Preparation method and application of energy-saving environment-friendly building material

A technology for building materials, energy saving and environmental protection, applied in the field of building materials, can solve the problem of not effectively solving energy saving and other problems, and achieve the effects of good thermal insulation effect, high self-strength and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

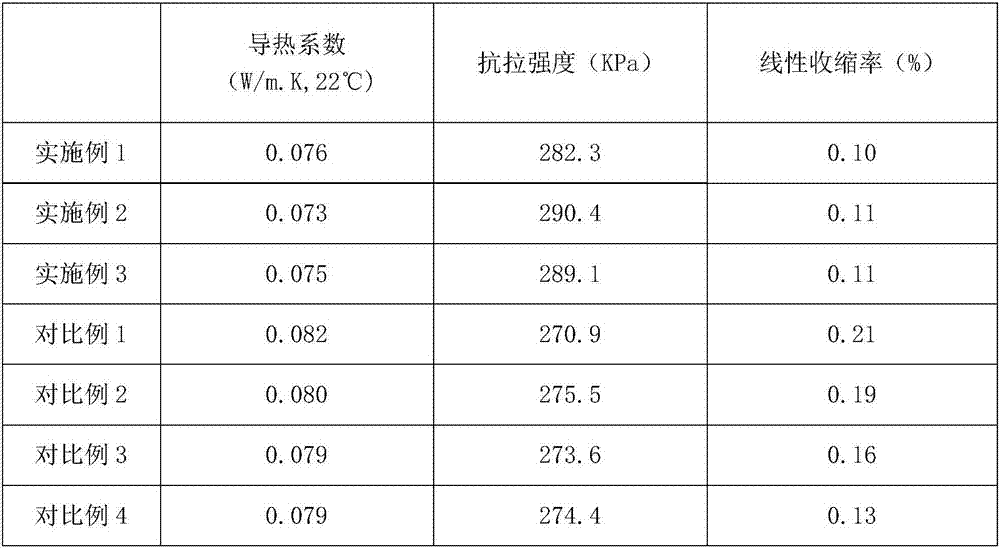

Examples

Embodiment 1

[0022] (1) After mixing 60 parts of fly ash, 40 parts of feldspar powder and 25 parts of silicon dioxide, they are fully ground in a grinder, the speed of the grinder is 1600r / min, the grinding time is 50min, and passed through a 200-mesh sieve to obtain grinding mixture;

[0023] (2) Mix 15 parts of methoxypolyethylene glycol, 10 parts of ethyl stearate, and 6 parts of polyamide, add 100 parts of deionized water, and perform ultrasonic treatment. The conditions of ultrasonic treatment are: temperature 70 ° C, ultrasonic treatment The power is 1000W, and the ultrasonic time is 40min to obtain the ultrasonic treatment mixture;

[0024] (3) Put the grinding mixture and ultrasonic treatment mixture into the reaction kettle, heat the temperature of the reaction kettle to 100°C, then add 4 parts of phenolic foam and 3 parts of citrate into the reaction kettle, mix well and react for 20 minutes to obtain the preliminary reaction product ;

[0025] (4) Pour the preliminary reaction...

Embodiment 2

[0029] (1) After mixing 65 parts of fly ash, 45 parts of feldspar powder and 30 parts of silicon dioxide, they are fully ground in a grinder, the speed of the grinder is 1700r / min, the grinding time is 60min, and passed through a 200-mesh sieve to obtain grinding mixture;

[0030] (2) Mix 18 parts of methoxypolyethylene glycol, 11 parts of ethyl stearate, and 7 parts of polyamide, add 100 parts of deionized water, and perform ultrasonic treatment. The conditions of ultrasonic treatment are: temperature 75 ° C, ultrasonic treatment The power is 1100W, and the ultrasonic time is 45min to obtain the ultrasonic treatment mixture;

[0031] (3) Put the grinding mixture and ultrasonic treatment mixture into the reaction kettle, heat the temperature of the reaction kettle to 105°C, then add 5 parts of phenolic foam and 4 parts of malate into the reaction kettle, mix well and react for 25 minutes to obtain the preliminary reaction product ;

[0032] (4) Pour the preliminary reaction ...

Embodiment 3

[0036] (1) After mixing 70 parts of fly ash, 50 parts of feldspar powder and 35 parts of silicon dioxide, they are fully ground in a grinder, the speed of the grinder is 1800r / min, the grinding time is 70min, and passed through a 200-mesh sieve to obtain grinding mixture;

[0037] (2) Mix 20 parts of methoxypolyethylene glycol, 12 parts of ethyl stearate, and 8 parts of polyamide, add 100 parts of deionized water, and perform ultrasonic treatment. The conditions of ultrasonic treatment are: temperature 80 ° C, ultrasonic treatment The power is 1200W, and the ultrasonic time is 50min to obtain the ultrasonic treatment mixture;

[0038] (3) Put the grinding mixture and ultrasonic treatment mixture into the reaction kettle, heat the temperature of the reaction kettle to 110°C, then add 6 parts of phenolic foam and 5 parts of pyrophosphate into the reaction kettle, mix well and react for 30 minutes to obtain the preliminary reaction product ;

[0039] (4) Pour the preliminary re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com