A kind of low-sulfur diesel oil additive and its preparation process

A low-sulfur diesel and additive technology, which is applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problem that the miscibility of biodiesel and low-sulfur diesel is not good enough, and cannot effectively improve the combustion rate of low-sulfur diesel, low-sulfur The lubricity of diesel oil has not been greatly improved, and the effects of reducing oxidation sediment, reducing emissions, and strong adsorption and capture capabilities have been achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

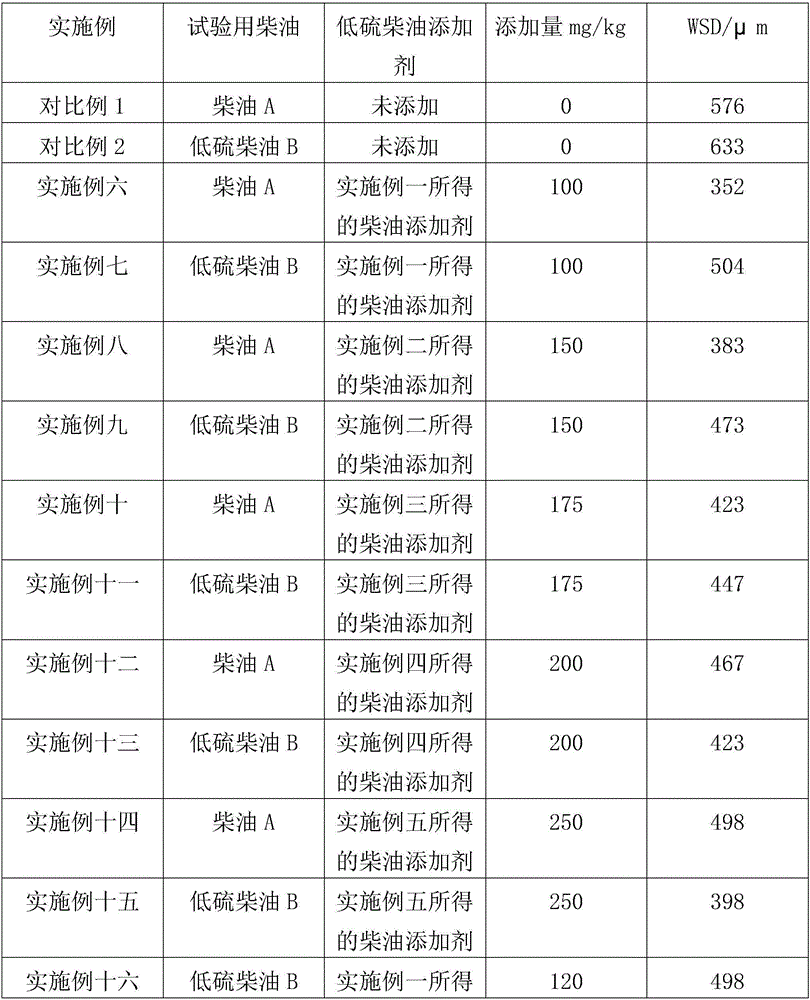

[0020] Embodiment one: the preparation method of low-sulfur diesel oil additive, it comprises the following steps: by weight ratio,

[0021] First add 40 parts of biodiesel and 20 parts of solubilizer in reaction vessel, wherein, contain in every hundred parts of solubilizer, 40 parts of sorbitan stearate, 45 parts of polyethylene oxide sorbitol monostearate Esters, 15 parts of sorbitan monooleate, slowly heated while stirring to raise the temperature to 90°C, then stirred at 90°C for 0.5h, then lowered the temperature to 55°C and kept it within the range of 55°C;

[0022] Then add 8 parts of glyceryl stearate, 2 parts of ethyl stearate and 15 parts of oleic acid amide, and stir for 1 hour to fully dissolve the raw materials; then add 10 parts of detergent and stir for 25 minutes, wherein, every hundred parts of detergent contains , 15 parts of imidazoline, 85 parts of T151A polyisobutenyl succinimide;

[0023] Add 5 parts of antioxidants at last, wherein, contain in every hu...

Embodiment 2

[0024] Embodiment two: the preparation method of low-sulfur diesel oil additive, it comprises the following steps: by weight ratio,

[0025] First add 43 parts of biodiesel and 22 parts of solubilizer in reaction vessel, wherein, contain in every hundred parts of solubilizer, 42 parts of sorbitan stearate, 40 parts of polyethylene oxide sorbitol monostearate Esters, 18 parts of sorbitan monooleate, slowly heated while stirring to raise the temperature to 92°C, then stirred at 92°C for 0.8h, then lowered the temperature to 60°C and kept it within the range of 60°C;

[0026] Then add 5 parts of glyceryl stearate, 4 parts of ethyl stearate and 12 parts of oleic acid amide, and stir for 1.2 hours to fully dissolve the raw materials; then add 7 parts of detergent and stir for 30 minutes, wherein, every hundred parts of detergent contains , 20 parts of imidazoline, 80 parts of T151A polyisobutenyl succinimide;

[0027] Add 7 parts of antioxidants at last, wherein, contain in every ...

Embodiment 3

[0028] Embodiment three: the preparation method of low-sulfur diesel oil additive, it comprises the following steps: by weight ratio,

[0029] First add 42 parts of biodiesel and 23 parts of solubilizer in reaction vessel, wherein, contain in every hundred parts of solubilizer, 43 parts of sorbitan stearate, 38 parts of polyethylene oxide sorbitol monostearate Esters, 19 parts of sorbitan monooleate, slowly heated while stirring to raise the temperature to 92°C, then stirred at 92°C for 0.8h, then lowered the temperature to 60°C and kept it within the range of 60°C;

[0030] Then add 6 parts of glyceryl stearate, 3 parts of ethyl stearate and 12 parts of oleic acid amide, and stir for 1.2 hours to make the raw materials fully dissolve; then add 8 parts of detergent and stir for 30 minutes, wherein, every hundred parts of detergent contains , 18 parts of imidazoline, 82 parts of T151A polyisobutenyl succinimide;

[0031] Finally, add 6 parts of antioxidants, wherein every one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com