Micro-arc oxidation electrolyte solution and micro-arc oxidation film preparation method for arc suppression by silane coupling agent

A technology of electrolyte solution and silane coupling agent, which is applied in the field of metal surface treatment, can solve the problems of long-term stable existence, and achieve the effect of good compactness, smooth coating surface and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a micro-arc oxidation film layer on the surface of a magnesium alloy, the steps are as follows,

[0047] 1) Magnesium alloy substrate pretreatment: the magnesium alloy substrate is treated with alkali washing or other degreasing processes to remove surface oil stains;

[0048] 2) Prepare the electrolyte solution: the electrolyte solution is composed of the above-mentioned basic solution and silane coupling agent, introduce the silane coupling agent into the basic solution according to the amount, and let it stand for a period of time until the hydrolysis is completed to obtain the electrolyte solution;

[0049] 3) Micro-arc oxidation treatment: the magnesium alloy substrate treated in step 1) is used as the anode or cathode, and the stainless steel is used as the counter electrode, placed in the electrolyte solution prepared in step 2), and the constant voltage or constant current or constant power of the power supply is used Controlling, micro-ar...

Embodiment 1

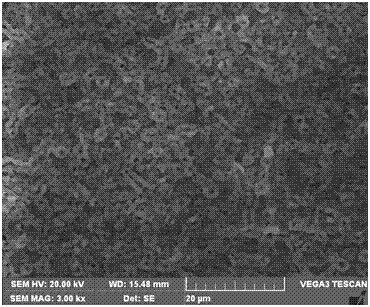

[0056] After the degreasing treatment, the AZ31 magnesium alloy is placed in the electrolyte solution composed of 5g / L KOH+5g / LNaF as the anode, and the stainless steel is used as the counter electrode. It is controlled by a DC pulse power supply, with a positive voltage of 350V, a negative voltage of 0V, and a frequency of 600HZ. The duty cycle is 30%, and the time is 5 minutes. After the oxidation is completed, the magnesium alloy substrate is taken out, rinsed and dried. Example 1 As a comparative example, the electrolytic solution does not include a silane coupling agent, and the surface topography of the obtained magnesium alloy substrate is shown in figure 1 .

Embodiment 2

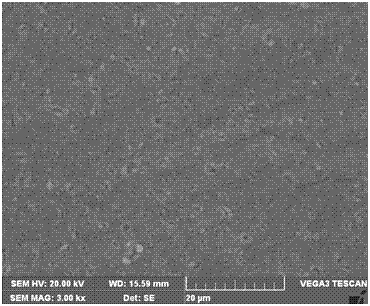

[0058] After the degreasing treatment, the AZ31 magnesium alloy is placed in the electrolyte solution composed of 5g / L KOH+5g / LNaF+5ml / L KH-550 as the anode, and the stainless steel is the counter electrode, which is controlled by a DC pulse power supply with a positive voltage of 350V. Negative voltage 0V, frequency 600HZ, duty cycle 30%, time 5min. After the oxidation is completed, the magnesium alloy substrate is taken out, rinsed and dried. Its surface topography is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com