Method for preparing heat-insulation mortar through organic silicone waste

A technology for thermal insulation mortar and waste, which is applied in the field of preparing thermal insulation mortar by using silicone waste, can solve problems such as effective resource waste, potential safety hazards, and cases of comprehensive utilization of no silicone slag slurry, and achieve the effect of reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

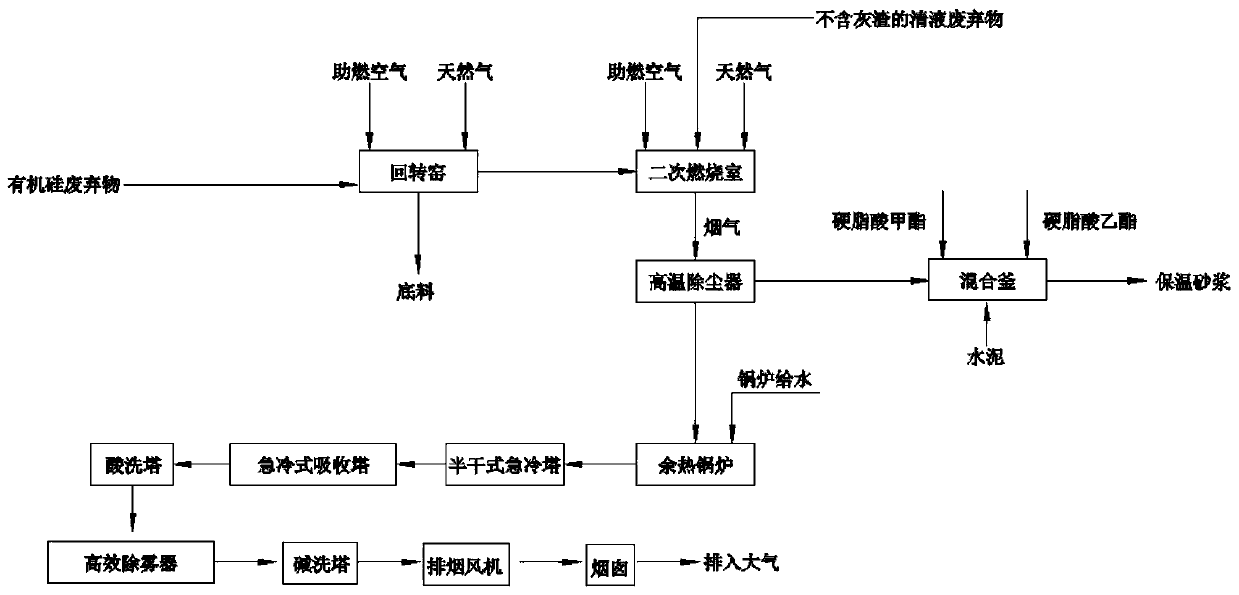

[0021] Such as figure 1 Shown, the present invention utilizes organosilicon waste to prepare the method implementation steps of insulation mortar as follows:

[0022] 1. Primary combustion: raise the temperature of the rotary kiln, and when the temperature of the rotary kiln rises to 400°C, feed combustion-supporting air, natural gas and synthetic slurry from the kiln inlet end of the rotary kiln, and raise the temperature of the flue gas from the rotary kiln to 800°C Carry out thermal decomposition, the roasting time is 3-5 seconds, the ash is discharged from the outlet end of the rotary kiln, and the roasting flue gas is discharged from the upper gas outlet of the outlet end of the rotary kiln;

[0023] 2. Secondary combustion: The roasting flue gas discharged from the rotary kiln enters the secondary combustion chamber, the furnace temperature is controlled at 700°C, and natural gas and combustion-supporting air are added. At the same time, the waste liquid in the productio...

Embodiment 2

[0029] Such as figure 1 Shown, the present invention utilizes organosilicon waste to prepare the method implementation steps of insulation mortar as follows:

[0030] 1. Primary combustion: raise the temperature of the rotary kiln, and when the temperature of the rotary kiln rises to 700°C, feed combustion-supporting air, natural gas and synthetic slurry from the kiln inlet end of the rotary kiln, and raise the temperature of the flue gas from the rotary kiln to 900°C Carry out thermal decomposition, the roasting time is 3-5 seconds, the ash is discharged from the outlet end of the rotary kiln, and the roasting flue gas is discharged from the upper gas outlet of the outlet end of the rotary kiln;

[0031] 2. Secondary combustion: The roasting flue gas discharged from the rotary kiln enters the secondary combustion chamber, the furnace temperature is controlled at 900°C, and natural gas and combustion-supporting air are added. At the same time, the waste liquid in the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com