Method and device for producing chromium tanning agent by using oxidized waste liquid obtained from S wax production

A chrome tanning agent and waste liquor technology, which is applied in the fields of montan wax deep processing, coal chemical industry and leather chemical industry, can solve the problems of high recovery cost and waste of oxidation waste liquor, and achieve sustainable development, low consumption and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

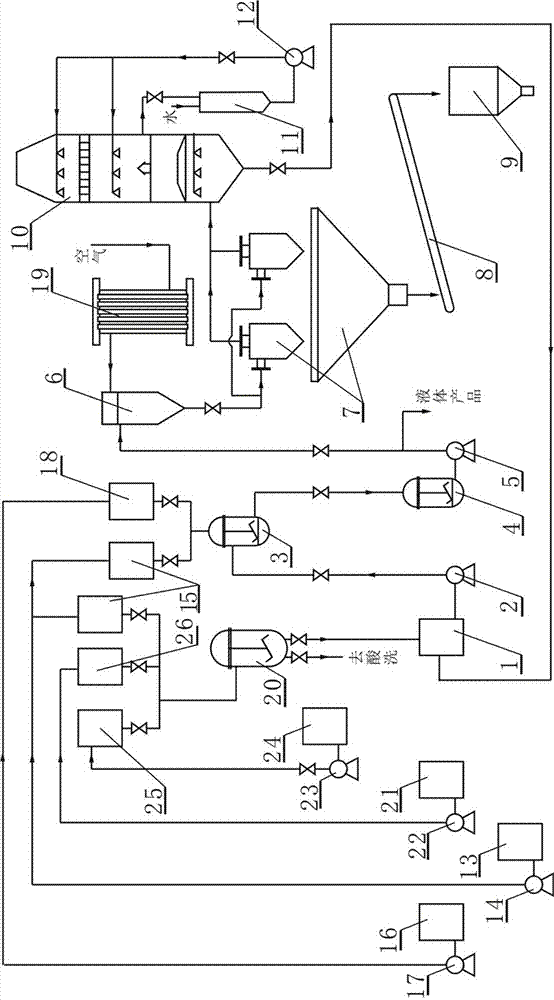

[0029] The mass percent of chromic anhydride solution, sodium dichromate solution, oxidizing acid solution, and glucose solution described in step A is 50%; add montan wax by 30% of oxidizing acid solution weight in B step, be heated to 90 ℃, with 60 ~ 100r / min was continuously stirred for 60min; the amount of sodium dichromate solution added in step C was 2 times of the weight of montan wax, and left to settle for 60min after stopping the reaction; step D was continuously stirred at 60~100r / min for 90min, Stand in the middle tank 4 for 390min.

[0030] The tail gas produced by the redox kettle 20, the modulation reaction kettle 3, the drying tower 6, and the separator 7 enters the tail gas absorption tower 10, and the water sent into the tail gas by the circulating water storage tank 11 absorbs the oxidized waste liquid therein. The residual gas is discharged, and the residual liquid rich in oxidized waste liquid is introduced into the oxidized waste liquid storage tank 1 . ...

Embodiment 1

[0050] Select the montan wax of resin content2 Cr 2 o 7 +4H 2 SO 4 → Na 2 SO 4 + Cr 2 (SO 4 ) 3 +4H 2 O+3{O} Calculate the theoretical addition of sodium dichromate solution, according to the reaction formula 4Na 2 Cr 2 o 7 +12H 2 SO 4 +C 6 h 12 o 6 →8Cr(OH)SO 4 +4Na 2 SO 4 +6CO 2 ↑+14H 2 O Calculate the theoretical addition amount of glucose solution; take sodium dichromate solution according to the theoretical addition amount, get glucose solution according to 110% of the theoretical addition amount, and then slowly add in the modulation reaction kettle 3; start stirring, at 105 ~ 110 ° C, Continue to react at 60r / min for 60min, wait until the oxidizing solution turns dark green until the pH value is 6, then introduce the chrome tanning solution into the middle tank 4 of the chrome tanning solution, let stand and age for 300min until the pH value is 8; the chrome tanning solution is sent to Enter the drying tower 6 for drying and dehydration at 110~1...

Embodiment 2

[0052] Select the montan wax of resin content2 Cr 2 o 7 +4H 2 SO 4 → Na 2 SO 4 + Cr 2 (SO 4 ) 3 +4H 2 O+3{O} Calculate the theoretical addition of sodium dichromate solution, according to the reaction formula 4Na 2 Cr 2 o 7 +12H 2 SO 4 +C 6 h 12 o 6 →8Cr(OH)SO 4 +4Na 2 SO 4 +6CO 2 ↑+14H 2 O Calculate the theoretical addition amount of glucose solution; take sodium dichromate solution according to the theoretical addition amount, get glucose solution according to 110% of the theoretical addition amount, and then slowly add in the modulation reaction kettle 3; start stirring, at 105 ~ 110 ° C, Continue to react at 70r / min for 120min, wait for the oxidizing solution to turn dark green until the pH value is 7, introduce the chrome tanning solution into the middle tank 4 of the chrome tanning solution, let stand and age for 480min until the pH value is 9; send the chrome tanning solution to Enter the drying tower 6 for drying and dehydration at 110~120°C un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com