Method for treating chromite by sulfuric acid leaching

A technology of chromite ore and chromium sulfate, which is applied in the field of chromite processing and sulfuric acid leaching treatment of chromite, can solve the problems of large consumption of oxidant and sulfuric acid, low chromium recovery rate, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

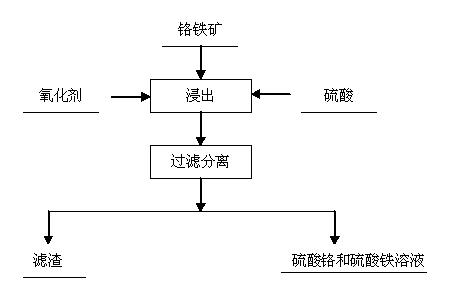

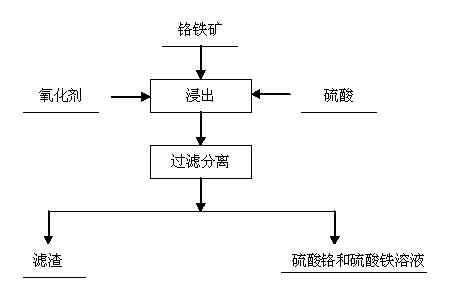

[0033] The process of sulfuric acid leaching method for treating chromite is as follows.

[0034] Grind chromite to size 100 The ore powder, add the sulfuric acid that mass concentration is 68% in the ore powder, and the sulfuric acid addition amount is 1.0 times of the ore powder quality, stirs, and stirring speed is 250 rev / mins, adds oxidant, and oxidant is chromic anhydride, and its addition is 3.2% of the mass of mineral powder, heating, the heating temperature is 155 ° C, the control reaction pressure is 0.7 MPa, and the reaction time is 60 min.

[0035] The main chemical reactions in the above process are as follows:

[0036] (1)

[0037] (2)

[0038] (3)

[0039] (4)

[0040] Chromium anhydride dissolves Fe(CrO 2 ) 2 The main equation of is as follows:

[0041] (5)

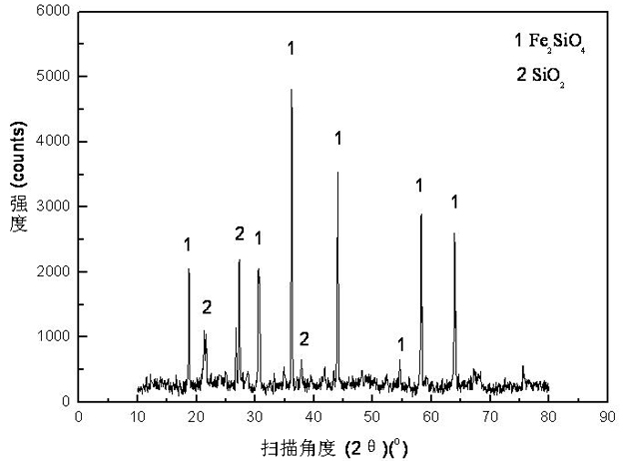

[0042] After the reaction is completed, filter. The filter equipment adopts a plate and frame filter press with a pressure of 1.6 MPa to separate s...

Embodiment 2

[0044] The process of sulfuric acid leaching method for treating chromite is as follows.

[0045] Grind the chromite to a grit size of 180 ore powder, add sulfuric acid with a mass concentration of 85% to the ore powder, the amount of sulfuric acid added is 0.5 times the mass of the ore powder, stir, the stirring speed is 500 rpm, add an oxidant, the oxidant is potassium chlorate, and its addition is ore 7% of powder mass, heating, heating temperature is 190°C, controlled reaction pressure is 1.2MPa, and reaction time is 30min.

[0046] The main chemical reactions in the above process are as follows:

[0047] (1)

[0048] (2)

[0049] (3)

[0050] (4)

[0051] Potassium chlorate dissolves Fe(CrO 2 ) 2 The main equation of is as follows:

[0052] (6)

[0053] After the reaction is completed, filter. The filter equipment adopts a plate and frame filter press with a pressure of 1.6 MPa to separate solid and liquid. The f...

Embodiment 3

[0055] The process of sulfuric acid leaching method for treating chromite is as follows.

[0056] Grind chromite to size 38 mineral powder, add sulfuric acid with a mass concentration of 50% to the mineral powder, the amount of sulfuric acid added is 1.5 times the mass of the mineral powder, stir, the stirring speed is 45 rpm, add an oxidant, the oxidant is ammonium persulfate, the amount of It is 0.2% of the mass of mineral powder, heated, the heating temperature is 120°C, the controlled reaction pressure is 0.2MPa, and the reaction time is 90min.

[0057] The main chemical reactions in the above process are as follows:

[0058] (1)

[0059] (2)

[0060] (3)

[0061] (4)

[0062] Ammonium persulfate dissolves Fe(CrO 2 ) 2 The main equation of is as follows:

[0063] (7)

[0064] After the reaction is completed, filter. The filter equipment adopts a plate and frame filter press with a pressure of 1.6MPa to separate solids and liquids....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com