Safe high-energy folding case lithium ion battery and its production technology

A lithium-ion battery and battery technology, applied in the direction of secondary batteries, electrochemical generators, battery components, etc., can solve the problems of reducing the market competitiveness of battery companies, difficult to achieve production technology, low battery capacity, etc., to achieve The effect of avoiding the deterioration of the internal condition of the battery, dredging and controlling the internal air pressure of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

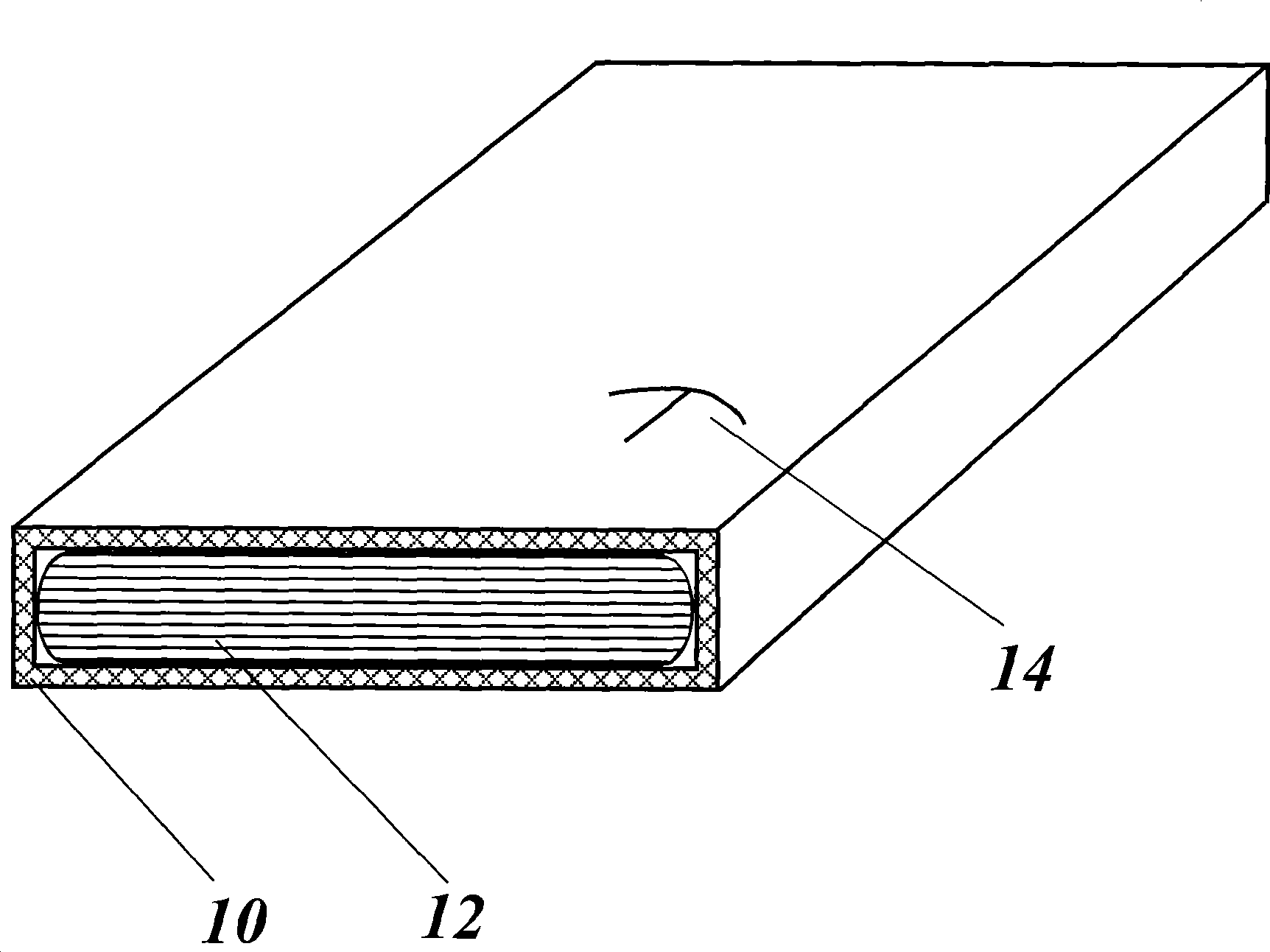

[0053] The following method was used to produce an aluminum folded case lithium-ion battery in which the battery core was wound.

[0054] Manufacturing method of negative electrode belt:

[0055] Dissolve 3 grams of polyvinylidene fluoride in N-methyl-2-pyrrolidinedione, then add 2.5 grams of acetone black, and finally add 115 grams of graphite powder. After high-speed stirring, vacuum or static degassing, the slurry-like negative electrode slurry is made. Coat the negative electrode slurry on both surfaces of a 10-micron thick copper foil. Dry at 120°C to remove the solvent N-methyl-2-pyrrolidinedione. The thickness of the electrode strip is controlled at 250±10 microns. The thickness of the tape after rolling is controlled at 110±5 microns. Cut negative electrode strip to 44 x 340mm 2 size. A nickel lead is then spot welded to the uncoated starting copper side.

[0056] Manufacturing method of positive electrode belt:

[0057] 6 grams of polyvinylidene fluoride are dis...

example 2

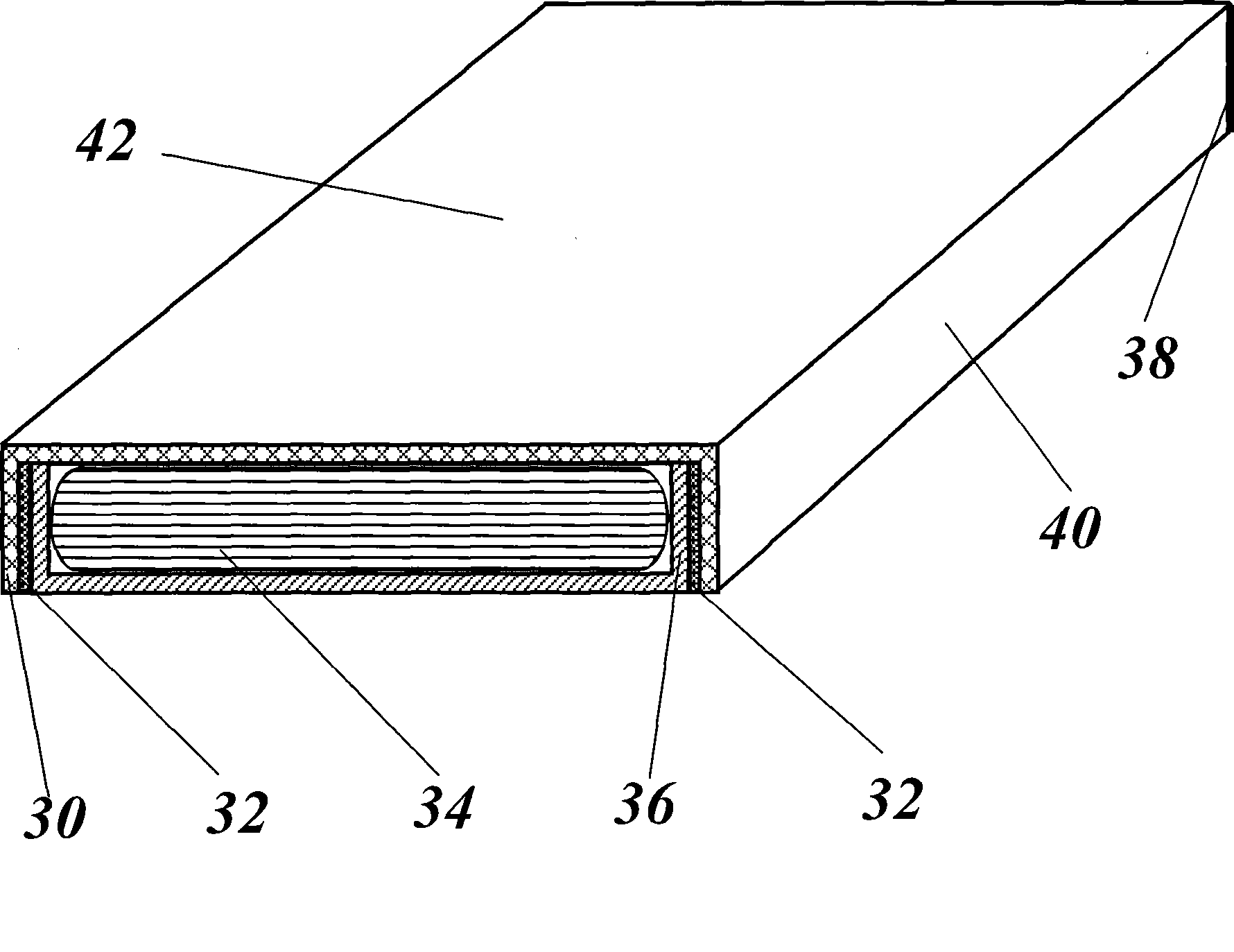

[0067] The following method was used to produce a steel folded case lithium-ion battery. Among them, the battery core is laminated

[0068] Manufacturing method of negative electrode belt:

[0069] Dissolve 3 grams of polyvinylidene fluoride in N-methyl-2-pyrrolidinedione, then add 3 grams of acetone black, and finally add 115 grams of graphite powder. After high-speed stirring, vacuum or static degassing, the slurry-like negative electrode slurry is made. The negative electrode slurry was coated on both surfaces of a 10 micron thick copper foil. The solvent N-methyl-2-pyrrolidinedione was dried and removed at 120°C, and the thickness of the electrode strip was controlled at 260±10 microns. The thickness of the electrode strip after rolling is controlled at 110±5 microns. Cut the negative electrode strip into a kitchen knife shape: the area of the main knife is 32 x 46mm 2 Dimensions, handle area 5 x 7mm 2 Size, the handle part is uncoated copper foil, and its surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com