Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

A technology for automatic production lines and mobile phone batteries, which is applied in the direction of measuring electricity, secondary batteries, measuring devices, etc., and can solve the problems of difficulty in guaranteeing structure and inspection quality, high labor intensity, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

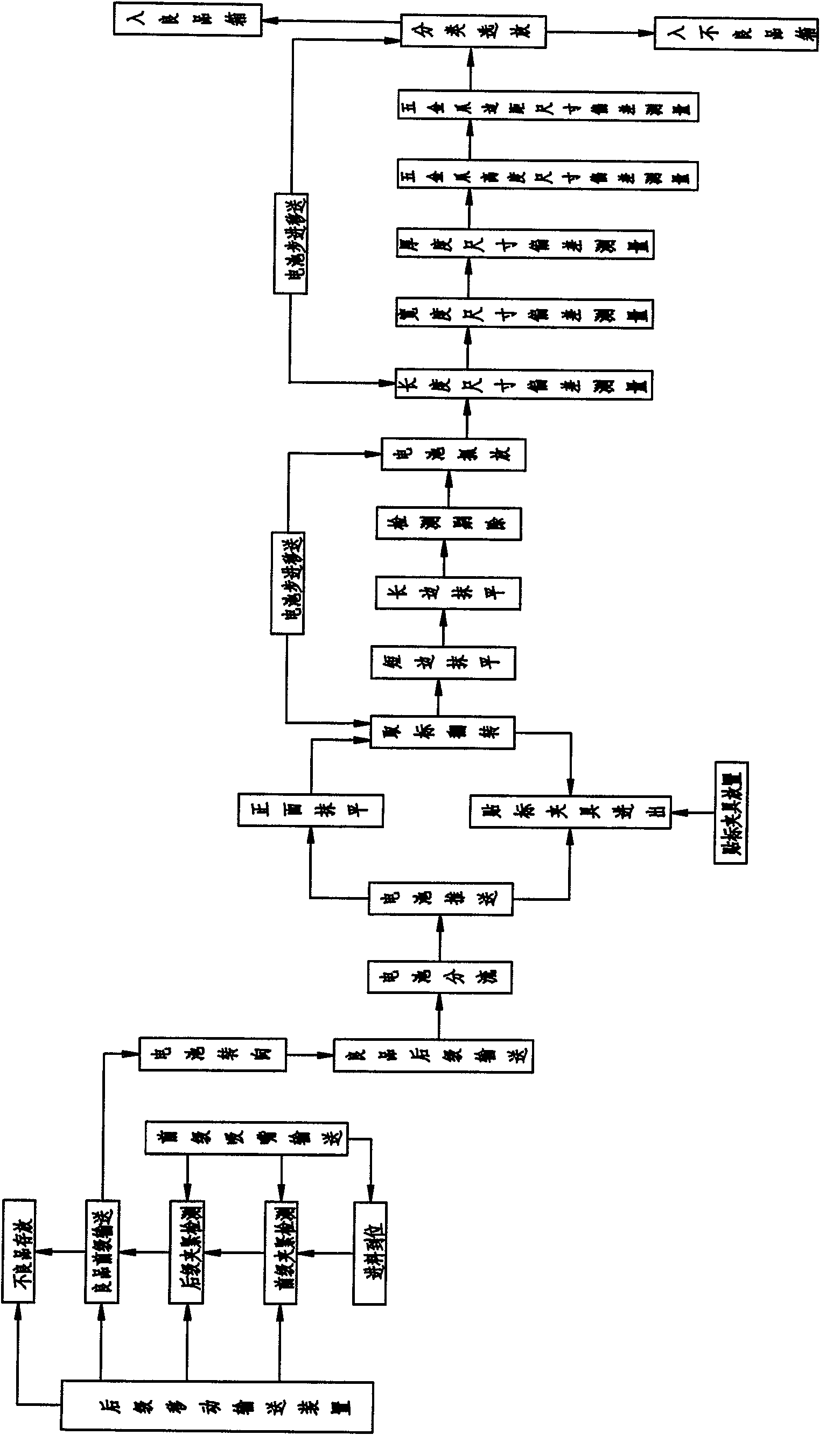

[0112] Such as figure 1 Shown, the technological process of mobile phone battery detection, wrapping label, measurement of the present invention is:

[0113] (1) Feeding: use the feeding device to send the battery to be tested to the positioning plate for positioning;

[0114] (2) Clamping detection: use the delivery device to transport the battery to be tested to the clamping detection device for detection;

[0115] (3) Sorting and releasing: transport the qualified batteries to the front-stage conveyor belt of the discharge device, and put the unqualified batteries into the defective product recycling box;

[0116] (4) Battery steering and conveying: Use the steering mechanism to turn the battery on the front conveyor belt and put it on the rear conveyor belt, and then transport it to the label wrapping station by the latter conveyor belt;

[0117] (5) Battery shunting: A row of batteries sent by the rear conveyor belt is divided into two rows by the shunting mechanism;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com