Method for preparing nano titanium dioxide coating on surface of base material made of transparent glass and polymer

A substrate surface, transparent glass technology, applied in the direction of coating, etc., can solve the problems that the liquid phase deposition method is not suitable for large-scale production, high raw material cost, low film strength, etc., and achieve simple post-processing, fast film formation rate, The effect of convenient equipment

Inactive Publication Date: 2014-11-26

BEIJING UNIV OF CHEM TECH

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the cost of raw materials for preparing precursors is relatively high; most of the obtained films are stacked by particles such as nanorods or nanocones, and the film strength is not high; and the liquid phase deposition method is not suitable for large-scale production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

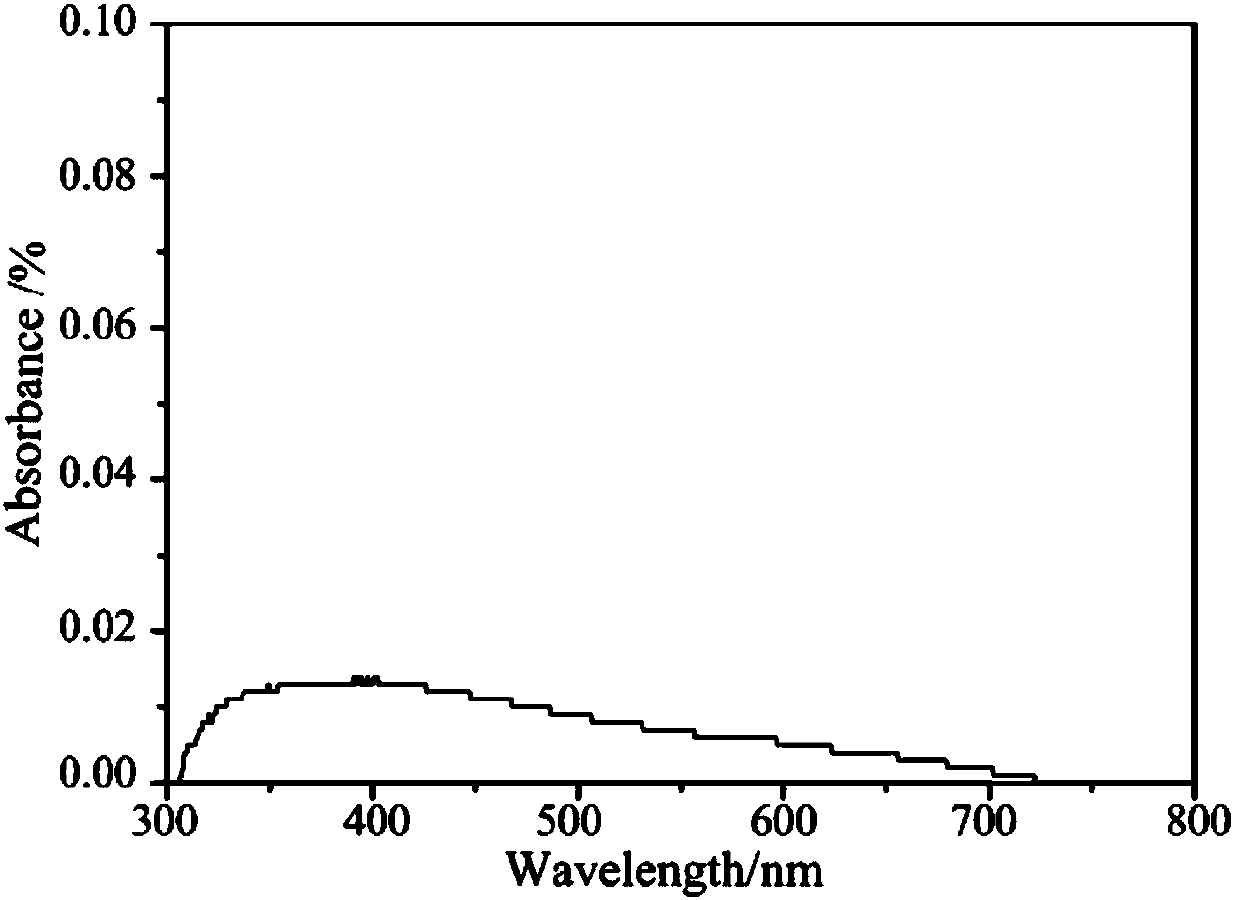

The invention discloses a method for preparing a nano titanium dioxide coating on the surface of a base material made of transparent glass and polymer. The method is characterized by comprising the following steps: taking TiCl4 as the titanium source to obtain a precursor reaction fluid, using a rotation coating instrument to paint 10 to 20 [mu]L of the precursor reaction fluid on a substrate, which has been subjected to a pretreatment, so as to obtain a uniform liquid membrane on the substrate; covering a BOPP film on the substrate, subjecting the substrate to light radiation in an ultraviolet lamp cabinet, taking out the substrate after 5 to 10 minutes, removing the BOPP film, washing the substrate, and finally drying so as to obtain the transparent TiO2 surface coating. If an ethyl stearate solution is painted on the substrate surface before the precursor reaction liquid is spin-painted on the substrate, and the post operations are not changed, a porous transparent TiO2 coating will be formed on the substrate surface. The precursor reaction fluid is prepared by the following steps: taking TiCl4 as the titanium source, and then orderly adding TiCl4 and H2O2 into an acidic water solution of HNO3 under stirring. The provided TiO2 film is composed of pure anatase crystalline phase having a high photocatalytic activity, and the surface structure of the TiO2 film is controllable. The technology is simple, the used facilities are convenient and easily available, the film-forming speed is fast, the post-treatment is convenient, and the reaction mediums are nontoxic and harmless.

Description

Technical field The invention relates to the preparation of nanometer titanium dioxide (Titanium dioxideTiO2) on the surface of transparent glass and polymer substrates by ultraviolet light (Mltraviolet UV). 2 ) Coating method. Specifically including 1) the preparation of the reaction solution, with titanium tetrachloride (TiCl 4 ) Is the titanium source, deionized water is the solvent, hydrogen peroxide is the compounding agent, HNO 3 For the hydrolysis inhibitor, a reaction solution is prepared as TiO 2 The precursor of the coating; 2) UV light irradiation, on the surface of transparent glass and polymer film substrates, through ultraviolet light to achieve low temperature, rapid and environmentally friendly preparation of TiO with controllable surface morphology and photo-generated hydrophilic properties 2 Surface coating. This TiO 2 The preparation method of the coating realizes the preparation of TiO on the surface of transparent substrates and substrates that are not resist...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C17/23C08J7/06C09D1/00

Inventor 邓建元王立伟曹西亮杨万泰

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com