Environment-friendly anti-corrosion large grounding grid with adjustable grounding impedance and construction method

A technology of grounding impedance and grounding grid, applied in the direction of connection, connection contact material, electrical components, etc., can solve the problems of difficult grounding impedance, inability to operate safely, erosion, etc., to prolong safe operation life, reduce soil resistivity, and resist Corrosion life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

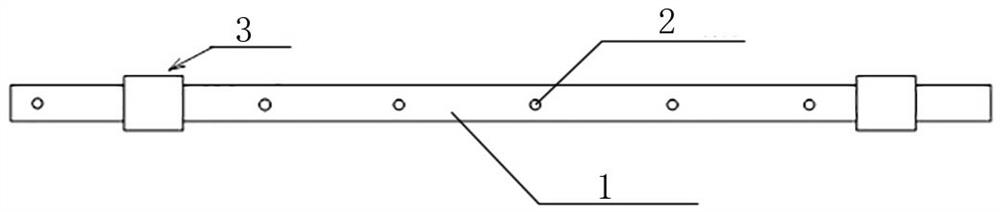

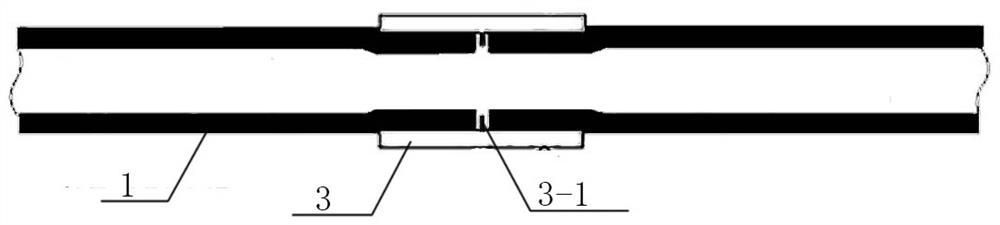

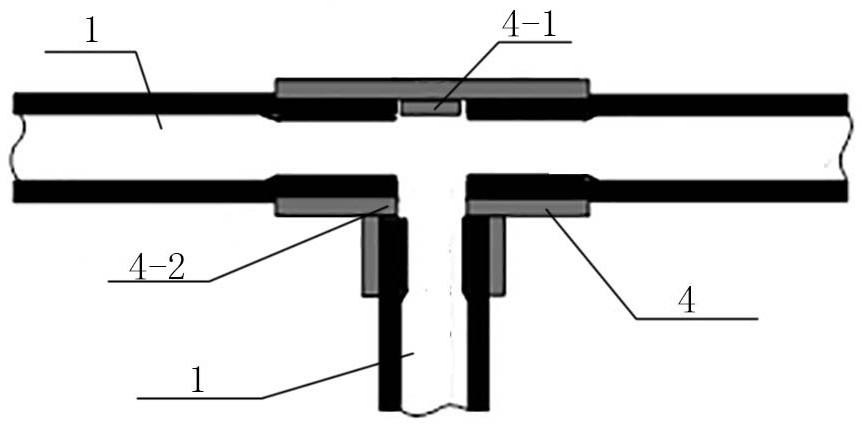

[0045] as attached Figures 1 to 10 Shown is an embodiment of an environment-friendly, anti-corrosion, and resistance-reducing large-scale grounding grid in the present invention. A release hole 2 capable of releasing a non-toxic and harmless liquid drag-reducing material.

[0046] The large-scale grounding grid includes a circle of closed-loop tubular outer edge equalizing busbars buried in the outermost edge of the power plant, substation, petroleum, chemical plant, and dangerous goods storage area, and a grounding grid buried in the equipment area The main body, the main body of the grounding grid includes the tubular equalizing busbars buried between each row of production equipment in the equipment area, as well as the protective grounding wires of high-voltage equipment and production equipment. connected;

[0047] Above the ground of the grounding network in each equipment area, install a steel pipe vertically connected with the equalizing busbar as the injection hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com