Determination method for chamfer dimensions of die head gasket and die head gasket implementing same

A method of determining the chamfering technology, which is applied in the direction of electrode manufacturing, measuring devices, instruments, etc., can solve the problems of high cost and inaccurate experimental results, and achieve the reduction of experimental costs, ensure accuracy and reliability, and determine the chamfer size accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

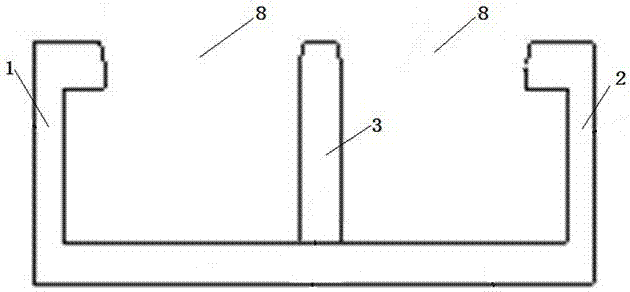

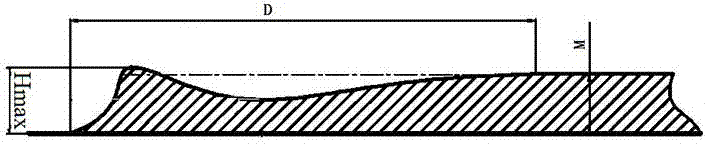

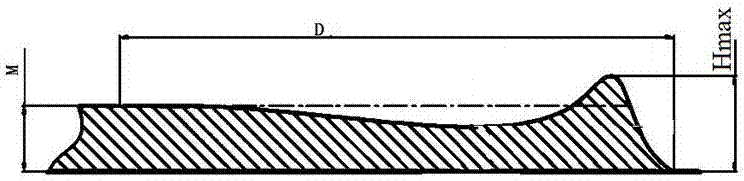

[0033] Embodiments of the die shims of the present invention, such as Figure 2 to Figure 7 As shown, the die gasket has a left side gasket part 1, a right side gasket part 2 and a shunt gasket 3 between the left and right side shim parts, the shunt gasket 3 is T-shaped, and the shunt Gasket 3 makes the die head gasket form two shunt outlets 8 of the shim. Both sides of the shunt outlet 8 of the two shims are provided with chamfers. The four chamfers have different sizes, and the length of the chamfers ranges from 0 mm to 10.0mm, the angle range of the four chamfers is 0°~90°, and the four chamfers increase sequentially from left to right. The four chamfers from left to right are the first chamfer 4, the second chamfer 5, the third chamfer 6 and the fourth chamfer 7, the size of the first chamfer is set to h4=2.0mm, L4=7.0 mm; the size of the second ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com