Waterproofing agent used on briquette surface and preparation method thereof, and waterproof briquette and manufacturing method thereof

A water-repellent and water-proof technology, which is applied in the field of briquette waterproofing process and waterproof briquette and waterproof agent, can solve the problems of large amount of binder added and complex preparation process, etc., and achieve reduction of briquette ash, simple process, and convenient The effect of transport and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A waterproofing agent for the surface of briquette, the components and the content of each component are: a variety of vitriol in equal mass ratio, including: potassium dichromate, potassium aluminum sulfate, copper sulfate, potassium chromium sulfate, 1 part each, 300 parts of water glass, 50 parts of water.

[0027] The preparation method of the waterproofing agent: heat 50 parts of water to 95-100℃, then add various kinds of alum simultaneously, stir to dissolve it completely, let it stand and cool to 40-55℃; finally add 300 parts of water glass, stir The water repellent is prepared until the color of the mixed solution is consistent, and the stirring time is 20-40 min.

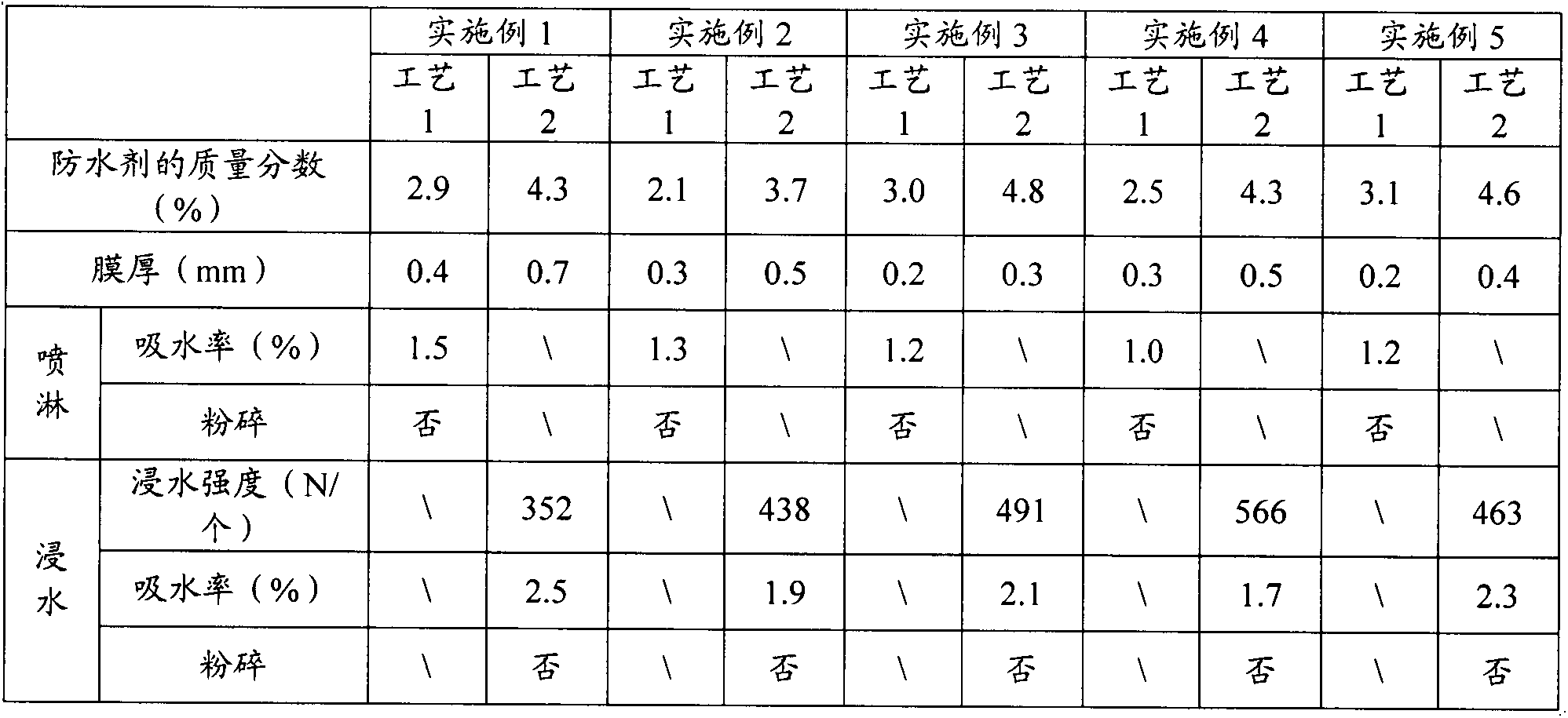

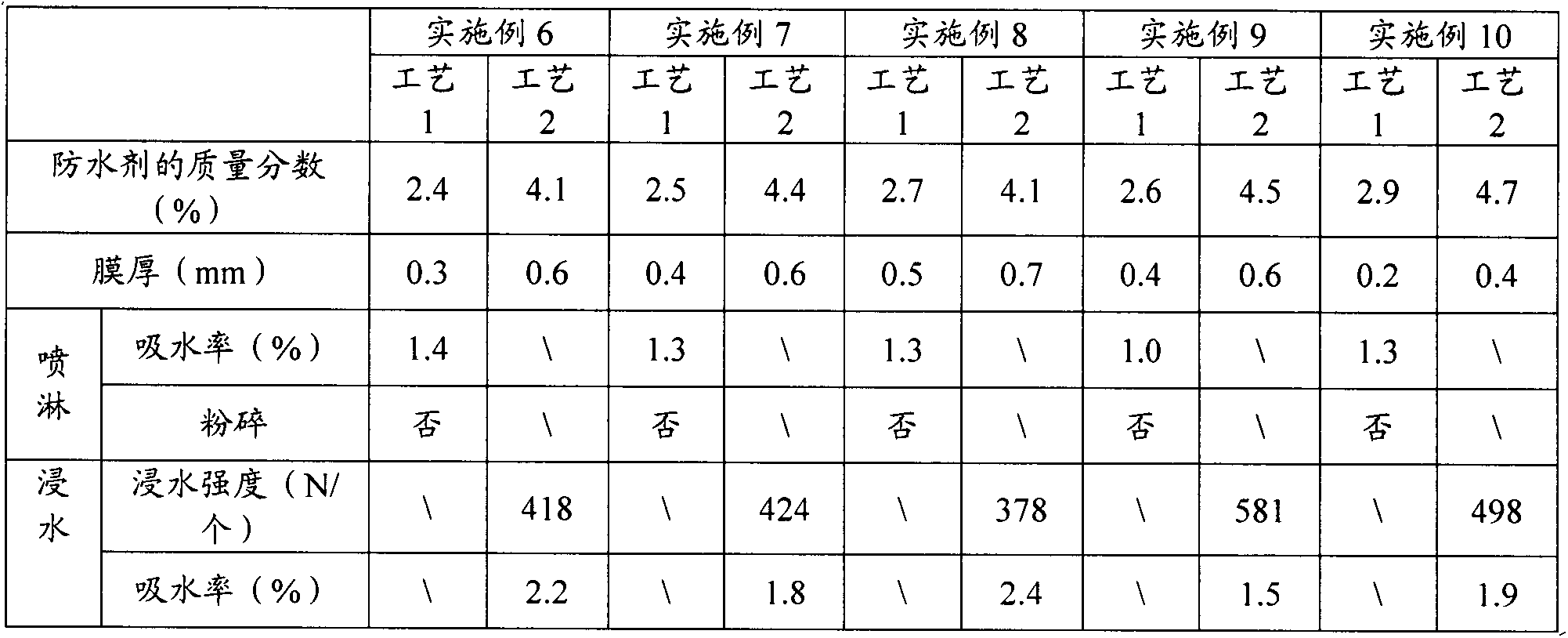

[0028] The performance test of the briquette prepared by using the waterproofing agent in Example 1 is as follows: the briquette produced by using the waterproofing agent of this embodiment according to Process 1, the mass fraction of the absorbed waterproofing agent is 2.9%, and the thickness of th...

Embodiment 2

[0030] A waterproofing agent for the surface of briquette, the components and the content of each component are: a variety of vitriol in equal mass ratio, including: potassium dichromate, potassium aluminum sulfate, copper sulfate, potassium chromium sulfate, 2 parts each, 400 parts of water glass, 60 parts of water.

[0031] Preparation method of waterproofing agent: heat 60 parts of water to 95-100℃, then add various kinds of alum at the same time, stir to dissolve it completely, let it stand for natural cooling to 40-55℃; finally add 400 parts of water glass, stir The water repellent is prepared until the color of the mixed solution is consistent, and the stirring time is 20-40 min.

[0032] The performance test data of the briquette prepared by using the water repellent in Example 2 are shown in Table 1.

Embodiment 3

[0034] A waterproofing agent for the surface of briquette, the components and the content of each component are: a variety of vitriol in equal mass ratio, including: potassium dichromate, potassium aluminum sulfate, copper sulfate, potassium chromium sulfate, 3 parts each, 500 parts of water glass, 70 parts of water.

[0035] The preparation method of the waterproofing agent: heat 70 parts of water to 95-100℃, then add various kinds of alum simultaneously, stir to dissolve it completely, let it stand for natural cooling to 40-55℃; finally add 500 parts of water glass, stir The water repellent is prepared until the color of the mixed solution is consistent, and the stirring time is 20-40 min.

[0036] Table 1 shows the performance test data of the briquette prepared by using the water repellent in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com