Graphene oxide-carbon quantum dot complex modified anticorrosive coating and preparation method thereof

A technology of carbon quantum dots and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of development limitations, the mechanical strength and performance of graphene composite anti-corrosion coatings to be improved, and achieve strong environmental protection and improved Effects of uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

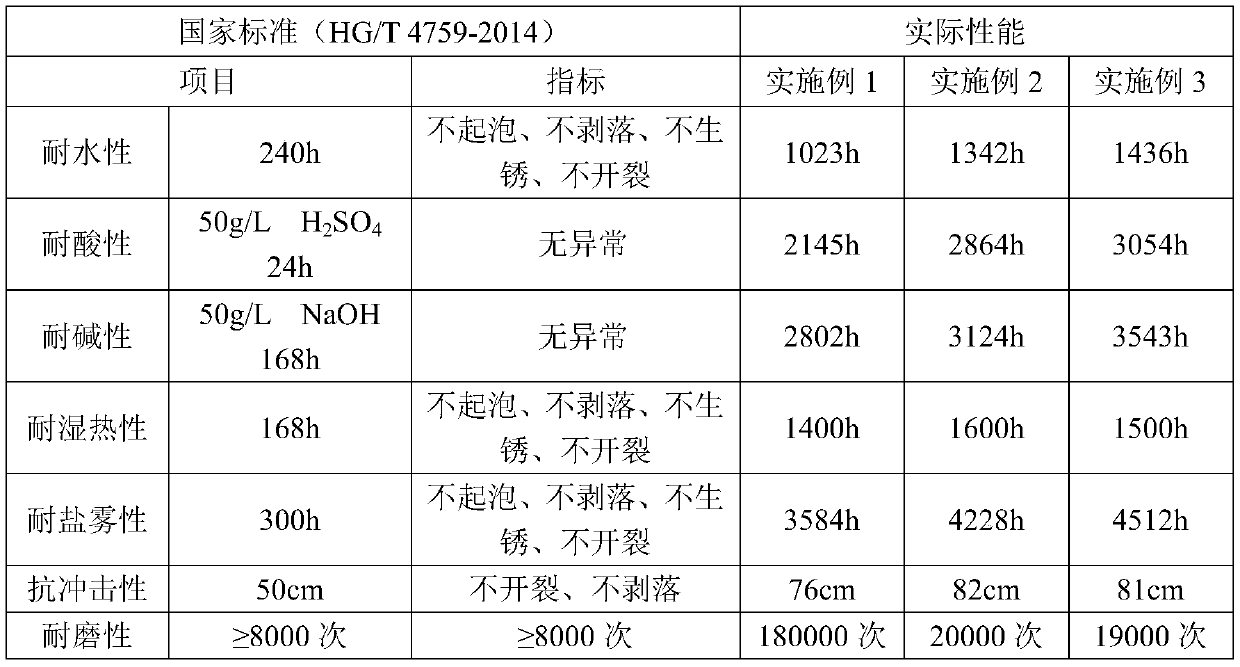

Examples

Embodiment 1

[0027] Graphene oxide-carbon quantum dot composite modified anti-corrosion coating, including the following raw materials in parts by mass: 2 parts of graphene oxide-carbon quantum dot nanocomposite, 25 parts of water-based alkyd resin, 5 parts of titanium dioxide, 6 parts of barium sulfate 1.5 parts of ethylene glycol dispersant, 0.2 parts of silicone defoamer, 0.1 part of sodium polyacrylate, 5 parts of additives, 30 parts of aliphatic polyamine curing agent, and 25 parts of deionized water. The additives are anti-settling agent, leveling agent, wetting agent, adhesion promoter and drier.

[0028] The preparation method of graphene oxide-carbon quantum dot composite modified anticorrosion coating comprises the following steps:

[0029] S1. Weigh 5 parts by mass of zinc citrate and 5 parts by mass of urea and dissolve them in water, then add 5 parts by mass of graphene oxide aqueous solution, conduct a hydrothermal reaction at 220°C for 5 hours, centrifuge to take the superna...

Embodiment 2

[0034] Graphene oxide-carbon quantum dot composite modified anti-corrosion coating, including the following raw materials in parts by mass: 5 parts of graphene oxide-carbon quantum dot nanocomposite, 20 parts of water-based alkyd resin, 10 parts of titanium dioxide, 20 parts of barium sulfate 1 part, 1 part of ethylene glycol dispersant, 0.5 part of silicone defoamer, 0.5 part of sodium polyacrylate, 3-10 parts of additives, 5 parts of aliphatic polyamine curing agent, 33 parts of deionized water. The additives are anti-settling agent, leveling agent, wetting agent, adhesion promoter and drier.

[0035] The preparation method of graphene oxide-carbon quantum dot composite modified anticorrosion coating comprises the following steps:

[0036] S1. Weigh 1 part by mass of zinc citrate and 1 part by mass of urea and dissolve them in water, then add 1 part by mass of graphene oxide aqueous solution, react hydrothermally at 160°C for 12 hours, centrifuge to take the supernatant, and...

Embodiment 3

[0041] Graphene oxide-carbon quantum dot composite modified anti-corrosion coating, including the following raw materials in parts by mass: 15 parts of graphene oxide-carbon quantum dot nanocomposite, 20 parts of water-based alkyd resin, 10 parts of titanium dioxide, 10 parts of barium sulfate 1.5 parts of ethylene glycol dispersant, 0.5 parts of silicone defoamer, 0.5 parts of sodium polyacrylate, 10 parts of additives, 5 parts of aliphatic polyamine curing agent, and 28 parts of deionized water. The additives are anti-settling agent, leveling agent, wetting agent, adhesion promoter and drier.

[0042] The preparation method of graphene oxide-carbon quantum dot composite modified anticorrosion coating comprises the following steps:

[0043]S1. Weigh 3 parts by mass of zinc citrate and 3 parts by mass of urea and dissolve them in water, then add 3 parts by mass of graphene oxide aqueous solution, perform hydrothermal reaction at 200°C for 8 hours, centrifuge to take the supern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com