Rapid taking and placing device for power battery module

A technology for power batteries and pick-and-place devices, which can be used in charging stations, electric vehicles, transportation and packaging, etc., and can solve problems such as loosening, battery damage, and affecting machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

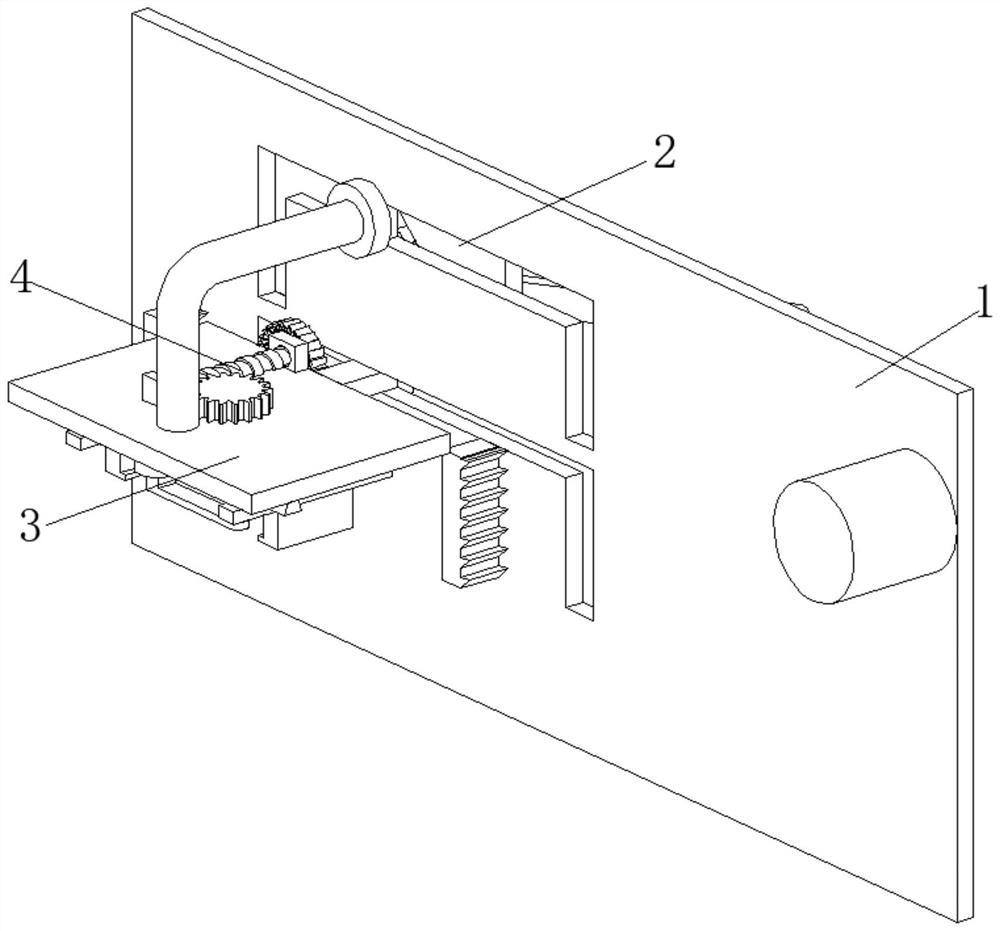

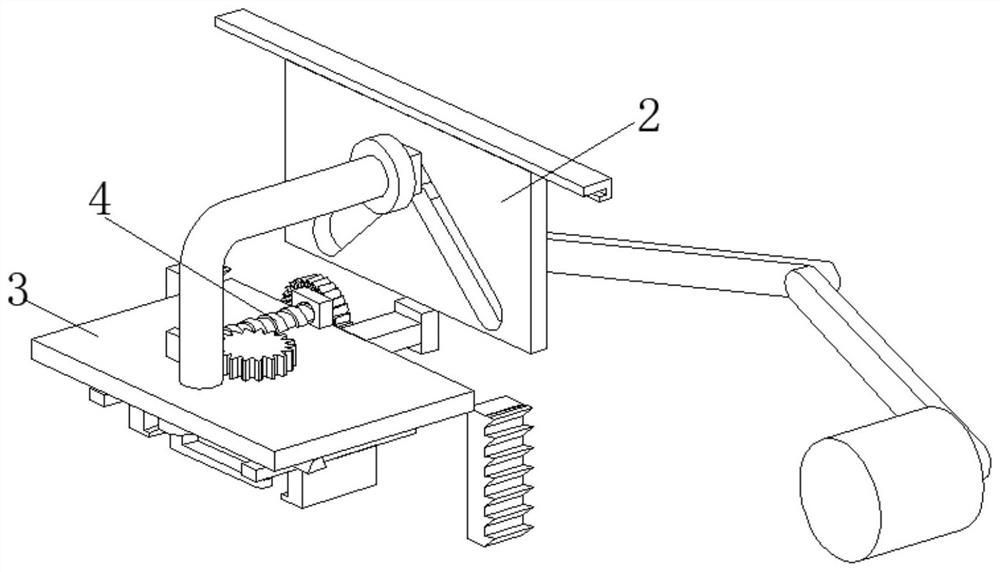

[0033] A quick pick-and-place device for a power battery module, such as Figure 1-Figure 6 As shown, including the mounting plate 1, the rear of the mounting plate 1 is provided with a working mechanism 2, the front of the mounting plate 1 is provided with a limit mechanism 3, and the surface of the limit mechanism 3 is provided with an adjustment mechanism 4; the working mechanism 2 pushes the limit The mechanism 3 moves to the left and triggers the adjustment mechanism 4, the adjustment mechanism 4 adjusts the position of the battery on the limit mechanism 3 and drives the limit mechanism 3 to clamp it up, the working mechanism 2 pushes the battery clamped by the limit mechanism 3 to move to the right And trigger the adjustment mechanism 4, and the adjustment mechanism 4 drives the limit mechanism 3 to release the battery.

[0034]Through the cooperative use of the working mechanism 2, the limit mechanism 3 and the adjusting mechanism 4, the device can be moved to the left ...

Embodiment 2

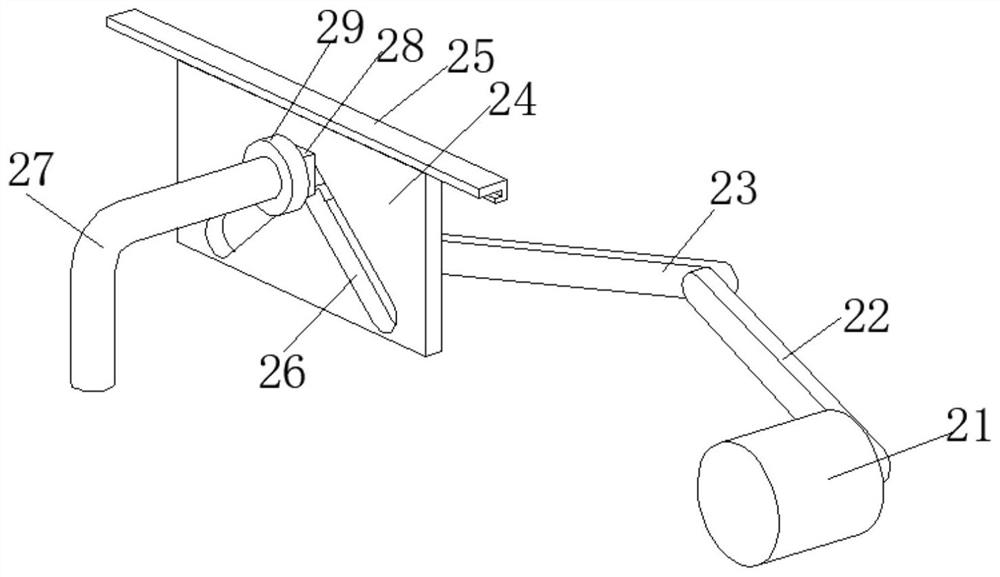

[0046] Such as Figure 5-Figure 9 As shown, on the basis of Embodiment 1, in this embodiment, the two ends of the torsion spring 344 are engaged and fixed with the limit block 342 and the inner wall of the connecting plate 341 respectively, and the rear part of the connecting plate 341 is connected with the inner wall of the mounting plate 1. Front welded fastening.

[0047] The torsion spring 344 can help the rotated limit block 342 to reset, which is convenient for the next use, but the limit block 342 cannot rotate clockwise, so the limit block 342 can drive the adjustment mechanism 4 to operate.

[0048] The adjustment mechanism 4 includes a mounting block 41, the inner wall of the mounting block 41 is rotatably connected with a worm 42, the surface of the worm 42 is meshed with a worm wheel 43, the rear end of the worm 42 is welded with a transmission gear 443, and the surface of the transmission gear 443 is meshed with teeth 441 A ratchet 44 is welded on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com