Method for dispersing micro-scale and nano-scale electrode materials

A micro-nano, electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of high cost of surfactants, affecting battery performance, reducing surface energy, etc., to achieve improved capacity, good adhesion, The effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

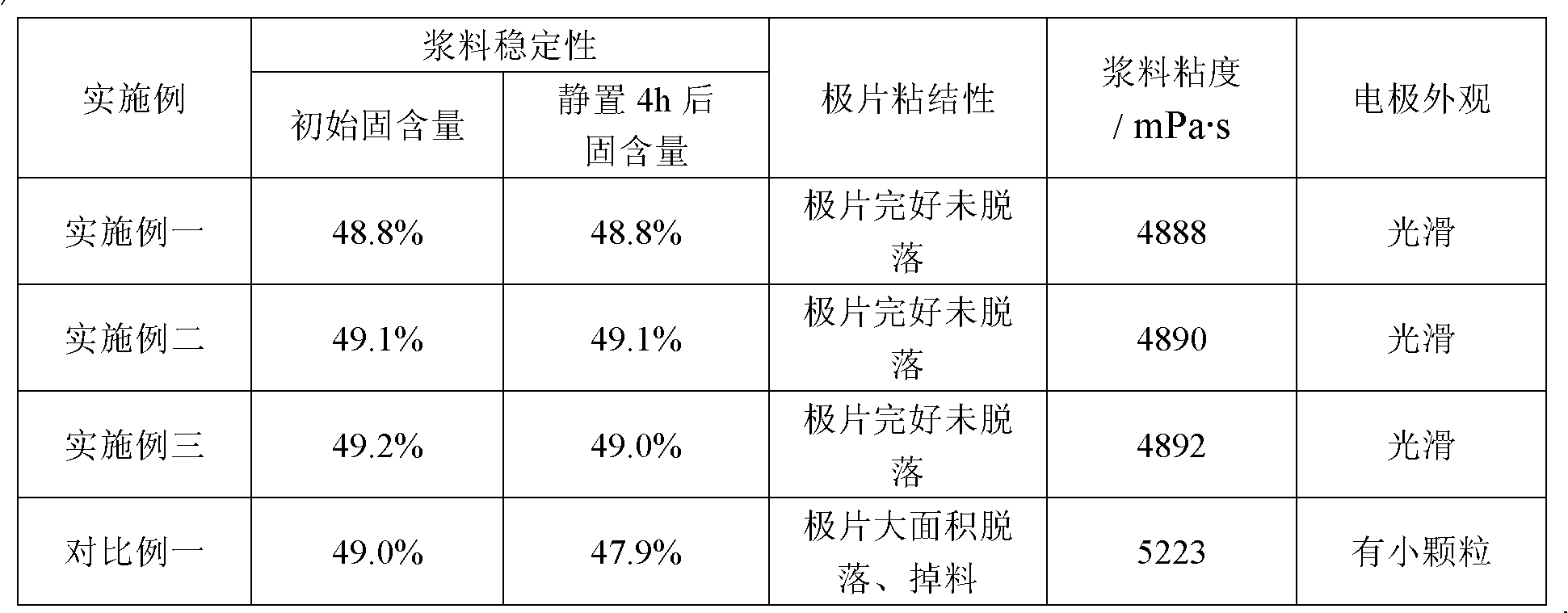

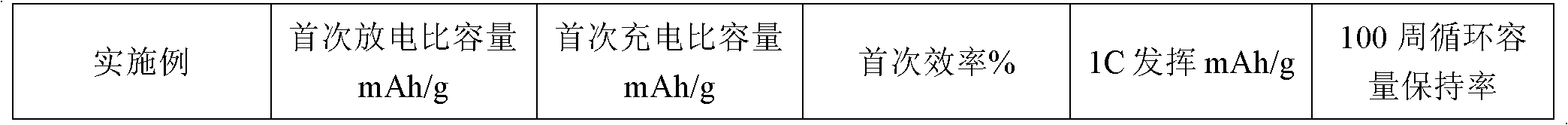

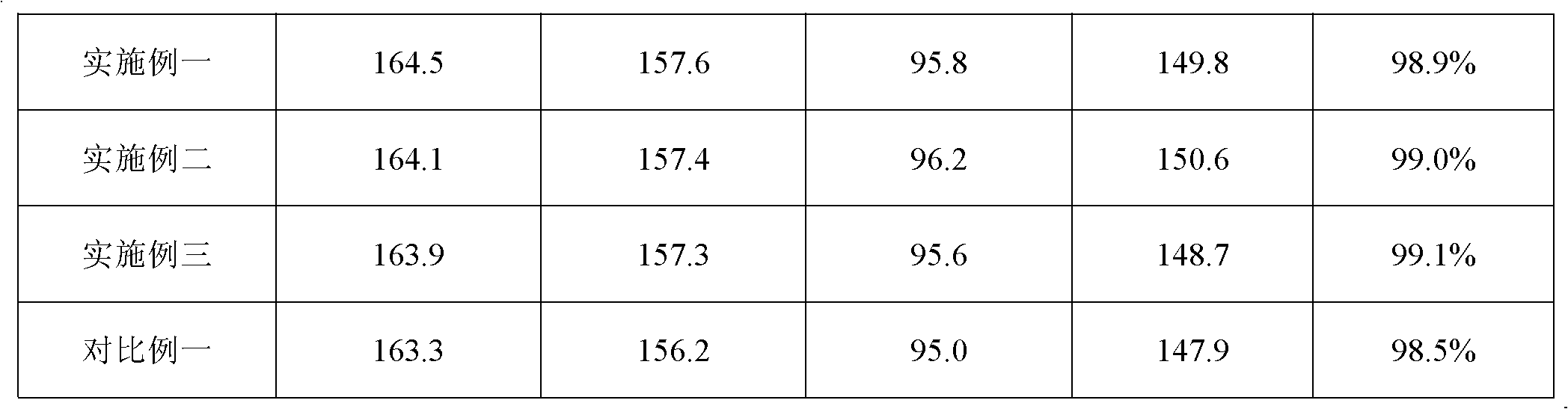

Embodiment 1

[0025] Active material, conductive agent, and PVDF are weighed according to the mass ratio of 80%: 10%: 10%, and NMP is used as a solvent. First, polyvinylidene fluoride (PVDF) and N-methylpyrrolidone (NMP) are mixed with a stirrer to form Transparent glue, then add oxalic acid to the dissolved PVDF glue according to the proportion of 3% of the total amount of active substance, conductive agent, and PVDF, and continue to stir. After the oxalic acid is completely dissolved, add conductive agent and active substance, and mix well Test slurry viscosity. Then the slurry is evenly coated on the aluminum foil with a coating machine, and rolled at 100°C for 12 hours after baking (the compacted density is 2.0g / cm 3 ) made into pole pieces. Take the rolled pole piece and punch it into a disc with a diameter of 7.0mm, and make a button battery on the metal lithium piece in the glove box, use Celgard separator, and the electrolyte is 1.0mol / L LiPF 6 (EC:DEC:DMC=1:1:1).

Embodiment 2

[0027] The dispersion method of the slurry in this embodiment is the same as that of Embodiment 1 except that the organic acid added is 6% malic acid.

Embodiment 3

[0029] The dispersion method of the slurry in this embodiment is the same as that in Embodiment 1 except that the organic acid added is 2% citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com