Method for preparing porous lithium battery silicon-carbon negative electrode by screw extruder

A technology of screw extrusion and lithium battery, which is applied to battery electrodes, negative electrodes, secondary batteries, etc., and can solve problems such as effective control of difficult porous structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

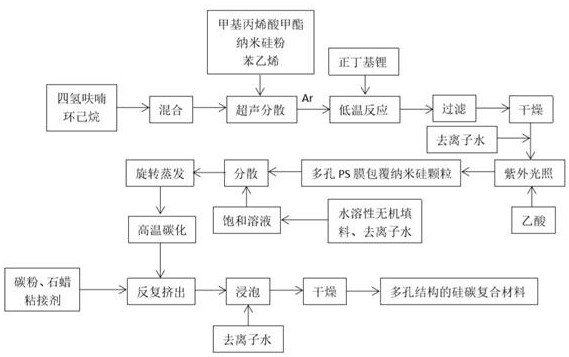

Method used

Image

Examples

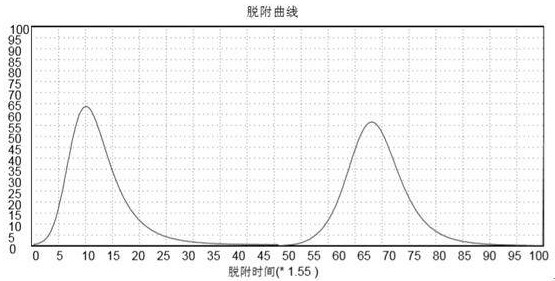

Embodiment 1

[0033] A kind of screw extruder prepares the preparation of silicon carbon negative electrode of porous lithium battery:

[0034] (1). Ultrasonic dispersion of 40 parts by weight of styrene, 50 parts by weight of methyl methacrylate and 40 parts by weight of nano silicon powder in a mixed solvent of 100 parts by weight of tetrahydrofuran and 100 parts by weight of cyclohexane is configured as a suspension, and added 10 parts by weight of n-butyllithium initiator, react under protection of argon, form PS-b-PMMA block polymer coating nano-silicon particle, with described PS-b-PMMA block polymer coating nano-silicon particle After filtering and drying, add deionized water, and slowly add 38%wt acetic acid solution dropwise under ultraviolet light irradiation to obtain porous PS membrane-coated nano-silicon particles;

[0035] (2). The inorganic filler sodium chloride was added into deionized water to form a saturated solution, and 200 parts by weight of the porous PS membrane-coa...

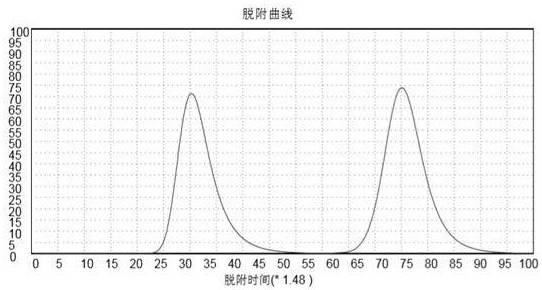

Embodiment 2

[0039] A kind of screw extruder prepares the preparation of silicon carbon negative electrode of porous lithium battery:

[0040] (1). Ultrasonic dispersion of 40 parts by weight of styrene, 50 parts by weight of methyl methacrylate and 50 parts by weight of nano silicon powder in a mixed solvent of 100 parts by weight of tetrahydrofuran and 100 parts by weight of cyclohexane is configured as a suspension, and added 10 parts by weight of n-butyllithium initiator, react under protection of argon, form PS-b-PMMA block polymer coating nano-silicon particle, with described PS-b-PMMA block polymer coating nano-silicon particle After filtering and drying, add deionized water, and slowly add 38%wt acetic acid solution dropwise under ultraviolet light irradiation to obtain porous PS membrane-coated nano-silicon particles;

[0041] (2). Add the water-soluble inorganic filler sodium chloride into deionized water to configure a saturated solution, and disperse 200 parts by weight of the ...

Embodiment 3

[0046] A kind of screw extruder prepares the preparation of silicon carbon negative electrode of porous lithium battery:

[0047] (1). Ultrasonic dispersion of 40 parts by weight of styrene, 50 parts by weight of methyl methacrylate and 40 parts by weight of nano silicon powder in a mixed solvent of 100 parts by weight of tetrahydrofuran and 100 parts by weight of cyclohexane is configured as a suspension, and added 10 parts by weight of n-butyllithium initiator, react under protection of argon, form PS-b-PMMA block polymer coating nano-silicon particle, with described PS-b-PMMA block polymer coating nano-silicon particle After filtering and drying, add deionized water, and slowly add 38%wt acetic acid solution dropwise under ultraviolet light irradiation to obtain porous PS membrane-coated nano-silicon particles;

[0048] (2). Add the water-soluble inorganic filler sodium chloride into deionized water to configure a saturated solution, and disperse 200 parts by weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com