Patents

Literature

80 results about "Chromic sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating chromite by sulfuric acid leaching

InactiveCN101979679AHigh yieldEmission reductionProcess efficiency improvementAmmonium sulfateAmmonium persulfate

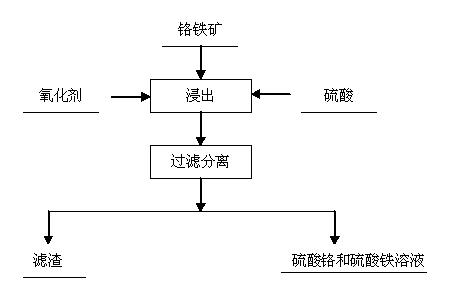

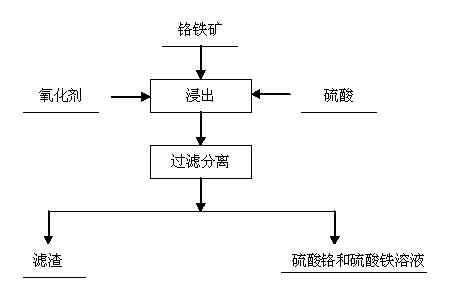

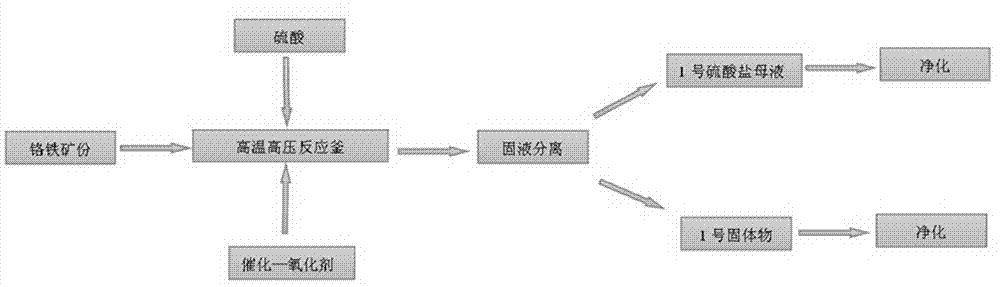

The invention discloses a method for treating chromite by sulfuric acid leaching, which comprises the following steps of: grinding the chromite into mineral powder, adding sulfuric acid into the mineral powder, stirring the mixture, and adding an oxidant into the mixture, wherein the oxidant is chromic anhydride, potassium chlorate or ammonium persulphate, and the adding amount of the oxidant is 0.2 to 7 percent of the mass of the mineral powder; heating the mixture at the temperature of between 120 and 190 DEG C for 30 to 90 minutes under the pressure of between 0.2 and 1.2MPa, filtering the reaction products after the reaction is finished, and performing solid-liquid separation, wherein the filter residue is directly used as a raw material for melting silicon iron; and removing iron from the filtrate to obtain chromium sulfate solution, and further preparing chromium sulfate by a direct crystallization method. Compared with the prior art, the method has the most remarkable characteristics of short process flow and no 'three-waste' emission. The filter residue does not contain hexavalent chromium, and the weight of the filter residue is light and only about 10 percent of the weight of the chromite, so the filter residue can be used as the raw material for melting the silicon iron.

Owner:NORTHEASTERN UNIV

Whole sulphate type trivalent chromium plating solution and electroplating method using the same

The invention relates to full sulfate type trivalent chromium electroplating solution. The electroplating solution includes chromic sulfate, potassium sulfate and / or sodium sulfate, boracic acid, complexing agent and water, wherein, the electroplating solution also includes additive A and additive B, the additive A is selected from one or more of OP emulsifier, water soluble borofluoride, water soluble silico fluoride, vinyl diamine acetic acid, cystine, 1,4-butynediol, thiourea and glycol; the additive B is selected from one or more of O-Sulfonylbenaylsuamine, glycerine, water soluble sulphosuccinate, Docusate sodium and water soluble alkyl ether sulfate. The electroplating solution provided by the invention ensures the current density scopes of the coating and the luminous area to be both improved to a great extent.

Owner:BYD CO LTD

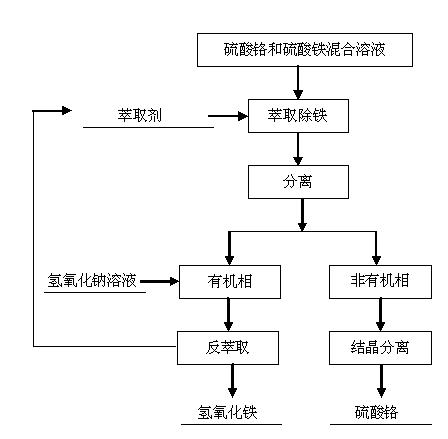

Method for separating chromium ions and iron ions in multicomponent solution

InactiveCN101974688AShort processNo "three wastes" dischargeProcess efficiency improvementChromium sulfatesFerric hydroxideIron sulfate

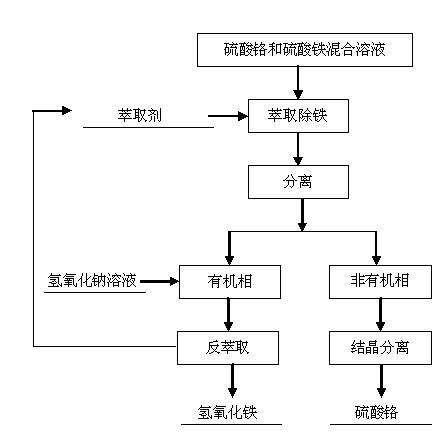

The invention provides a method for separating chromium ions and iron ions in a multicomponent solution, comprising the following steps of: with a mixed solution of chromic sulfate and ferric sulfate, generated by leaching out chromite by using sulfuric acid, as a raw material, adding an extractant to carry out extraction; obtaining an inorganic phase of a chromic sulfate solution and obtaining organic phases of the extractant and the ferric sulfate after extraction; then carrying out back extraction on the organic phases by using a sodium hydroxide solution and regulating a pH value to be 9-10 to obtain ferric hydroxide, a sodium sulfate solution and an extractant; recycling the extractant, and preparing the chromic sulfate by utilizing the extracted chromic sulfate solution and adopting a direct crystallization method; and preparing iron oxide red pigment by utilizing the ferric hydroxide as a raw material through a high-temperature crystallization method. Compared with the traditional technology for removing iron from the mixed solution of the chromic sulfate and the ferric sulfate, the invention has the most remarkable advantages that a process flow is short without three waste emission and extractant is recycled. Iron oxide red as a by-product does not contain hexavalent chromium and can be applied to industries of buildings, coatings, vehicles and the like.

Owner:NORTHEASTERN UNIV

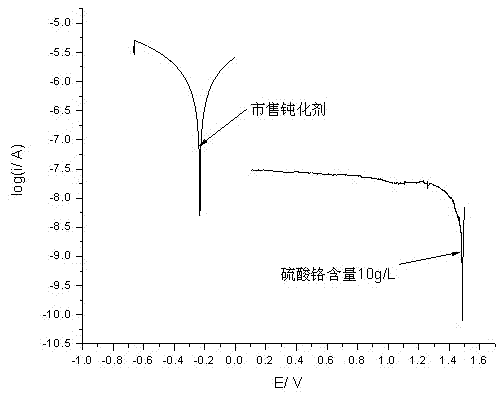

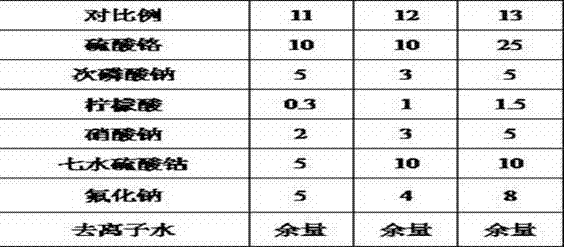

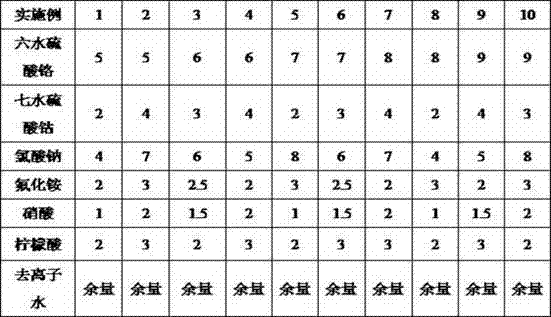

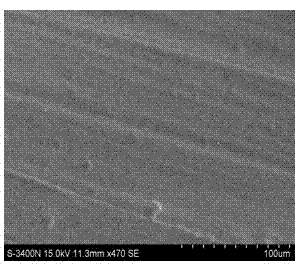

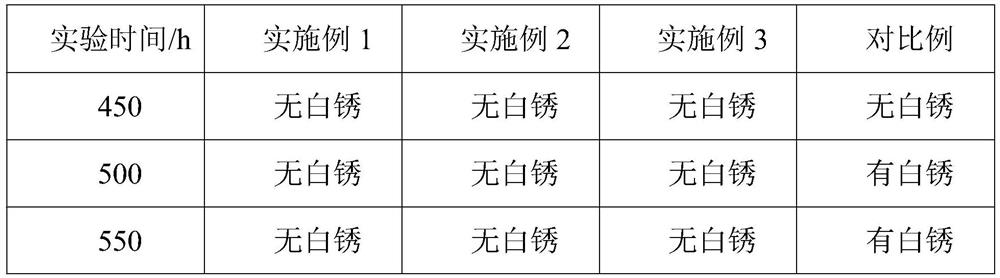

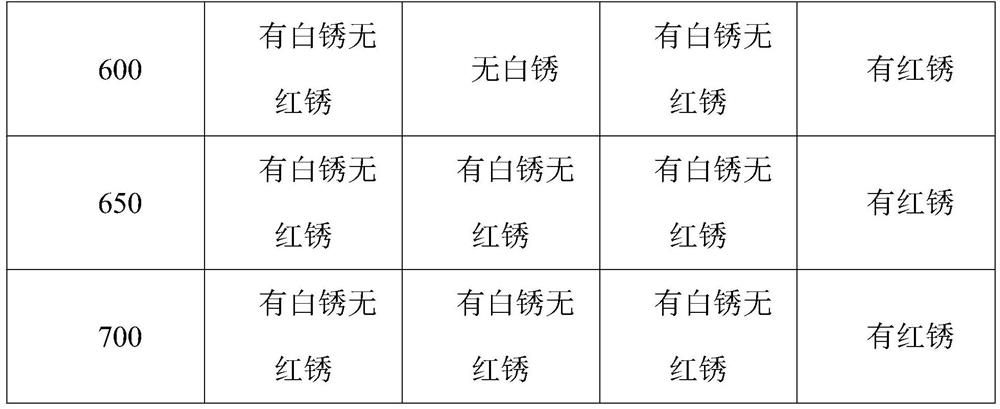

High corrosion resistance trivalent chromium blue and white passivating liquid as well as preparation method and application of blue and white passivating liquid

ActiveCN103046037AImprove performanceExtended service lifeMetallic material coating processesSodium Hypophosphite MonohydrateSodium phosphates

The invention discloses high corrosion resistance trivalent chromium blue and white passivating liquid and a preparation method of the blue and white passivating liquid. Calculated by each litre, the high corrosion resistance trivalent chromium blue and white passivating liquid consists of 5-25g of chromium sulfate, 2-8g of sodium fluoride, 1-6g of sodium hypophosphite, 0.3-1.5g of citric acid, 1-5g of sodium nitrate, 5-15g of cobaltous sulfate heptahydrate and the balance of deionized water. The preparation method comprises the following steps of: dissolving the chromium sulfate into the deionized water; adding citric acid to stir and dissolve; adding the sodium hypophosphite and the sodium nitrate to stir again until the solutions are completely dissolved; adding the cobaltous sulfate heptahydrate into the solutions to be dissolved; and finally adding the sodium fluoride to continuously stir to uniformly mix the raw materials to obtain the high corrosion resistance trivalent chromium blue and white passivating liquid which is stable in performance, long in service life, low in production cost and environment-friendly, and avoids toxicity. The preparation method for the trivalent chromium blue and white passivating liquid is simple, easy to operate, and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Method for synthesizing 3-methyl-4-nitrobenzoic acid by using stepped heating method and indirect electrosynthesis method

The invention discloses a method for synthesizing 3-methyl-4-nitrobenzoic acid by using a stepped heating method and an indirect electrosynthesis method. The method is implemented by taking 2,4-dimethylnitrobenzene and chromium sulfate as main raw materials through the following steps of: firstly, carrying out electrolytic oxidation on chromium sulfate by using an electrolytic process so as to obtain chromium trioxide; then, selectively oxidizing 2,4-dimethylnitrobenzene into a 3-methyl-4-nitrobenzoic acid by using chromium trioxide through using the stepped heating method. According to the invention, through adopting the stepped heating method, the oxidation reaction rate of 2,4-dimethylnitrobenzene is controlled, and the selectivity and conversion rate of reaction are remarkably improved. The conversion rate of chromium trioxide obtained by using an electrolytic oxidation method is 85-95%, and the conversion rate of 3-methyl-4-nitrobenzoic acid obtained by using the stepped heating method can reach 65-86%. According to the invention, the problem that in the process of reaction, the reaction rate declines due to the consumption of acids is solved; through carrying out electrolytic oxidation on chromium sulfate produced after reaction, chromium trioxide is circularly produced, thereby not only avoiding the environment pollution, but also greatly saving the cost.

Owner:HUNAN UNIV OF SCI & TECH

High-salt-fog-resistance aluminum product passivator and preparation method thereof

InactiveCN102965654AImprove corrosion resistanceImprove adhesionMetallic material coating processesNickel saltNitrite

The invention relates to a high-salt-fog-resistance aluminum product passivator which is an environment-friendly passivator having excellent adhesive force and high corrosion resistance, remarkably prolonging the corrosion resistance time and containing no phosphate, nitrite or other toxic heavy metal ions. The aluminum product passivator mainly comprises the following components: fluozirconate, chromic sulfate, sodium hydroxide, fluoride salt, nitrate, nickel salt and water. A preparation method of the aluminum product passivator comprises the following steps: mixing the fluozirconate and the fluoride salt, dissolving in water; fully dissolving the chromic sulfate in water of 70-75 DEG C, then adding into the former solution, and evenly mixing; and then, sequentially adding the sodium hydroxide, the nitrate and the nickel salt into the mixed solution, evenly stirring, and adding water to a specified volume, thus obtaining the aluminum product passivator. The method is simple to operate and short in processing time; and the aluminum product passivator can be repeatedly used. Thus, the cost can be saved.

Owner:况金权 +2

Corrosion resistant coatings for aluminum and aluminum alloys

This invention is for the protection and surface treatment of aluminum, aluminum alloys and coated aluminum substrates against corrosion. The aluminum substrates are treated with an acidic aqueous solution containing small but effective amounts of at least one trivalent chromium salt such as a trivalent chromium sulfate, at least one alkali metal hexafluorazirconate such as potassium hexafluorozirconate in combination with small but effective amounts of at least one water soluble or dispersible thickening agent such as a cellulose compound and at least one water soluble surfactant. The corrosion resistant aluminum substrates of this invention have improved adhesion for overlaying coatings e.g. paints and a lower electrical resistance contact.

Owner:美国海军部

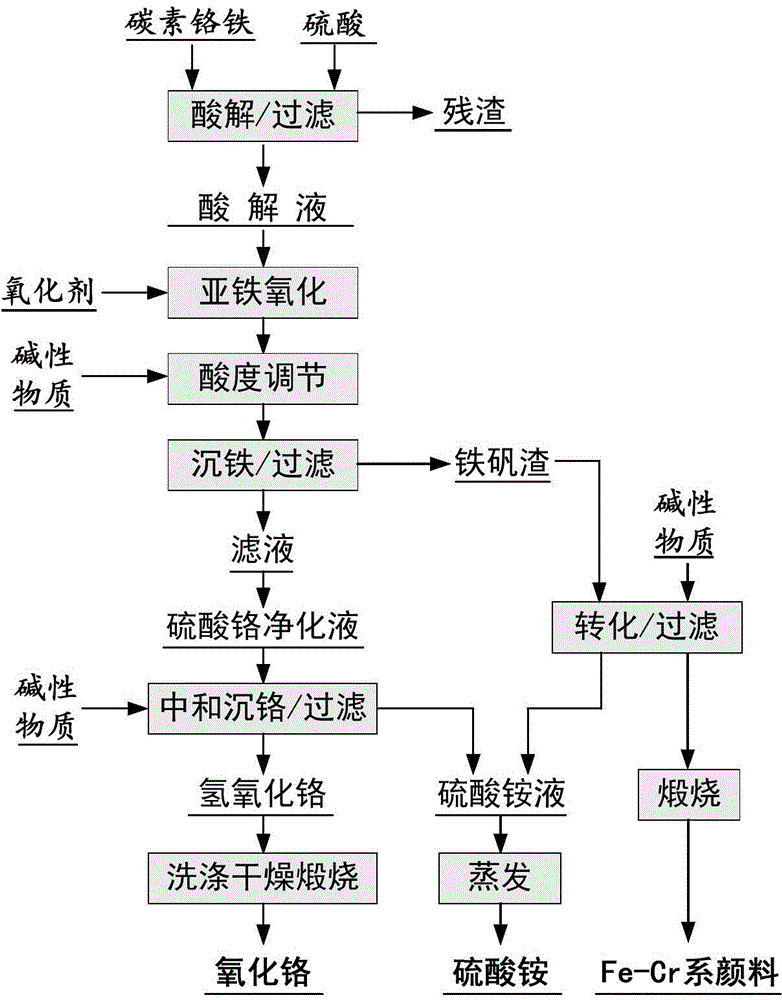

Method for producing chromic oxide from carbon ferrochrome

InactiveCN104973627AReduce manufacturing costReduce pollutionAmmonium sulfatesIron compoundsFerrochromeCalcination

The invention relates to a method for producing chromic oxide from carbon ferrochrome which is a novel method that is basically different from the chromic oxide preparation technique. The method comprises the following steps: by using carbon ferrochrome with fewer impurity varieties as the raw material, dissolving in a sulfuric acid solution to obtain a chromic sulfate-ferrous sulfate acid hydrolysis solution, efficiently separating chrome and iron in the acid leaching solution by using an ammonium salt efficient iron removal technique, carrying out chrome precipitation, washing and calcination on the purified chromic sulfate solution to obtain a chromic oxide product, keeping the temperature of the chrome precipitation slag, converting with an alkali medium, calcining to obtain an Fe-Cr pigment, and carrying out evaporative crystallization on the ammonium sulfate solution subjected to chrome precipitation to obtain the ammonium sulfate solid. The novel method uses the ferrochrome as the raw material to form an efficient pollution-free chromic oxide preparation technique and synchronously obtain the Fe-Cr pigment and ammonium sulfate product. The technical line has the characteristic of diversified products. The invention provides an environment-friendly economical method for producing chromic oxide, and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

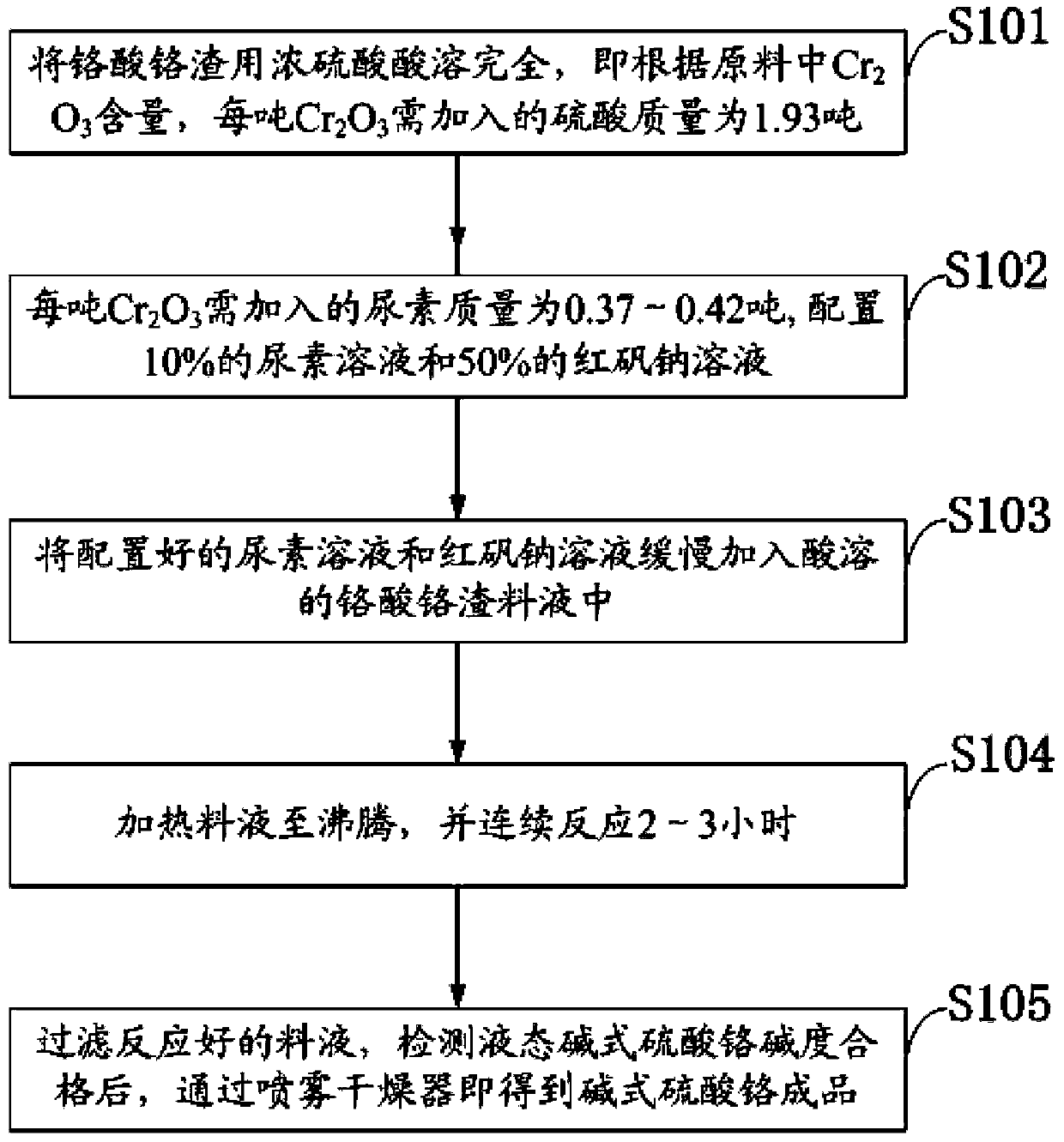

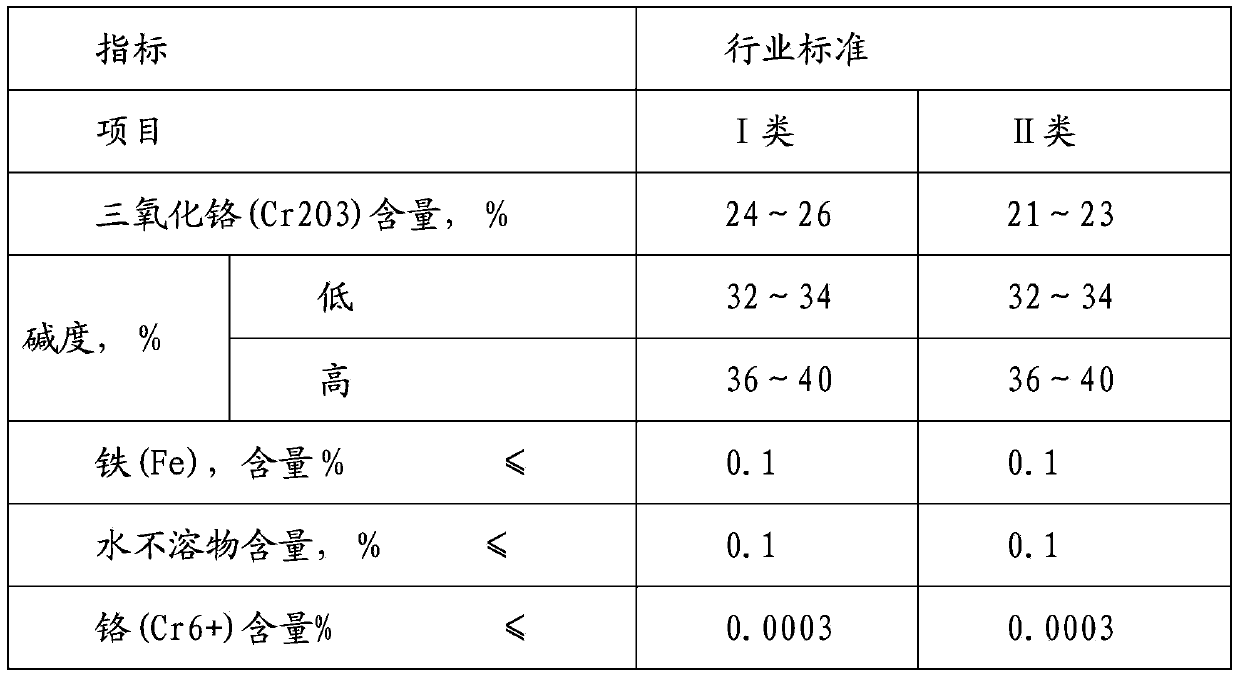

Method for producing basic chrome sulphate with dichromiumtris (chromate) slag

ActiveCN103466708AReduce unit consumptionReduced environmental benefitsChromium sulfatesAlkalinitySlag

The invention discloses a method for producing basic chrome sulphate with dichromiumtris (chromate) slag. The method for producing basic chrome sulphate with the dichromiumtris (chromate) slag comprises the following steps of completely dissolving the dichromiumtris (chromate) slag with concentrated sulfuric acid, that is, adding 1.93t sulfuric acid per ton of Cr2O3 according to a Cr2O3 content in a raw material, adding 0.37-0.42t urea per ton of Cr2O3 to prepare a 10% urea solution and a 50% sodium bichromate solution, slowly adding the prepared urea solution and the sodium bichromate solution into acid soluble dichromiumtris (chromate) slag slurry, heating the slurry to be boiled, performing continuous reaction for 2-3h, filtering the reacted slurry, and after alkalinity of liquid basic chrome sulphate is detected to be qualified, obtaining a basic chrome sulphate finish product through a spray dryer. The method takes the waste dichromiumtris (chromate) slag as a raw material, is environment-friendly, saves resources, reduces unit consumption, produces obvious economic benefits, and provides an energy-saving, environment-friendly and synergetic novel production technology.

Owner:GANSU JINSHI CHEM

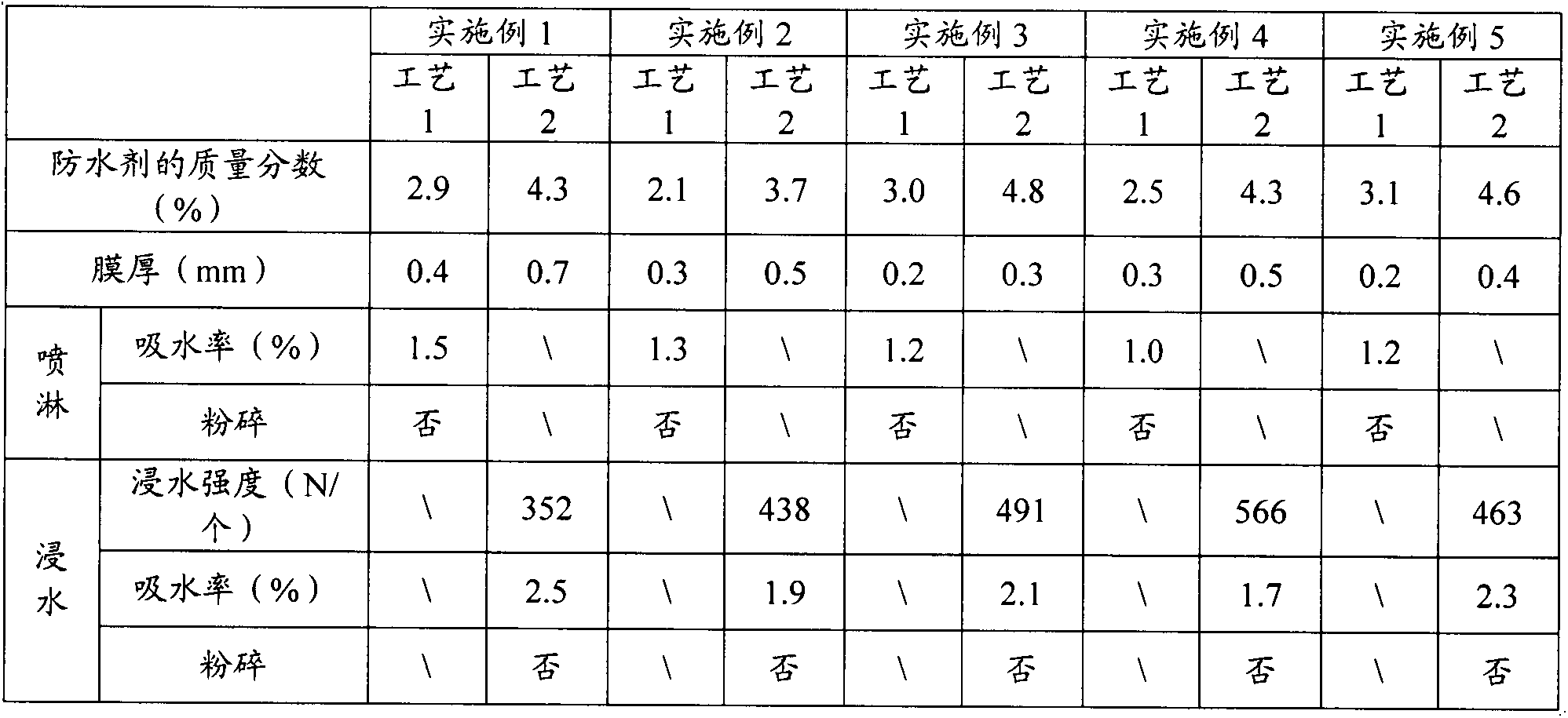

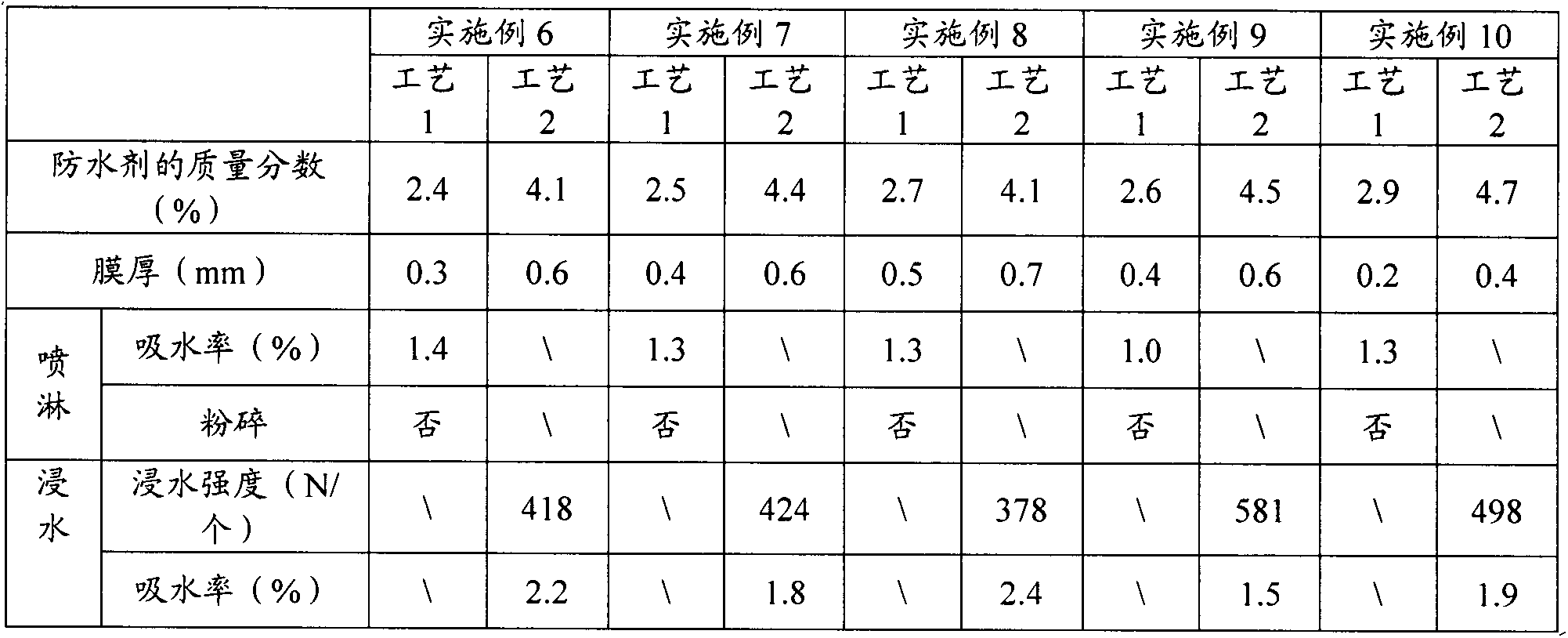

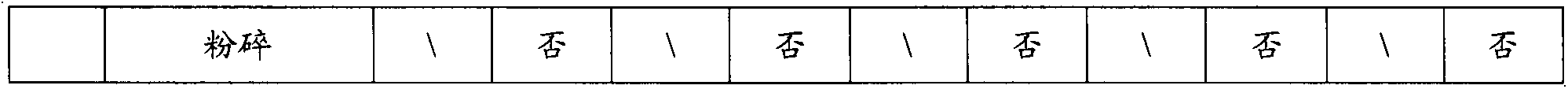

Waterproofing agent used on briquette surface and preparation method thereof, and waterproof briquette and manufacturing method thereof

InactiveCN103060042AImprove waterproof performanceEasy to transportSolid fuelsPotassiumPotassium dichromate

The invention relates to a waterproof agent used on briquette surface and a preparation method thereof, and a waterproof briquette and a manufacturing method thereof. The waterproof agent comprises, by weight, 1-3 parts of potassium dichromate, 1-3 parts of potassium aluminum sulfate, 1-3 parts of copper sulfate, and 1-3 parts of potassium chromium sulfate with equal mass proportions, and 300-500 parts of water glass and 50-70 parts of water. According to the invention, the 50-70 parts by weight of water is heated to 95-100 DEG C; various alums are added, and are completely dissolved by stirring; the material is subjected to standing, and is naturally cooled to 40-55 DEG C; 300-500 parts by weight of the water glass is added; and the mixture is stirred for 20-40min, such that the waterproofing agent is obtained. Briquette is soaked in the waterproofing agent for a certain period of time, and is air-dried, such that waterproof briquette is obtained. The waterproof briquette provided by the invention has the advantages of small additive dose, good waterproof performance, easy transportation, and easy storage.

Owner:孟越峰

Preparation process of chromium glucosaminic acid and use thereof

The invention relates to chromium amino gluconate (III) having a molecular formula of Crn(C6H12NO6)3Ap, n=1 or 2, its preparing process and use, wherein the compound is obtained through the reaction between amino glucose acid, chromic sulfate and barium hydroxide in solution. The compound can be used as highly effective replenisher for trace elements in human body and for the treatment of high blood sugar.

Owner:NANJING UNIV

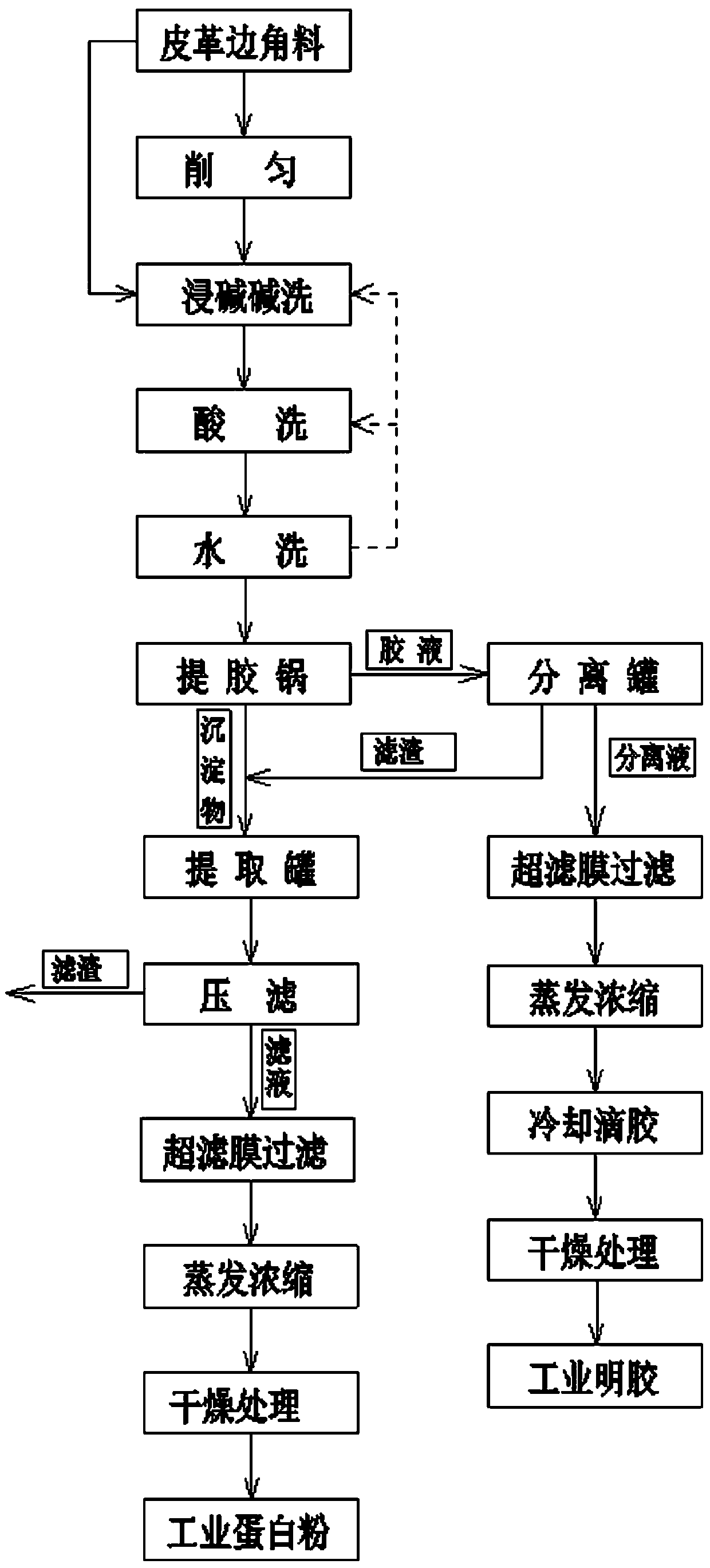

Method for preparing industrial gelatin and industrial protein powder by using waste leftover materials of leather

PendingCN109796878AReduce pollutionLower Disposal CostsPeptide preparation methodsGlue/gelatin preparationFiberSolubility

The invention discloses a method for preparing industrial gelatin and industrial protein powder by using waste leftover materials of leather, and belongs to the technical field of leather waste recycling. The method comprises the following steps of alkali soaking and cleaning-pickling-water washing-extracting, the leather leftover materials are soaked in alkali to form chromium hydroxide flocculent precipitate by most chromium and hydroxide radical ions in the leather leftover materials, wherein the removal rate reaches more than 98%; the residual heavy metal chromium in the leather leftover materials can be removed by acid washing to generate soluble chromium sulfate salt; water washing is carried out to remove a small amount of impurities remaining in the inner layer of the skin and opena skin fiber interstitial channel, and the water washing is carried out until the pH value is neutral; in the extraction process, the upper layer glue solution is concentrated and used for preparingindustrial gelatin, and the residual precipitate is subjected to secondary extraction and is concentrated and used for preparing industrial protein powder. According to the invention, the leather leftover materials can be effectively treated, the environmental pollution and the treatment cost are reduced, industrial products are formed, the economic benefits are generated, and the economic and social benefits caused by changing waste into valuable are achieved.

Owner:张昭

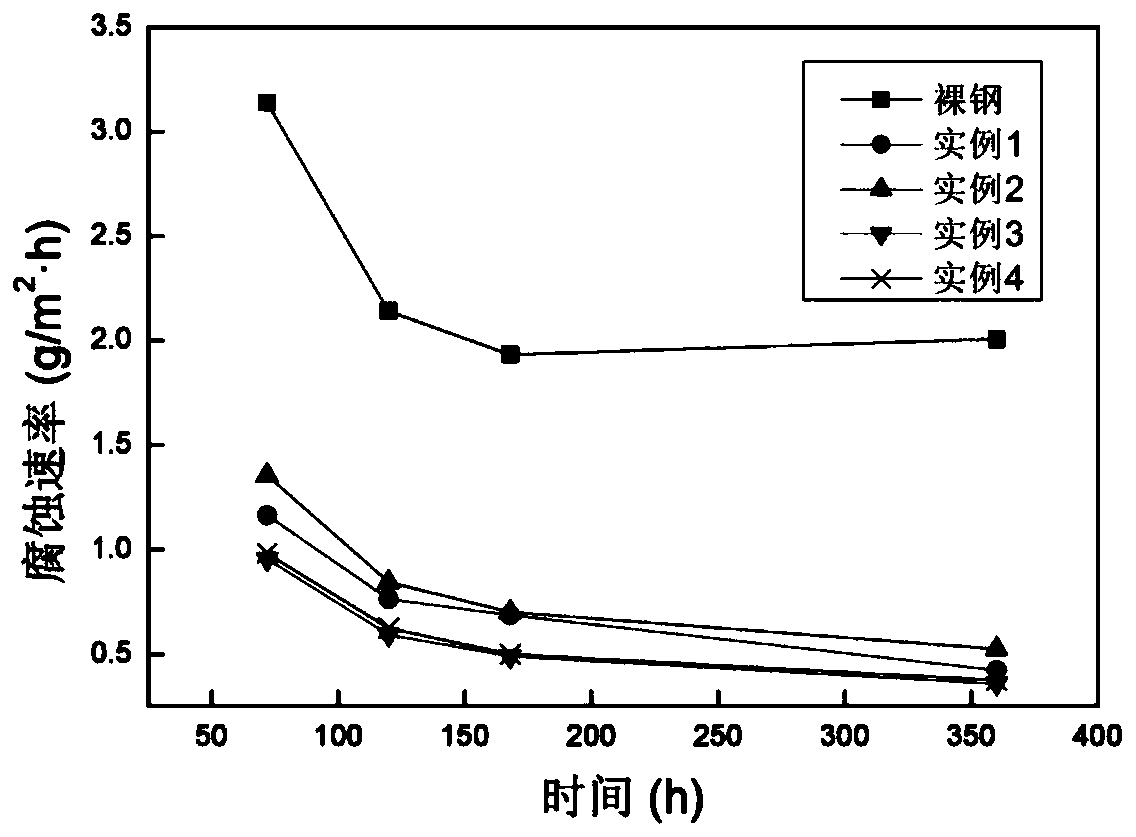

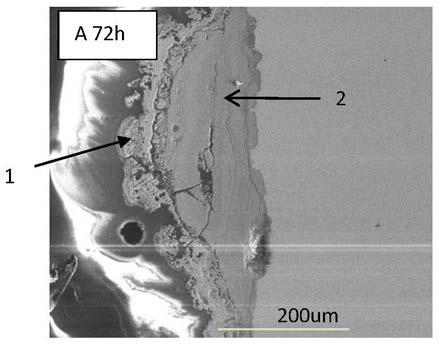

Weathering resistant steel surface rust layer stabilizing agent and preparing and use method thereof

PendingCN111575689ASimple processSimple to useMetallic material coating processesPolyvinyl alcoholSesquioxide

The invention discloses a weathering resistant steel surface rust layer stabilizing agent and a preparing and use method thereof, and belongs to the technical field of metal corrosion and protection.The problem that in the prior art, weathering resistant steel is in rust liquid sagging, and rust layer stabilizing is slow can be solved, the weathering resistant steel rust layer stabilizing is promoted, meanwhile, the corrosion rate and the corrosion amount of the steel can be greatly reduced, the weathering resistant steel surface rust layer stabilizing agent is used for weathering resistant corrosion resistant steel surface coating in a self weathering type, stabilizing of a weathering resistant corrosion resistant steel surface rust layer can be promoted, the stable rust layer forming time is shortened, and the stabilizing agent comprises, by mass percent, 2 to 10% of polyvinyl butyral ester, 5 to 12% of chromium sulfate, 5 to 18% of iron sesquioxide, 1 to 20% of ferroferric oxide and the balance ethyl alcohol or ethyl acetate. The weathering resistant steel surface rust layer stabilizing agent is simple in treatment process, and suitable for being used on site, the rust layer stabilizing agent is used for greatly reducing the corrosion rate of weathering resistant corrosion resistant steel, forming of a dense inner rust layer is accelerated, and a steel corrosion resistanceproperty and the use safety can be improved.

Owner:CENT IRON & STEEL RES INST +1

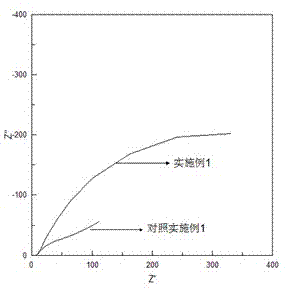

Passivation solution capable of inhibiting formation of hexavalent chromium in trivalent chromium passivation layer as well as preparation method and application of passivation solution

ActiveCN103320779AInhibition formationReduce oxidation rateMetallic material coating processesHydrogen fluorideAcetic acid

The invention discloses a passivation solution capable of inhibiting formation of hexavalent chromium in a trivalent chromium passivation layer as well as a preparation method of the passivation solution. Every liter of the passivation solution capable of inhibiting formation of hexavalent chromium in the trivalent chromium passivation layer comprises 15-25g of chromium sulphate, 1.5-3.0g of sodium nitrate, 4.0-9.0g of cobaltous sulphate heptahydrate, 2.5-5.0g of sodium hypophosphite, 0.4-1.0g of citric acid, 0.15-0.25g of ammonium hydrogen fluoride, 0.8-1.25g of D-sodium gluconate, 0.4-1.0g of acetic acid and the balance of deionized water. The preparation method of the passivation solution capable of inhibiting formation of hexavalent chromium in the trivalent chromium passivation layer comprises the following steps of: firstly sequentially adding sodium hypophosphite, citric acid, sodium nitrate and cobaltous sulphate heptahydrate into a chromium sulphate aqueous solution and dissolving, then sequentially adding ammonium hydrogen fluoride and D-sodium gluconate, and finally dropwise adding acetic acid, and adding water to maintain constant volume, thus the passivation solution capable of inhibiting formation of hexavalent chromium in the trivalent chromium passivation layer is obtained. The passivation solution can improve stability and tightness of a passivation layer and inhibit formation of hexavalent chromium.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

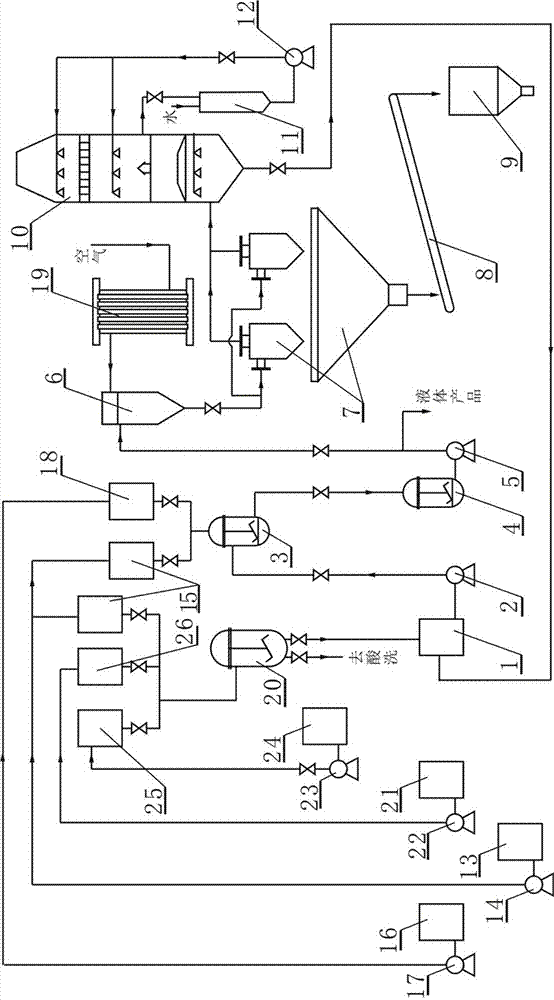

Method and device for producing chromium tanning agent by using oxidized waste liquid obtained from S wax production

ActiveCN103642951AStrong transposition effectImprove waterproof performanceTanning treatmentChromium sulfatesLiquid wasteChromium trioxide

The invention discloses a method and device for producing a chromium tanning agent by using oxidized waste liquid obtained from S wax production. The method comprises the steps of carrying out acidification and two-stage oxidation on raw materials, namely lignite wax, sodium bichromate, chromic anhydride (chromium trioxide, CrO3) and sulfuric acid, so as to obtain the oxidized waste liquid; treating the oxidized waste liquid by using glucose serving as a reducing agent in a manner that glucose cooperates with sodium bichromate, so as to obtain a chromium tanning solution; drying and dewatering the chromium tanning solution, thereby obtaining the chromium tanning agent. The device comprises an oxidized waste liquid storage tank, an oxidized liquid reduction device, a chromium tanning agent recovery device, a high-position liquid supplying device and a supporting liquid distribution device. According to the method, the chromium tanning agent (alkaline chromic sulfate-chromium powder tanning agent) is prepared through reducing the chromium-containing oxidized waste liquid, formed during the production of S wax from lignite wax, by using glucose which cooperates with sodium bichromate, and tanned leather is plump, soft and elastic. According to the method and the device, the process is simple and energy-saving, the consumption of sulfuric acid and glucose is low, and the device is easy to implement, so that the large-scale, continuous and automated production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

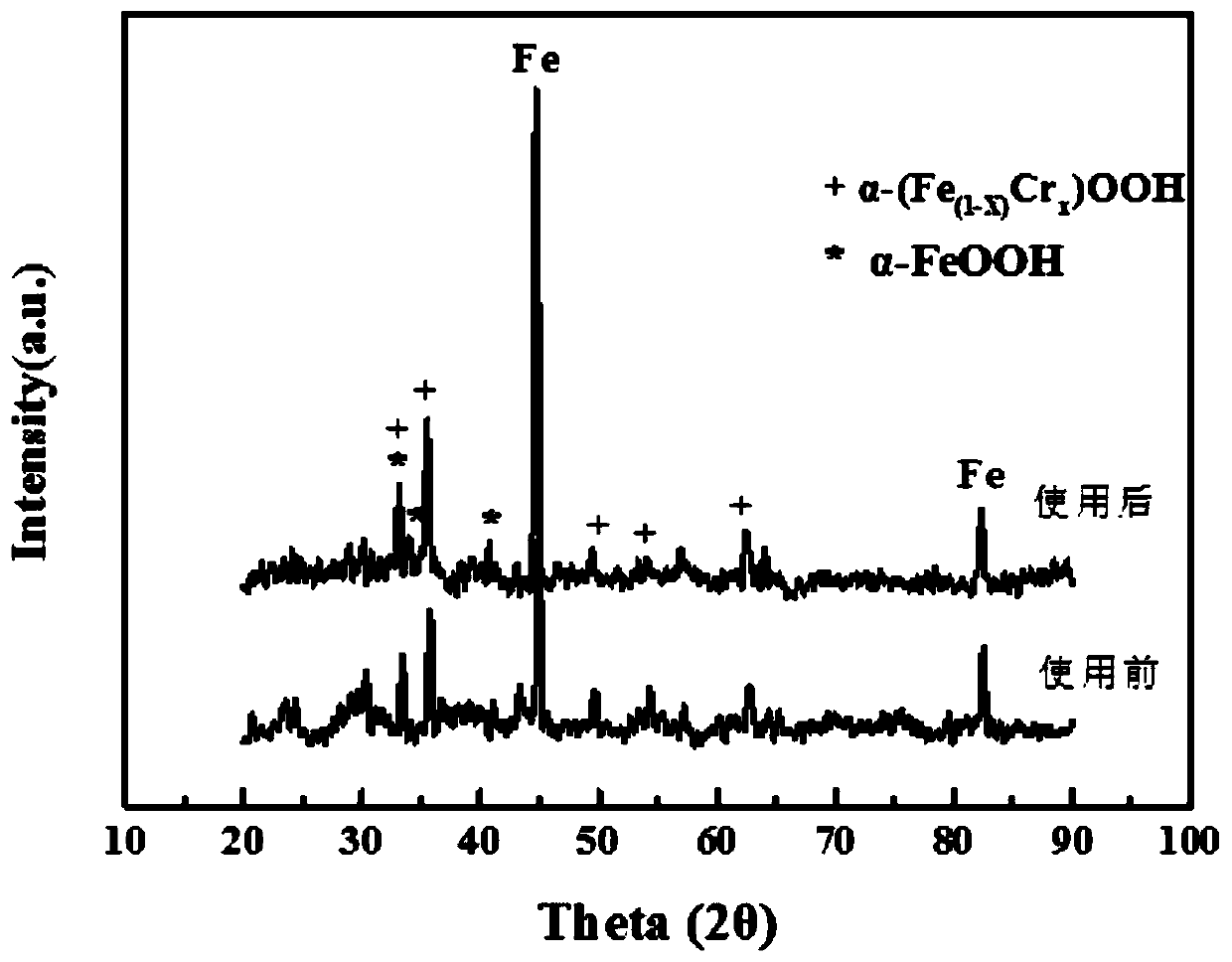

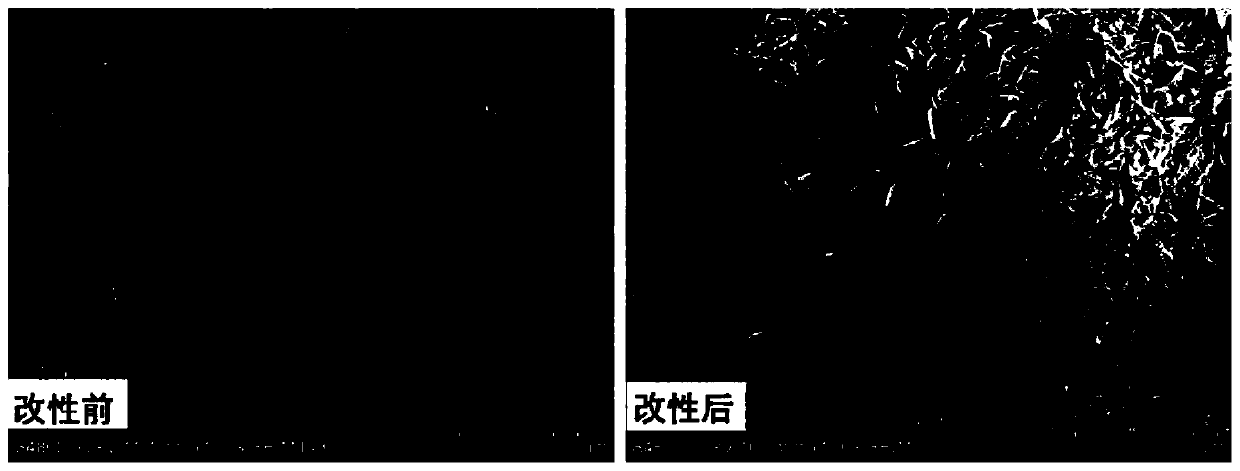

Iron filings surface modifier and method for preparing alpha-Fe<(1-x)>Cr<x>OOH active layer

ActiveCN110813305AEasy to preparePromote formationCatalyst protectionWater contaminantsPtru catalystSodium phosphates

The invention relates to an iron filings surface modifier and a method for preparing an alpha-Fe<(1-x)>Cr<x>OOH active layer. The surface modifier comprises the following components in percentage by mass: 30-50% of polyethylene butyral resin, 3-10% of chromium sulfate, 3-10% of ferric oxide, 0.2-2% of sodium phosphate, 0.5-5% of sodium dodecylsulfonate, and the balance water. The modification is performed by the following steps: (1) performing degreasing cleaning on waste iron filings; (2) performing surface modification in the iron filings surface modifier; and (3) cleanly rinsing the surfacewith water after the surface modification is completed, and then performing natural air-drying. Compared with the prior art, the method uses iron filings as a raw material, and the surface of the iron filings is modified by an appropriate chemical method, so that surface components of the iron filings have catalytic ozone activity, and a dense structure to protect the iron filings matrix, the total iron content in outlet water is reduced, the catalyst's dissolution loss is inhibited, and thereby the method is a feasible way to reduce the catalyst cost of an advanced oxidation method and improve the outlet water quality, and has important practical value.

Owner:TONGJI UNIV

Method for producing basic chromic sulfate by utilizing tannery waste chromium mud

ActiveCN106315675AAvoid pollutionSolve pollutionChromium trioxideChromium sulfatesFiltrationWater circulation

The invention discloses a method for producing basic chromic sulfate by utilizing tannery waste chromium mud. The method comprises the following steps: airing and drying waste chromium mud, uniformly mixing the dried chromium mud and sodium hydroxide in a rotary kiln, and adding an oxidant for roasting; performing water circulation suction filtration washing on the roasted materials, and removing impurities, thereby obtaining a sodium chromate solution; adding sulfuric acid into the obtained solution for reacting, thereby obtaining sodium dichromate; continuously adding sulfuric acid for reacting, slowly adding cane sugar, and reacting, thereby obtaining liquid basic chromic sulfate; and finally, drying the basic chromic sulfate solution, thereby obtaining the powdered basic chromic sulfate. According to the technical scheme of the invention, the waste chromium mud is fully utilized, and changed into valuable things to be recycled, and the resources and the energy are saved. The problem of chromium pollution in tannery industry is solved, and the tannery cost can be reduced. The chromium pollution is solved, and meanwhile, the economic benefits and social benefits of enterprises are obviously improved.

Owner:菏泽泓泽贸易有限公司

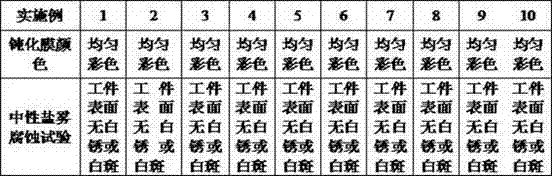

Colorful trivalent chromium passivation liquid, preparation method and use method thereof

ActiveCN104498923AQuality improvementStable passivation working fluidMetallic material coating processesSodium chlorateSalt spray test

The invention provides a colorful trivalent chromium passivation liquid. A plurality of raw materials are dissolved in deionized water to form the passivation liquid. The passivation liquid comprises the following components by a ratio: 5-9 g / L chromium sulfate hexahydrate, 2-4 g / L cobalt sulfate heptahydrate, 4-8 g / L sodium chlorate, 2-3 g / L ammonium fluoride, 1-2 g / L of nitric acid, 2-3 g / L citric acid, and the balance of water. The resulting passive film has good corrosion resistance, the time can be up to 120 hours or more in a salt spray test, the surface has no any white rust or white spots, the porosity is low, and a blocking agent does not need to be used for treating.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Phosphorus-free abrasion-resisting steel passivation treatment method

InactiveCN104152889AAvoid pollutionReduce water and electricity consumptionMetallic material coating processesPotassium sulfatePassivation

The invention discloses a process for improving the abrasion resistance of steel by using a soaking method. The process comprises the following steps: (1) washing and removing oil, namely, removing dirty stain and grease on the surface of steel; (2) micro-etching, namely, micro-etching the surface of steel by using a chemical method so as to increase the reaction area of a steel workpiece; and (3) passivating, namely, depositing a layer of chromium potassium sulfate and cobaltous sulfate onto the surface of steel after micro-etching, and reacting with steel to generate a steel mixture, wherein the steel mixture has a relatively high binding capability with steel and is good in abrasion resistance. The treated steel is good in abrasion resistance, and compared with a conventional phosphorization process, according to the process disclosed by the invention, the water and power consumption is reduced, the labor is reduced, the production efficiency is improved, and pollution caused by phosphorus wastewater is avoided.

Owner:合肥奥福表面处理科技有限公司

Bright chrome plating solution

The invention discloses a bright chrome plating solution which comprises 5-20 g / L chromic sulfate, 10-50 g / L potassium sulfate, 15-50 g / L oxalic acid, 5-30 g / L sodium hypophosphite, 0.5-2 g / L ferrous sulfate, 5-40 g / L nitrilotriacetic acid, 1-10 g / L glycine, 3-15 g / L ethanedioic acid and the balance of water. The invention has the advantages of reasonable formula, high crystallization rate, high crystallization efficiency, high coating bonding strength, high surface smoothness and high stability.

Owner:李振萍

Nickel-chromium-copper-cobalt alloy electroplating solution and preparation method thereof

The invention discloses a nickel-chromium-copper-cobalt alloy electroplating solution which comprises 10-20 g / L nickel sulfate, 23-38 g / L nickel nitrate, 12-18 g / L chromic sulfate dodecahydrate, 8-12 g / L copper sulfate hexahydrate, 1-3 g / L cobalt acetate, 5-9 mL / L brightening agent, 0.2-0.5 g / L ascorbic acid and 6-10 g / L citric acid. The pH value is 5-6. The electroplating solution has favorable stability; by adding the copper, chromium and cobalt, the corrosion resistance of the electroplated coating is enhanced, and the coating can not easily shed; and the addition of the cobalt salt can enhance the gloss of the nickel coating.

Owner:JURONG BOYUAN ELECTRONICS

Method for performing pulse chromium plating based on trivalent chromium in sulfate system

The invention discloses a high-efficiency environment-friendly pulse plating metallurgy method for performing thick chromium plating based on trivalent chromium in a sulfate system. The method is characterized by comprising the following steps: dissolving rare earth oxides in an acid, so as to obtain a rare-earth salt solution; dissolving chromium sulfate salt, aluminum sulfate, boric acid, a complexing agent and methanol with water, and adding the rare-earth salt solution, so as to obtain a chromium sulfate salt-aluminum sulfate-boric acid-complexing agent-methanol-rare-earth salt plating solution; electroplating a to-be-plated plating piece into the electroplating solution; controlling the electroplating process conditions as follows: the distance between a pulse electroplating power supply and a plating tank is 2-3m, a wire refers to a multi-stranded core wire, and an anode refers to a Cu-matrix coating electrode plate; the current density of a connecting wire is 28-90A / dm<2> and needs to be far higher than the average current, the pH value of the electroplating solution is 2-4, the temperature refers to 25-60 DEG C, the stirring speed is 100-600rpm, the plating time refers to 30-90 minutes, the pulse frequency refers to 100-500Hz, and the duty ratio is 5-100 percent; and washing the plating piece subjected to complete electroplating, and airing. The method disclosed by the invention has the advantages of coating flatness and compactness, good adhesiveness, high current efficiency, high environmental friendliness and the like.

Owner:TIANJIN BINYONGSHENG ELECTRICAL LEAD TECH

Process for preparing grist powder contained chrome-enriched yeast

The preparation method of chromium-enriched yeast containing malt powder for improving sugar tolerence includes the following steps: 1. preparing chromium-enriched malt powder, culturing malt in chromium chloride or chromium sulfate solution, drying by airing and pulverizing for stand-by; 2. preparing chromium-enriched yeast, using malt wort or basic culture medium, adding chromium chloride or chromium sulfate, inoculating yeast, culturing and extracting for stand-by; 3. combining the above-mentioned chromium-enriched malt and chromium-enriched yeast paste so as to obtain the invented product with the health-care functions of reducing sugar and reducing blood fat, etc.

Owner:郑彦巍

Bamboo product color processing agent and processing method thereof

InactiveCN107662262ASolve monotonous colorsColorfulWood treatment detailsReed/straw treatmentSucroseAdditive ingredient

The invention discloses a bamboo product color processing agent and a processing method thereof. The processing agent is prepared from an ingredient A and an ingredient B, wherein the ingredient A isprepared from sodium pyrophosphate, sodium thiosulfate pentahydrate, potassium ferric sulfate dodecahydrate, white alum, ammonium chromic sulfate, sodium imide and olive oil; the ingredient B is prepared from one or several kinds of materials from an alginate water solution, a dextrin water solution and a sucrose water solution. The processing agent has color adjusting and dying substances; when being used, the processing agent can synchronously complete the color adjusting and the dyeing; more colors can be obtained; the problems of single color of bamboo products in the prior art are solved;the market requirements can be met; the processing cost can be reduced; higher economic benefits are obtained. The processing method combines the color adjusting and the dyeing into one step. The bamboo product color processing method has the advantages that the process is simple; the cost is low; the operation is simple and convenient, and the like.

Owner:重庆瑞海竹艺有限公司

Rare earth neodymium containing trivalent chromium blue and white passivation liquid and preparation method thereof

InactiveCN103757625AImprove air tightnessAccelerated corrosionMetallic material coating processesSodium phosphatesSodium nitrate

The invention discloses a rare earth neodymium containing trivalent chromium blue and white passivation liquid and a preparation method thereof. Every liter of rare earth neodymium containing trivalent chromium blue and white passivation liquid comprises 15-20g of chromium sulfate, 2.0-3.0g of sodium nitrate, 6.0-8.0g of cobaltous sulfate heptahydrate, 2.5-4.0g of sodium hypophosphite, 0.5-0.8g of citric acid, 0.15-0.25g of ammonium bifluoride, 0.14-0.42g of neodymium nitrate and the balance of deionized water. The preparation method comprises steps of under a continuously stirring state, firstly dissolving chromium sulfate into part of deionized water, then sequentially adding citric acid, sodium hypophosphite and sodium nitrate and dissolving, adding cobaltous sulfate heptahydrate and fully dissolving, finally adding ammonium bifluoride and neodymium nitrate, adding the balance of deionized water, standing for 24 hours so as to obtain the rare earth neodymium containing the trivalent chromium blue and white passivation liquid. After a zinc plating piece is passivated by the passivation liquid, a bright, uniform and compact blue and white passivation membrane with good corrosion resistance can be formed.

Owner:SHANGHAI INST OF TECH

Blue passivator for steel parts and preparation method thereof

InactiveCN112725785AImprove corrosion resistanceClosed poresMetallic material coating processesSodium nitrateMaterials science

The invention discloses a blue passivator for steel parts and a preparation method thereof. The blue passivator comprises the following raw materials in parts by weight: 150 to 220 parts of chromium sulfate, 80 to 120 parts of nano silica sol, 20 to 30 parts of malonic acid, 70 to 80 parts of sodium hydroxide, 100 to 120 parts of cobalt sulfate, 40 to 50 parts of citric acid, 10 to 20 parts of sodium nitrate, 20 to 30 parts of nitric acid, 30 to 40 parts of sulfuric acid, 10 to 20 parts of sodium fluoride and a proper amount of deionized water. According to the blue passivator for the steel parts provided by the invention, after the nanoscale silica sol is added, micropores of a passivating film layer can be filled with the nanoscale silica sol, so that a prepared film layer is thick, pores of the passivating film are sealed, and the corrosion resistance of the passivating film is greatly improved.

Owner:安徽鼎旺环保材料科技有限公司

Preparation method of sealed passivation two-in-one treatment agent

InactiveCN103668159AUniform appearance and colorImprove performanceMetallic material coating processesSalt spray testSilanes

The invention discloses a preparation method of a sealed passivation two-in-one treatment agent. The formula of the treatment agent comprises chromium sulfate, sodium silicate, cobalt nitrate, sodium nitrate, malonic acid, nickel sulfate, a KH550 silane coupling agent and deionized water. The preparation method has the advantages that the passivation film obtained by the formula is uniform is appearance color and free of colors, and achieves 8-9 level by a neutral salt spray test 96H, and the passivation solution is stable in performance, low in cost price and good in property.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

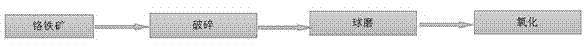

Comprehensive utilization method and device for acid dissolution extraction of valuable element chromium silicon iron magnesium aluminum nickel from chromite

ActiveCN104762637AEmission reductionHigh energy consumptionSilicaChromium compoundsIron sulfateHydration reaction

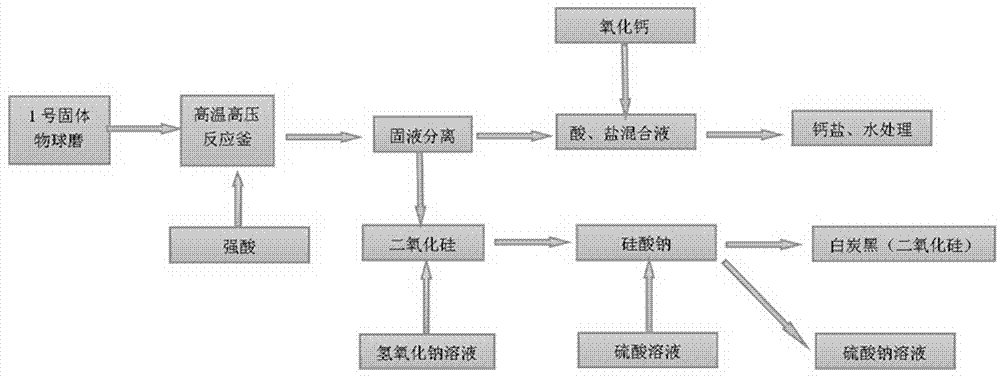

The invention discloses a comprehensive utilization method for acid dissolution extraction of valuable element chromium silicon iron magnesium aluminum nickel from chromite, first the chromite is crushed and ground into micro powder, the micro powder is blew with air for oxidation at the bottom of an electrode oxidation pool for oxidation of ferrous ion into iron ion; chrome spinel lattice is destructed, the oxidized chromite micro powder is reacted with sulfuric acid in a high temperature high pressure reaction kettle to produce a mixed liquid containing chromium sulfate, magnesium sulfate, aluminum sulfate, ferric sulfate and nickel sulfate and a deposit mainly comprising silicon dioxide and insoluble minerals under the oxidation-catalyst effect; after solid-liquid separation, a solid is again purified to obtain white carbon black; and chromium sulfate hexahydrate, high purity magnesium hydroxide, high purity aluminum hydroxide, high purity ferrous oxalate and nickel sulfide can be obtained by liquid fractional extraction of liquid phase. All the valuable elements, acids, alkalis, water and other raw materials can be extracted for cyclic utilization after front oxidation and high temperature and high pressure acid dissolution of the chromite ore powder.

Owner:于志远

Process for producing chromic anhydride and ferrous oxalate by taking ferrochrome as raw material

ActiveCN112429776ANo emissionsEradicate pollutionOrganic compound preparationChromium trioxideOXALIC ACID DIHYDRATEChromium(III) hydroxide

Owner:乔柏人

Preparation method of high-purity chromic oxide

PendingCN110655109ASolve the problem of difficult suction and filtrationChromium oxides/hydratesPolyacrylamideCarbonate

The invention discloses a preparation method of high-purity chromic oxide, and relates to the technical field of high-purity oxide preparation. The preparation method comprises the following steps: reacting high-purity chromium particles with sulfuric acid under the action of hydrogen peroxide, carrying out suction filtration on the obtained reaction solution after the reaction is finished to obtain a chromium sulfate solution, stirring and heating the chromium sulfate solution, dropwise adding an ammonium bicarbonate solution, adding a cationic polyacrylamide flocculant when the pH value reaches 3.5-4.5, dropwise adding the ammonium bicarbonate solution until the pH value of the reaction solution reaches 7-8, aging the obtained reaction solution, carrying out suction filtration on the reaction solution after aging, drying the obtained green precipitate, grinding and screening the dried precipitate, and calcining the ground and screened dried precipitate to obtain the high-purity chromic oxide. The high-purity oxide is directly generated from the metal elementary substance through a chemical process, so the problems of waste of raw materials and reagents and difficulty in subsequent suction filtration of chromium carbonate colloid, caused by direct reaction of the metal elementary substance and the sulfuric acid, are solved.

Owner:宁夏中科欧德科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com