Highly-flame-retardant polypropylene composite material for new energy automobiles, and preparation method thereof

A technology for new energy vehicles and composite materials, applied in the field of preparation of polypropylene composite materials, can solve problems such as insufficient aging resistance of polypropylene composite materials, and achieve the effects of improving light stability, thermal conductivity, and light stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

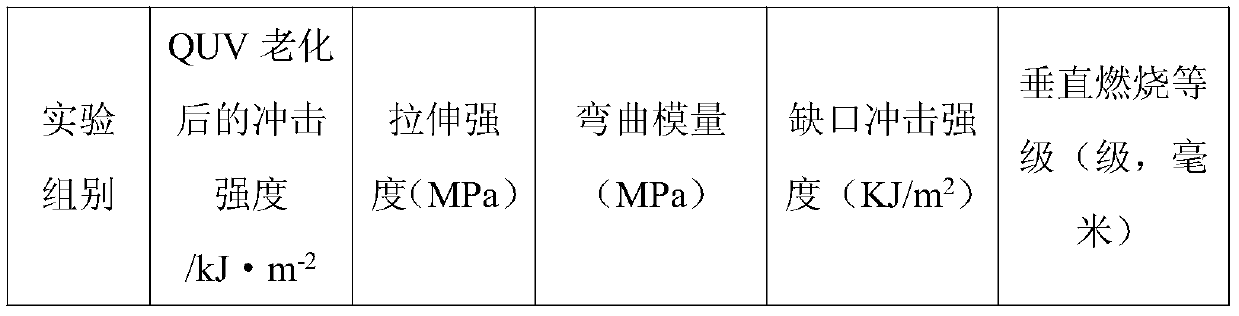

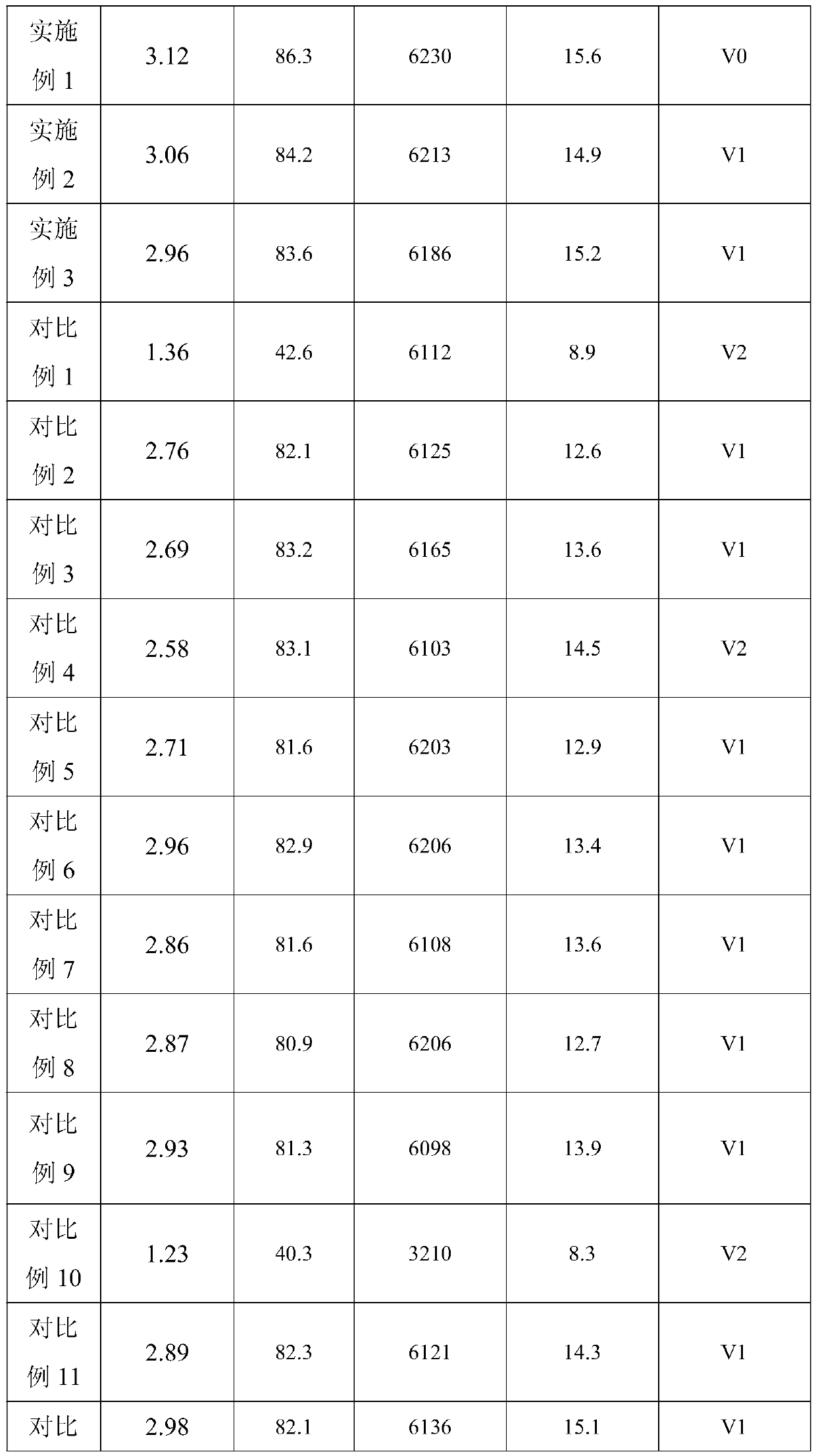

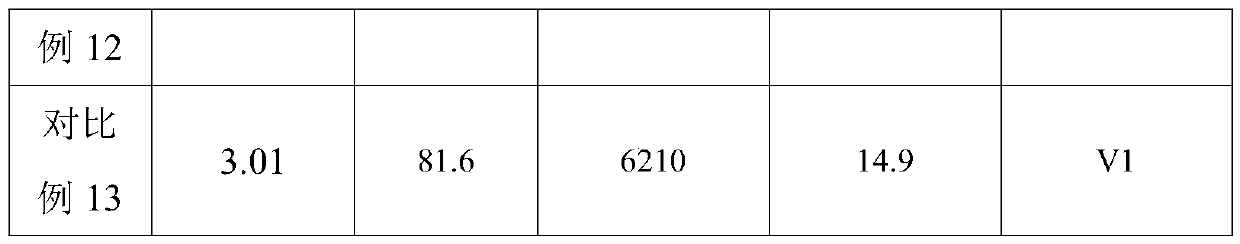

Examples

Embodiment 1

[0028] A kind of high flame-retardant polypropylene composite material for new energy vehicles, in parts by weight, comprising the following raw materials: 105 parts of polypropylene resin, 32 parts of polyacrylamide microspheres, 21 parts of ethyl stearate, 5.7 parts of paraffin, 5.6 parts of lauric acid, 5.6 parts of p-dimethyldibenzylidene sorbitol, 3.4 parts of dimethyl malonate, 2.7 parts of sodium ferric tartrate, 4.4 parts of melamine, 5.8 parts of magnesium salt whiskers, 4.6 parts of lithium china stone , 3.2 parts of calcium stearate, 14.6 parts of diethylene glycol monoacrylate, 11.5 parts of nano-aluminum powder, 4.7 parts of carbon fiber, 4.1 parts of hydroxyethyl acrylate, 2.6 parts of acrylic acid, 7.4 parts of nano-copper powder, and 2.6 parts of microcrystalline graphite , 3.4 parts of diphenylmethane diisocyanate.

[0029] The preparation method of the high flame-retardant polypropylene composite material for the new energy vehicle comprises the following ste...

Embodiment 2

[0035] A kind of high flame-retardant polypropylene composite material for new energy vehicles, in parts by weight, comprising the following raw materials: 80 parts of polypropylene resin, 40 parts of polyacrylamide microspheres, 15 parts of ethyl stearate, 8 parts of paraffin, 3 parts of lauric acid, 8 parts of p-dimethyldibenzylidene sorbitol, 2 parts of dimethyl malonate, 5 parts of sodium ferric tartrate, 3 parts of melamine, 8 parts of magnesium salt whiskers, 2 parts of lithium china stone , 5 parts of calcium stearate, 10 parts of diethylene glycol monoacrylate, 16 parts of nano-aluminum powder, 2 parts of carbon fiber, 5 parts of hydroxyethyl acrylate, 2 parts of acrylic acid, 9 parts of nano-copper powder, and 1 part of microcrystalline graphite , 5 parts of diphenylmethane diisocyanate.

[0036] The preparation method of the high flame-retardant polypropylene composite material for the new energy vehicle comprises the following steps:

[0037] S1, take each raw mate...

Embodiment 3

[0042] A kind of high flame-retardant polypropylene composite material for new energy vehicles, in parts by weight, comprising the following raw materials: 120 parts of polypropylene resin, 20 parts of polyacrylamide microspheres, 25 parts of ethyl stearate, 4 parts of paraffin, 9 parts of lauric acid, 4 parts of p-dimethyldibenzylidene sorbitol, 5 parts of dimethyl malonate, 1 part of sodium ferric tartrate, 6 parts of melamine, 4 parts of magnesium salt whiskers, 7 parts of lithium china stone , 1 part of calcium stearate, 20 parts of diethylene glycol monoacrylate, 8 parts of nano-aluminum powder, 6 parts of carbon fiber, 3 parts of hydroxyethyl acrylate, 3 parts of acrylic acid, 6 parts of nano-copper powder, and 4 parts of microcrystalline graphite , 2 parts of diphenylmethane diisocyanate.

[0043] The preparation method of the high flame-retardant polypropylene composite material for the new energy vehicle comprises the following steps:

[0044] S1, take each raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com