Phase change microcapsule, and phase change microcapsule fiber and preparation method thereof

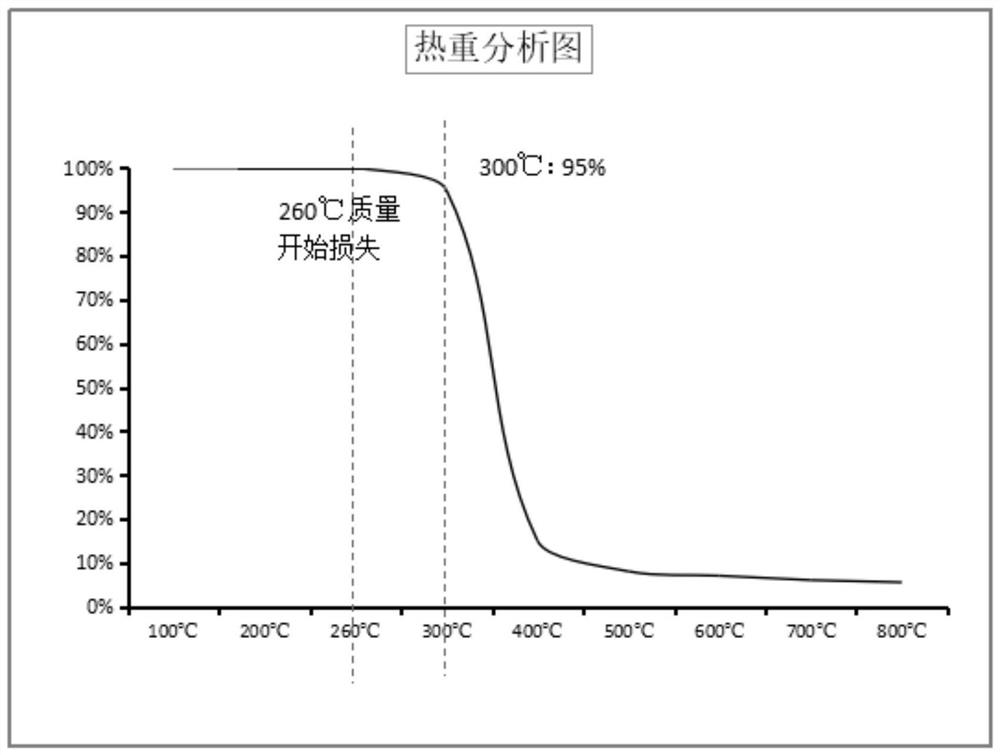

A phase-change microcapsule and phase-change technology, applied in the field of fibers, can solve the problems of material leakage, lack of intelligent temperature adjustment, etc., and achieve good high temperature resistance and comfortable wearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

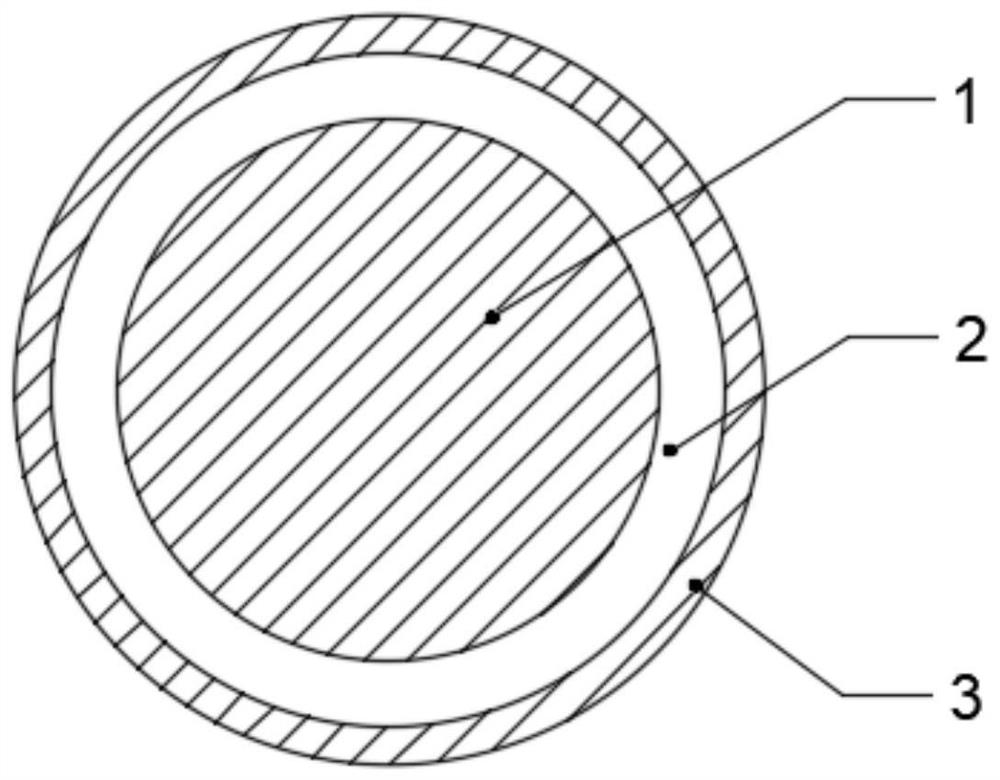

[0030] This embodiment provides a kind of phase-change microcapsules, which is composed of a phase-change core and a shell, and the shell is coated outside the phase-change core; the phase-change core includes methyl myristate, and the shell includes polyurethane, wherein the phase-change microcapsules The mass ratio of phase change core to shell is 5:5.

[0031] This embodiment also provides a phase-change microcapsule fiber, including phase-change microcapsules and a dyeable shell, where the dyeable shell includes silicon dioxide.

[0032] This embodiment also provides a preparation method of phase change microcapsule fiber, comprising the following steps:

[0033] (1) Mix 5.5g of ethyl palmitate, 4.5g of starch, 2g of polysorbate-80 and 2g of polyvinyl alcohol, then slowly add 150ml into the water, stir while adding, when emulsified to a uniform dispersion system, slowly add 8g of polyethylene glycol and 0.03g of triethylenediamine were stirred at 20°C for 30mins, the stir...

Embodiment 2

[0037] A kind of preparation method of phase change microcapsule fiber of the present embodiment, comprises the following steps:

[0038] (1) Mix 6g of butyl stearate, 4g of polyurethane, polyurethane as polyethylene glycol, 3g of polysorbate-80 and 2g of polyvinyl alcohol, and then slowly add it to 200ml of water, stir while adding, and emulsify until uniform When dispersing the system, slowly add 8g of polyethylene glycol and triethylenediamine, stir at 30°C for 30mins, stir at 3000rpm, slowly raise the temperature to 80°C, add 4ml of ethylene glycol and react for 1.5h, that is, the phase change core is prepared phase change microcapsules.

[0039] (2) Add a layer of dyeable shell outside the shell of the phase change microcapsule, the dyeable shell is silicon dioxide. Add citric acid, acetic acid and ethanol to the microcapsule solution through ethyl orthosilicate, hydrolyze at 40°C for 12 hours at pH = 6, and pass through ammonia gas after hydrolysis, and the silica sol b...

Embodiment 3

[0042] A kind of preparation method of phase change microcapsule fiber of the present embodiment, comprises the following steps:

[0043] (1) Mix 7g of methyl myristate, 3g of polyurethane, polyurethane is toluene diisocyanate, 2g of polysorbate-80 and 2g of polyvinyl alcohol, and then slowly add it to 150ml of water, stir while adding, when emulsified to uniform dispersion In the system, slowly add 6g of polyethylene glycol and 0.02g of triethylenediamine, stir at 20°C for 30mins, the stirring speed is 6000rpm, slowly raise the temperature to 80°C, add 4ml of ethylene glycol and react for 1h, that is, the phase change core is prepared phase change microcapsules.

[0044] (2) Add a layer of dyeable shell outside the shell of the phase change microcapsule, the dyeable shell is silicon dioxide. Add citric acid, acetic acid and ethanol to the microcapsule solution through ethyl orthosilicate, hydrolyze at 60°C for 12 hours at pH = 5, and pass through ammonia gas after hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com