Corrosion resistant coating of silver combined coating

A corrosion-resistant, silver coating technology, applied in the field of corrosion-resistant coating, can solve the problems of reduced electrical conductivity, limited thickness, neglect of the bonding of base materials, etc., to achieve the effect of good adhesion and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

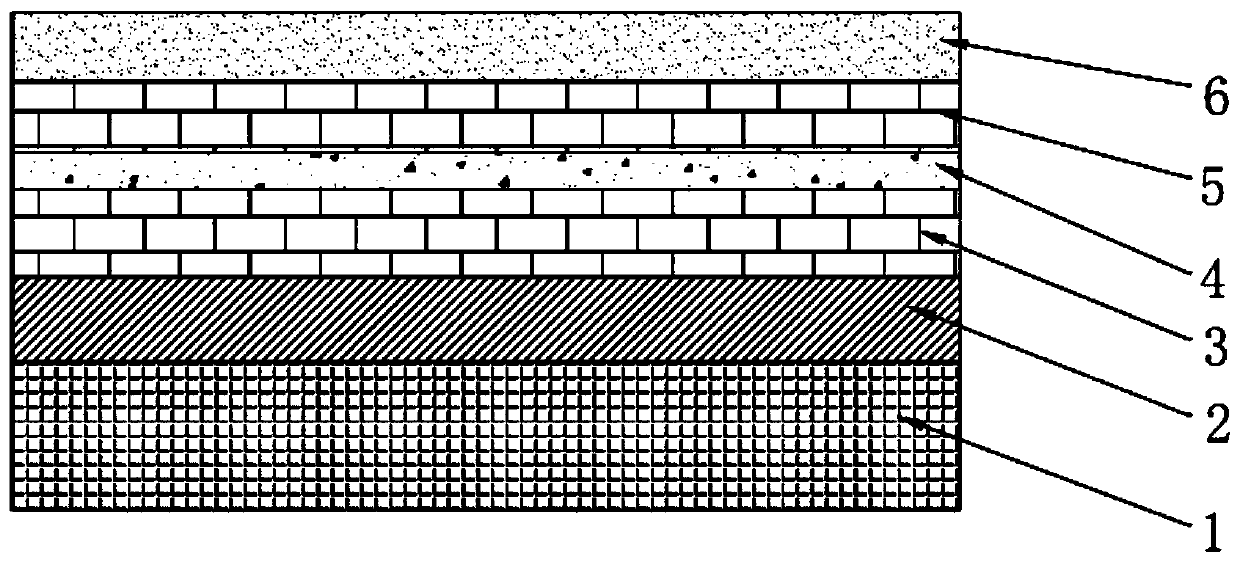

[0026] This embodiment provides a coating with good wear resistance and corrosion resistance, including a nickel coating, a first silver coating 3 , a first gold coating 4 and a rhodium-ruthenium coating 5 electroplated on the surface of the substrate in sequence.

[0027] The coating structure of the above coating combination has good wear resistance, oxidation resistance, electrical conductivity and corrosion resistance, and the adhesion between the electroplating coating and the base material is good.

Embodiment 2

[0029] On the basis of embodiment 1, this embodiment provides a kind of the thinnest plating layer, and the thickness of described nickel plating layer is 0.5 micron, and the thickness of described first silver plating layer 3 is 0.5 micron, and the thickness of described first gold plating layer 4 has a thickness of 0.025 microns, and the rhodium-ruthenium coating 5 has a thickness of 0.25 microns.

Embodiment 3

[0031] On the basis of embodiment 1, this embodiment provides a corrosion-resistant coating with the best adhesion performance, and a pre-plating layer 2 is provided between the nickel coating layer and the first silver coating layer 3 . The bonding force between the nickel plating layer and the first silver plating layer 3 is increased by the pre-plating layer 2, and the first silver plating layer 3 and the rhodium-ruthenium plating layer 5 are also provided with the first gold plating layer to increase the bonding force between the two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com