Graphene/ferric oxide composite material-containing resin anticorrosive coating and preparation method thereof

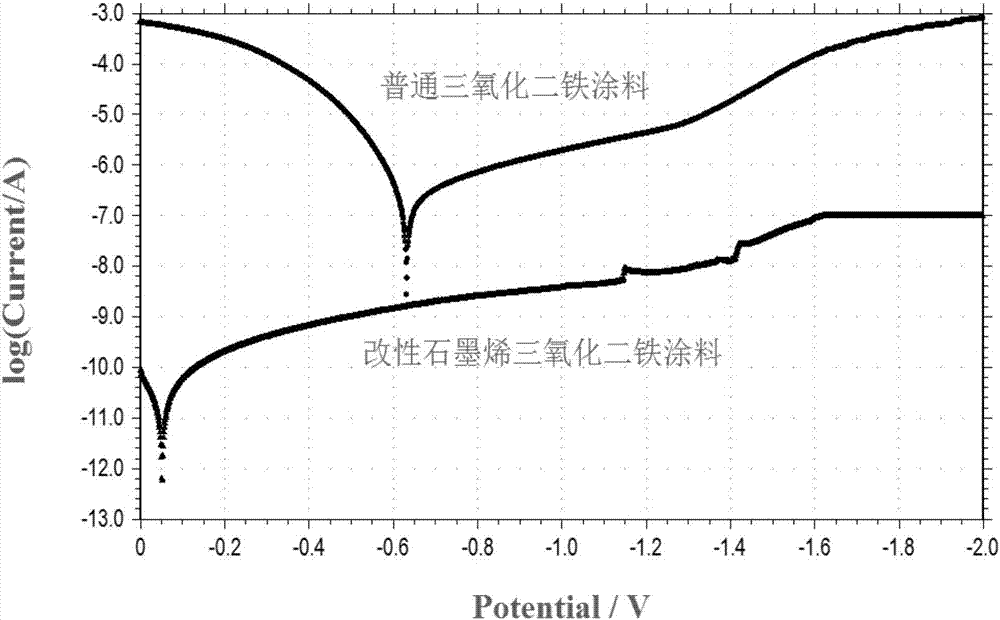

A technology of ferric oxide and anti-corrosion coatings, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as affecting the effect of graphene, inability to stably disperse, and easy agglomeration of graphene, and solve uneven mixing. Easy to reunite, good tiling state, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The present invention also provides a kind of preparation method of resin anticorrosion coating, comprises the following steps:

[0082] A) after mixing graphene and ferric oxide for the first time, obtain the composite material of graphene and ferric oxide;

[0083] B) the composite material, resin and solvent of the graphene and ferric oxide obtained in the above steps are mixed, and after rotary evaporation again, the mixture is obtained;

[0084] C) After mixing the mixture obtained in the above steps and the auxiliary agent again, the resin anticorrosion coating is obtained.

[0085] The present invention can correspond to the selection and composition of the raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, and the selection and composition of the corresponding raw materials in the aforementioned resin anticorrosion coatings, as well as the corresponding optimization principles, and will not re...

Embodiment 1

[0139] Graphene / Fe2O3 Composite

[0140] 1) Take a 0.5% graphene ethanol solution and stir it ultrasonically for 3 hours;

[0141] 2) Slowly add 250g of ferric oxide into the graphene solution obtained in step 1) under mechanical stirring according to the proportion of 0.1% graphene, and keep stirring for 30min;

[0142] 3) Add the mixed solution obtained in step 2) into the rotary evaporator;

[0143] 4) Control the degree of vacuum to 0.09Mpa, the temperature of the water bath to 60°C, and the rotation speed to 50RPM, and continue until the material is in a dry state to obtain ferric oxide particles with graphene evenly dispersed on the surface, that is, graphene-coated particles;

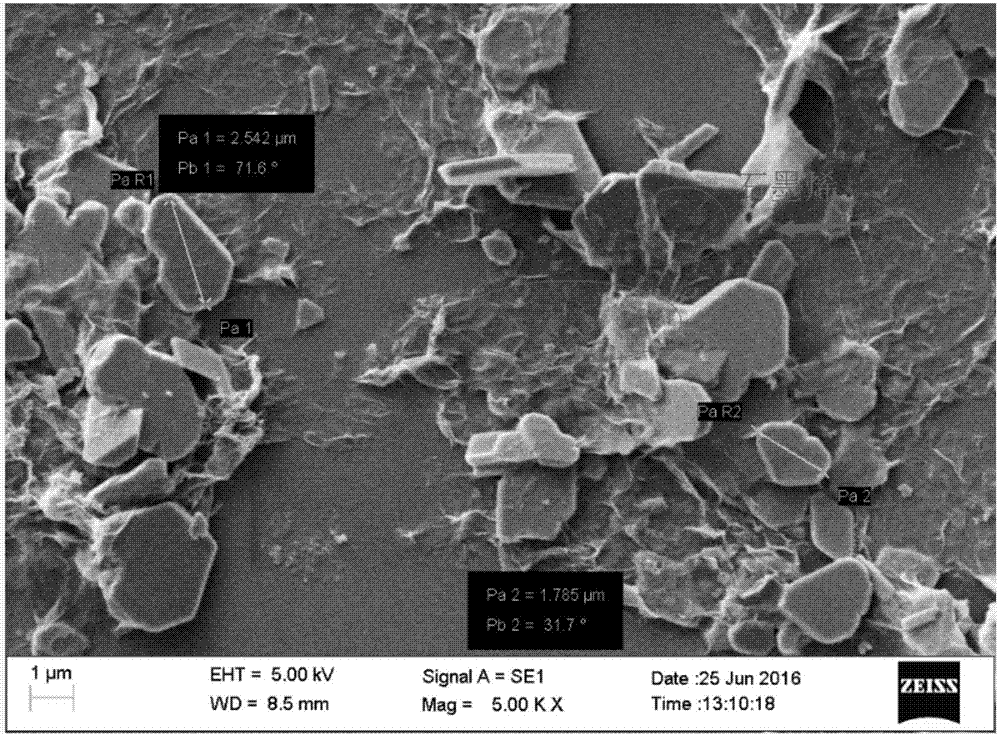

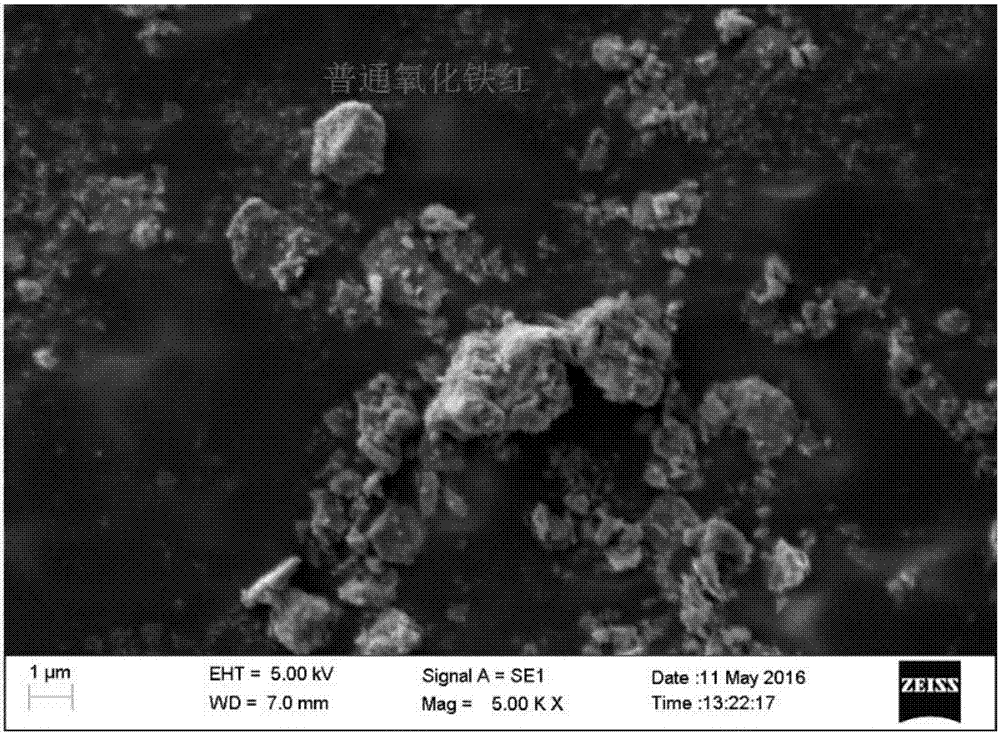

[0144] The graphene / ferric oxide composite material prepared by the above steps of the present invention is macroscopically analyzed, and the color of the ferric oxide after coating is obviously darker than that before coating.

[0145] The graphene / ferric oxide composite material that above-me...

Embodiment 2

[0164] 1) Take 50g of 0.1% graphene-modified ferric oxide and 50g of epoxy resin in 110g of xylene and n-butanol in a mixed solvent mixed at 3:1, and ultrasonically stir for 1h;

[0165] 2) Add the mixed solution obtained in step 1) into a rotary evaporator;

[0166] 3) Control the vacuum degree to 0.09Mpa, the temperature of the water bath is 60°C, and the rotation speed is 60RPM, and continue until the material is in a viscous state;

[0167] 4) Add the mixed material obtained in step 3) into a high-speed mixer, add 5.1g zinc oxide, 12.2g talcum powder, 2.8g organic clay, 1g defoamer, 0.6g MONORAL 3300, stir at high speed for 30min, and rotate at 1500r / min;

[0168] 5) Add the mixture obtained in step 4) into a three-roll machine and grind it to 25-55 μm to obtain component A.

[0169] B component

[0170] 6) Xylene and n-butanol are mixed into 30g of mixed solvent in a weight ratio of 3:1;

[0171] 7) Add 1 g of DMP-30 and 25 g of polyamide 200 to step 6) in sequence, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com