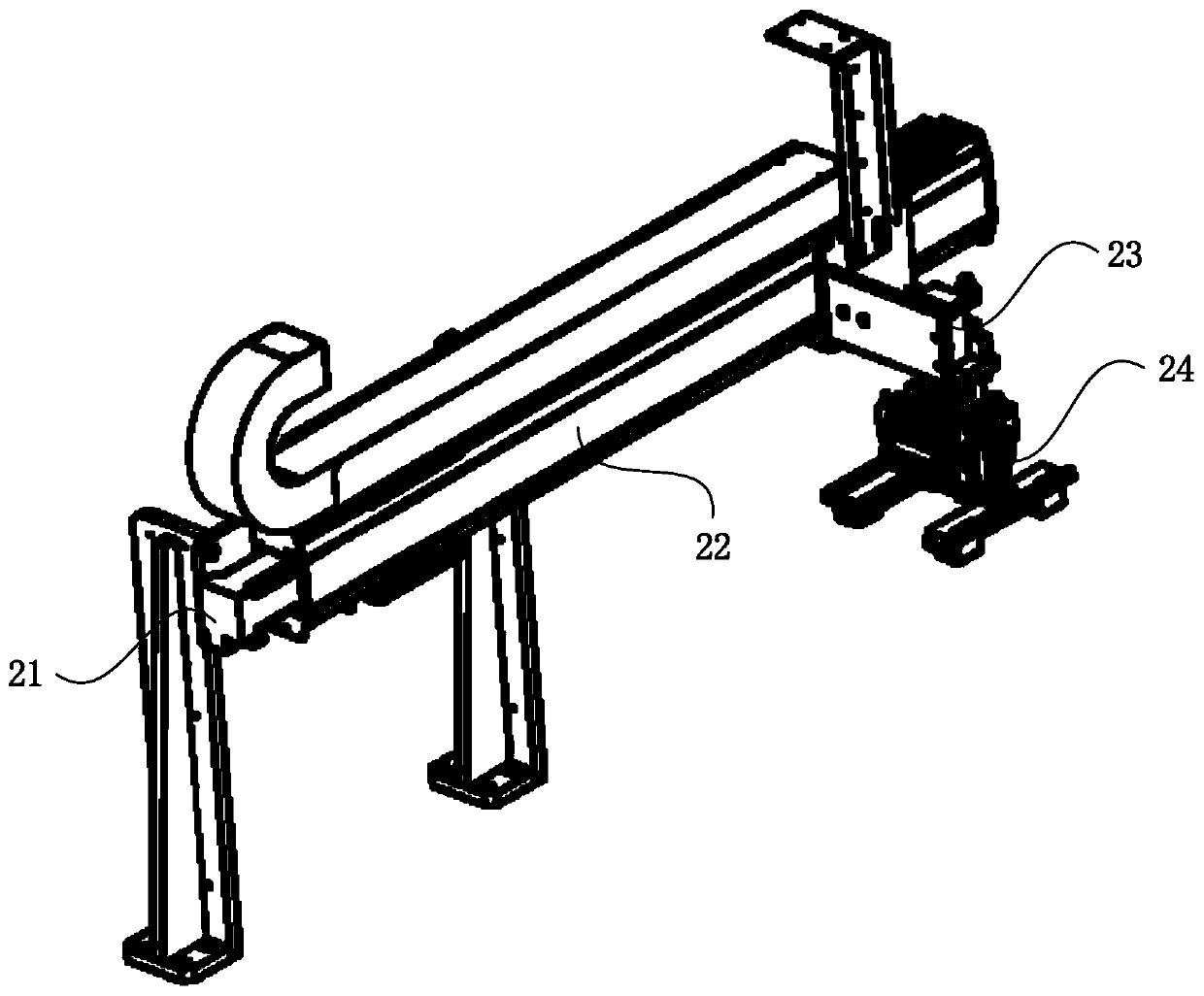

Automatic OCV test equipment for flexibly packaged power lithium ion battery

PendingCN110794318AImplement automatic detectionImprove automation production efficiencyElectrical testingMeasurement instrument housingAutomatic test equipmentElectrical battery

The invention relates to automatic OCV test equipment for a flexibly packaged power lithium ion battery. The automatic OCV test equipment comprises a rack, a movement mechanism unit, a tray conveyingunit, a battery tray, an OCV test unit and a controller, wherein the rack is used for mounting a working part; the movement mechanism unit is arranged in a mounting cavity of the rack and comprises aprobe plate component and a movement mechanism; the tray conveying unit is used for placing a tray and conveying the tray to a tray conveying line outside the rack; the OCV test unit is used for acquiring an OCV parameter of a to-be-tested flexibly packaged power lithium ion battery; the controller is arranged in the mounting cavity of the rack; the control terminals of the movement mechanism unitand the tray conveying unit are respectively electrically connected with a corresponding pin of the controller; and the signal output terminal of the movement mechanism unit is electrically connectedwith the OCV test unit, and the signal output terminal of the controller is connected with the signal input terminal of an external server by virtue of a signal. The automatic OCV test equipment provided by the invention has the beneficial effects that the automatic OCV test equipment can be compatible with multiple battery sizes, automation production efficiency is improved, automatic detectionon the OCV parameter of the battery is realized and operation is easy.

Owner:ZHEJIANG HANGKE TECH

Tungstic oxide semiconductor battery and preparation method therefor

InactiveCN102148267BHigh currentPhotovoltaic energy generationSemiconductor devicesElectrical batteryMetal foil

Owner:NANCHANG UNIV

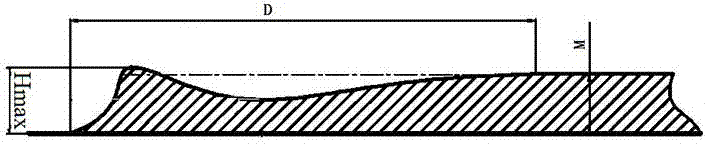

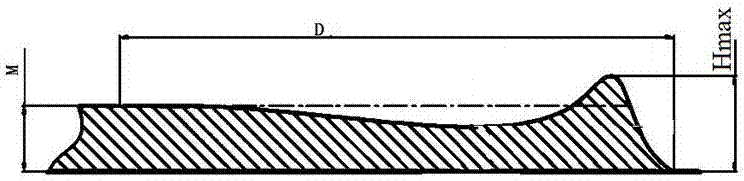

Determination method for chamfer dimensions of die head gasket and die head gasket implementing same

ActiveCN107978729AGuaranteed accuracyGuaranteed reliabilityMeasurement devicesElectrode collector coatingEngineeringBattery sizing

The invention relates to a determination method for the chamfer dimensions of a die head gasket and the die head gasket implementing the method. The determination method for the chamfer dimensions ofthe die head gasket comprises the following steps: step one, arranging at least two chamfers of different dimensions on the die head gasket; step two, mounting the die head gasket on a die head of anextrusion coating machine, and coating a foil with a uniformity mixed battery sizing agent; and step three, after the coasting is stabilized, carrying out sampling measurement and drawing a profile curve of the coating along the thickness direction, and determining the chamfer dimensions of the die head gasket applicable for the battery sizing agent according to the profile curve. According to thedetermination method for the chamfer dimensions of the die head gasket, the chamfer dimensions of the die head gasket applicable for the battery sizing agent can be determined by only one die head gasket, so that the experiment cost is obviously reduced; and moreover, the chamfer dimensions are of only one variable, the influences (such as pump speed, sizing agent batch and man-made operation factors) of other factors among different tests are eliminated, and the accuracy and reliability of experimental result are guaranteed.

Owner:CALB CO LTD

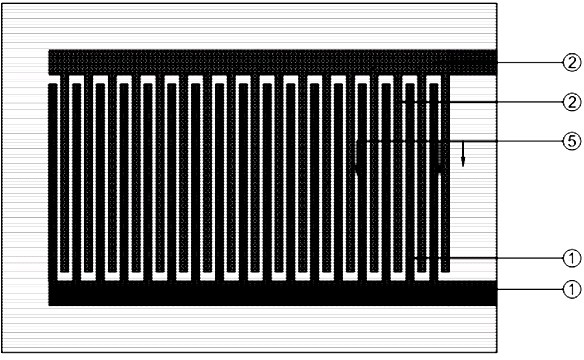

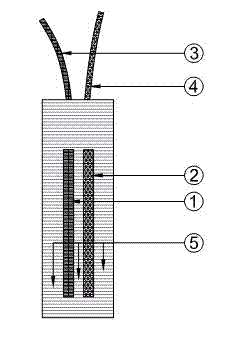

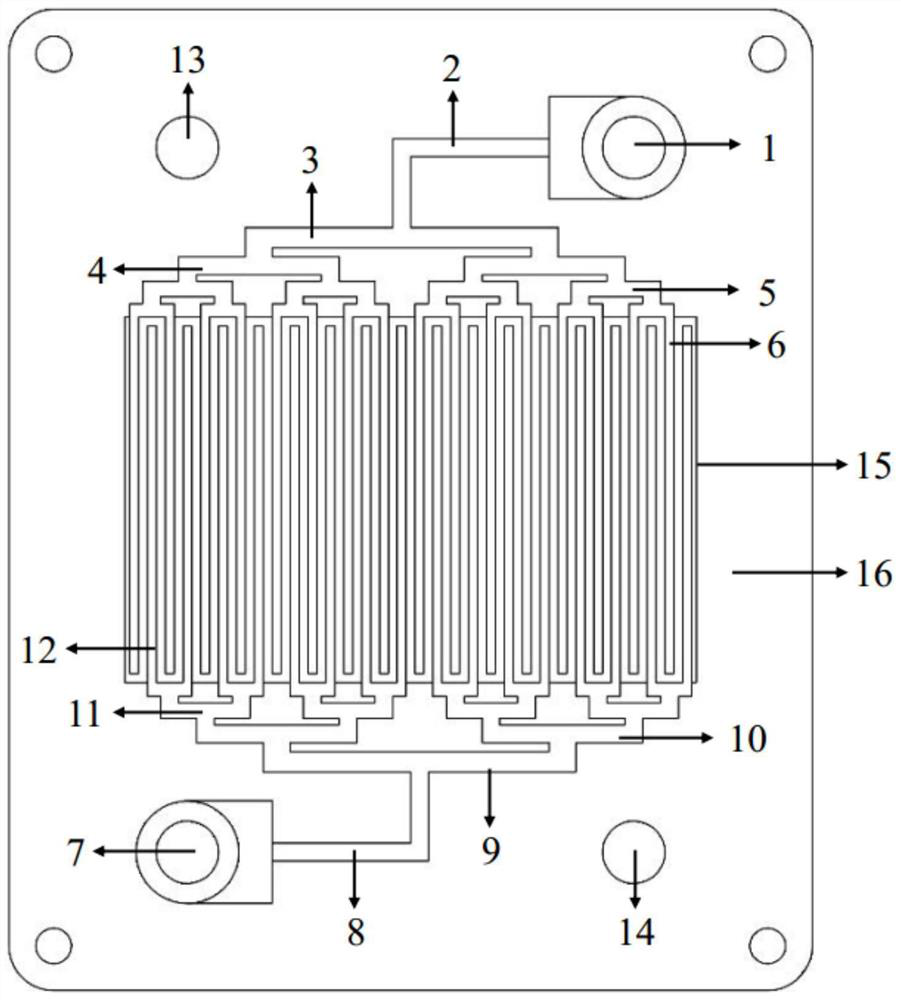

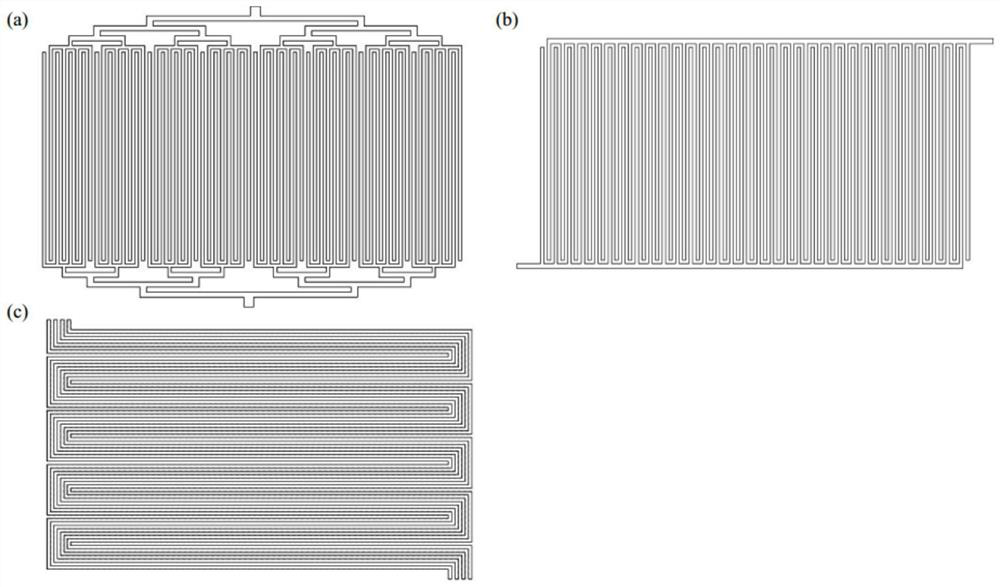

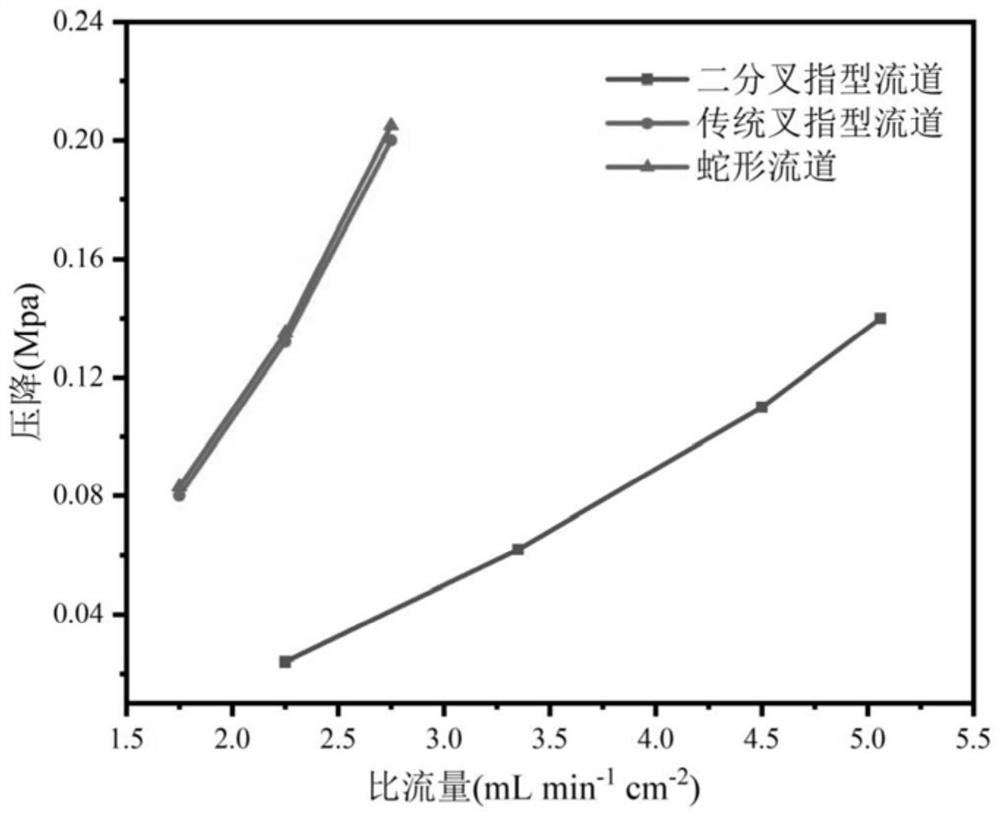

Flow battery flow channel with bifurcated finger-type structure on bipolar plate

PendingCN114824338AHigh trafficGuaranteed uniformityCollectors/separatorsElectrolytic agentElectrical battery

The invention relates to the technical field of flow batteries, in particular to a flow battery flow channel with a bifurcated finger-type structure on a bipolar plate. Electrolyte is evenly distributed to the liquid inlet flow channels of all the subunits of the flow channel step by step from an inlet in a step-by-step two-way mode, and the electrolyte of the liquid outlet flow channels is collected to an outlet step by step in the step-by-step two-way mode. The liquid inlet branch flow channels and the liquid outlet branch flow channels are alternately arranged and distributed in an interdigital manner and are not communicated with one another, so that electrolyte is forced to enter the porous electrode from the liquid inlet branch flow channels and then flow into the liquid outlet branch flow channels to be discharged. According to the two-branch finger-type flow channel, the electrolyte is uniformly distributed in each branch flow channel, so that on one hand, the uniformity of active substance supply is ensured, on the other hand, the pressure drop and the pump work loss are reduced, the sealing performance of a system is ensured, the flow of the electrolyte can be further improved, the mass transfer loss is further reduced, and the service life of the system is prolonged. And the battery voltage efficiency and the system efficiency are improved. The invention is suitable for flow batteries with different sizes, and the larger the size of the battery is, the more obvious the effect is.

Owner:THE HONG KONG UNIV OF SCI & TECH

Support member and battery module

PendingUS20220045396A1Reduce stress concentrationCurrent conducting connectionsSecondary cellsControl engineeringMechanical engineering

Provided are a support member and a battery module in consideration of variations in dimensions of the battery. At the same time, stress concentration on the support member is alleviated. A sliding portion 127 of one of adjacent support cases 121 of the plurality of support cases 121 connected to each other is slidably housed in the main body portion 122 of the other support case 121. Apart of the sliding portion 127 of the one support case 121 is pulled out from the main body portion 122 of the other support case 121. Thus, a distance between the one support case 121 and the other support case 121 is increased. At least a part of the sliding portion 127 of the one support case 121 is housed in the main body portion 122 of the other support case 121. Thus, the distance between the one support case 122 and the other support case 122 is decreased.

Owner:NIPPON MEKTRON LTD

Laminated battery detection equipment

PendingCN110788018AAvoid secondary damageImprove detection efficiencySortingMechanical engineeringBattery cell

The invention relates to the technical field of battery quality detection and discloses laminated battery detection equipment. The laminated battery detection equipment comprises a detection platform,a loading device, a detection assembly and an unloading device, wherein the detection platform is used for placing batteries and comprises a first sliding rail, a second sliding rail, a first drivingstructure and a battery placing plate; the first sliding rail and the second sliding rail are arranged in parallel; one side of the battery placing plate is in sliding connection with the first sliding rail; the other side of the battery placing plate is in sliding connection with the second sliding rail; the loading device is used for carrying to-be-detected batteries to the detection platform;the detection assembly is used for performing size detection on the battery placed on a detection position; and the unloading device is used for carrying away the detected batteries on the detection platform. Compared with detection equipment for detecting the battery size by a manual detection mode, the laminated battery detection equipment provided by the invention can automatically perform sizedetection on the to-be-detected batteries and greatly improves detection efficiency.

Owner:SHENZHEN HAOTIANCHEN SCI & TECH CO LTD

Slotted battery cavity for multiple cell sizes

ActiveUS9954205B2Point-like light sourceWith electric batteriesElectrical batteryElectrical connection

A battery compartment for a device has a single cavity that is segmented into discrete slots, each slot associated with projections that secure and immobilize any batteries inserted into the compartment. Each slot is sized to receive a different size of battery, and the slots are positioned relative to one another to prevent batteries of different sizes from being inserted into the compartment. A shelf may be integrated within the slot(s), and the shelf may include a channel or a multi-planar yet unitary contact member to establish a single point of electrical connection between the battery compartment and the device.

Owner:ENERGIZER BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com