Petroleum ester oxide barium soap corrosion inhibitor

A technology for oxidizing petroleum grease and corrosion inhibitors, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of corrosiveness, color deepening, and corrosion inhibitor color depth, etc., and achieve low production costs and good product quality , coating bright and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

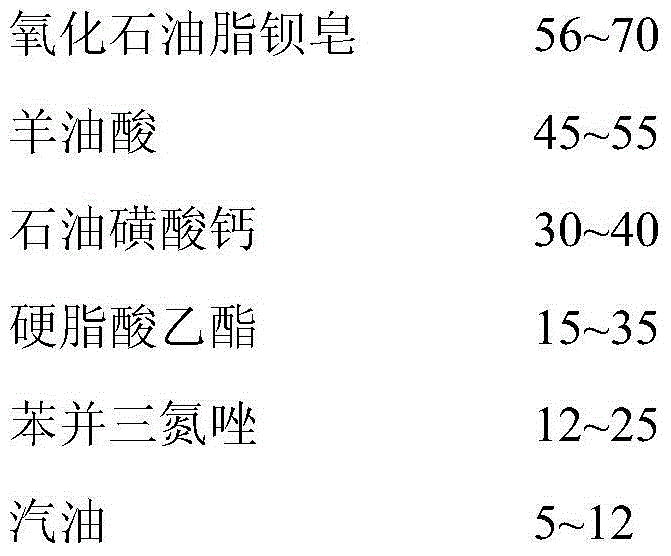

Image

Examples

Embodiment 1

[0015]

[0016] The preparation method is as follows: each component is mixed uniformly at room temperature according to the formula to obtain the product.

[0017] Oxidized petroleum grease has good corrosion inhibition effect. Because its molecules contain polar groups such as carboxyl groups and hydroxyl groups, it has strong adsorption capacity on metal surfaces and good oil solubility. The presence of hydroxyl groups can emulsify water on the metal surface.

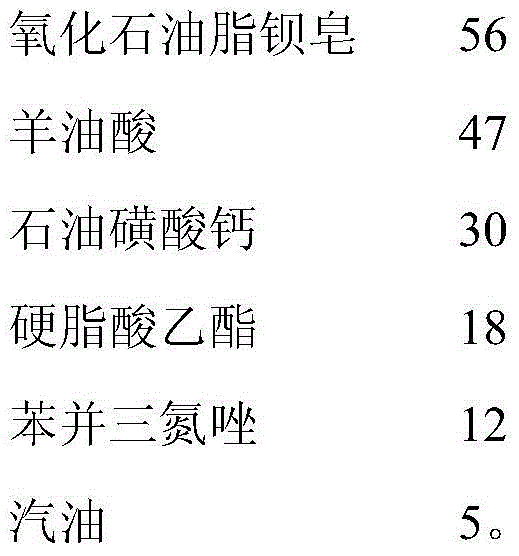

Embodiment 2

[0019]

[0020]

[0021] The preparation method is the same as above.

[0022] The corrosion inhibitor of the invention has low price, less consumption, excellent corrosion inhibition effect, bright and transparent coating, clean and beautiful appearance and no influence on product quality, and can be used for rust prevention of materials such as steel, cast iron and copper alloy.

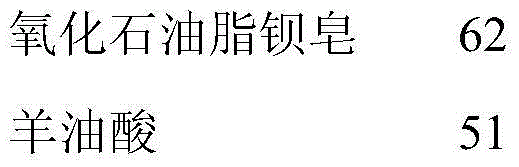

Embodiment 3

[0024]

[0025] The preparation method is the same as above.

[0026] The preparation method of the present invention has the advantages of simple process, mild reaction conditions, low production cost, and good product quality. The product is often used in turbine oil, added to internal combustion engine oil, instrument oil, gear oil and hydraulic oil, and is effective for metal in the oil. Play the role of corrosion inhibition and rust prevention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com