One-step method for preparing flaky manganese dioxide/carbon fiber low-temperature denitration catalyst

A manganese dioxide, low-temperature denitration technology, applied in physical/chemical process catalysts, catalyst activation/preparation, chemical/physical processes, etc., to achieve the effects of excellent low-temperature activity and water resistance, beneficial to large-scale production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

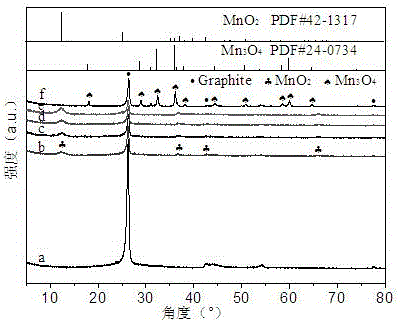

Embodiment 1

[0029] Weigh the following raw materials in parts by weight: 0.2-0.4 parts of nano-carbon fiber, 0.1-1 part of potassium permanganate, 0.01-0.05 part of sodium bisulfate, 0.01-0.1 part of sodium dodecylbenzenesulfonate and 10-70 parts of deionized water share;

[0030] a) Add 0.3g of original carbon nanofibers and 0.0237g of sodium dodecylbenzenesulfonate to 50mL of deionized water and stir for 5min, then mix it with 25mL of 0.04mol / L sodium bisulfate aqueous solution and 25mL of 0.04mol / L high Potassium manganate aqueous solution is mixed, wherein the consumption of potassium permanganate is calculated according to the molar ratio of Mn7+ / C=4%, and the consumption of sodium bisulfate is consistent with potassium permanganate.

[0031] b) Place the uniformly mixed solution in an ultrasonic cleaner for ultrasonic reaction for 1 hour, while raising the reaction system to 65°C;

[0032] c) The catalyst obtained in step (b) is filtered, washed, and dried in a vacuum oven at 105°C...

Embodiment 2

[0036] a) Add 0.3g of original carbon nanofibers and 0.0237g of sodium dodecylbenzenesulfonate to 50mL of deionized water and stir for 5min, then mix it with 38mL of 0.04mol / L sodium bisulfate aqueous solution and 38mL of 0.04mol / L high Potassium manganate aqueous solution is mixed, wherein the consumption of potassium permanganate is calculated according to the molar ratio of Mn7+ / C=6%, and the consumption of sodium bisulfate is consistent with that of potassium permanganate.

[0037] b) Put the uniformly mixed solution in an ultrasonic cleaner for ultrasonic reaction for 1 hour, and raise the reaction system to 70°C at the same time;

[0038] c) The catalyst obtained in step (b) is filtered, washed, and dried in a vacuum oven at 105°C to obtain 6% MnO 2 / CNFs catalyst.

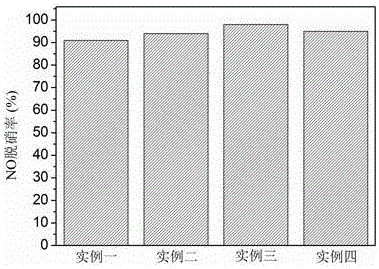

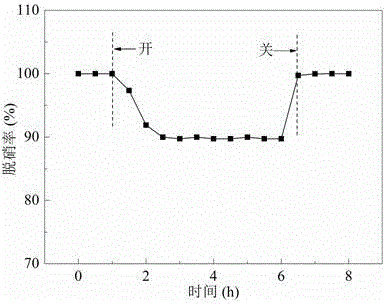

[0039] Denitrification efficiency test conditions: [NO]=[NH 3 ]= 400 ppm, [O 2 ]= 5%, N 2 As balance gas, the mass space velocity is 210000mL•g cat −1 • h −1 , 200mg catalyst;

[0040] The result is...

Embodiment 3

[0042] a) Add 0.3g of original carbon nanofibers and 0.0237g of sodium dodecylbenzenesulfonate to 50mL of deionized water and stir for 5min, then mix it with 50mL of 0.04mol / L sodium bisulfate aqueous solution and 50mL of 0.04mol / L high Potassium manganate aqueous solution is mixed, wherein the dosage of potassium permanganate is calculated according to the molar ratio of Mn7+ / C=8%, and the dosage of sodium bisulfate is consistent with that of potassium permanganate.

[0043] b) Put the uniformly mixed solution in an ultrasonic cleaner for ultrasonic reaction for 1 hour, and at the same time raise the reaction system to 75°C;

[0044] c) The catalyst obtained in step (b) is filtered, washed, and dried in a vacuum oven at 105°C to obtain 8% MnO 2 / CNFs catalyst.

[0045] Denitrification efficiency test conditions: [NO]=[NH 3 ]= 400 ppm, [O 2 ] = 5%, N 2 As balance gas, the mass space velocity is 210000mL•g cat −1 • h −1 , 200mg catalyst;

[0046] The result is 180 o T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com