Preparation method of anti-wear agent

An anti-wear agent and technology of preparation steps, applied in the field of lubricating material preparation, can solve the problems of precipitation, affecting the anti-wear effect of anti-wear agent, easy oxidation of inorganic nanoparticles, etc., to enhance the lubrication and dispersion effect, improve extreme pressure lubrication and The effect of antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

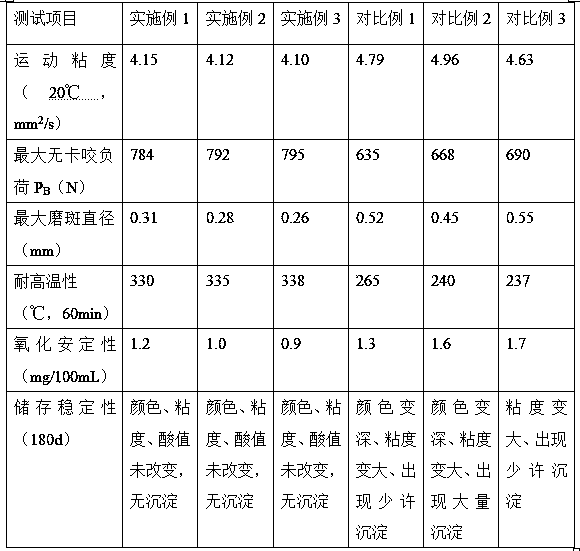

Examples

Embodiment 1

[0031] Preparation of carbon nanotube dispersion:

[0032] In parts by weight, add 20 parts of multi-walled carbon nanotubes to 100 parts of ethyl acetate to obtain a mixed solution, place the mixed solution in a high-speed disperser, and disperse at a high speed of 7000r / min for 18 minutes to obtain carbon nanotubes Dispersions.

[0033] Preparation of anti-wear suspension:

[0034] In parts by weight, mix 30 parts of polytetrafluoroethylene powder with 50 parts of carbon nanotube dispersion liquid, place in a stirred tank and stir at a speed of 700r / min for 20min, then reduce the stirring speed to 300r / min, and pour into the stirred tank 20 parts of hexamethylene diisocyanate, 10 parts of acetic acid, 20 parts of nano-aluminum powder and 8 parts of heptadecylfluorodecyltriethoxysilane were added to the mixture, and stirred for 30 minutes to obtain an anti-wear suspension.

[0035] Preparation of active molybdenite powder:

[0036] Take 200g of molybdenite ore and put it i...

Embodiment 2

[0044] Preparation of carbon nanotube dispersion:

[0045] In parts by weight, add 23 parts of multi-walled carbon nanotubes to 110 parts of ethyl acetate to obtain a mixed solution, place the mixed solution in a high-speed disperser, and disperse at a high speed of 7250r / min for 19 minutes to obtain carbon nanotubes Dispersions.

[0046] Preparation of anti-wear suspension:

[0047] In parts by weight, 33 parts of polytetrafluoroethylene powder and 53 parts of carbon nanotube dispersion were mixed, placed in a stirred tank and stirred at a speed of 750r / min for 23min, then the stirring speed was reduced to 350r / min, and poured into the stirred tank 23 parts of hexamethylene diisocyanate, 13 parts of acetic acid, 21 parts of nano-aluminum powder and 9 parts of heptadecafluorodecyltriethoxysilane were added to it, and stirred for 33 minutes to obtain an anti-wear suspension.

[0048] Preparation of active molybdenite powder:

[0049] Take 210g of molybdenite ore and put it i...

Embodiment 3

[0057] Preparation of carbon nanotube dispersion:

[0058] In parts by weight, add 25 parts of multi-walled carbon nanotubes to 120 parts of ethyl acetate to obtain a mixed solution, place the mixed solution in a high-speed disperser, and disperse at a high speed of 7500r / min for 20 minutes to obtain carbon nanotubes Dispersions.

[0059] Preparation of anti-wear suspension:

[0060] In parts by weight, 35 parts of polytetrafluoroethylene powder and 55 parts of carbon nanotube dispersion were mixed, placed in a stirred tank and stirred at a speed of 800r / min for 25min, then the stirring speed was reduced to 400r / min, and poured into the stirred tank 25 parts of hexamethylene diisocyanate, 15 parts of acetic acid, 22 parts of nano-aluminum powder and 10 parts of heptadecafluorodecyltriethoxysilane were added, and stirred for 35 minutes to obtain an anti-wear suspension.

[0061] Preparation of active molybdenite powder:

[0062] Take 220g of molybdenite ore and put it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com