Automatic OCV test equipment for flexibly packaged power lithium ion battery

A lithium-ion battery and testing equipment technology, applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of battery stability, production efficiency, labor consumption, high cost, and improve automatic production efficiency, Realize the effect of automatic detection and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

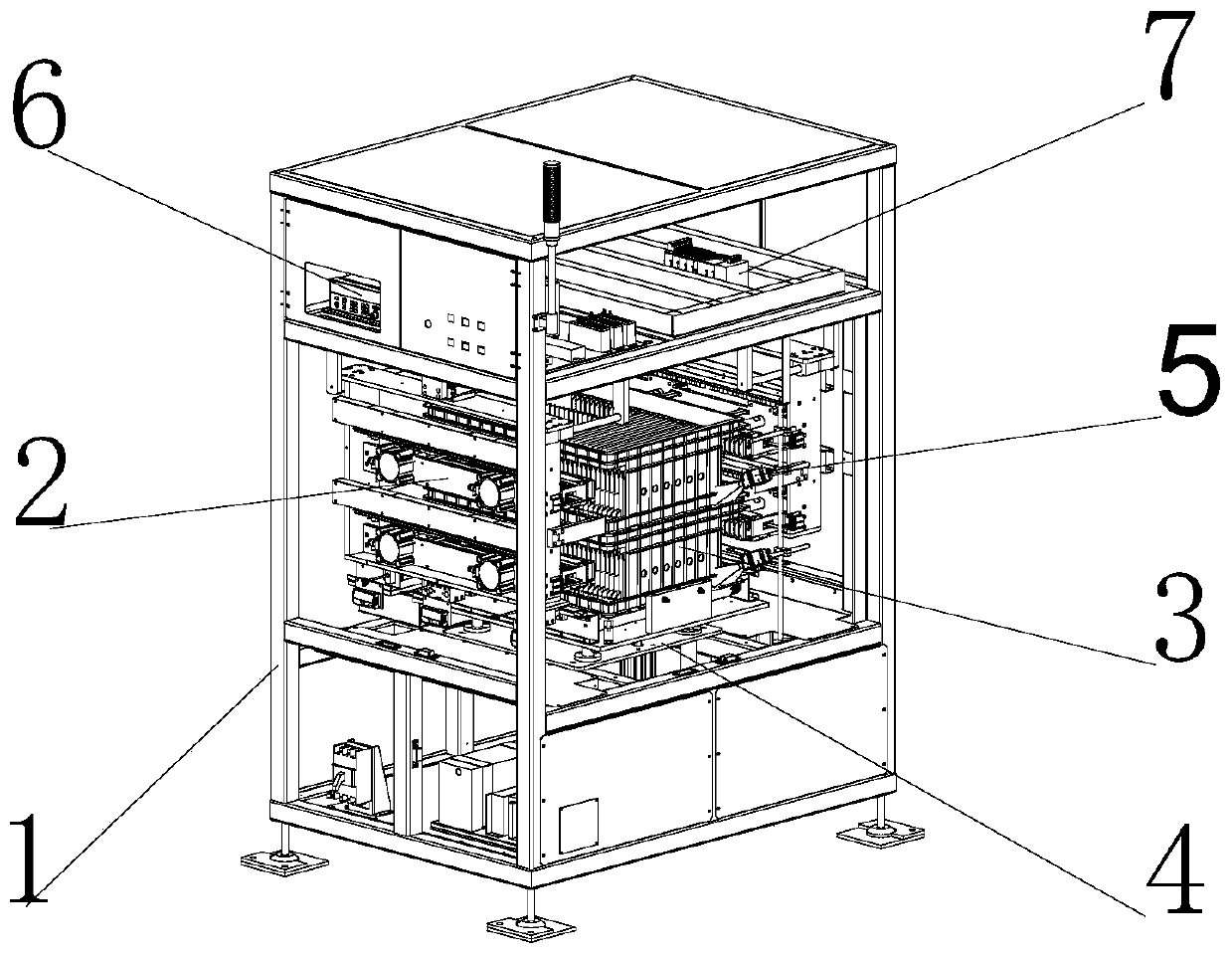

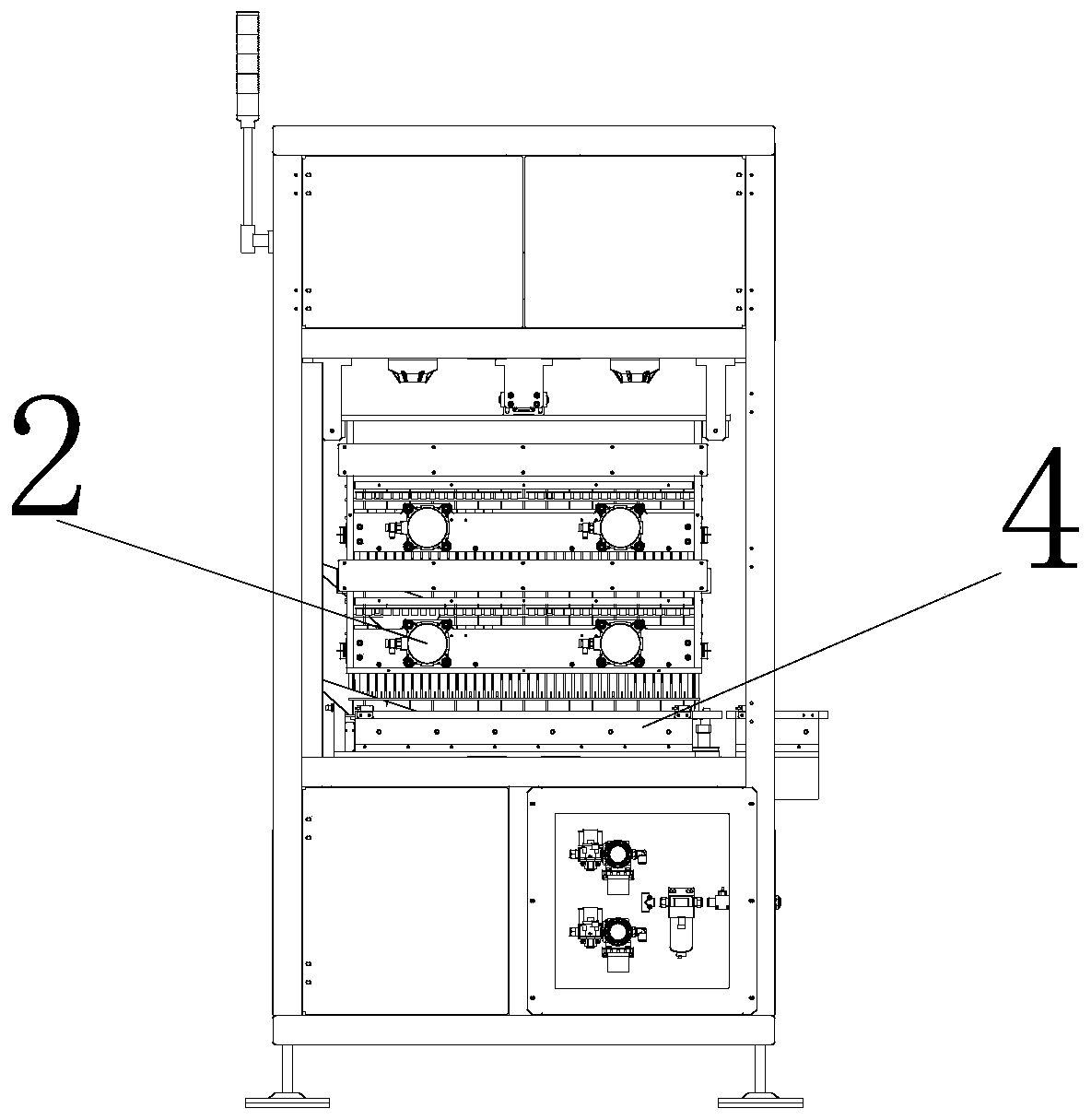

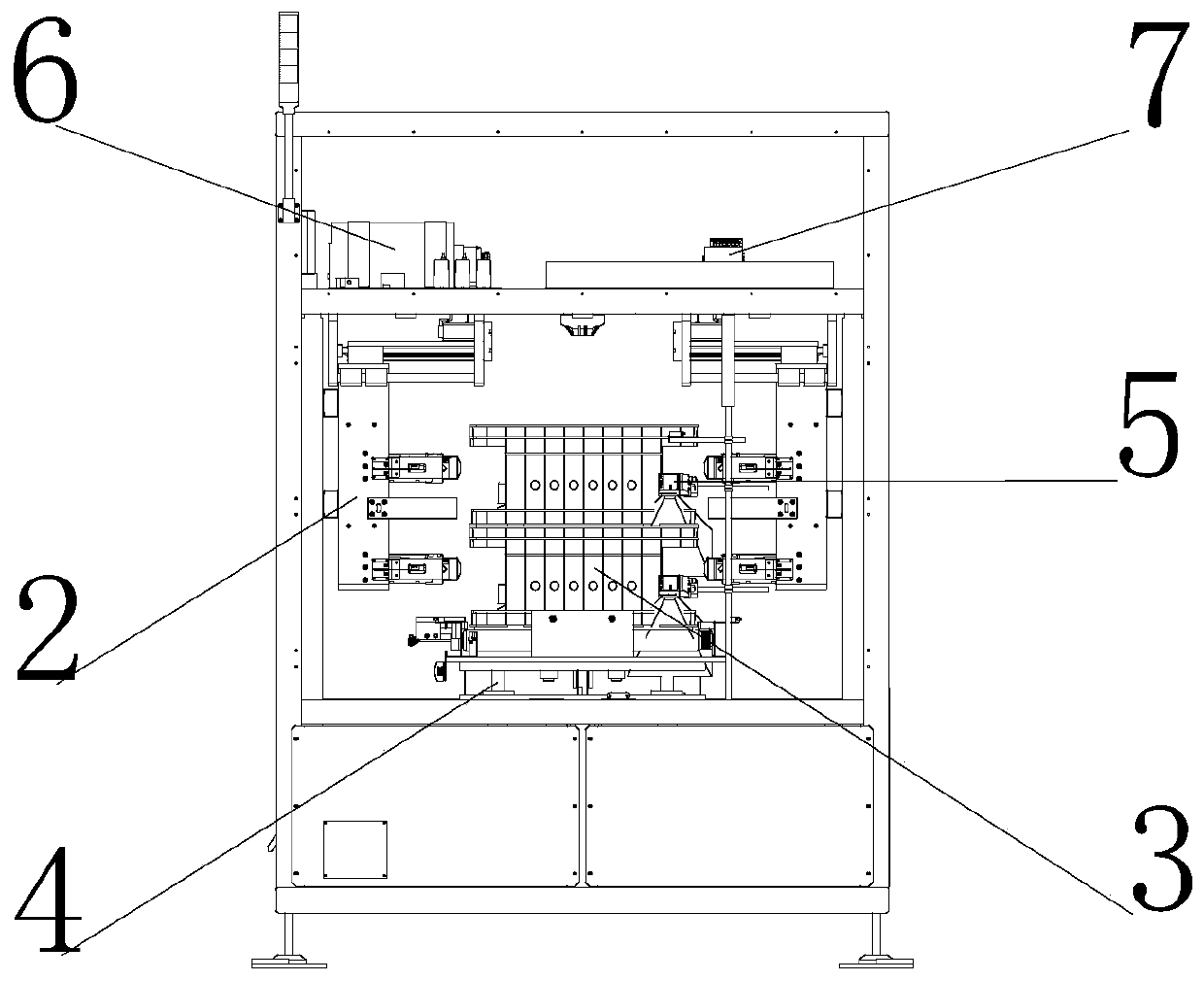

[0045] Embodiment 1 The automatic OCV testing equipment for the soft pack power lithium-ion battery of the present invention includes:

[0046] The frame 1 has an installation cavity, and a plurality of installation stations are arranged in the installation cavity for installing working parts;

[0047] The motion mechanism unit 2 is arranged in the installation cavity of the frame, including the probe board assembly and the motion mechanism, wherein the clamping part of the motion mechanism is installed on the motion part of the motion mechanism, and moves with the movement of the corresponding motion part; There is a battery tray clamping space between the oppositely arranged clamping parts, which is used to clamp the positive and negative electrode tabs of the soft pack power battery installed in the battery tray; each clamping part faces the side of the storage space to install the probe card Components, and the probes of the probe card assembly face the battery tray, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com