Long glass fiber reinforced nylon composite material, preparation method thereof, and application of composite material in electric cutters

A nylon composite material and long glass fiber technology, applied in the application, preparation, and long glass fiber reinforced nylon composite material field of electric tools, can solve the problems of poor material performance, achieve high impact performance, reduce use, and increase toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

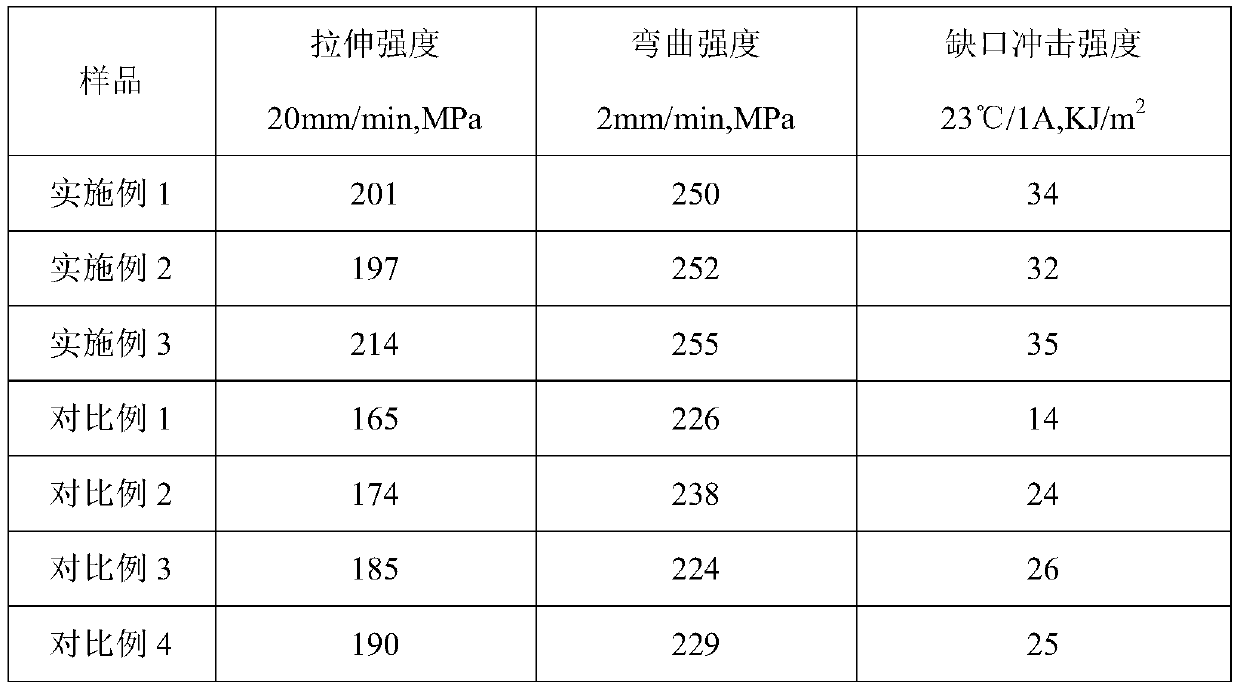

Examples

Embodiment 1

[0026] Embodiment 1: In parts by weight, 1 part of cyclohexane, 5 parts of ethyl stearate, 3 parts of maleic anhydride and 1 part of bisphenol A liquid epoxy resin E51 are mixed, the mixing temperature is 80 ° C, the mixing speed 1000 rpm;

[0027] 50 parts of nylon resin PA6, 0.2 part of antioxidant 2,6-di-tert-butylphenol, 0.1 part of lubricant stearic acid, 20 parts of glass fiber TCR736 and 1 part of pigment benzidine yellow are mixed with the above raw materials, and the mixing temperature is 80°C, with a mixing speed of 1500 rpm, put the mixed materials into a twin-screw extruder, and melt and granulate at 230°C.

Embodiment 2

[0028] Embodiment 2: In parts by weight, 2 parts of cyclohexane, 7 parts of ethyl stearate, 4 parts of maleic anhydride and 2 parts of bisphenol A liquid epoxy resin E51 are mixed, the mixing temperature is 80 ° C, and the mixing speed 1000 rpm;

[0029] 70 parts of nylon resin PA6, 1 part of antioxidant 2,6-di-tert-butylphenol, 1 part of lubricant stearic acid, 40 parts of glass fiber TCR736 and 1 part of pigment benzidine yellow are mixed with the above raw materials, and the mixing temperature is 80°C, with a mixing speed of 1500 rpm, put the mixed materials into a twin-screw extruder, and melt and granulate at 230°C.

Embodiment 3

[0030] Embodiment 3: In parts by weight, 2 parts of cyclohexane, 6 parts of ethyl stearate, 4 parts of maleic anhydride and 2 parts of bisphenol A liquid epoxy resin E51 are mixed, the mixing temperature is 80 ° C, the mixing speed 1000 rpm;

[0031] 60 parts of nylon resin PA6, 1 part of antioxidant 2,6-di-tert-butylphenol, 1 part of lubricant stearic acid, 30 parts of glass fiber TCR736 and 1 part of pigment benzidine yellow are mixed with the above raw materials, and the mixing temperature is 80°C, with a mixing speed of 1500 rpm, put the mixed materials into a twin-screw extruder, and melt and granulate at 230°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com