Superhydrophobic porous film and its preparation method and application

A porous membrane, super-hydrophobic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as inability to cope with membrane distillation scaling and fouling, membrane distillation scaling problems, and cost increases. , to achieve the effect of increasing flux, easy mass production, and improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

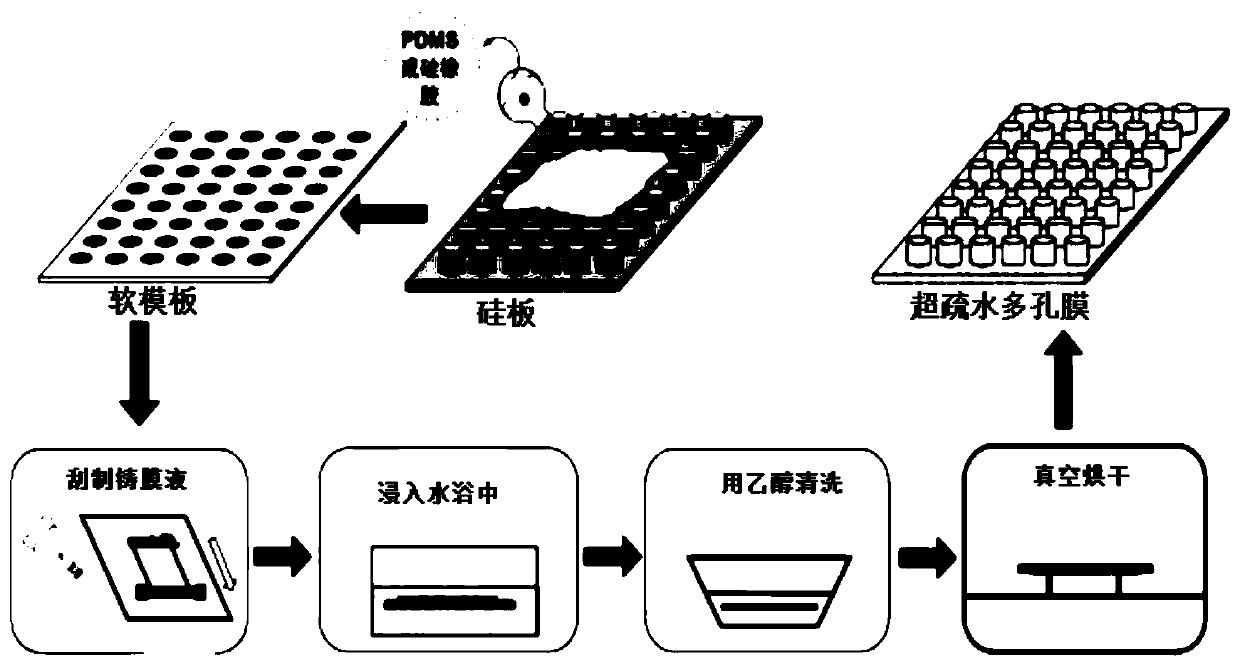

[0040] 4. Preparation of superhydrophobic porous membrane

[0041] Pour the prepared casting solution on the prepared soft template, and use a scraper of a specific size to scrape the film; put the scraped casting solution and soft template into a water bath at a specific temperature, and control the temperature of the environment. Temperature and humidity, through phase separation to form a film; then the formed film material is peeled off to obtain a porous film material with a super-hydrophobic surface; finally, ethanol is used as a cleaning agent for ultrasonic cleaning, and after drying, the surface with micro-columns / Superhydrophobic porous membrane materials with cone array structure.

[0042] In the above process, the specific size of the scraper refers to a scraper with a thickness of 50-500 μm. The water bath temperature is controlled to be 5-90°C; the ambient temperature is 10-40°C, and the humidity is 10-90%, preferably the water bath temperature is 20-75°C, the...

Embodiment 1

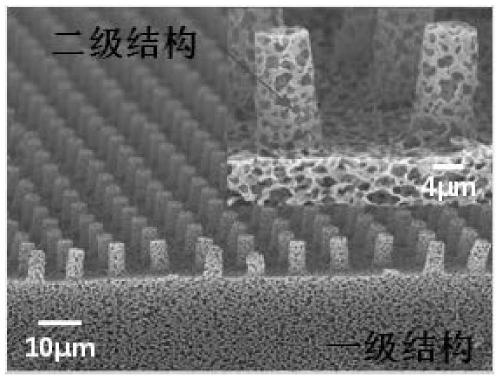

[0047] The micromolded polyvinylidene fluoride (PVDF) hydrophobic membrane of the present invention has a secondary structure such as figure 2 As shown, the polyvinylidene fluoride body is a primary structure with a three-dimensional pore-like structure, and the pores are uniform and interconnected. The secondary structure also has the same primary three-dimensional porous structure as the original primary structure, with an effective porosity of 0.7.

[0048] The preparation method of the micromolded polyvinylidene fluoride (PVDF) hydrophobic membrane is as follows:

[0049] (1) Select a smooth and flat silicon plate with a cylinder array with a height of 10 μm, an equivalent diameter of 5 μm, and a cylinder center distance of 10 μm on the surface.

[0050] (2) Mix polydimethylsiloxane (PDMS) and curing agent in a ratio of 10:1, let the mixed solution stand still for degassing for 10 minutes, slowly pour the degassed PDMS mixed solution on the silicon plate, and put the who...

Embodiment 2

[0055] The micromolded polyethersulfone (PES) hydrophobic membrane of the present invention has a secondary structure, wherein the polyethersulfone body is a primary structure with a three-dimensional porous structure, and the pores are uniform and interpenetrating. On the upper surface of sulfone, there is a secondary structure with uniform arrangement and uniform size. This secondary structure also has the same primary three-dimensional porous structure as the original primary structure, with an effective porosity of 0.65.

[0056] The preparation method of this micromolded polyethersulfone (PES) hydrophobic membrane is as follows:

[0057] (1) Select a smooth and flat silicon plate with a pyramid array with a height of 10 μm, an equivalent diameter of 5 μm, and a square pyramid center distance of 10 μm on the surface.

[0058](2) Use epoxy resin, mix the curing agent at a ratio of 10:1, let the mixture stand still for degassing for 10 minutes, slowly pour the degassed epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com