Patents

Literature

59 results about "Ethyl palmitate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

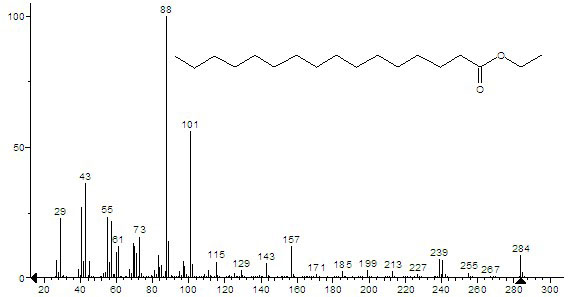

Ethyl palmitate is an organic compound with the chemical formula C₁₈H₃₆O₂. It is a colorless solid with a wax-like odor. Chemically, ethyl palmitate is the ethyl ester of palmitic acid. Ethyl palmitate is used as a hair- and skin-conditioning agent.

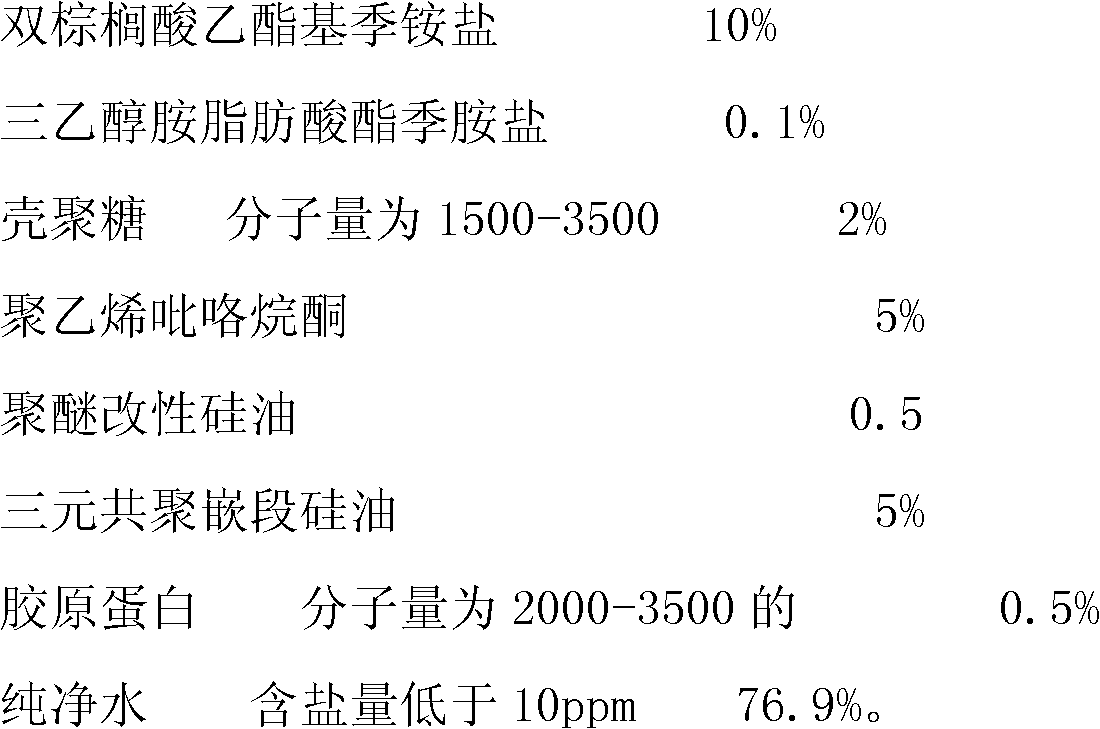

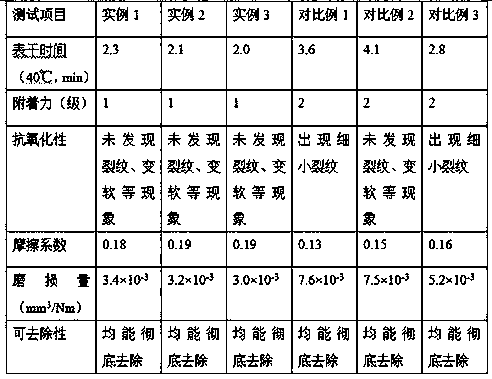

Softening agent capable of improving sublimation fastness of disperse dye and wet friction fastness of reactive dye

The invention relates to the field of textile dyeing of polyester and dark fabrics such as blended fabrics, pure cotton, adhesives and hemp, in particular to a softening agent capable of improving the sublimation fastness of a disperse dye and the wet friction fastness of a reactive dye. The softening agent is characterized by mainly comprising the following raw materials in percentage by weight: bi-ethyl palmitate based quaternary ammonium salt, triethanolamine fatty acid ester quaternary ammonium salt, chitosan, polyvinyl pyrrolidone, polyether modified silicone oil, ternary polymerization block silicon oil, collagen and purified water. Compared with the prior art, the softening agent has the advantages that the sublimation fastness of the disperse dye can be improved by 0.5 to 1 grade and the wet friction fastness of the reactive dye can be improved by 0.5 grade after the sizing of a dyed fabric; and simultaneously, the neatened fabric is endowed with elastic and exquisite handfeel, so that the fabric is high in pollution resistance, dust resistance, shrinkage resistance, pilling resistance and static electricity resistance.

Owner:祝洪哲

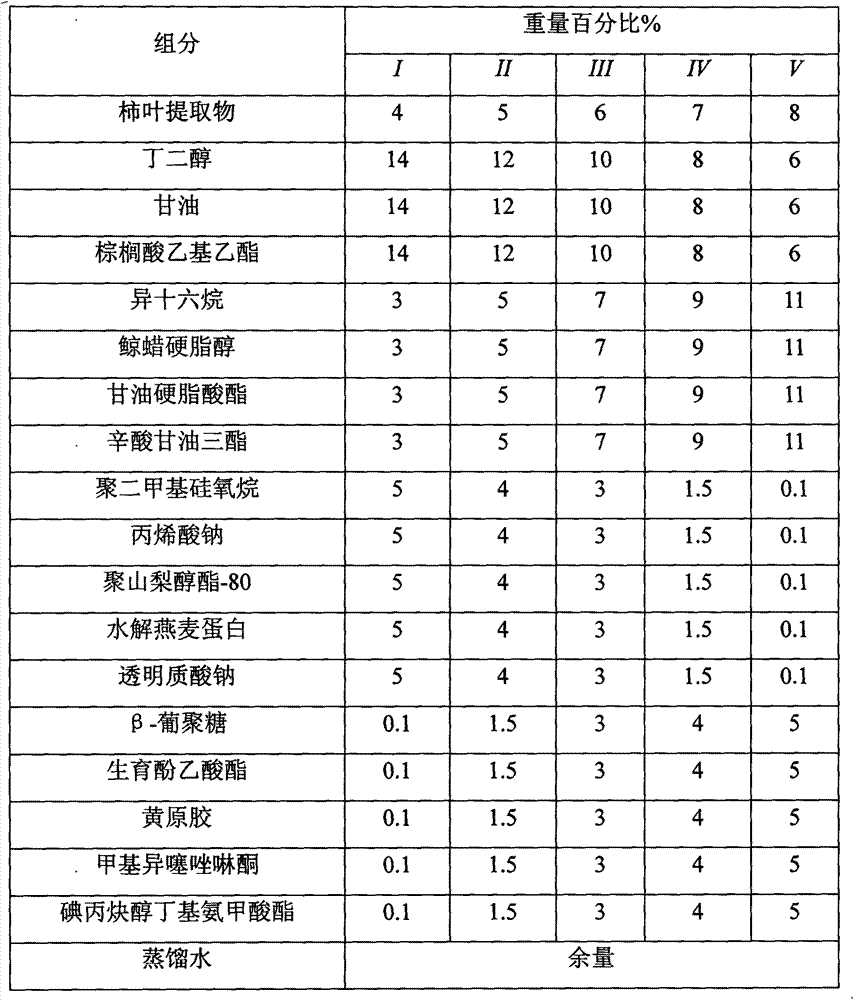

Spot-fading cream taking persimmon leaf extract as functional raw material

InactiveCN103202788AVisibly brightening and lightening effectTo promote metabolismCosmetic preparationsAntipyreticAdditive ingredientEthyl palmitate

The invention relates to a spot-fading cream taking a persimmon leaf extract as a functional raw material. The spot-fading cream comprises the following main ingredients in percentage by weight: 4-8% of persimmon leaf extract, 6-14% of butanediol, 0.1-5% of xanthan gum, 0.1-5% of methylisothiazolinone, and the like. A preparation method comprises the following specific steps of: pouring persimmon leaf extract, butanediol, glycerol, xanthan gum, ethyl palmitate, sodium acrylate and sodium hyaluronate in a proportioning tank, uniformly stirring, and heating to 50 DEG C; pouring isohexadecane, cetostearyl alcohol, glyceryl stearate, capric triglyceride, polydimethylsiloxane, polysorbate-80, hydrolyzed oat protein, beta-glucan, tocopheryl acetate, methylisothiazolinone and iodopropynyl butylcarbamate in the proportioning tank aforementioned, stirring the mixture in the proportioning tank to form a homogeneous liquid, properly supplementing distilled water, continuously and uniformly stirring, then cooling to a room temperature; and obtaining the finished products after sampling inspection is passed.

Owner:NANNING JIAOYANG PHARM

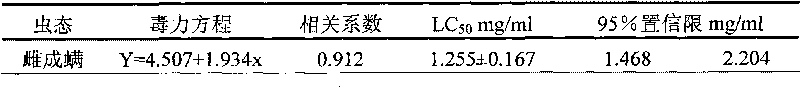

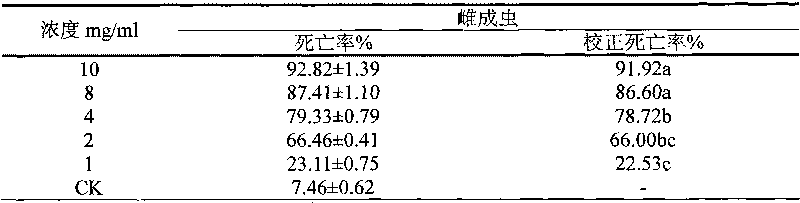

Application of ethyl palmitate in preventing and controlling pine wilt disease

The invention relates to application of ethyl palmitate in preventing and controlling pine wilt disease. A method provided by the invention for preventing and controlling the pine wilt disease by using ethyl palmitate is that: the ethyl palmitate is placed into pine trees which contain generative bursaphelenchus xylophilus. The method provided by the invention can be used for treating pine trees which are infected with bursaphelenchus xylophilus in a forest. The problems of mass reproduction and rapid diffusion of bursaphelenchus xylophilus under a bursaphelenchus xylophilus epidemic situation can be solved.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI

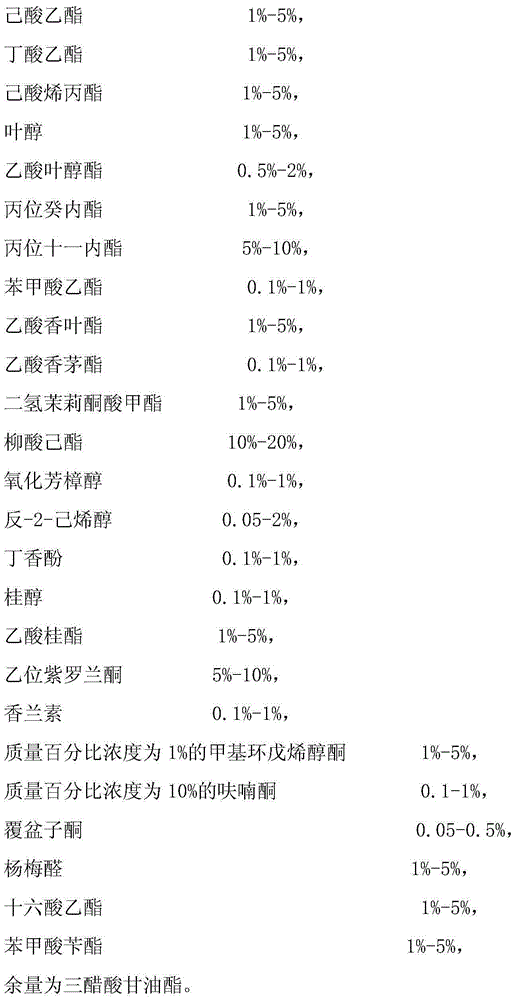

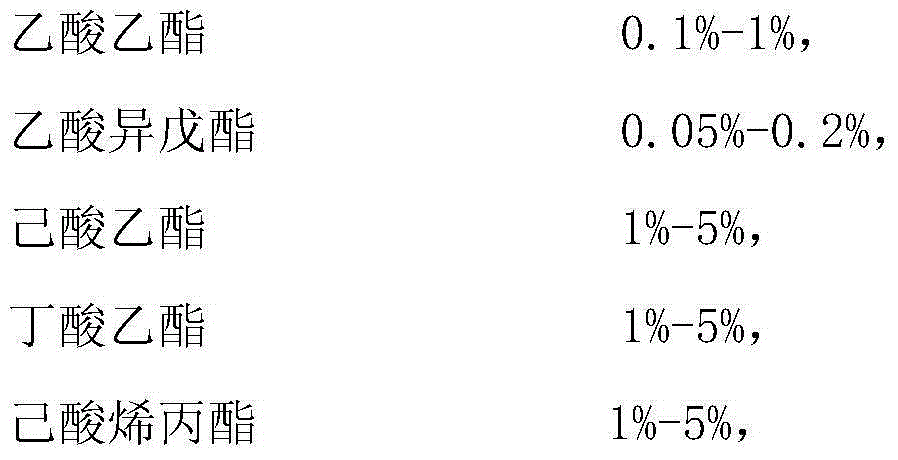

Strawberry essence for oil-based ink and preparation method of strawberry essence

InactiveCN105132175AIncrease added valueEasy to useInksEssential-oils/perfumesSolubilityCinnamyl acetate

The invention relates to strawberry essence for oil-based ink. The strawberry essence consists of strawberry essence, maltodextrin and starch sodium octenylsuccinate, wherein the strawberry essence consists of ethyl acetate, isoamyl acetate, ethyl caproate, ethyl butyrate, allyl hexanoate, leaf alcohol, cis-3-hexenyl acetate, decalactone, peach aldehyde, ethyl benzoate, geranyl acetate, citronellyl acetate, dihydrojasmonic acid methyl ester, hexyl salicylate, linalool oxide, trans-2-hexenol, eugenol, cinnamyl alcohol, cinnamyl acetate, beta-Ionone, vanillin, methyl cyclopentenolone, furanone, raspberry ketone, ethyl methylphenylglycidate, ethyl palmitate, benzyl benzoate and glycerol triacetate. The invention also provides a preparation method of the strawberry essence for the oil-based ink. The strawberry essence, the maltodextrin, the starch sodium octenylsuccinate and water are mixed; homogenizing and emulsification are performed; then, spray drying is carried out; particular strawberry essence is formed, so that the aroma retaining effect and the oil solubility of the essence are improved; the strawberry essence is applicable to perfuming of the oil-based ink.

Owner:SHANGHAI INST OF TECH

New application of ethyl palmitate

InactiveCN101692811AImprove compatibilityGood development resourceBiocideAnimal repellantsFruit treeOctyl palmitate

The invention relates to a botanical acaricides applied to preventing mites on industrial crops such as fruit trees, vegetables and the like as well as a preparation method and application thereof. The botanical acaricides is prepared from ethyl palmitate adding with surfactant, emulsifier, penetrant, synergist and the like, and has the characteristics of high efficiency, low toxicity, low residue, environment friendliness and the like.

Owner:BEIJING UNIV OF AGRI

Soy sauce essence and preparation method thereof

Owner:TIANJIN CHUNFA BIO TECH GRP

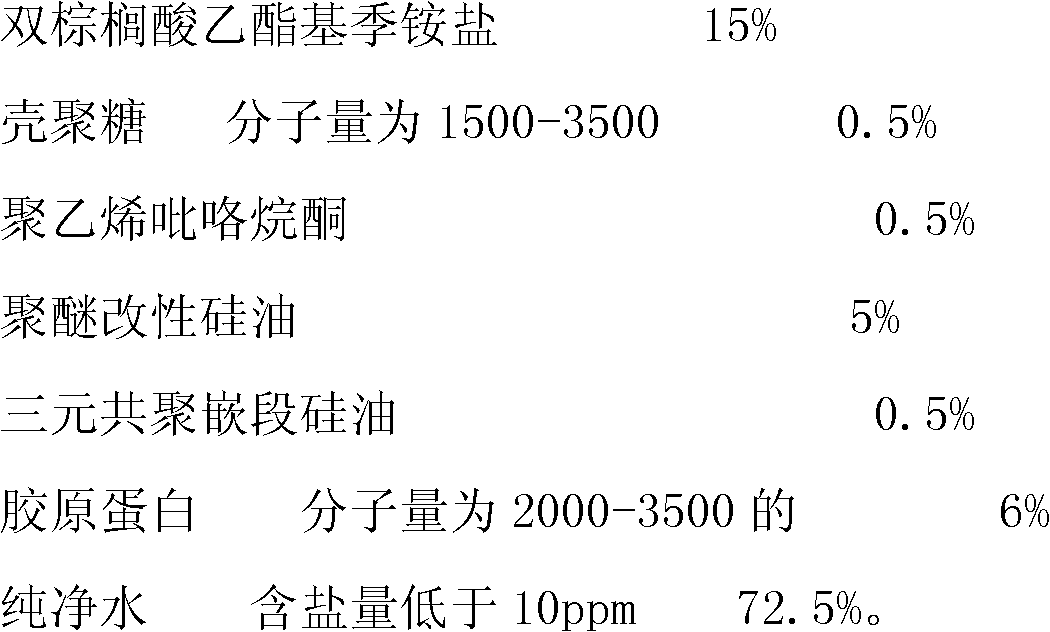

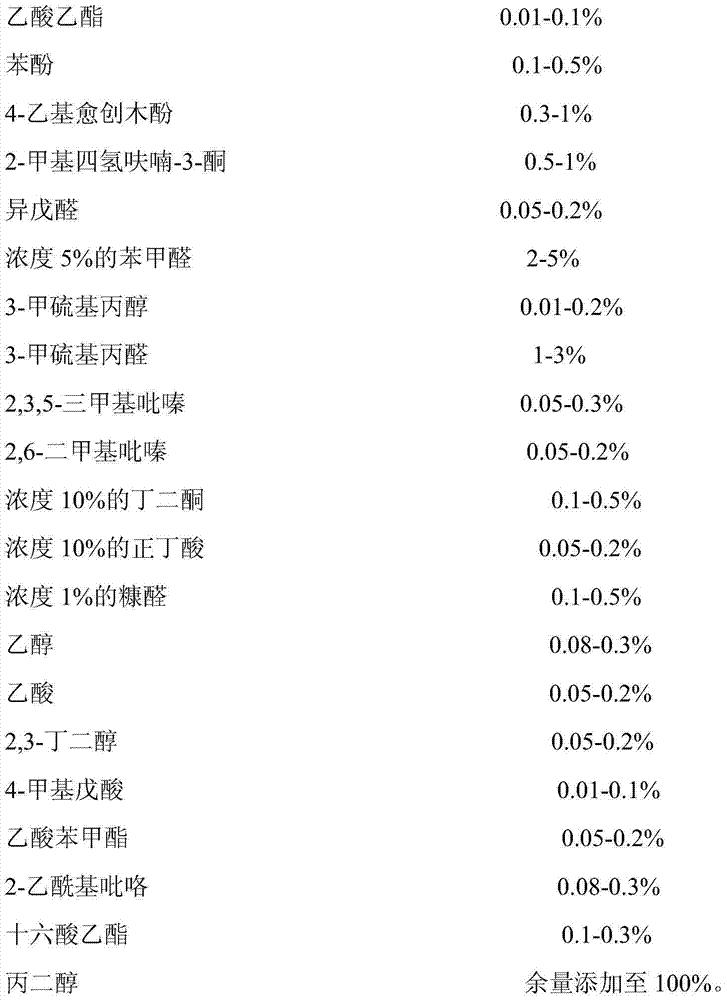

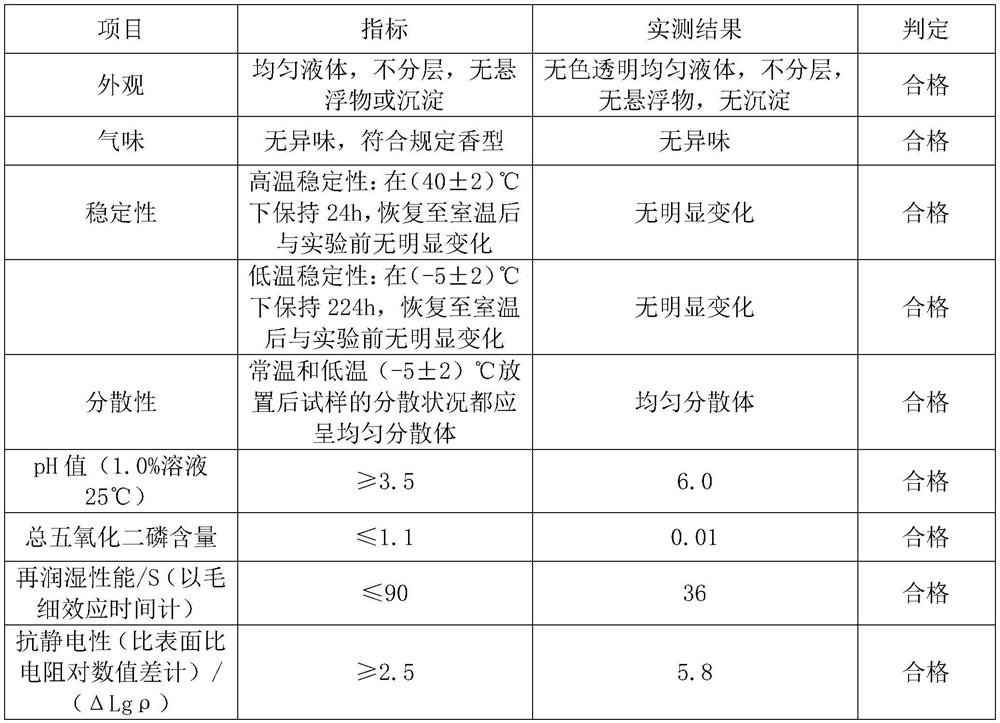

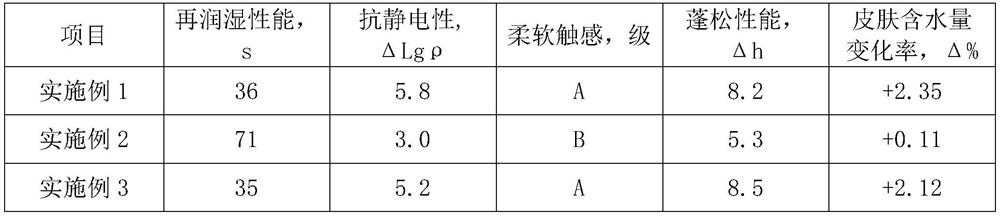

Fabric softening care agent and preparation method thereof

The invention discloses a fabric softening care agent and a preparation method thereof, and relates to the technical field of fabric care. According to the main points of the technical solution, the fabric softening care agent comprises, by weight percent, 1-10% of quaternary ammonium salts, 0.1-1% of silicone softener, 1-5% of nonionic polyurethane thickener, 0.5% of flavor, 0.01-0.03% of preservative, and the balance water, wherein the quaternary ammonium salts comprise ethyl dipalmitate hydroxyethyl ammonium methyl sulfate; and the silicone softener comprises an amino-modified silicone polyether copolymer. The fabric softening care agent disclosed by the invention has the advantages of improving the softness, bulkiness, water absorbability and re-wetting capability of fabric.

Owner:北京金鱼科技有限责任公司

Underwear type laundry condensate beads and preparation method thereof

InactiveCN111471543ANo pollution in the processGood decontamination effectCationic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsEthyl palmitateFatty alcohol

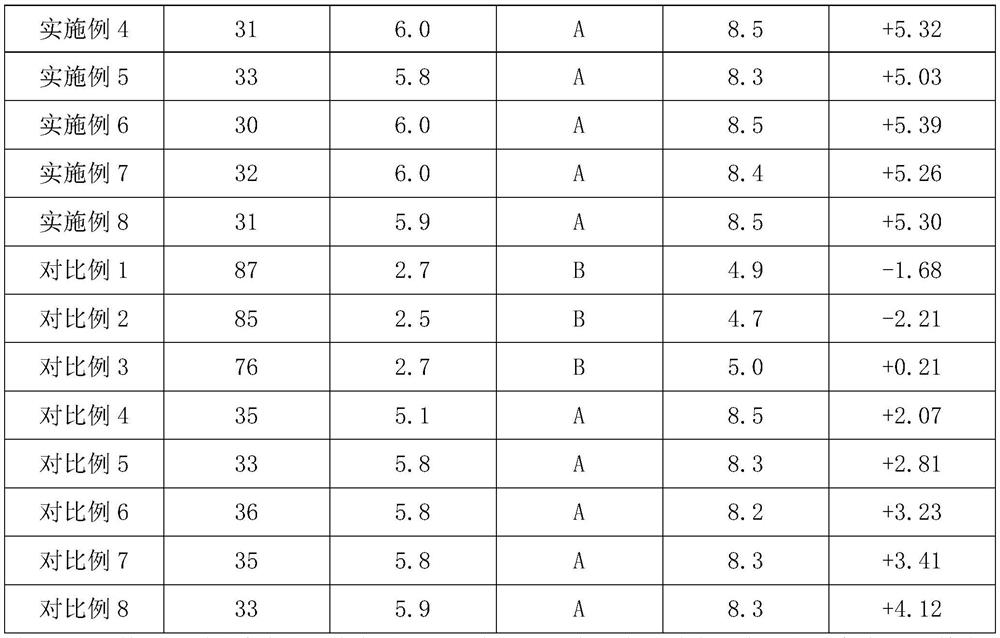

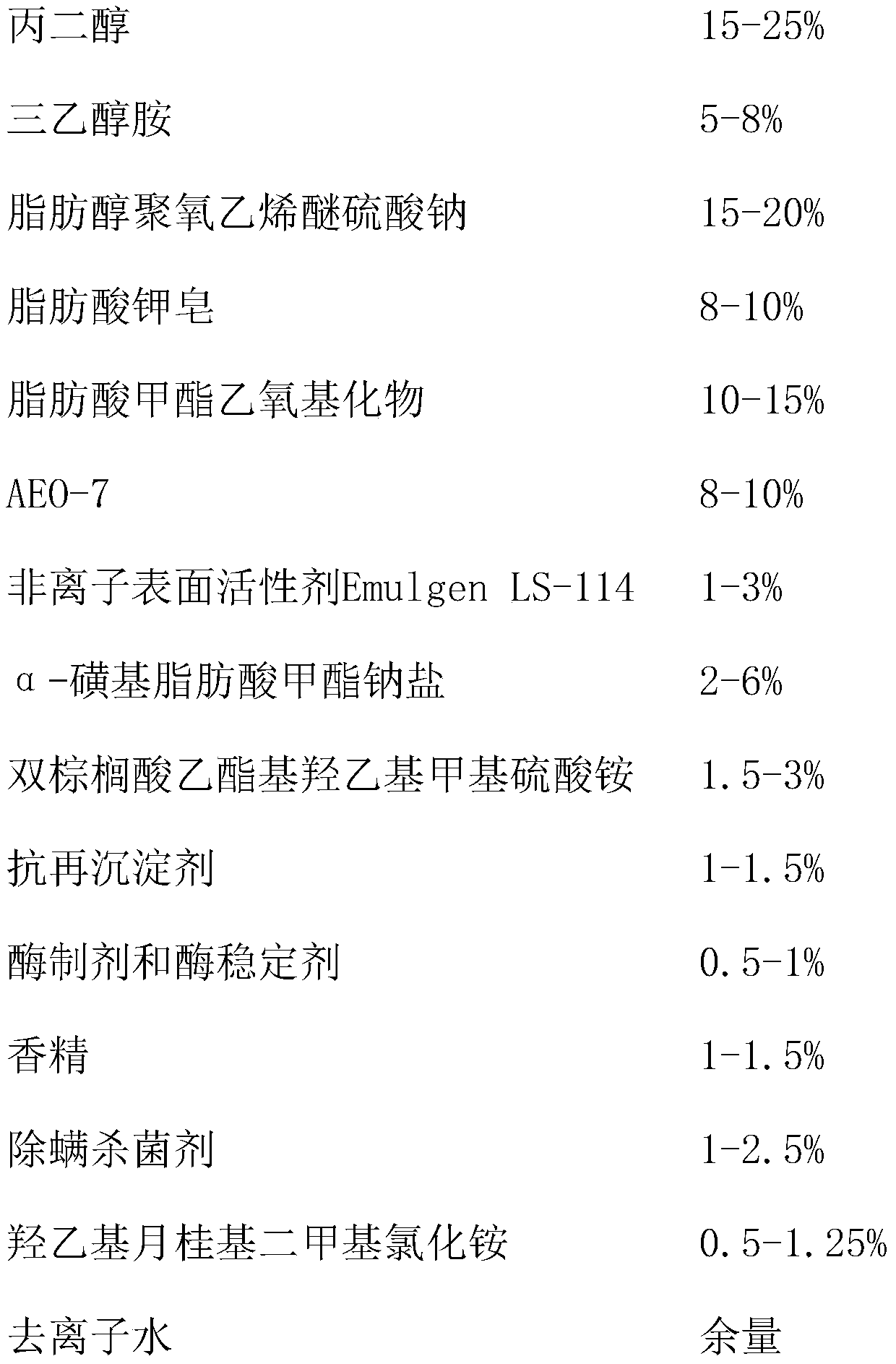

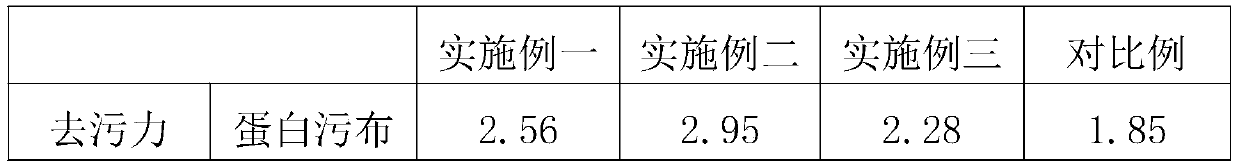

The invention relates to the field of daily chemical detergents. The invention provides underwear type laundry condensate beads and a preparation method thereof. The underwear type laundry condensatebeads comprise the following components in percentage by mass: 15 to 25% of propylene glycol, 15 to 20% of fatty alcohol-polyoxyethylene ether sodium sulfate; 8 to 10% of fatty acid potassium soap; 10to 15% of fatty acid methyl ester ethoxylate; 8 to 10% AEO-7, 1-3% of nonionic surfactant Emulgen LS-114, 2 to 6% of alpha-sulfo fatty acid methyl ester sodium salt, 1.5%-3% of dipalmitic acid ethylester hydroxyethyl methyl ammonium sulfate, 1%-1.5% of an anti-reprecipitation agent, 0.5%-1% of an enzyme preparation and enzyme stabilizer, 1%-1.5% of an essence, 1%-2.5% of an acarus killing bactericide, 0.5%-1.25% of hydroxyethyl lauryl dimethyl ammonium chloride and the balance deionized water. The problems that existing laundry condensate beads only have efficient decontamination capacity and cannot give consideration to bacteriostasis and acarus killing are solved.

Owner:FUJIAN HENGAN HLDG CO LTD +1

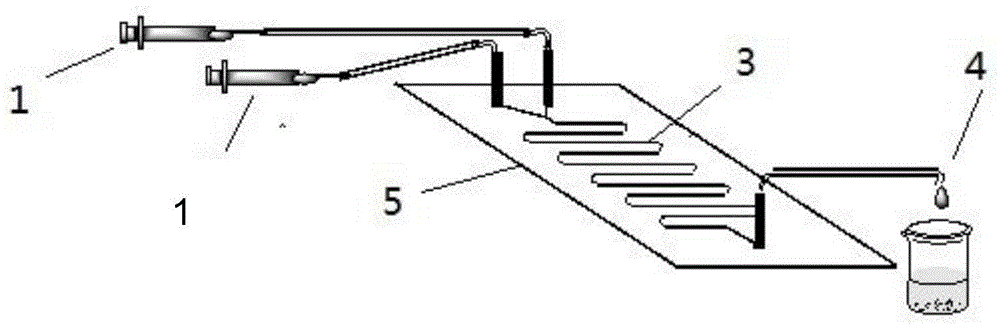

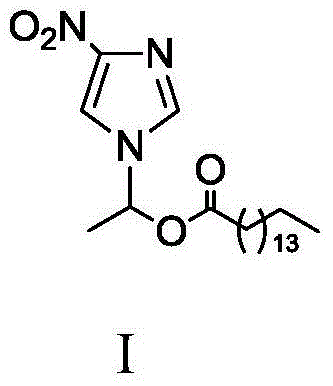

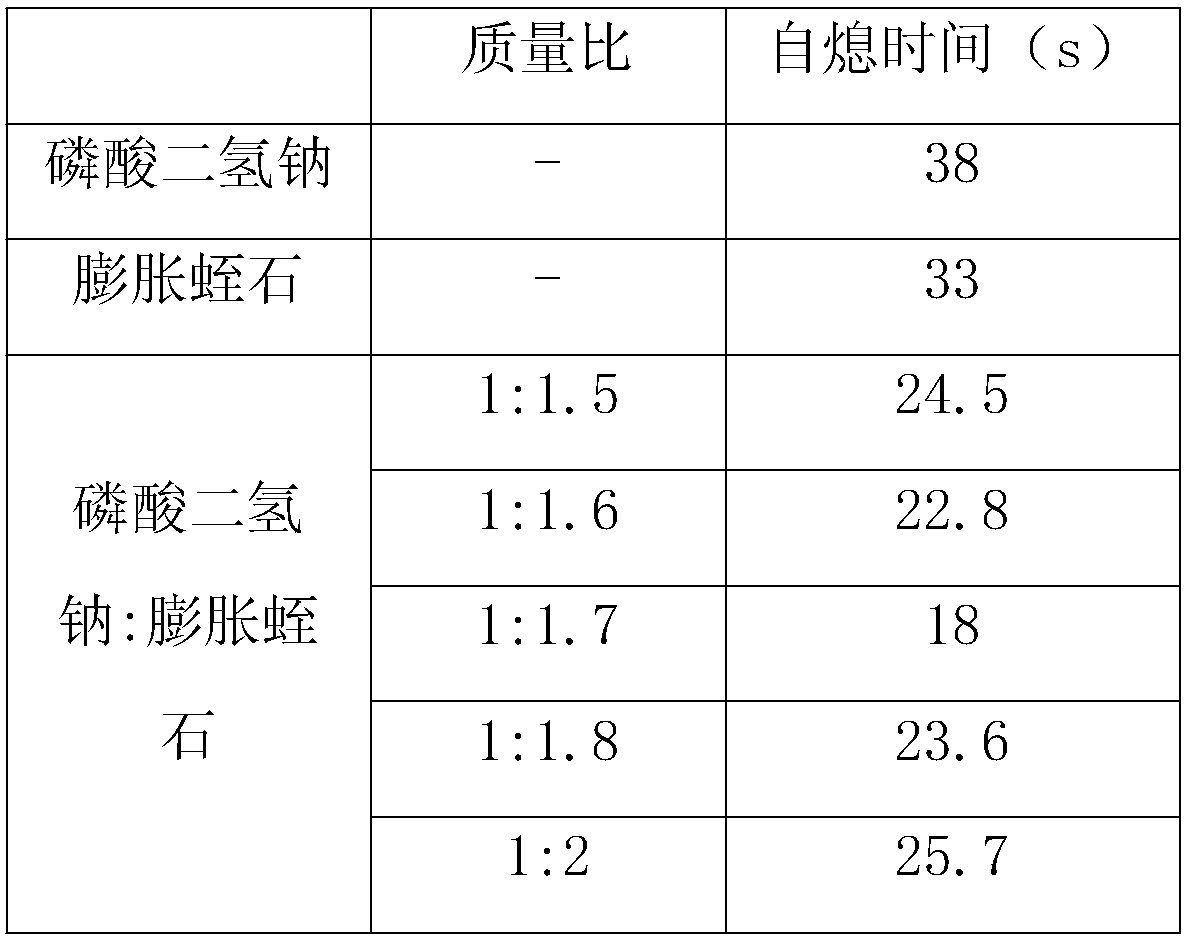

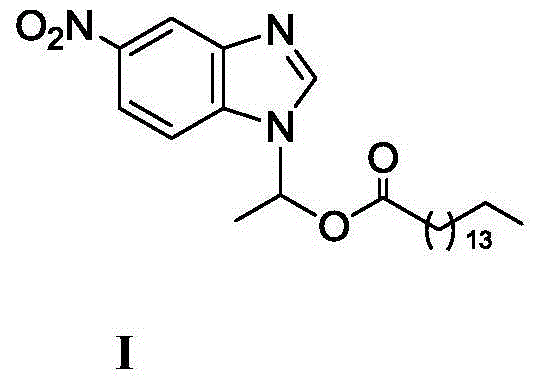

Method for synthesizing 1-(4-nitroimidazolyl)ethyl palmitate on line under catalysis of lipase

ActiveCN104561174AShort reaction timeImprove conversion rateFermentationNitroimidazoleReaction temperature

The invention discloses a method for synthesizing 1-(4-nitroimidazolyl)ethyl palmitate on line under the catalysis of lipase. The method comprises the steps of with 4-nitro-imidazole and vinyl palmitate which are in the molar ratio of 1:(1-8) as raw materials, 0.5-1.0g of lipase Lipozyme TLIM as a catalyst and a DMSO solvent as a reaction solvent, uniformly filling a reaction channel of a microfluidic channel reactor with the lipase Lipozyme TLIM, wherein the internal diameter of the reaction channel of the microfluidic channel reactor is 0.8-2.4mm, and the reaction channel is 0.5-1.0m long; and continuously introducing the raw materials and the reaction solvent to the reaction channel to carry out Markovnikov addition reaction, controlling the reaction temperature at 40-55 DEG C and the reaction time at 20-35 minutes, collecting a reaction solution on line, and carrying out conventional treatment on the reaction solution to obtain 1-(4-nitroimidazolyl)ethyl palmitate. The method has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

Skin care cleansing oil

InactiveCN106137859AFormulation ScienceImprove stabilityCosmetic preparationsMake-upVegetable oilAdditive ingredient

The invention discloses skin care cleansing oil which is mainly composed of the following raw material components in parts by mass: 40-50 parts of vegetable oil, 10-15 parts of coconut oil, 4-15 parts of ethyl acetate, 3-8 parts of an emulsifier, 30-50 parts of ethyl palmitate and 2-8 parts of other components. The components adopted by the cleansing oil are natural and non-irritating, and the skin care cleansing oil is scientific in formula, mild, non-irritating and high in stability, can be used by the crowd with sensitive skin and can well provide moisture and various nutritional ingredients for the skin.

Owner:黄亚景

Method for preventing pine wood nematode diseases

InactiveCN111066823AImprove diapause rateReduce transmissionBiocideAnimal repellantsNematodeEthyl palmitate

The invention belongs to the technical field of agricultural pest control, and particularly relates to a method for controlling pine wood nematode disease. The invention discloses a method for preventing and treating pine wood nematodes. On the basis of a scheme for preventing and treating pine wood nematode disease by using ethyl palmitate in the prior art; fluorite nano powder modified by juiceof selected succulent plants is added into ethyl palmitate; under the condition that the application amount of the low-dosage ethyl palmitate of the pine tree body is 0.5 to 5mu l / m <3>; the diapauserate of the pine wood nematodes is further improved, a large number of pine wood nematodes stop breeding, diffusion type pine wood nematodes (including diffusion type three-year-old larvae (LIII) anddiffusion type four-year-old larvae (LIV)) are formed, propagation of vector insects during eclosion of monochamus alternatus in January to May of the next year is reduced, and pine wood nematode diseases can be effectively prevented.

Owner:HEZE UNIV

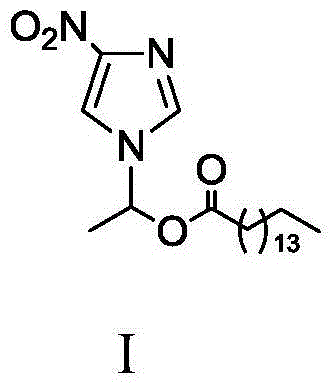

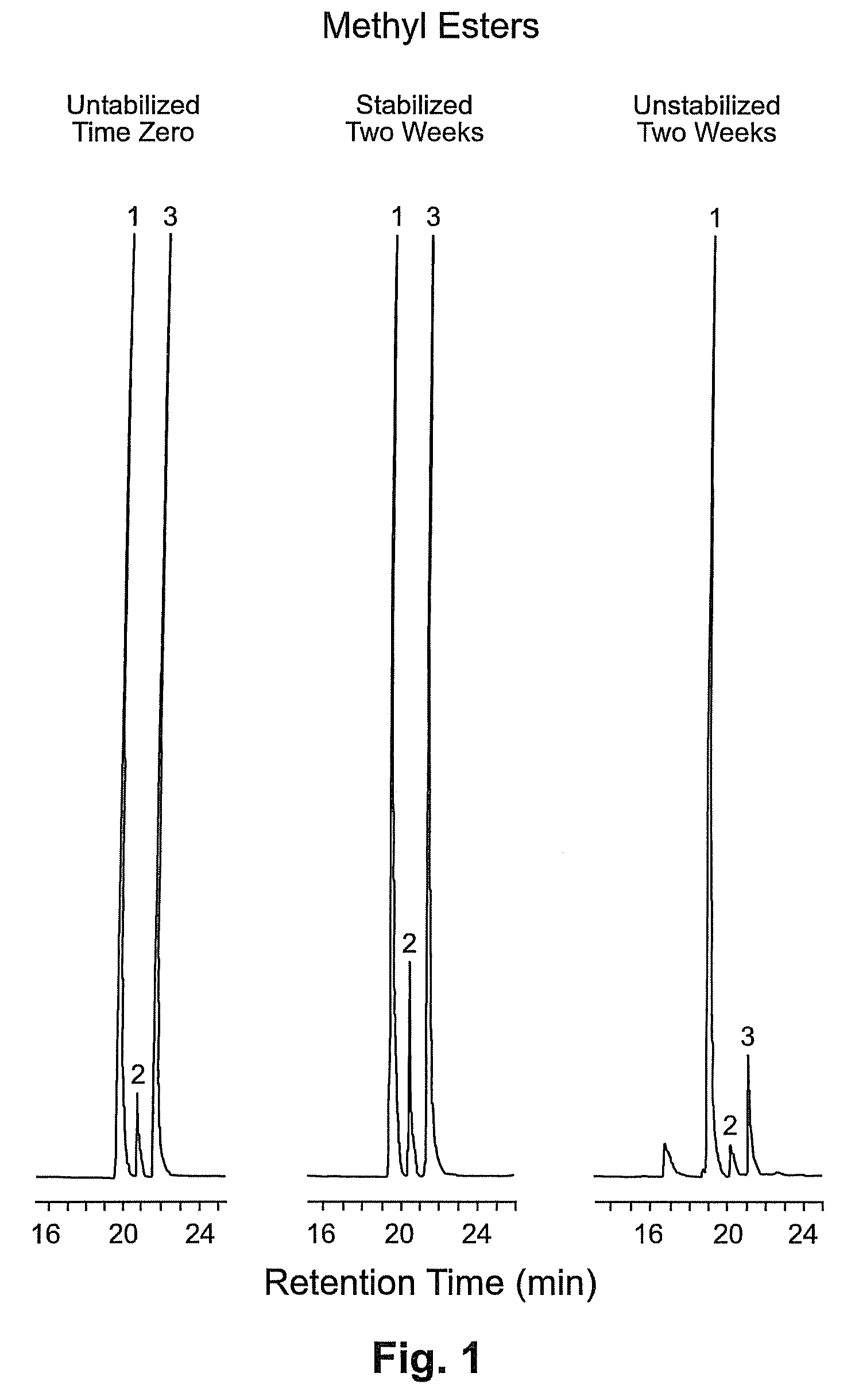

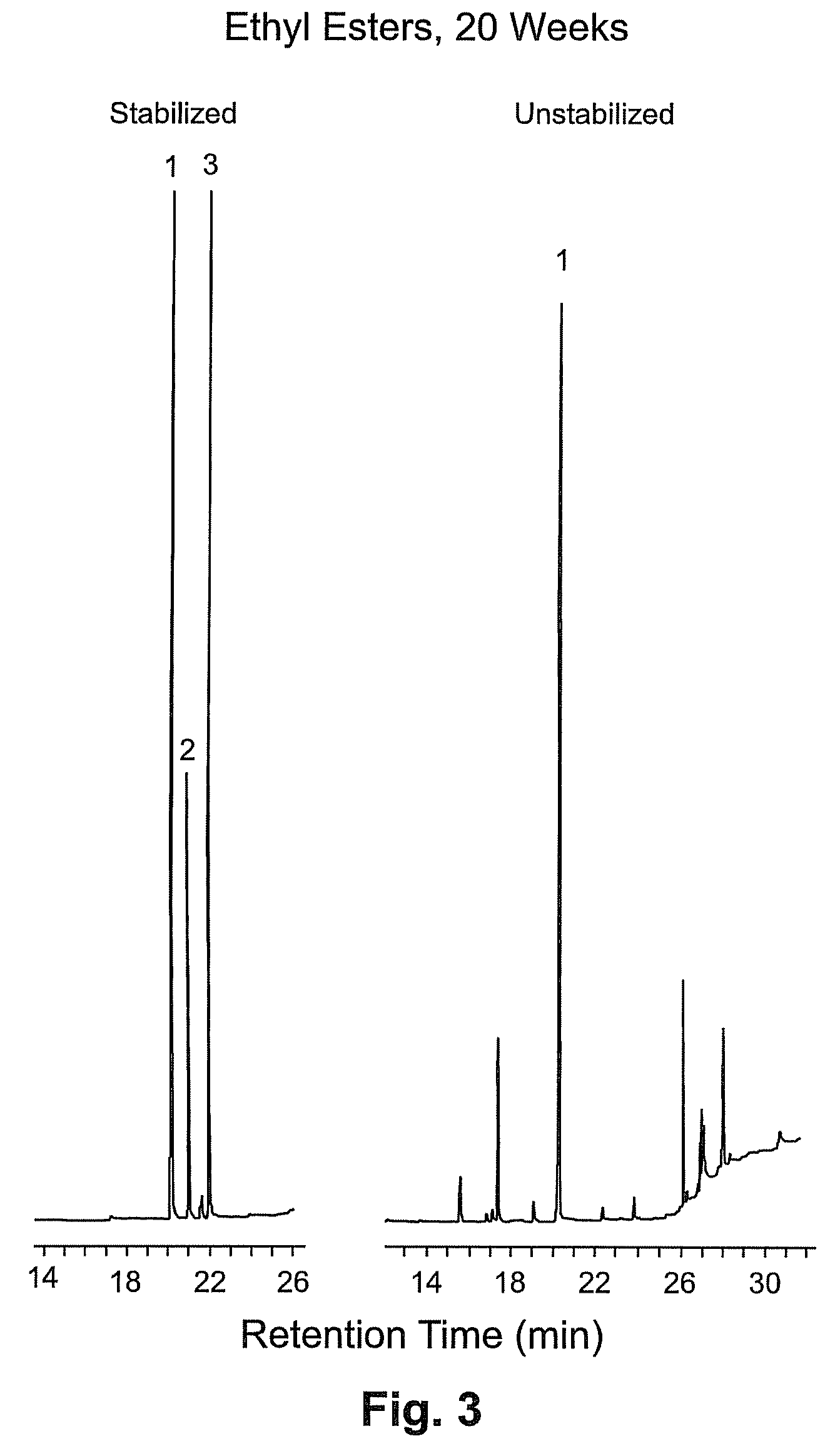

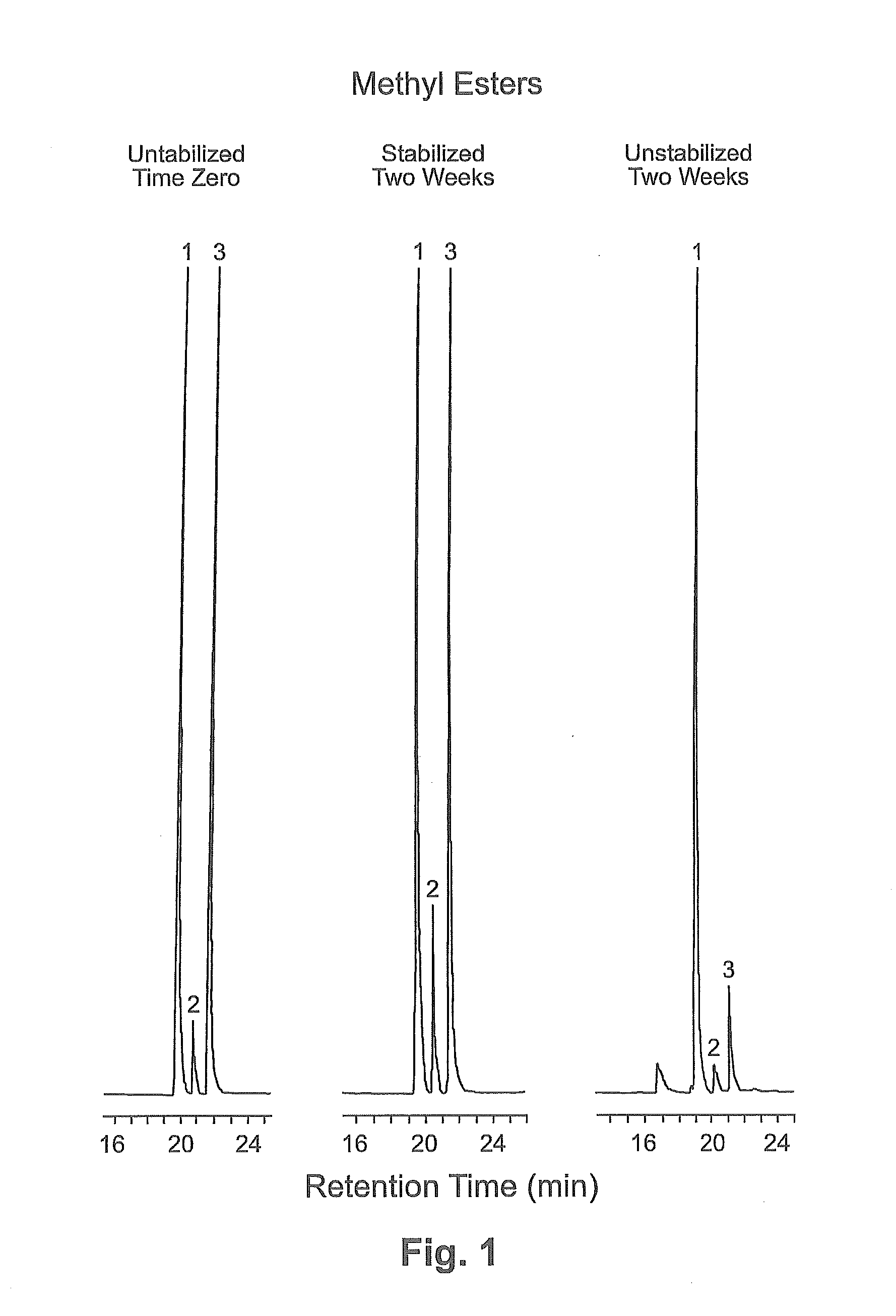

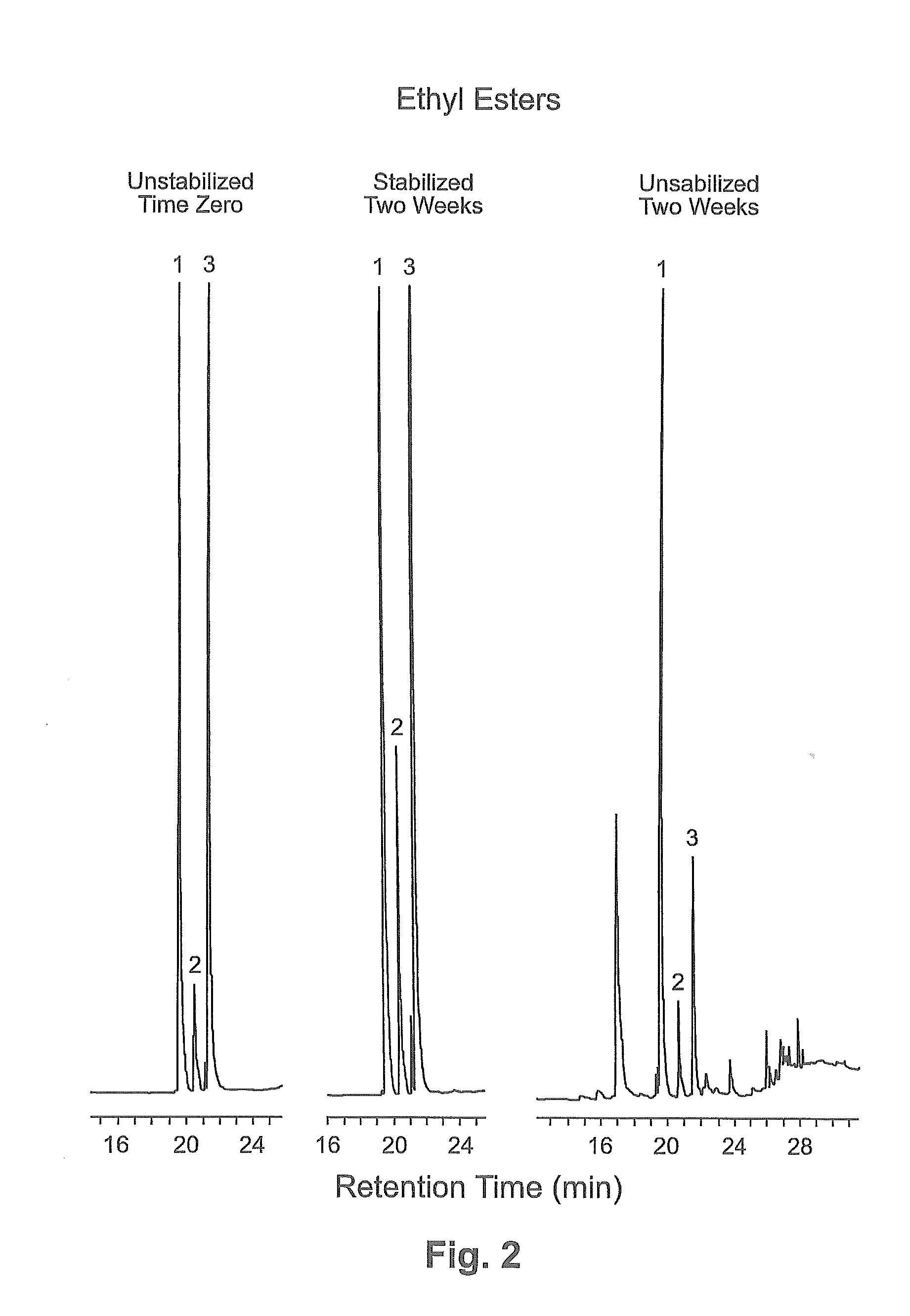

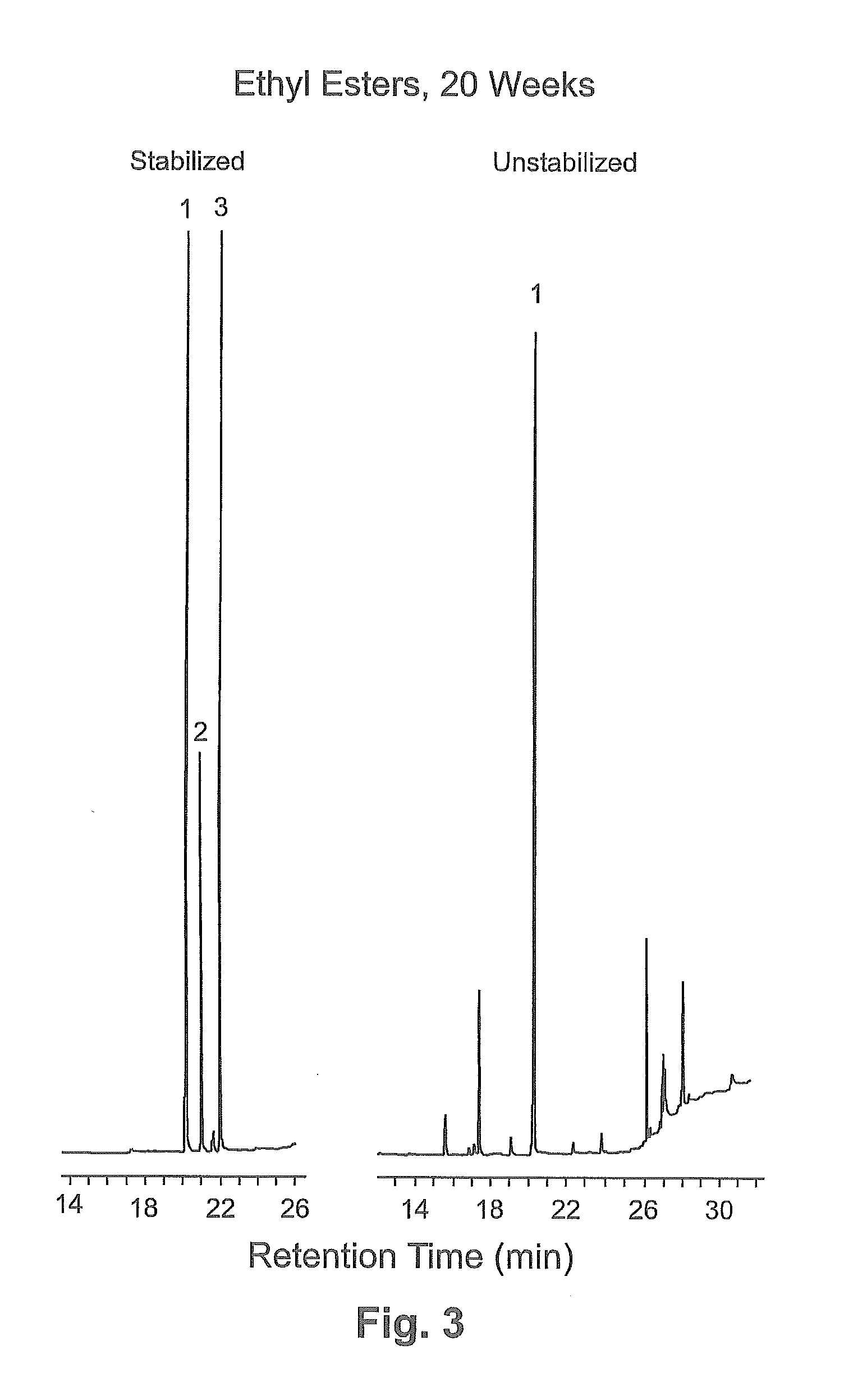

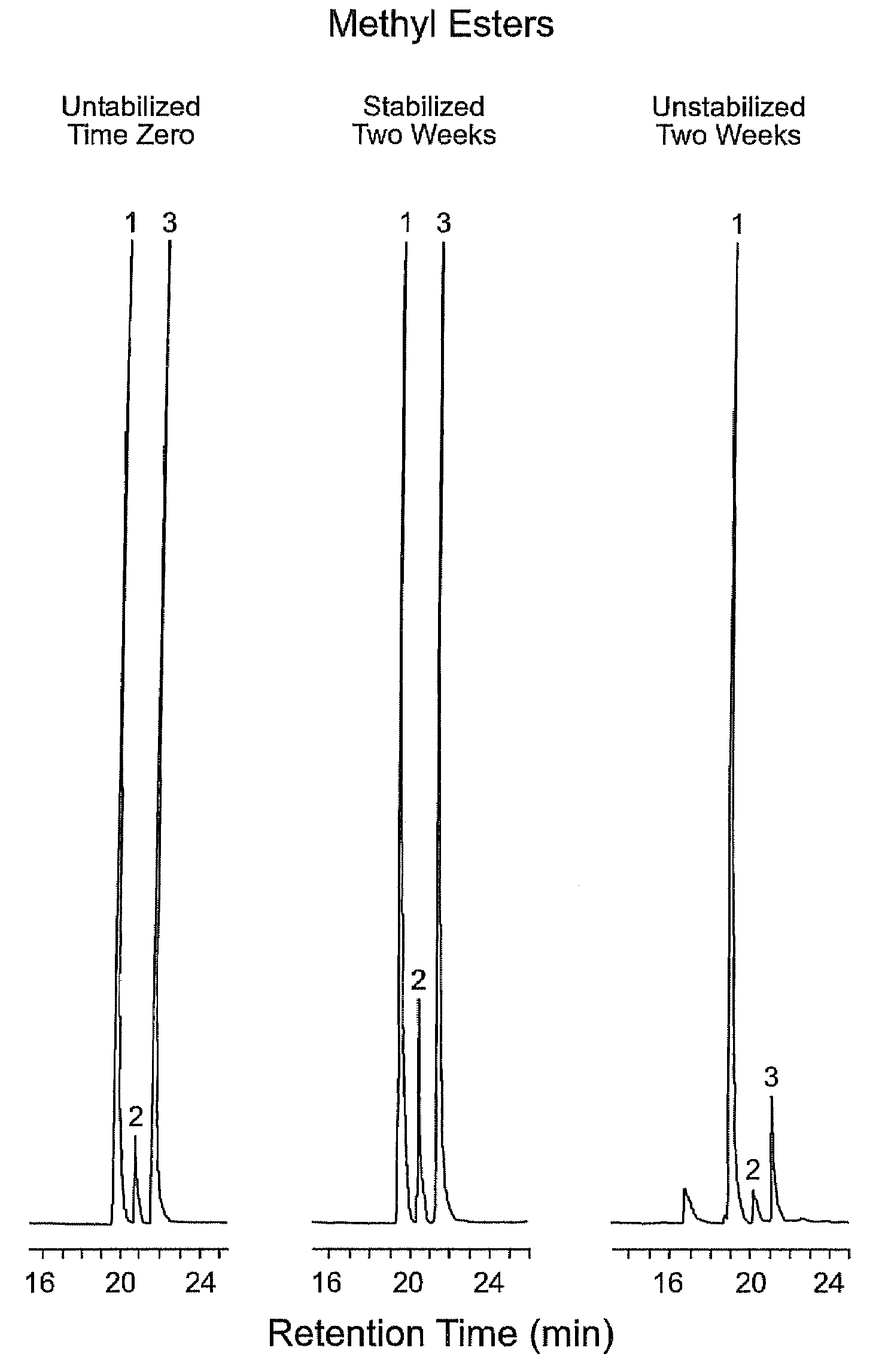

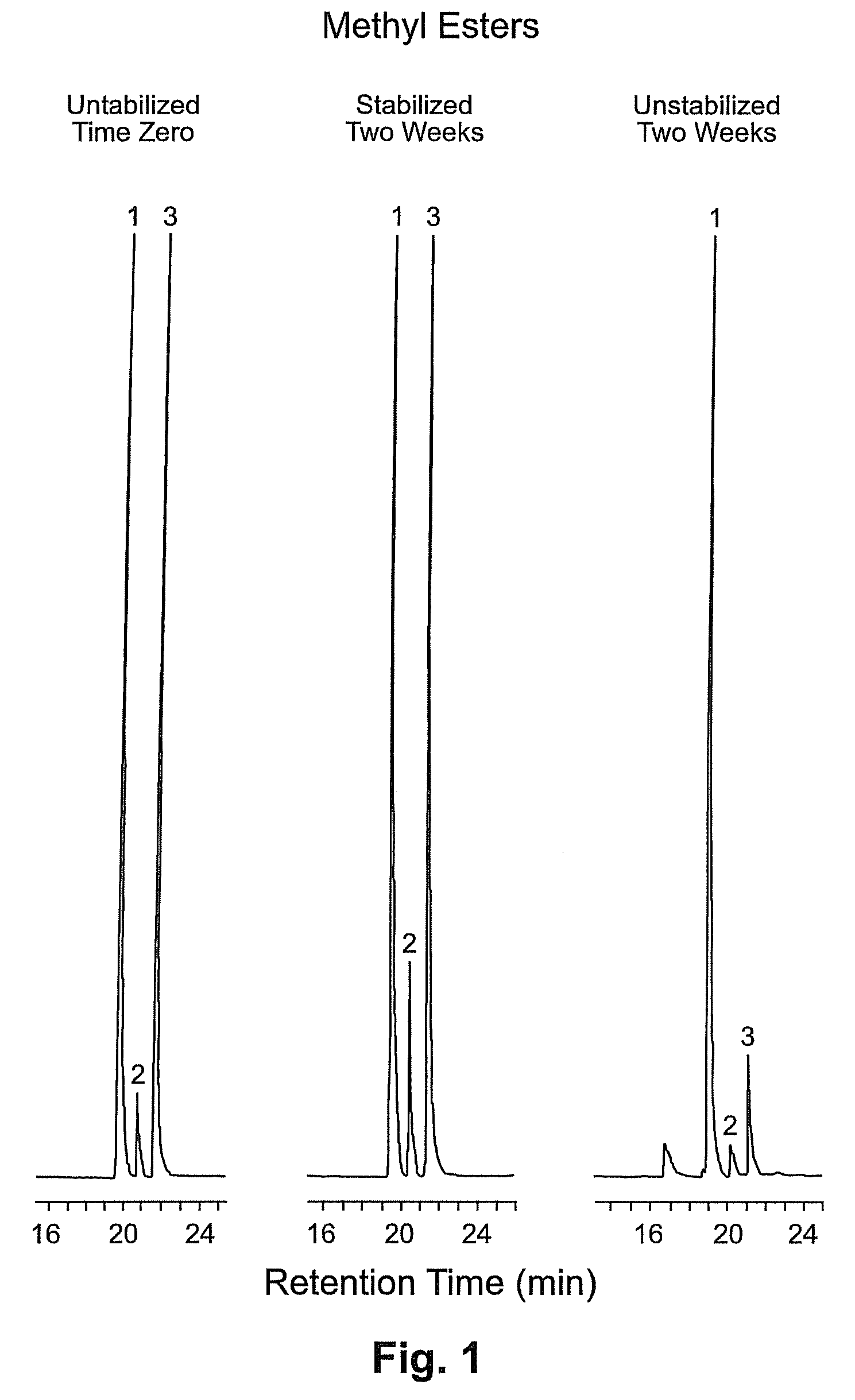

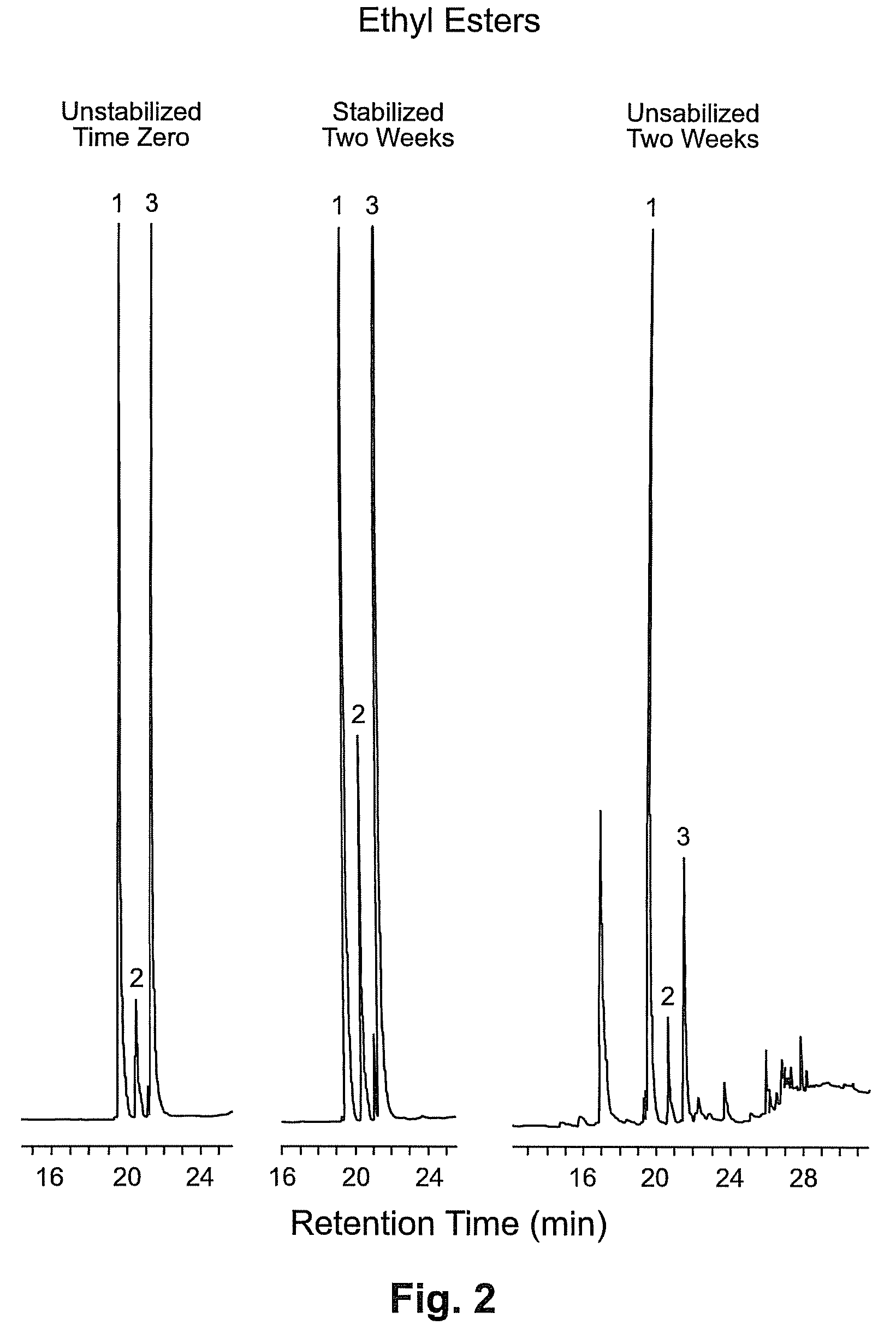

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

ActiveUS7727517B2Raise the ratioLower latencyBiocideHydroxy compound active ingredientsMethyl linoleateEthyl stearate

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

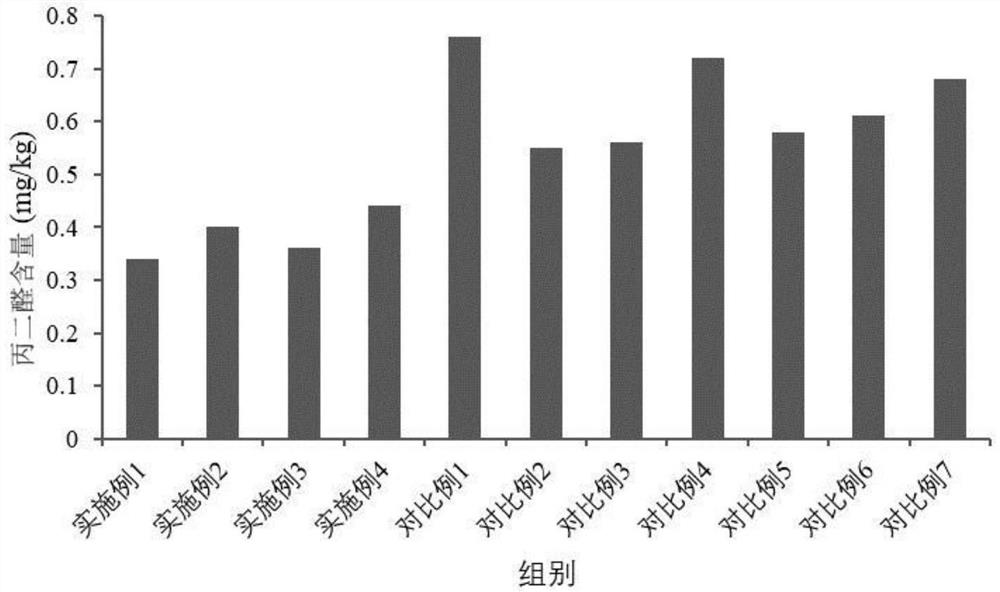

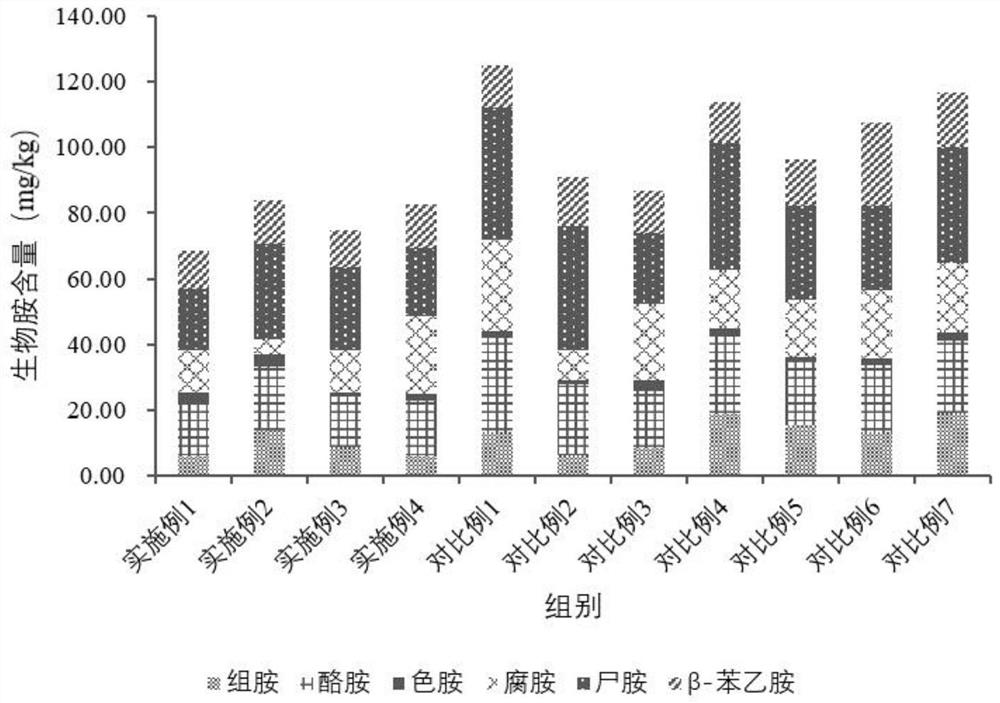

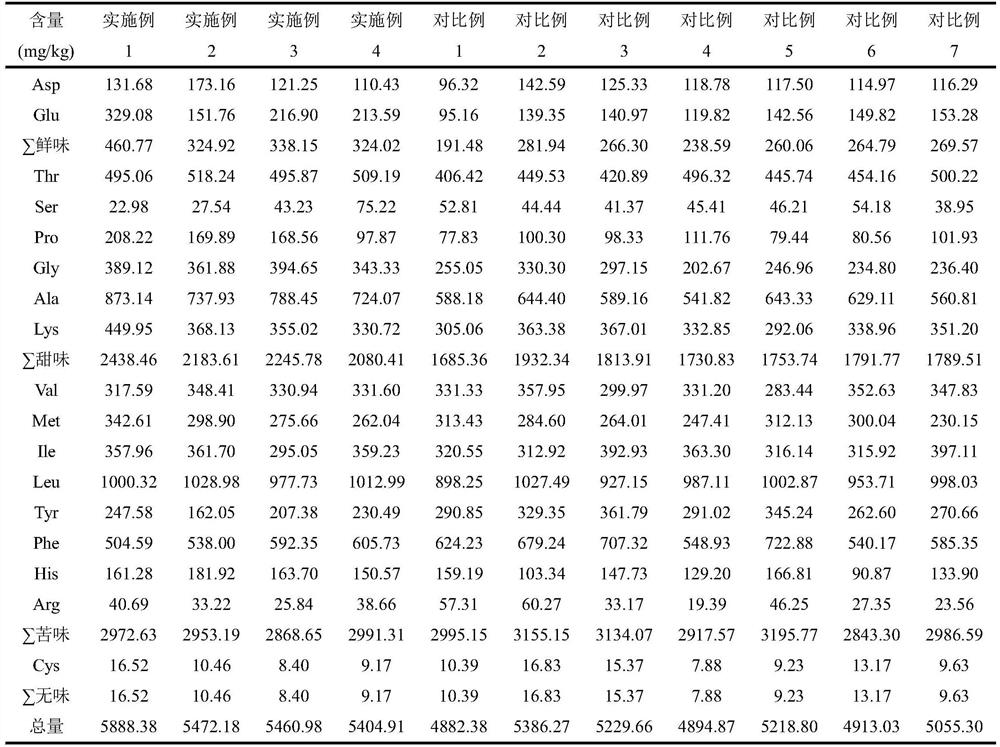

Ester-producing saccharomycetes and application thereof in sour meat production

ActiveCN112940951APrevent fat oxidationImprove qualityFungiClimate change adaptationBiotechnologyPropanoic acid

The invention provides a saccharomycetes LXPSC1, the preservation number of which is CGMCC No. 21289. The invention also provides a sour meat food prepared based on the saccharomycetes and a preparation method of the sour meat food. The preparation method of the sour meat food specifically comprises the following steps that: meat and saccharomycetes LXPSC1 are proportioned according to a proportion of 1g: (7-9) logCFU; and a proper amount of pickling materials and mixing materials are added. The saccharomyces cerevisiae LXPSC1 can inhibit oxidation of acid meat lipid and reduce the content of biogenic amine, so that the safety of the product is improved; besides, the contents of flavor amino acids and esters in the product are increased, and the contents of ethyl caprylate, ethyl caprate, ethyl propionate, ethyl palmitate, ethyl hexanoate and ethyl butyrate are respectively 1.42 times, 2.74 times, 7.49 times, 12.73 times, 4.20 times and 4.00 times of those of sour meat prepared in the prior art, so that the sensory quality such as smell, taste and the like of the sour meat can be effectively improved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

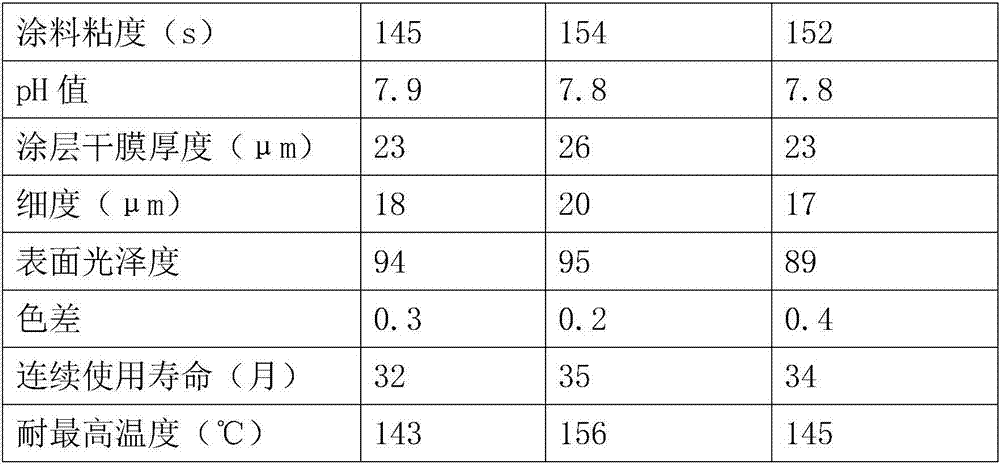

Outer protective paint of glue-injection aluminum alloy profile and preparation method of outer protective paint

InactiveCN106800850AEasy to produceReasonable ratioFireproof paintsDiethylene glycol monobutyl etherPentachlorophenol

The invention discloses an outer protective paint of a glue-injection aluminum alloy profile and a preparation method of the outer protective paint and relates to the technical field of aluminum alloy production. The outer protective paint is prepared from the following materials in parts by weight: acrylate resin, mica powder, red gold powder, polypropylene adipate, dimethicone, isocyanate, phthalic anhydride, zinc pyrithione, ethyl palmitate, an anti-aging agent, diethylene glycol monobutyl ether, a VAE emulsion, ammonium persulfate, lithium bentonite, potassium acetate and pentachlorophenol ketone. The method comprises the steps of (1) fully mixing materials except for a liquid material, stirring and dispersing at 600-650r / min for 10-20min; (2) mixing and stirring the materials in the step (1) and the remaining material, heating the mixture to 90-110 DEG C and lasting for 1-2h; (3) cooling the materials in the step (2) to 50-60 DEG C and carrying out heat preservation for 20-30 minutes; and (4) cooling to a room temperature, lastingly grinding the materials into gel, sealing and carrying out vacuum storage. The outer protective paint is convenient to produce, reasonable in ratio, waterproof, heat-resistant, long in service life, high in caking property, not easy to fall off and low in production cost.

Owner:ANHUI JINGCHANG ALUMINUM

Regeneration method for absorbed and saturated granular active carbons of processing base liquor

The technical scheme of the invention relates to a regeneration method for absorbed and saturated granular active carbon of processing base liquor, which comprises the steps of: combusting and ashing absorbed substances, which mainly comprises higher aliphatic acids as well as incendive substances, such as ethyl palmitate, ethyl oleate, ethyl linoleate and the like, of the absorbed and saturated granular active carbons of the processed base liquor at the high temperature 500-6000 DEG C; measuring the iodine absorption rate after the saturated granular active carbons are subjected to washing, activating by high temperature steam, drying and cooling; sieving and grading packaging the processed absorbed and saturated granular active carbons; and using coarse active carbons as granular active carbons and fine active carbons as powder active carbons after crushing. Therefore, the regeneration purpose is realized.

Owner:桂林湘山酒业有限公司

Additive for preparing butter sculpture

The invention relates to an additive for preparing butter sculpture and belongs to the technical field of building materials. The additive is prepared from, by weight, 0.2-0.6 part of glyceryl caprylate-caprate, 0.03-0.06 part of ethyl palmitate, 0.2-0.4 part of acetic acid, 0.3-0.5 part of capric acid, 0.02-0.08 part of trioctyl phosphate, 0.1-0.3 part of 2,6-ditert-butyl-4-methylphenol, 0.02-0.04 part of p-phenylenediamine and 0.2-0.5 part of stearic acid. By fully utilizing the characteristics of the raw material butter, raw material plasticity and stability are improved during butter sculpture preparation, the oxidation resistance of the finished butter sculpture is improved during storage and does not change much with temperature, the exhibition period of the butter sculpture can be prolonged, and the artistic value of the butter sculpture is increased.

Owner:王永妍

Stabilized Synthetic Brood Pheromone and Race-Specific Ratios of Components for Manipulating the Behavior and Physiology of Honey Bees

ActiveUS20110021622A1Raise the ratioIncrease load weightBiocideDead animal preservationMethyl linoleateEthyl stearate

This invention relates to a 10-component stabilized synthetic honey bee brood pheromone and methods of stabilizing said pheromone by adding one or more antioxidants, thereby enabling the production and sustained use of commercial products based on that pheromone. The 11-component stabilized pheromone composition formed by adding the antioxidant tertiary-butyl hydroquinone to a synthetic blend of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate can be used in generic or race-specific ratios to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive.

Owner:TEXAS A&M UNIVERSITY +1

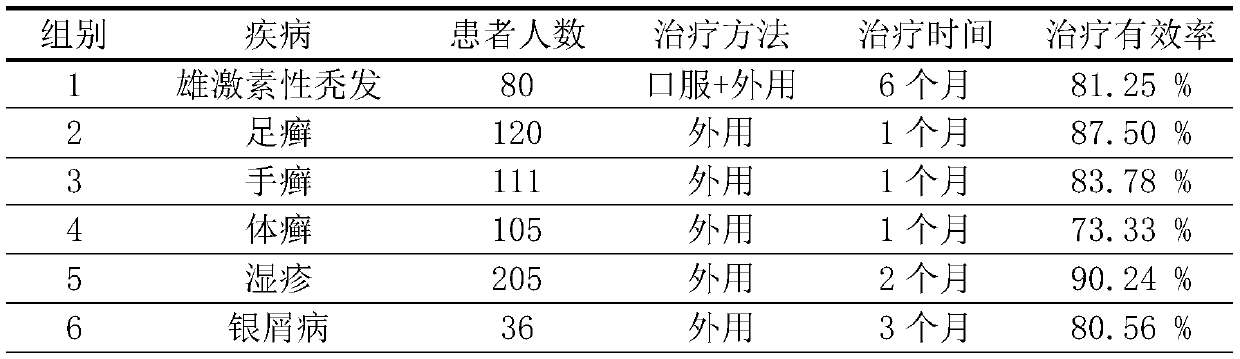

No-clean soldering flux for copper wire processing

InactiveCN104084713AAvoid disadvantagesImprove solderabilityWelding/cutting media/materialsMetal working apparatusEthylenediamineGlutaric acid

The invention discloses a no-clean soldering flux for copper wire processing, which is characterized by comprising the following components in percentage by weight: 60-120 g / l of isopropanol, 60-120 g / l of ethylene glycol, 2-6 g / l of oxidized polyethlene wax, 2-6 g / l of glutaric acid, 2-6 g / l of tetraethylene glycol dimethyl ether, 60-120 g / l of hydrogenated rosin, 30-60 g / l of ethyl palmitate, 2-6 g / l of benzotriazole, 2-6 g / l of lauryl alcohol-polyoxyethylene ether, 2-6 g / l of calcium chloride, 60-120 g / l of methanol, 2-6 g / l of ethanediamine and the balance of water. The no-clean soldering flux has the benefits of no halogen contained, good weldability, low solid content, less residue after welding, no cleaning needed and high insulation resistance; as deionized water is used as a solvent, VOCs (Volatile Organic Compounds) can be completely prevented; the no-clean soldering flux is an environmentally-friendly soldering flux and cannot be burned at all; the no-clean soldering flux has excellent performance and can overcome the defect of an existing no-clean soldering flux, and well meet the environment-friendly requirement requirements during the use.

Owner:NINGGUO XINBONENG ELECTRONICS

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

ActiveUS20080124300A1Raise the ratioIncrease load weightBiocideHydroxy compound active ingredientsMethyl linoleateAntioxidant

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

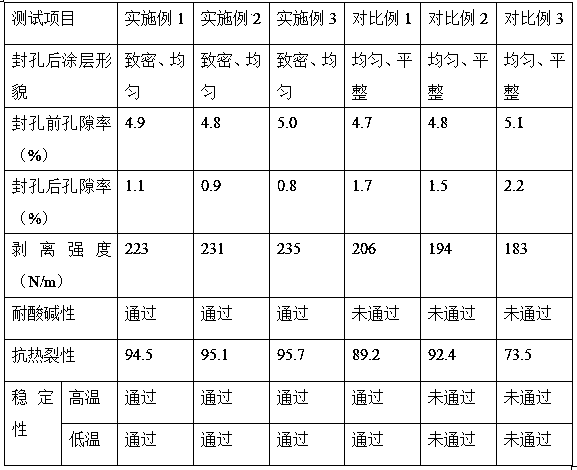

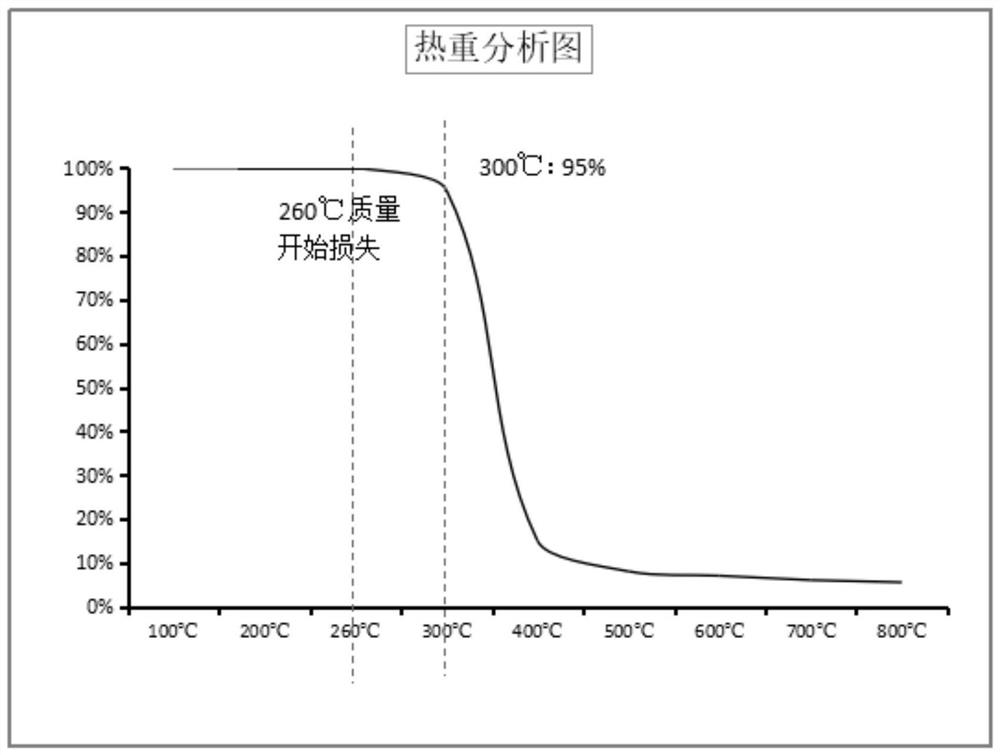

Preparation method of hole sealing agent of aluminum alloy anode oxidation film

PendingCN110453265AIncrease penetration depthPrevent hardeningSurface reaction electrolytic coatingChemical treatmentFriction reduction

The invention belongs to the technical field of material surface chemical treatment, and particularly relates to a preparation method of a hole sealing agent of an aluminum alloy anode oxidation film.The preparation method comprises the following steps of preparing dry gel, oleic acid, hexogen into explosive, carrying out detonation to obtain carbon-coated aluminum nano-particles, then mixing microbial oil, ethyl palmitate, amino lithium and the like to obtain lubricating dispersied oil, by using rapeseed oil acid, azelaic acid, and neopentyl glycol as a raw material to be subjected to esterification to obtain mixed ester, doping the carbon-coated aluminum nano-particles into the mixed ester, and preparing the hole sealing agent of the aluminum alloy anode oxidation film, aluminum plays arole in friction reduction and wear resistance when a microhole of the aluminum alloy anodized film is worn, part of the aluminum can still be oxidized to form aluminum oxide and fused with the anodic oxidation film to form homogeneous phase, so that the wear resistance and the anti-oxidation effect of the hole sealing agent are improved; the lubricating dispersed oil plays an excellent dispersing effect, so that the penetration depth of the hole sealing agent is improved; and the carbon-coated aluminum nano-particles have an anti-oxidation function, hardened organic components after hole sealing are prevented from being oxidized, and the preparation method has a wide application prospect.

Owner:刘军伟

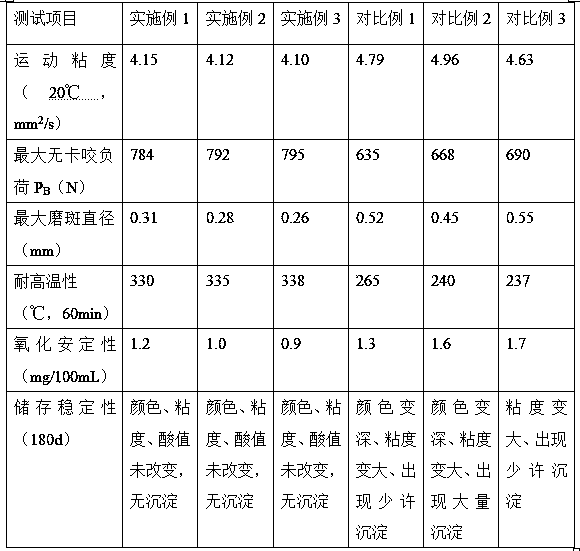

Preparation method of anti-wear agent

InactiveCN110484330AWith surface modificationWith anti-friction and anti-wear effectAdditivesMicrobial oilCalcite

The invention belongs to the technical field of preparation of lubricating materials, and particularly relates to a preparation method of an anti-wear agent. The preparation method comprises the following steps: preparing anti-wear suspension by taking multi-walled carbon nanotubes as a raw material; mixing and heating microbial oil, ethyl palmitate, lithium amide and the like to obtain an esterification product; finally, distilling an antioxidant lubricating grease crude product to obtain antioxidant lubricating grease; subjecting rapeseed oleic acid, azelaic acid and neopentyl glycol which are used as raw materials to esterification to obtain mixed ester; adding the mixed ester into the anti-wear suspension to obtain the anti-wear agent. Aluminum in the anti-wear suspension in the anti-wear agent participates in a local metallurgical reaction to achieve surface modification so that the anti-friction and anti-wear effects are achieved; an aluminum oxide passivation film can be formedto improve extreme pressure lubricating and antioxidant performance. Through the high polarity of the antioxidant lubricating grease, the conversion rate of the calcite crystal form formed by calciumlignosulphonate is improved, and the high-temperature resistance and the self-repairing performance of a lubricant are improved, such that the prepared anti-wear agent has broad application prospects.

Owner:刘群艳

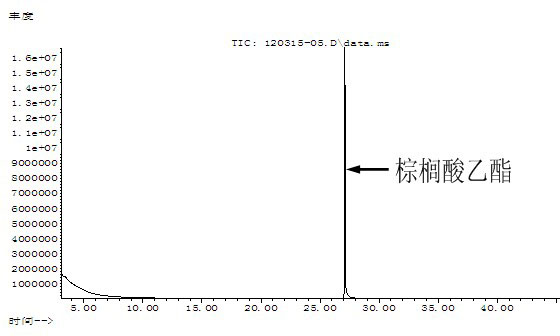

Method for synthesizing ethyl palmitate by using deep eutectic solvent catalyst based on dodecyltrimethylammonium chloride

PendingCN111153794ALess corrosiveReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystDistillation

The invention discloses a method for preparing ethyl palmitate by using a deep eutectic solvent DTAC-DES based on dodecyltrimethylammonium chloride as a catalyst. The catalyst DTAC-DES is prepared bymixing dodecyltrimethylammonium chloride and p-toluenesulfonic acid according to a molar ratio of 1:3; and the ethyl palmitate is prepared by performing an esterification reaction on palmitic acid andexcessive anhydrous ethanol at a certain temperature, and sequentially performing phase separation, atmospheric distillation, reduced pressure distillation and other processes. The method has the advantages of mild reaction conditions, small corrosion of the catalyst to equipment, no waste acid discharge, no pollution and environmental friendliness; and the acidic eutectic solvent is high in catalytic activity, can be repeatedly used after being recycled, and is low in industrial production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Water pump external layer protection coating and preparation method thereof

InactiveCN107163757AHigh strengthImprove uniformityFireproof paintsMulticolor effect coatingsSodium PyrithioneAcrylic resin

The invention relates to a water pump external layer protection coating and a preparation method thereof, and relates to the technical field of pump productions. The coating is prepared from acrylic resin, mica powder, cupric gold powder, polypropylene adipate, dimethicone, isocyanate, phthalic anhydride, zinc pyrithione, ethyl palmitate, an antioxidant, diethylene glycol butyl ether, a VAE emulsion, white latex, beeswax, an antifoaming agent, a thickener, petroleum coke powder, aqueous stock white and deionized water. The preparation method comprises the following steps: 1, fully mixing all above materials except liquid materials, and stirring and dispersing the mixed materials; 2, milling all solid raw materials, adding all the solid raw materials into a container, adding the above liquids, and fully mixing the solid raw materials with the liquids to carry out emulsifying treatment; 3, cooing a material obtained in step 2 to 50-60 DEG C, and keeping the temperature for 20-30 min; and 4, cooing the stirred material to normal temperature, and continuously grinding the cooled material to form gel. The coating has the advantages of difficulty in scratch, convenience in production, long service life, good resistance to water and a high temperature, and long service life.

Owner:张黎明

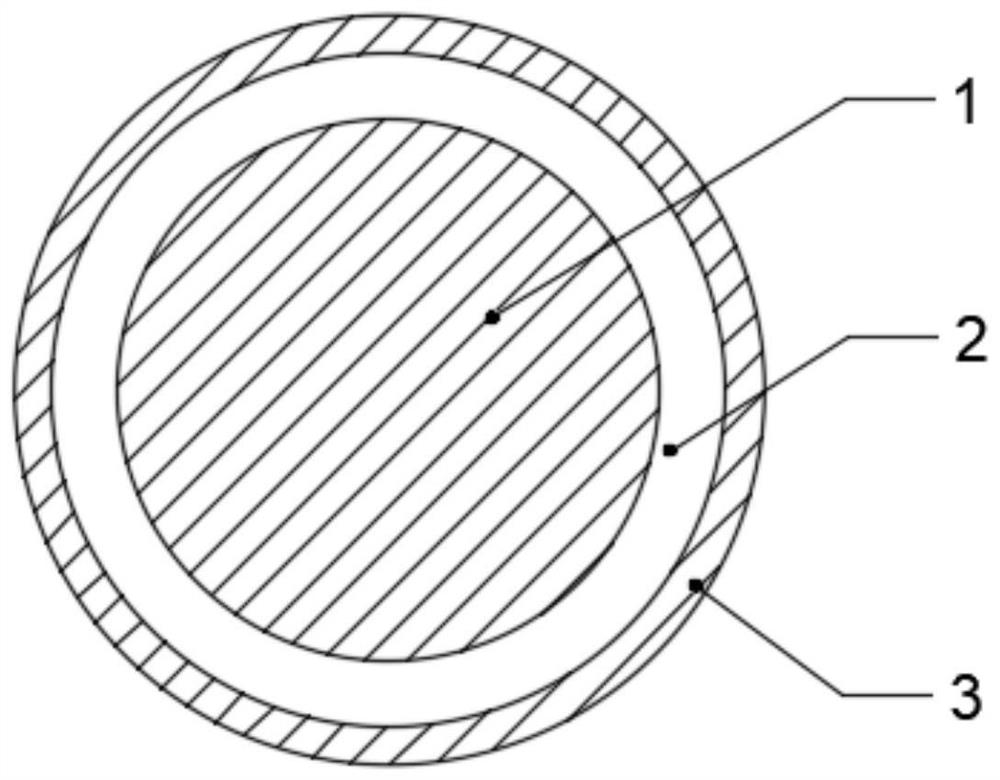

Phase change microcapsule, and phase change microcapsule fiber and preparation method thereof

PendingCN112552878AHas a high enthalpy valueImprove high temperature resistanceHeat-exchange elementsConjugated synthetic polymer artificial filamentsPolymer scienceMethyl tetradecanoate

The invention belongs to the technical field of fibers, and particularly relates to a phase change microcapsule, which is composed of a phase change core and a shell, wherein the phase change core iscoated with the shell, the phase change core comprises one or more of methyl myristate, ethyl palmitate, butyl stearate and ph, ph is n-alkane with 18 carbon atoms, and the shell comprises one or moreof starch, polyurethane, urea resin and PMMA. The invention also relates to a phase change microcapsule fiber, which comprises a phase change microcapsule and a dyeable shell, wherein the dyeable shell is coated outside the phase change microcapsule. The invention also relates to a preparation method of the phase change microcapsule fiber. The preparation method comprises the following steps: preparing an emulsion; preparing a phase change microcapsule; and preparing a dyeable shell, and preparing phase change microcapsule fibers from the phase change microcapsules added with the dyeable shell through melt spinning. According to the invention, the phase change microcapsule has the functions of high temperature resistance and oxidation resistance, and the fiber prepared from the phase change microcapsule has a high enthalpy value and good high temperature resistance.

Owner:杭州乐铭科技有限公司

Preparation method of antioxidant dry film lubricating agent

InactiveCN110041988AImprove high temperature resistanceAvoid surface hardeningAdditivesMicrobial oilFriction reduction

The invention belongs to the technical field of preparation of lubricating agents, and particularly relates to a preparation method of an antioxidant dry film lubricating agent. The preparation methodcomprises the steps that xerogel, oleic acid and hexogen are produced to be explosive, carbon-coated aluminum nano particles are obtained through detonation, microbial oil, ethyl palmitate and lithium amide are mixed to obtain an esterified product, and finally a biological lubricating oil crude product is distilled to obtain biological lubricating oil. Rapeseed oleic acid and azelaic acid serveas raw materials to prepare the antioxidant dry film lubricating agent, the substance ingredient of the frictional surface is changed after carbon-coated aluminum nano particles are blended in the lubricating oil, thus the friction reduction and abrasion resistant effects are achieved, and the extreme pressure lubricating property is improved. The lubricating effect is enhanced by utilizing the biological grease, the transformation rate from lignin sulfonic acid calcium to calcite crystal form is increased through the high polarity of the biological lubricating oil, the high temperature resistance of the lubricating agent is improved, the microbial lubricating oil is subjected to oxidation to generate high temperature antioxidant groups under the factors of high temperature and oxygen generated by friction, and the antioxidant dry film lubricating agent has the wide application prospect.

Owner:李辉

Method of using macroporous strongly acidic type cation exchange resin to catalytically synthesize ethyl palmitate

InactiveCN102617346ANo emissionsMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationPtru catalystDistillation

The invention discloses an ethyl palmitate preparation method, which belongs to the field of organic chemical industrial synthesis. The method includes: using strongly acidic type cation exchange resin which is NKC-9 macroporous dry hydrogen catalyst resin as catalyst, using cyclohexane as a water carrying agent, and reacting palmitic acid with excessive absolute ethyl alcohol; subjecting the solution containing resin after reaction to filtering, cyclohexane washing and separating to recover the catalyst, removing redundant ethanol and cyclohexane through atmospheric distillation, and obtaining ethyl palmitate after reduced pressure distillation and drying. The ethyl palmitate preparation method is mild in reaction condition, the catalyst is noncorrosive to equipment, waste acid discharge is avoided, and accordingly pollution is avoided while environment friendliness is achieved. The strongly acidic type cation exchange resin is high in catalytic activity and recyclable after recovery and activation, so that catalyst production cost is reduced. Moreover, the ethyl palmitate preparation method is simple in synthesis process and high in yield and meets the green synthesis process requirements.

Owner:NORTHWEST NORMAL UNIVERSITY

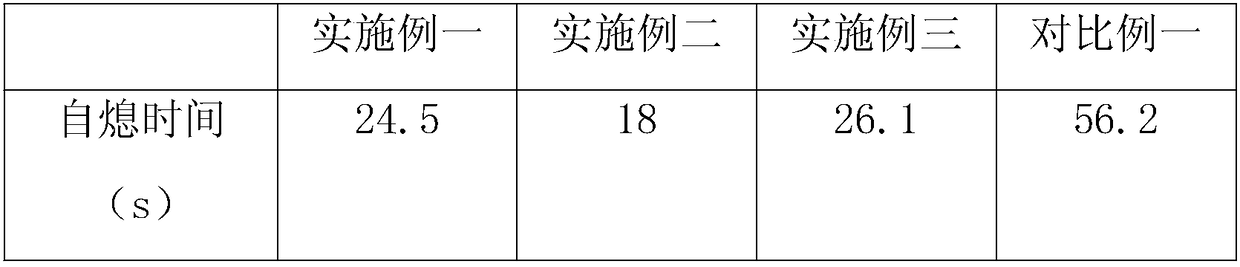

Thermoplastic elastomer halogen-free flame retardant cable material for external use and preparation method thereof

InactiveCN108641344AImprove thermoplasticityThermoplastic Reinforced ElasticityPlastic/resin/waxes insulatorsEthyl palmitateEngineering

The invention belongs to the technical field of cable materials for external use and particularly discloses a thermoplastic elastomer halogen-free flame retardant cable material for external use and apreparation method thereof. The problems are solved that due to mixing of a large number of inorganic flame retardants, the thermoplasticity and elasticity of filling materials in the prior art are weakened, the flexibility performance of the materials declines, and the service life is short. The thermoplastic elastomer halogen-free flame retardant cable material for external use is prepared from20-30 parts of thermoplastic polyurethane, 15-35 parts of polyethylene resin, 1-2.5 parts of sodium dihydrogen phosphate, 1.5-5 parts of expanded vermiculite, 2-3 parts of ethyl palmitate, 0.2-0.3 part of anti-aging agent and 0.2-0.5 part of heat stabilizer. The cable material has excellent thermoplasticity, elasticity, fire resistance, anti-aging performance and thermostability. Adopted raw materials are safe and environmentally friendly, a formula is scientific, the proportion is rigorous, the preparation method is simple, reaction conditions are mild, industrial production is easily achieved, and the thermoplastic elastomer halogen-free flame retardant cable material is worthy of popularization.

Owner:ANHUI NIKOLA ELECTRONICS TECH CO LTD

Method for synthesizing 1-(6-nitrobenzimidazolyl)ethyl palmitate on line under catalysis of lipase

ActiveCN104561173AShort reaction timeImprove conversion rateFermentationEthyl palmitateReaction temperature

The invention discloses a method for synthesizing 1-(6-nitrobenzimidazolyl)ethyl palmitate on line under the catalysis of lipase. The method comprises the steps of with 6-nitro-benzimidazole and vinyl palmitate which are in the molar ratio of 1:(1-8) as raw materials, 0.5-1.0g of lipase Lipozyme TLIM as a catalyst and a DMSO solvent as a reaction solvent, uniformly filling a reaction channel of a microfluidic channel reactor with the lipase Lipozyme TLIM, wherein the internal diameter of the reaction channel of the microfluidic channel reactor is 0.8-2.4mm, and the reaction channel is 0.5-1.0m long; and continuously introducing the raw materials and the reaction solvent to the reaction channel to carry out Markovnikov addition reaction, controlling the reaction temperature at 40-55 DEG C and the reaction time at 20-35 minutes, collecting a reaction solution on line, and carrying out conventional treatment on the reaction solution to obtain 1-(6-nitrobenzimidazolyl)ethyl palmitate. The method has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

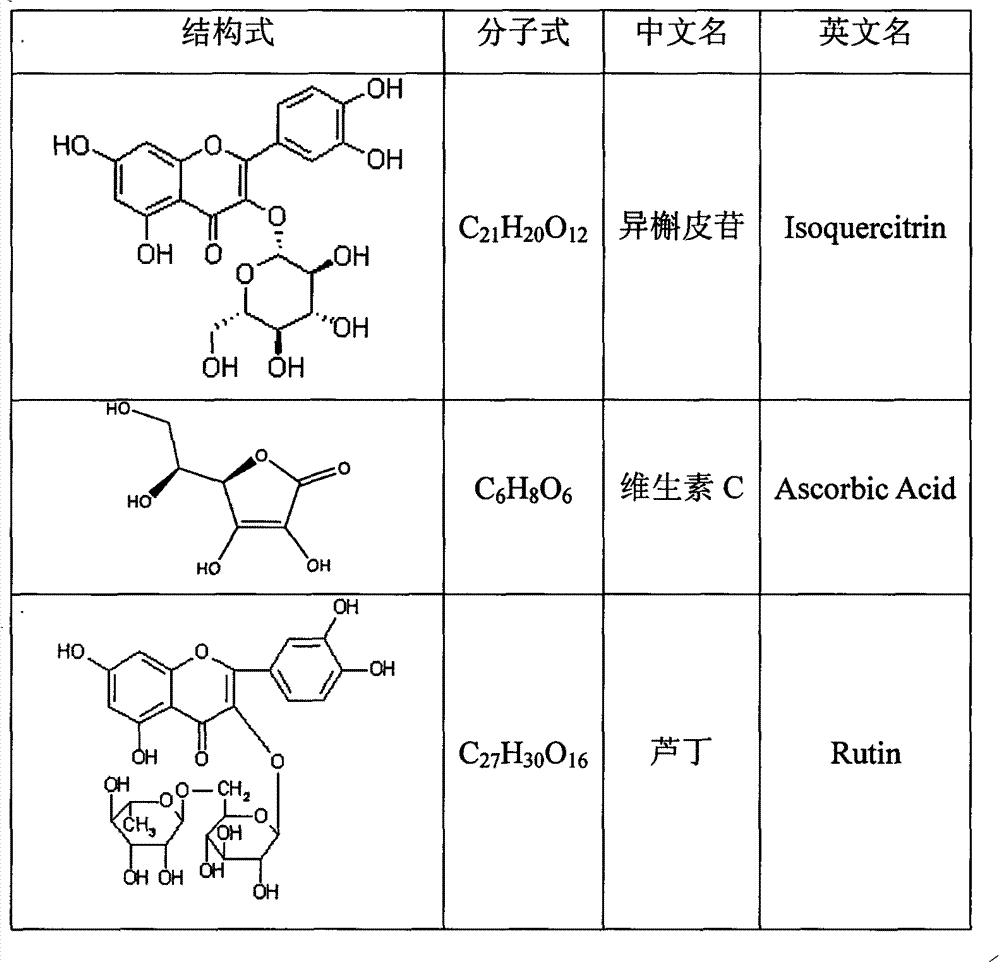

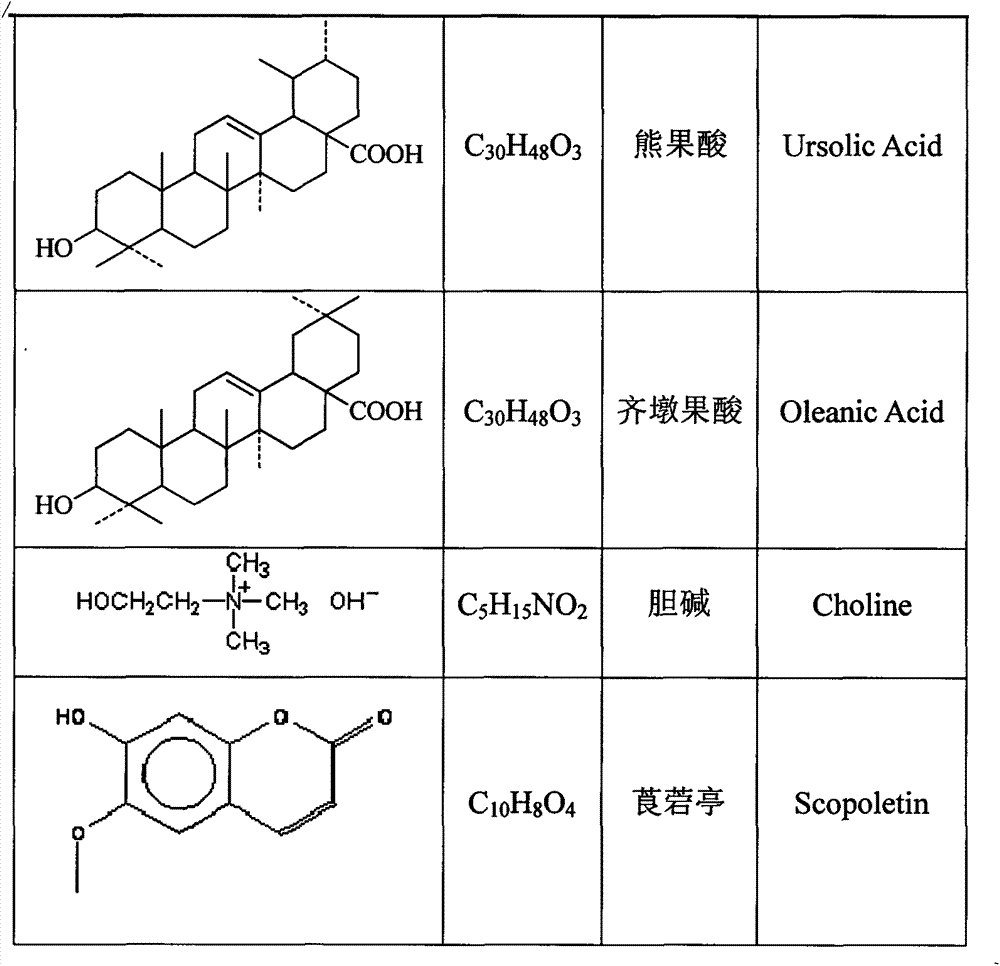

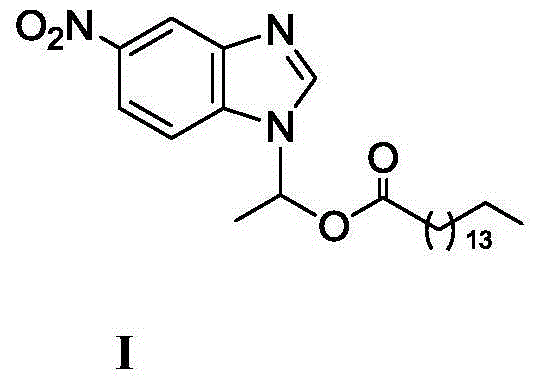

Herba speranskiae tuberculatae and cacumen platycladi mixed extract and extraction process and application thereof

ActiveCN110051719AEnsure the uniformity of qualityAccurate removalAntimycoticsDermatological disorderPhellandreneEthyl palmitate

The invention discloses a herba speranskiae tuberculatae and cacumen platycladi mixed extract. The mixed extract comprises pinene, 2-carene, limonene, trans-caryophyllene, terpinyl acetate, phellandrene, palmitic acid, ethyl palmitate, 1-methoxy butane, 5,6,7,7A-tetrahydro-2(4H)-benzofuranone, 6,10,14-trimethyl-2-pentadecanone, methyl hexadecanoate and dibutyl phthalate. The herba speranskiae tuberculatae and cacumen platycladi mixed extract is mainly applicable to treatment of androgenetic alopecia and dermatomycosis such as tinea pedis, tinea manuum and tinea corporis. Herba speranskiae tuberculatae and cacumen platycladi are both clinical common medicines and are cheap, convenient to acquire, high in safety coefficient and available for oral administration and external application. Theextract is simple in use, high technical requirements on extraction are avoided, conventional traditional Chinese medicine impurities can be effectively removed, medicine purity is improved, extract effective components and reasonable compatibility are realized, a utilization process is simplified, and medicine quality uniformity is guaranteed.

Owner:嘉兴市中医医院

Poplar pencil coating and preparation method thereof

Owner:安徽杰可森木业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com