Patents

Literature

33results about How to "Avoid surface "hardening"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tobacco shred drying method

InactiveCN102511913AGood quality characteristicsImprove stabilityTobacco preparationDrying timeVacuum chamber

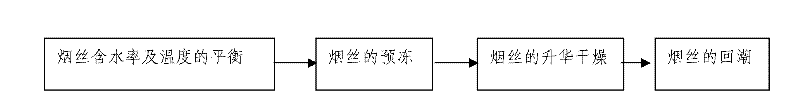

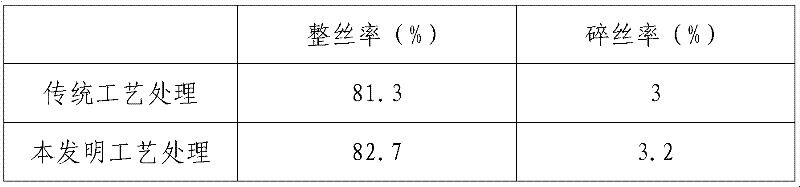

The invention discloses a tobacco shred drying method. The moisture content of cut tobacco shreds is balanced to 20-24%, and the temperature is balanced to 10-30 DEG C. The balanced tobacco shreds are quickly frozen to be under the temperature of -40 DEG C to -35 DEG C at a cooling rate of -0.06 DEG C / min to -1.0 DEG C / min and maintained for 1-4 hours. Pre-frozen tobacco shreds are placed into a vacuum chamber to be dried, wherein absolute pressure in the vacuum chamber is 50-70 Pa, the temperature of a heating plate is 20-40 DEG C, and drying time is 0.5-4 hours. Finally, the moisture content of tobacco shreds is regained to 11-13%. By means of the method, quality characteristics and original shape of raw materials can be maintained well, and the phenomena including surface hardening, fragrance loss and the like caused by surface precipitation of soluble matter contained in the tobacco shreds are avoided. The method is simple and low in energy consumption, can improve smoking quality of the tobacco shreds remarkably, and has good application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

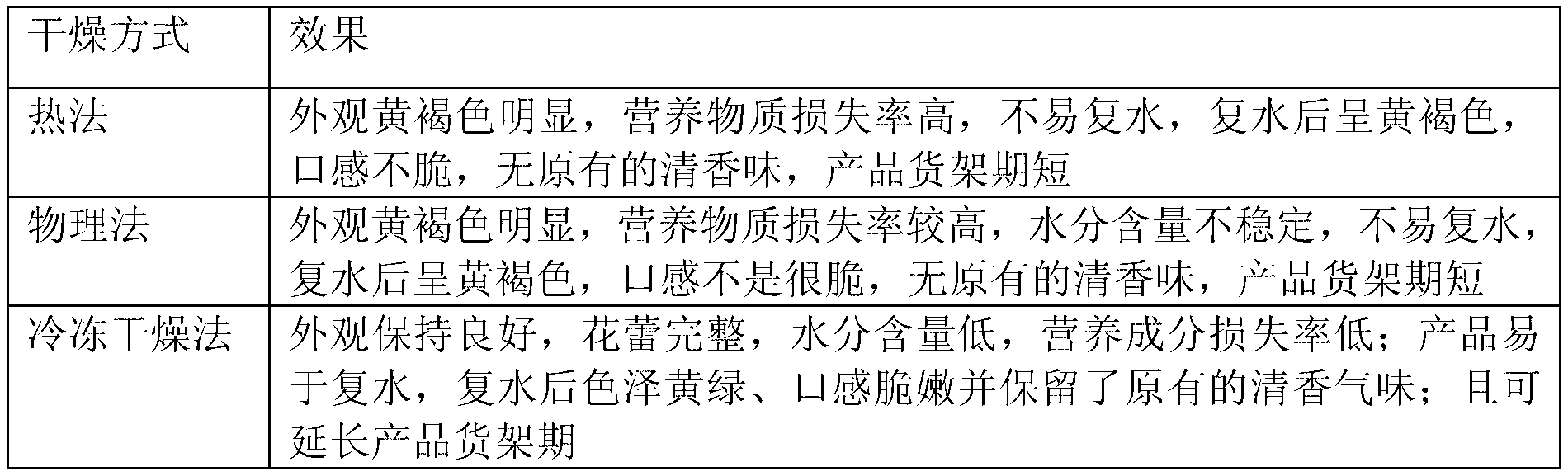

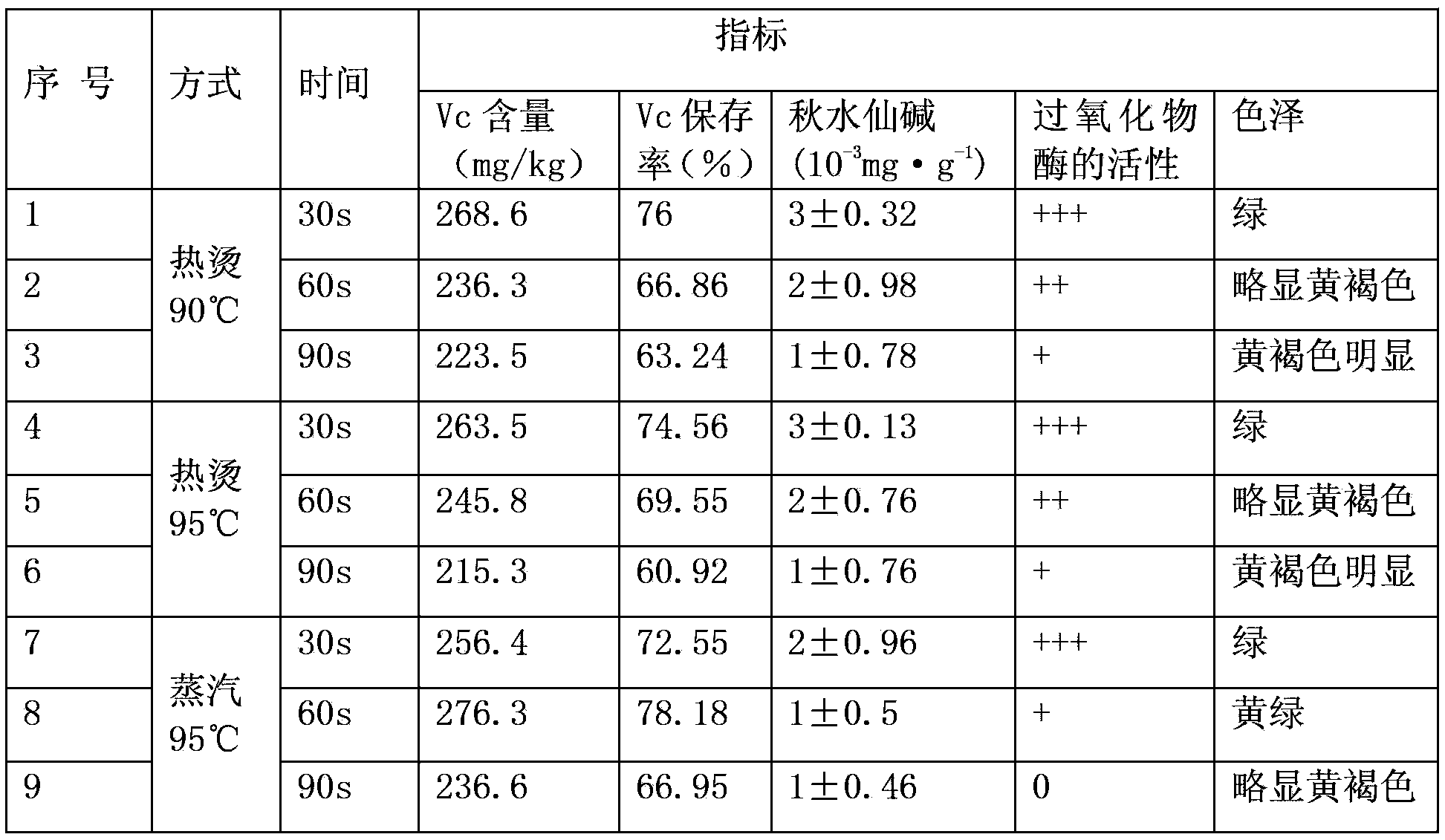

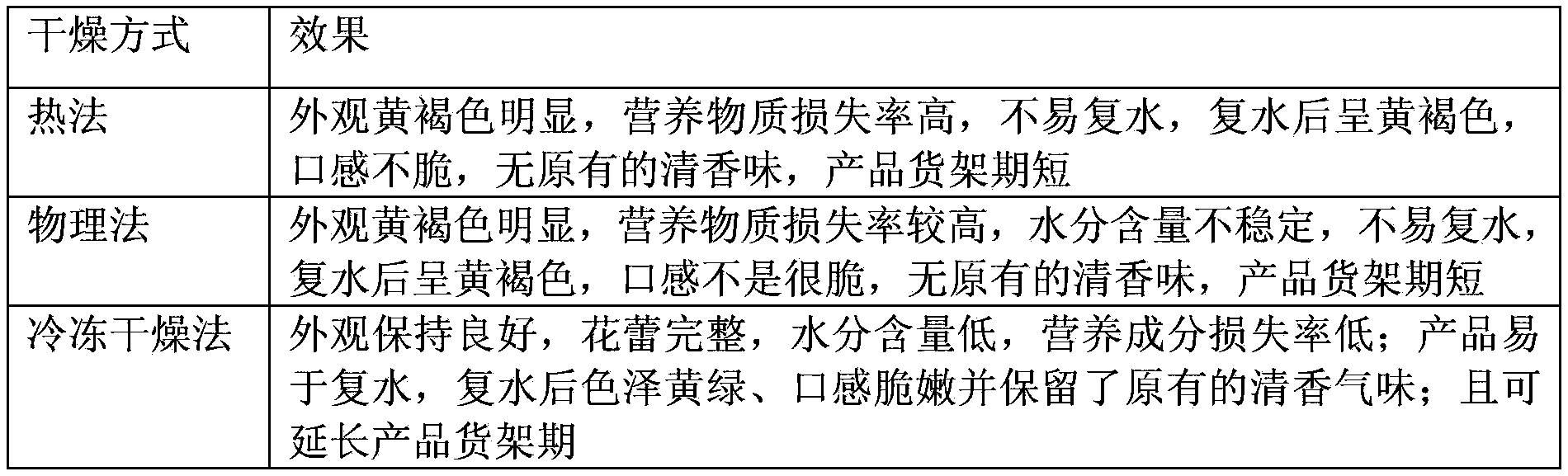

Processing method for vacuum freeze drying of Hemerocallis fulva L.

ActiveCN103283819AYellow-green colorCrisp and tenderFruit and vegetables preservationVitamin CAdditive ingredient

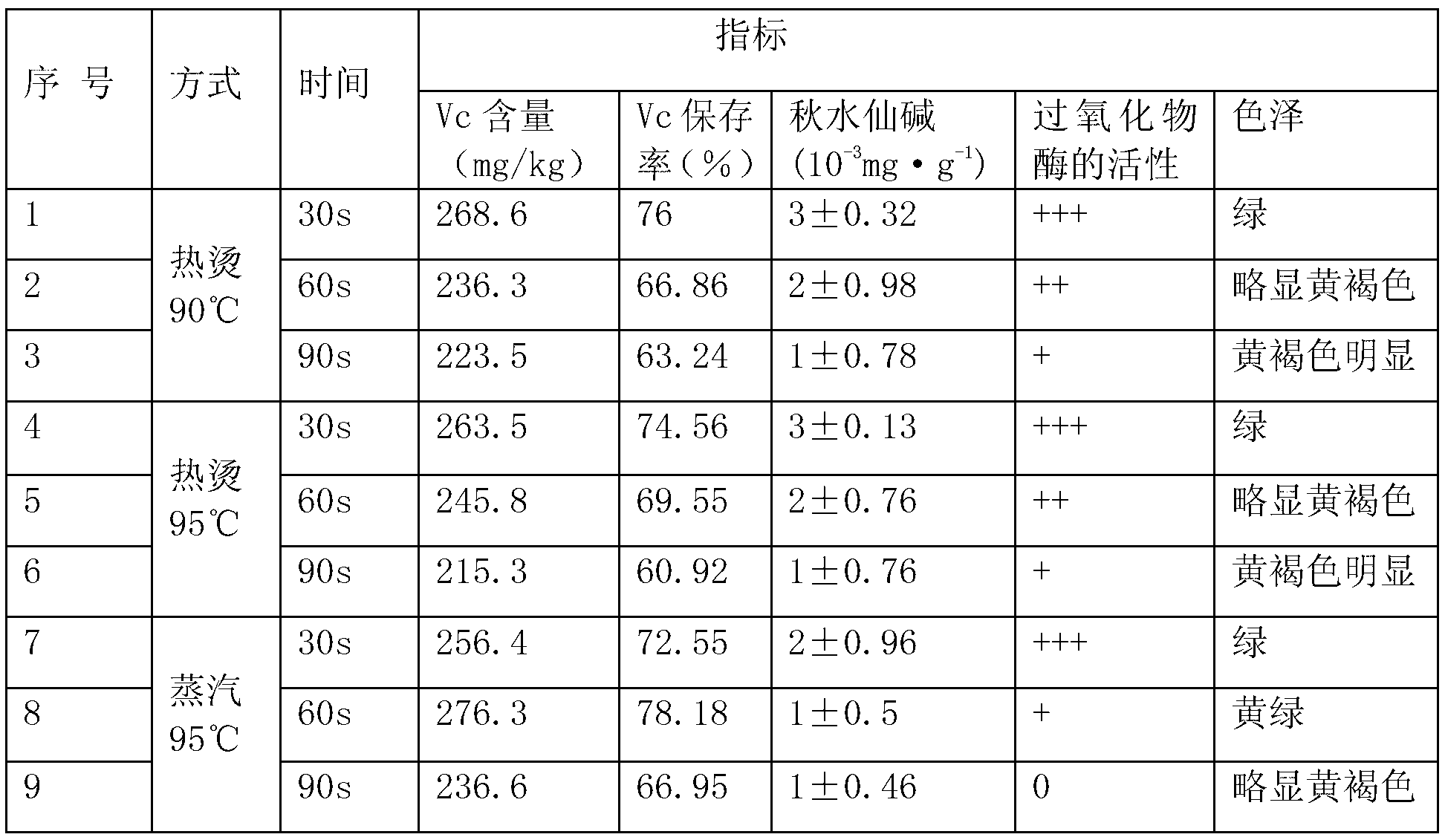

The invention discloses a processing method for vacuum freeze drying of Hemerocallis fulva L. The processing method comprises the following steps: S1, pre-freezing pretreated fresh Hemerocallis fulva L. at a temperature of -40 DEG C for more than 10 h; and S2, freeze drying the prefrozen Hemerocallis fulva L. at a temperature of -40 to -50 DEG C in a high vacuum state for 12 to 16 h. The invention has the following beneficial effects: pretreated Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and is safe to eat since colchicine is inactivated; the process of vacuum freeze drying is employed, so the processed Hemerocallis fulva L. maintains good appearance, intact flower buds and the original color, fragrance, flavor and shape of Hemerocallis fulva L., water content in the processed Hemerocallis fulva L. is low, a loss late of nutritional ingredients like protein, vitamin C, a dietary fiber and the like is low, and a storage life of the processed Hemerocallis fulva L. is long; rehydration of the processed Hemerocallis fulva L. is easy, and the processed Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and retains original delicate fragrance after rehydration.

Owner:四川省宕府王食品有限责任公司

Drunken tilapia snack food and processing method thereof

The invention discloses a drunken tilapia snack food and a processing method thereof. Tilapia fillets are prepared into semi-dried drunken fillets through the steps of picking, inebriating, vacuum microwave drying and the like. By controlling the drying conditions, the flavoring material and original chewiness of the drunken fish are well maintained while the water content of the drunken fish is improved, and thus the drunken fish is good in flavor and taste. The process is capable of shortening the production period, reducing the production cost, and facilitating production. The drunken tilapia snack food processed by the method disclosed by the invention is natural in flesh color, compact, fresh and tender in meat, proper in salt taste, hardness and moisture, free from intermuscular fishbone, and suitable for people of all ages. The method is further suitable for small and medium freshwater fish, such as colussoma brachypomum, without or with less intermuscular fishbone.

Owner:GUANGDONG YUJIA AQUATIC FOOD

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

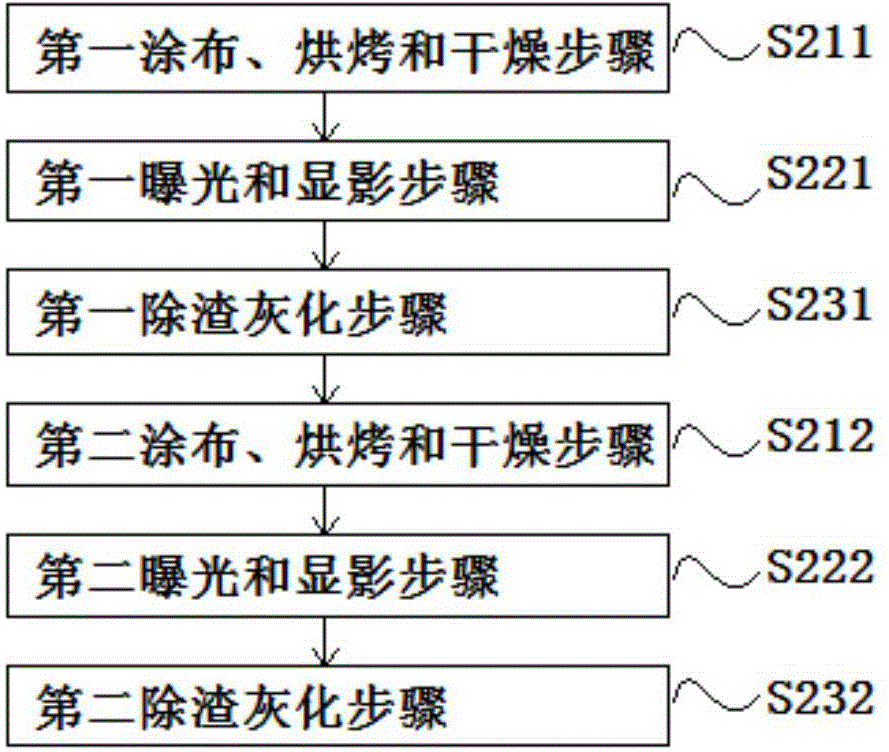

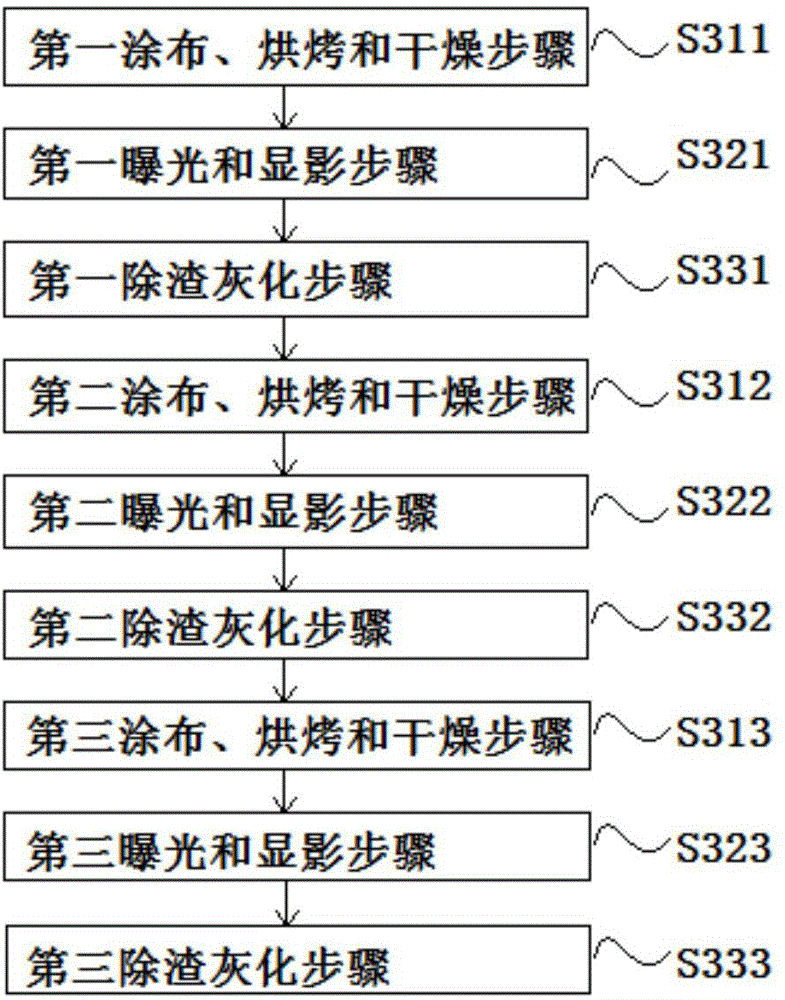

Manufacturing method of semiconductor planarization layer

ActiveCN104658906AAvoid surface hardeningEnsure consistencyPhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingPhotoresist

The invention provides a manufacturing method of a semiconductor planarization layer. The manufacturing method comprises the following steps: a coating, baking and drying step, that is, a photoresist for forming a planarization layer is coated on a lower layer film and then the baking treatment and drying treatment are performed; an exposure and development step, that is, the exposure treatment and the development treatment are performed on the planarization layer after the coating, baking and drying step; the manufacturing method is characterized in that the coating, baking and drying step is carried out in at least twice according to the required coating thickness of the planarization layer to be manufactured; the exposure and development step is carried out for at least once. The manufacturing method can improve the taper angle of the planarization layer, reduce the undercut phenomenon of the planarization layer, and prevent the breakage of an upper layer film of the planarization layer, so as to improve the reliability of products.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Rustproofing composition

ActiveUS20060003904A1Improve corrosion resistanceEasy to getOrganic chemistryLiquid carbonaceous fuelsWaxVegetable oil

A rustproofing composition has superior properties satisfying rustproofing quality requirements and work quality requirements for parts around tires, parts with pockets, and plate-bonded parts, and having volatile organic solvent of not more than 10 mass %. A rustproofing composition has 5 to 60 mass % of the overall composition of at least one kind of heat-polymerized drying oil in which oil having an iodine value of not less than 130 is heat-polymerized, and 1 to 50 mass % of the overall composition of at least one kind of wax selected from natural waxes and synthetic waxes, and / or at least one kind of rustproofing additive dissolved or dispersed in mineral oil type lubricant based oils, synthetic lubricant based materials or liquid saturated-hydrocarbon mixtures vegetable oil based semidrying oils, and vegetable oil based nondrying oils. In the rustproofing composition, nonvolatile content at 105° C. for 3 hours is not less than 90 mass %.

Owner:PARKER IND +1

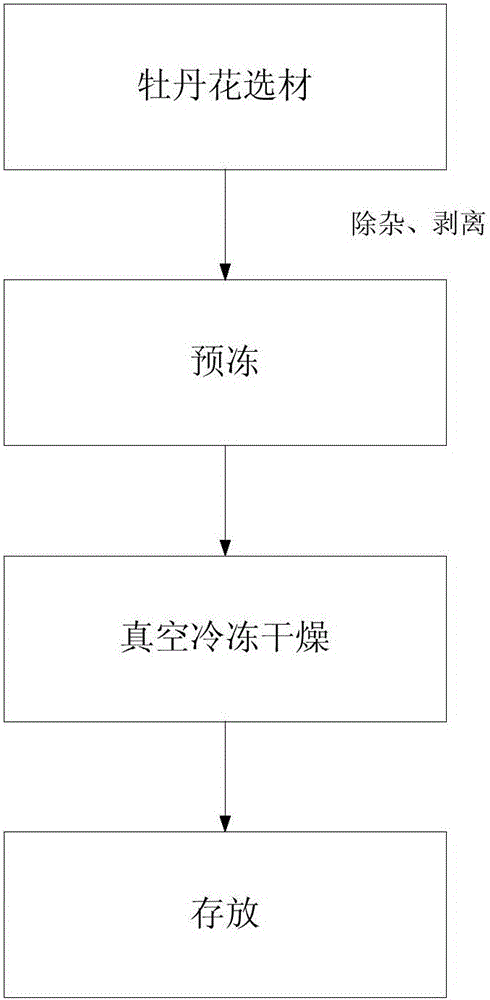

Drying method of flower materials in peony flower tea preparation technology

The invention discloses a drying method of flower materials in a peony flower tea preparation technology. The drying method includes the following steps that fresh peony flowers are picked; outermost petals of the peony flowers are stripped off, dirt is removed, and the integrity of petals is kept; the treated peony flowers are put into a cryogenic refrigerator in the optimum form to be pre-cooled; the pre-cooled peony flowers are rapidly put into a vacuum freezing dryer, the freezing temperature, the vacuum degree of a drying chamber, the temperature of a heating plate and the thickness of the material are set, and freezing drying is carried out; the dried peony flowers are stored in a sealed shady place. The dried peony flowers obtained through the drying method hardly shrink, the original color and flavor are kept basically, and the dried peony flowers have the advantages of being high in phenolic substance content and high in oxidation resistance, can serve as a high-quality raw material of peony flower tea and also have high ornamental value. According to the drying method, on the basis of vacuum freezing drying, the drying time is short, the process is simple, no contamination is caused, the product is good in sensory quality, high in nutrient retention rate and good in rehydration property, and the defects of high time consumption and labor consumption, low efficiency and the like of a traditional drying method are overcome.

Owner:NORTHWEST A & F UNIV

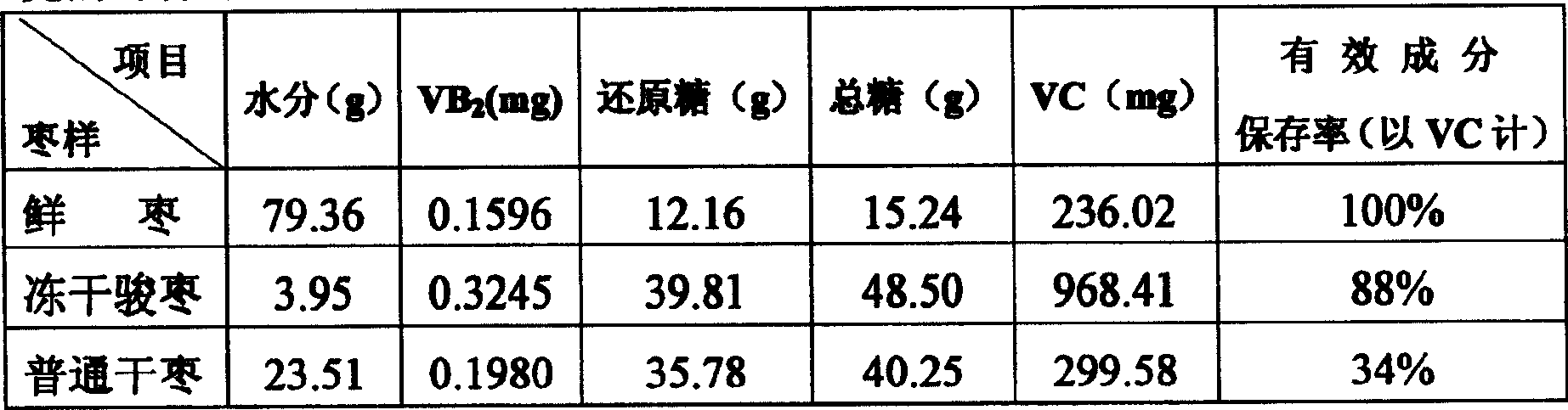

Frozen dry jujube and preparation thereof

InactiveCN1423950AAvoid breaking downReduce lossesFruit and vegetables preservationAdditive ingredientFreeze-drying

A freeze dried jujube is prepared from fresh jujube through removing kernel, pre-freezing and freeze drying in vacuum freeze drier where water is directly sublimated. Its advantages are less loss of nutrients, and original color and taste.

Owner:FOOD INST LULIANG DISTRICT SHANXI PROV

Boron-containing calcium sulfonate complex lubricating grease composition and preparation method thereof

ActiveCN108611159AImprove high temperature performanceDrop point highThickenersHydroxystearic AcidBoronic acid

The invention discloses a boron-containing calcium sulfonate complex lubricating grease composition which comprises base oil and a thickening agent, and is characterized in that the thickening agent comprises a ) or b), wherein a) comprises a reactant of 12-hydroxy stearic acid, mono hydrocarbyl substituted boronic acid and a calcium hydroxide aqueous solution, the molar ratio of the 12-hydroxy stearic acid to the mono hydrocarbyl substituted boronic acid is 1 to (0.1-1); and b) comprises a reactant of 12-hydroxy stearic acid, mono hydrocarbyl substituted boronic acid, benzene sulfonic acid and a calcium hydroxide aqueous solution, and the molar ratio of the 12-hydroxy stearic acid to the mono hydrocarbyl substituted boronic acid to the benzene sulfonic acid is 1 to (0.1-1) to (0.1-1). Theinvention further provides a preparation method of the lubricating grease composition. The prepared lubricating grease is outstanding in high-temperature property, and high in dropping point, the lubricating grease composition is not likely to generate surface hardening, borate is not separated out, crystalline calcium carbonate and other inorganic salts formed in the product are controllable ingrain size, and the reliability of the product in the bearing lubricating process is ensured.

Owner:PETROCHINA CO LTD

Novel vacuum freezing production method for herba dendrobii

InactiveCN110613127AReduce moisture contentRapid dissolutionFood freezingTea substituesThree levelAdditive ingredient

The invention discloses a novel vacuum freezing production process for herba dendrobii, belongs to the technical field of food processing, and aims to provide a novel vacuum freezing production process. The novel vacuum freezing production process for the herba dendrobii is characterized in that a vacuum freeze-drying single-factor test and a three-factor three-level orthogonal test are carried out by taking pre-freezing time, vacuum drying time and raw material shape as influencing factors according to the physiological characteristics of the herba dendrobii, the moisture content of a dried product of the herba dendrobii is measured, and thus, optimal conditions of the vacuum freeze-drying production process of the herba dendrobii are obtained. Under the condition that nutritional ingredients and physiological activity of the herba dendrobii are maintained to a great extent, energy consumption is greatly reduced, the production cost is reduced, and industrialized production of the herba dendrobii in China is promoted to a high level.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

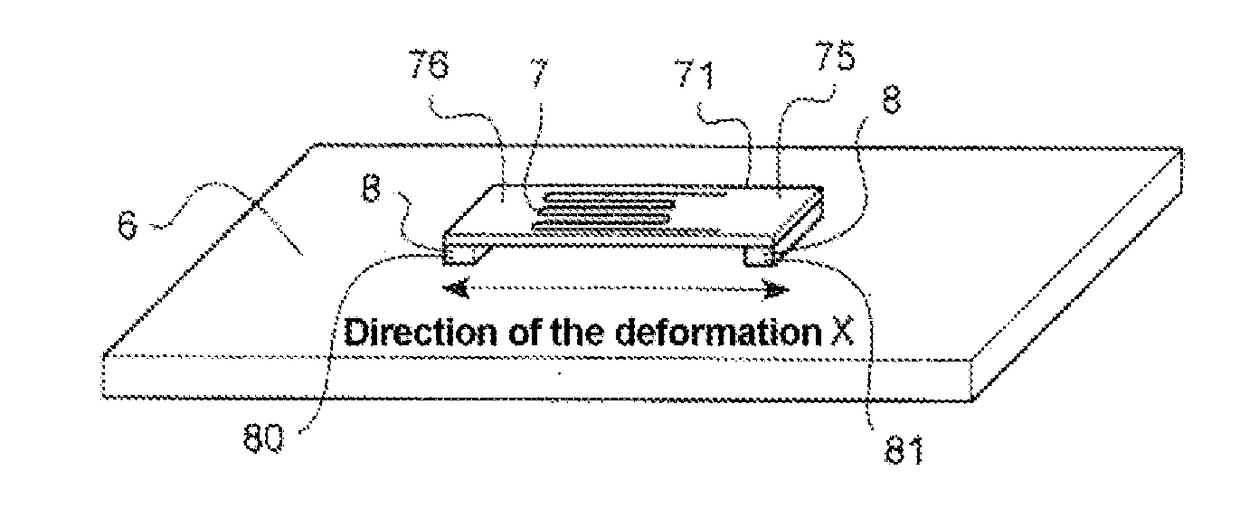

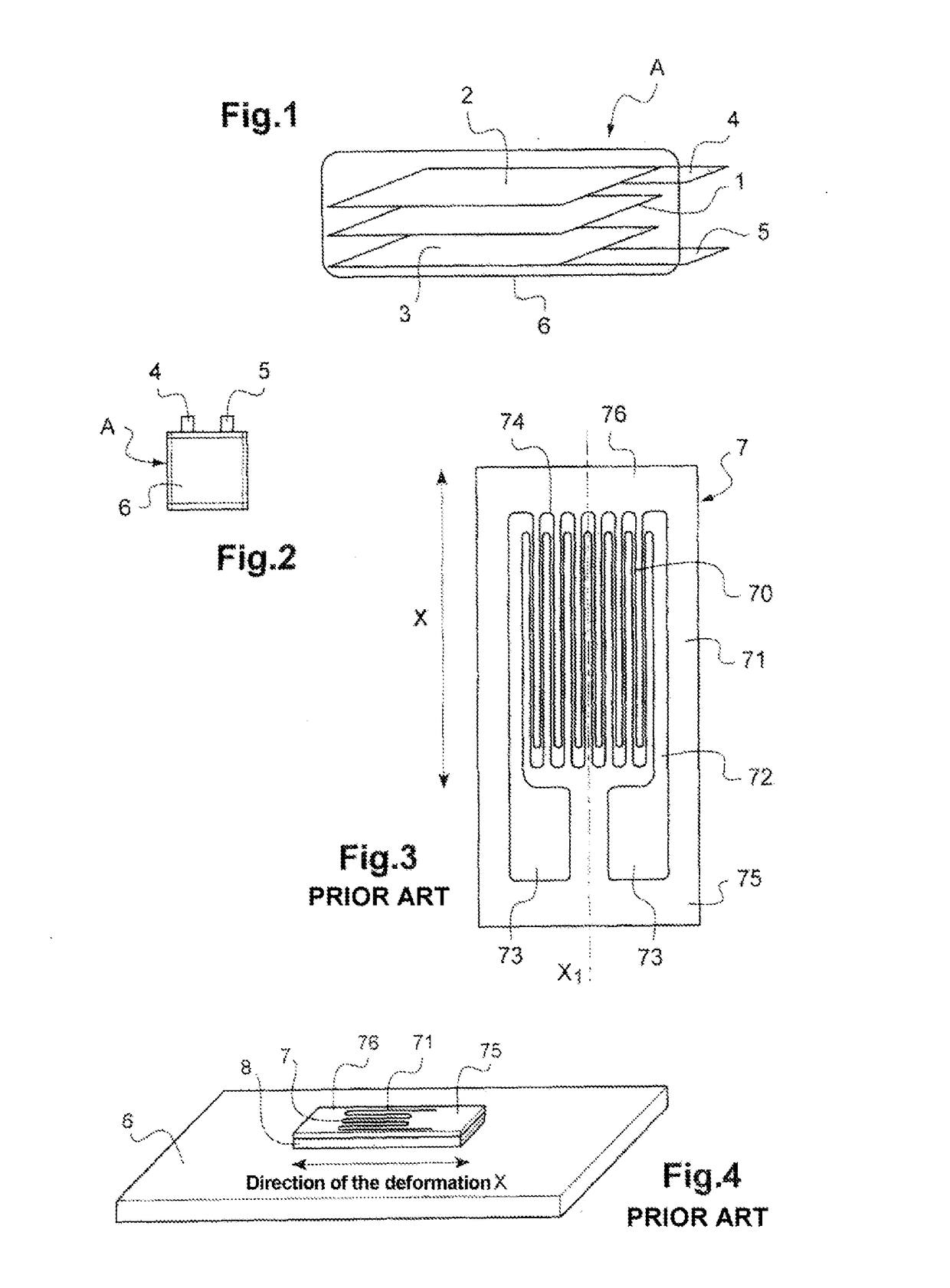

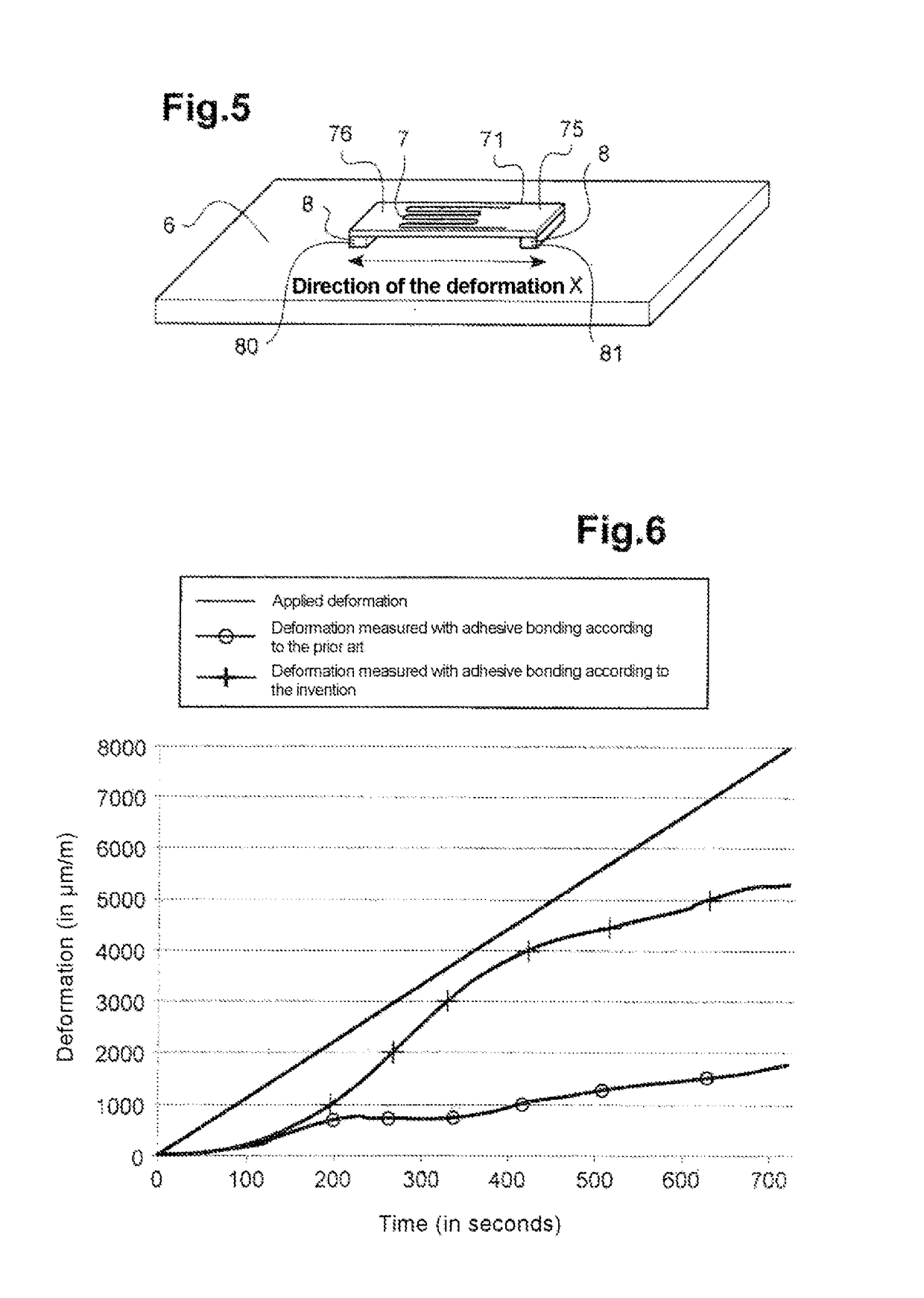

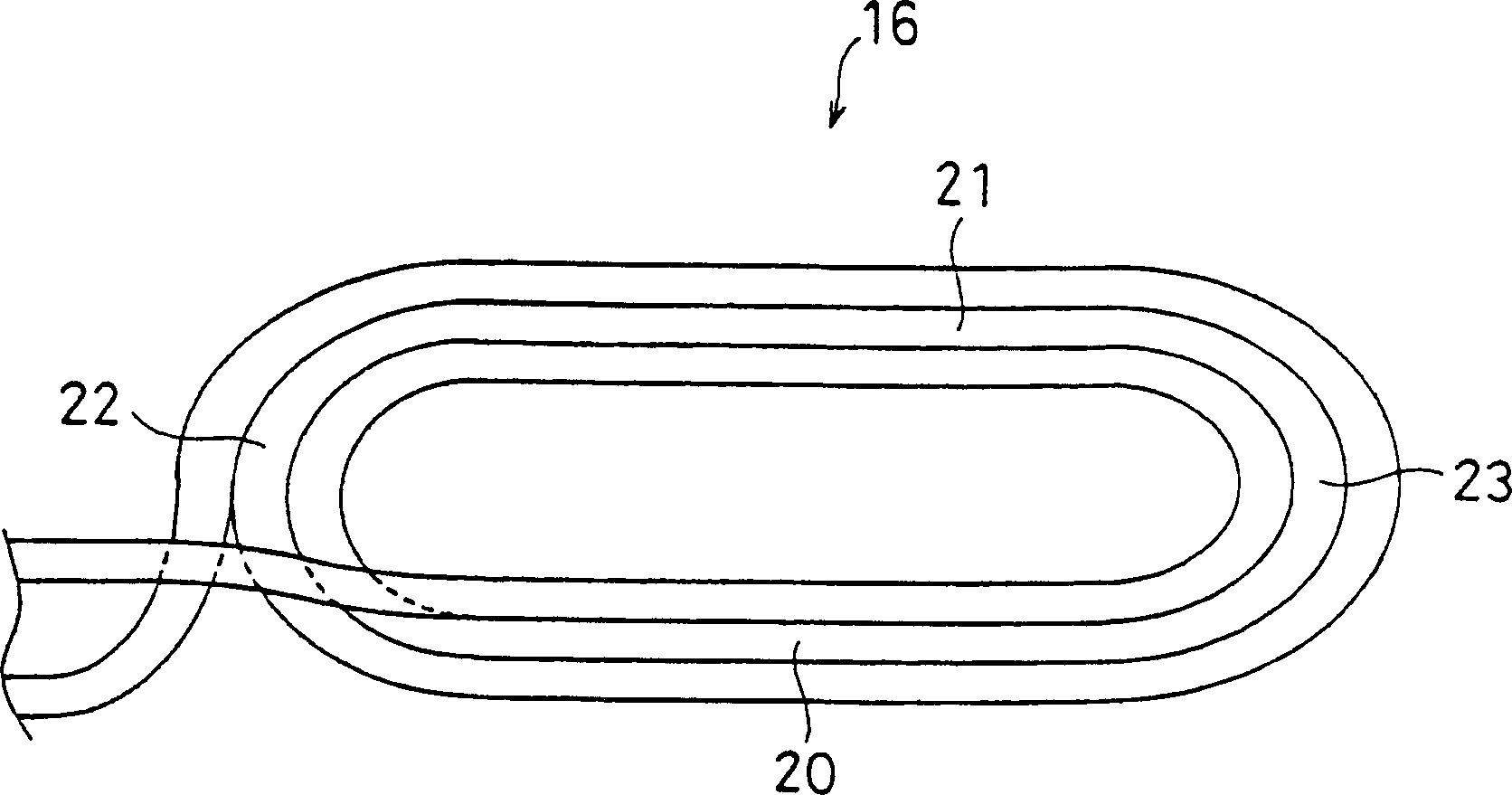

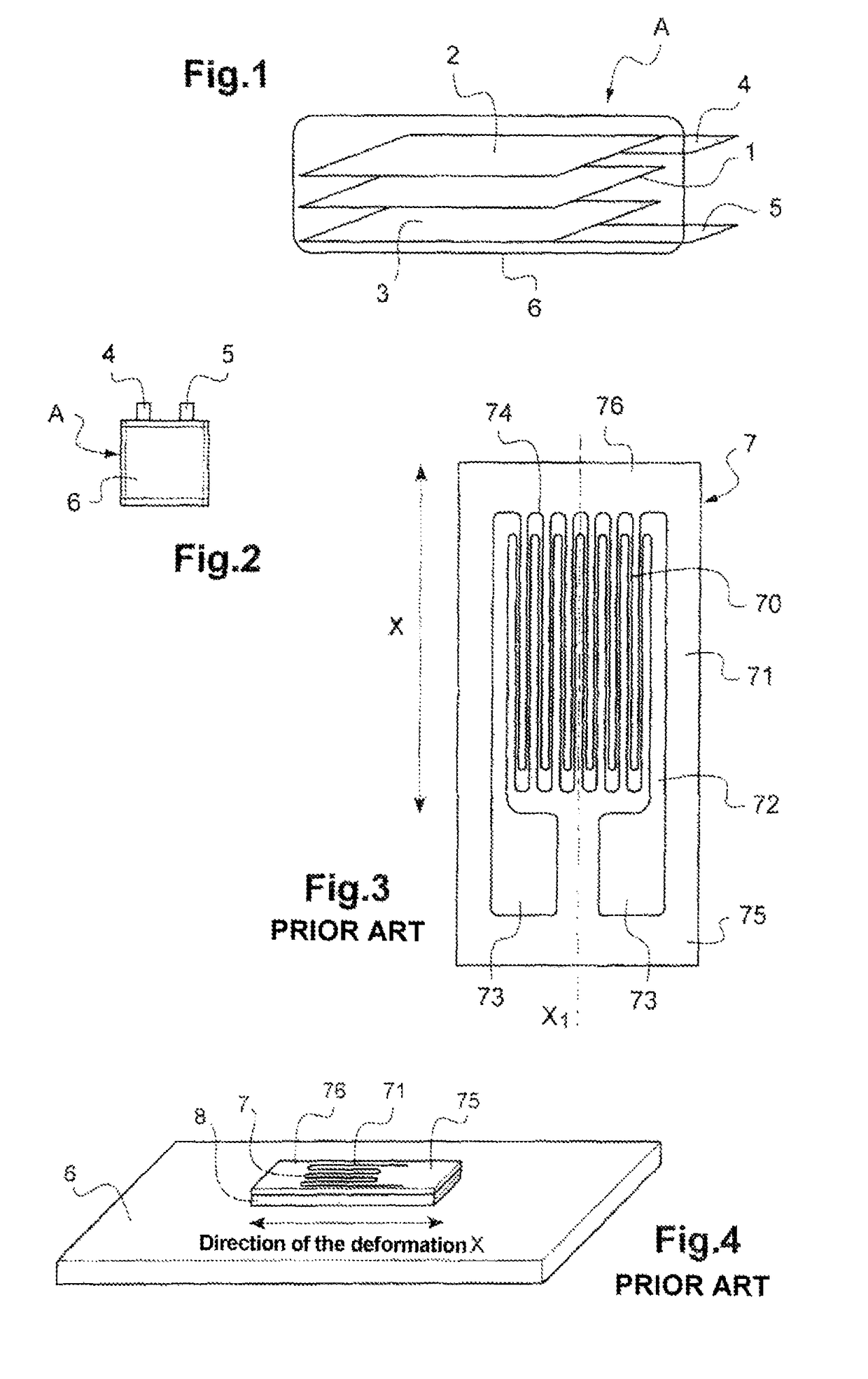

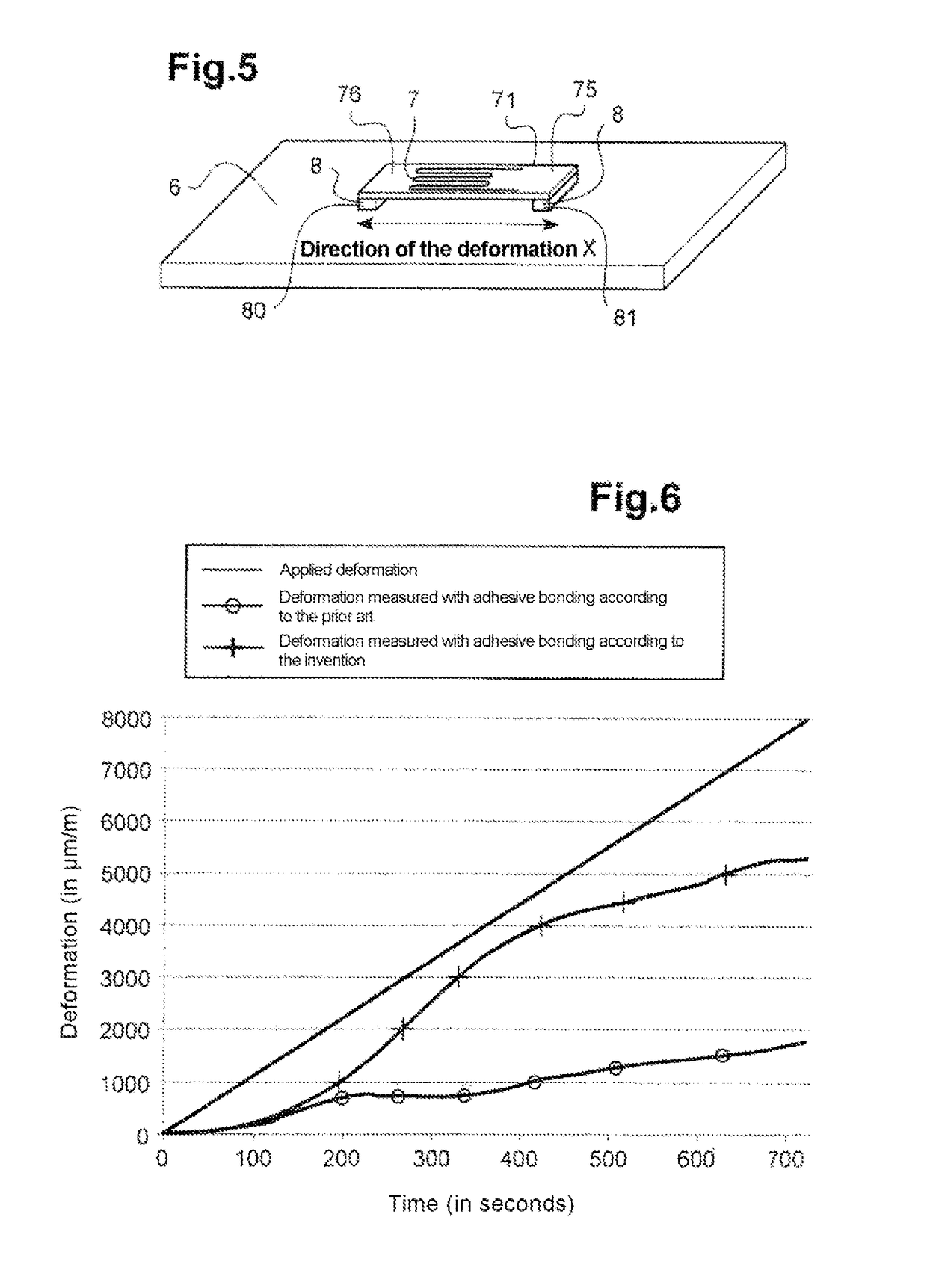

Flexible structure with strain gauge, application to electrochemical lithium-ion batteries in a flexible packaging

ActiveUS20170141360A1Easy to measureReliable indicatorFinal product manufactureSecondary cellsElectrical conductorElectrical battery

The present invention relates to a flexible structure (6) comprising a strain gauge (7) that is elongate along a longitudinal axis X1, and intended to measure the deformation of the flexible structure in a direction X parallel to the axis X1, the strain-gauge support (71) being bonded to the flexible structure only via the lateral ends (75, 76) thereof. One particularly targeted application is the bonding of strain tool gauges to the packaging of a flexible lithium battery, such as an Li-ion battery.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Technology for manufacturing dendrobium officinale freeze-dried powder

InactiveCN107802744AKeep active ingredientsReservation of validityPowder deliveryDigestive systemCuticleFreeze-drying

The invention provides a technology for manufacturing dendrobium officinale freeze-dried powder. The technology includes steps of acquiring dendrobium officinale conforming to standards; washing the dendrobium officinale, removing sundries and rinsing the dendrobium officinale by the aid of purified water; removing skin of fresh stem branches of the dendrobium officinale; carrying out sectioning treatment on branch stems and the skin; adding the branch stems into purified water and smashing and mashing the branch stems; carrying out filtering to obtain slurry and residues; concentrating and purifying the slurry by the aid of organic membrane concentration equipment; carrying out freeze-drying and smashing; sectioning and pre-freezing partial skin and then mixing the partial skin, remainingskin sections and the residues with one another; carrying out freeze-drying and smashing; mixing slurry smashed substances, the skin and residue smashed substances with one another to obtain the dendrobium officinale freeze-dried powder. The technology has the advantages that original active components of the dendrobium officinale can be reserved in dendrobium officinale freeze-dried powder products processed by the aid of the technology, the dendrobium officinale freeze-dried powder products are similar to fresh products after being rehydrated, the surfaces of the products can be prevented from being hardened, nutrition loss can be prevented, the dendrobium officinale freeze-dried powder can be stored and transported at the normal temperature, the fixed number of years of the shelf livescan be prolonged, and the like.

Owner:浙江龙之源生物科技有限公司

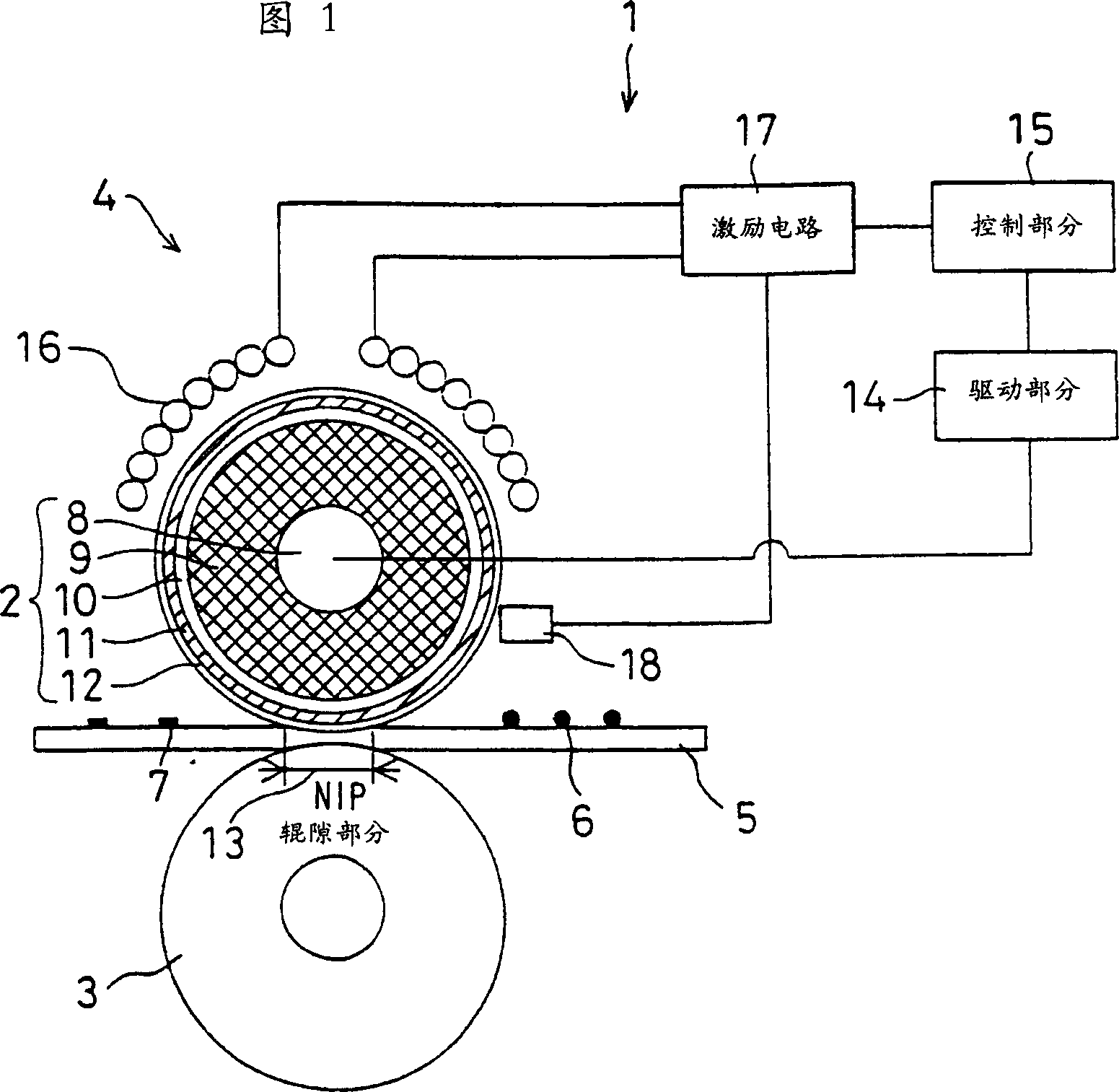

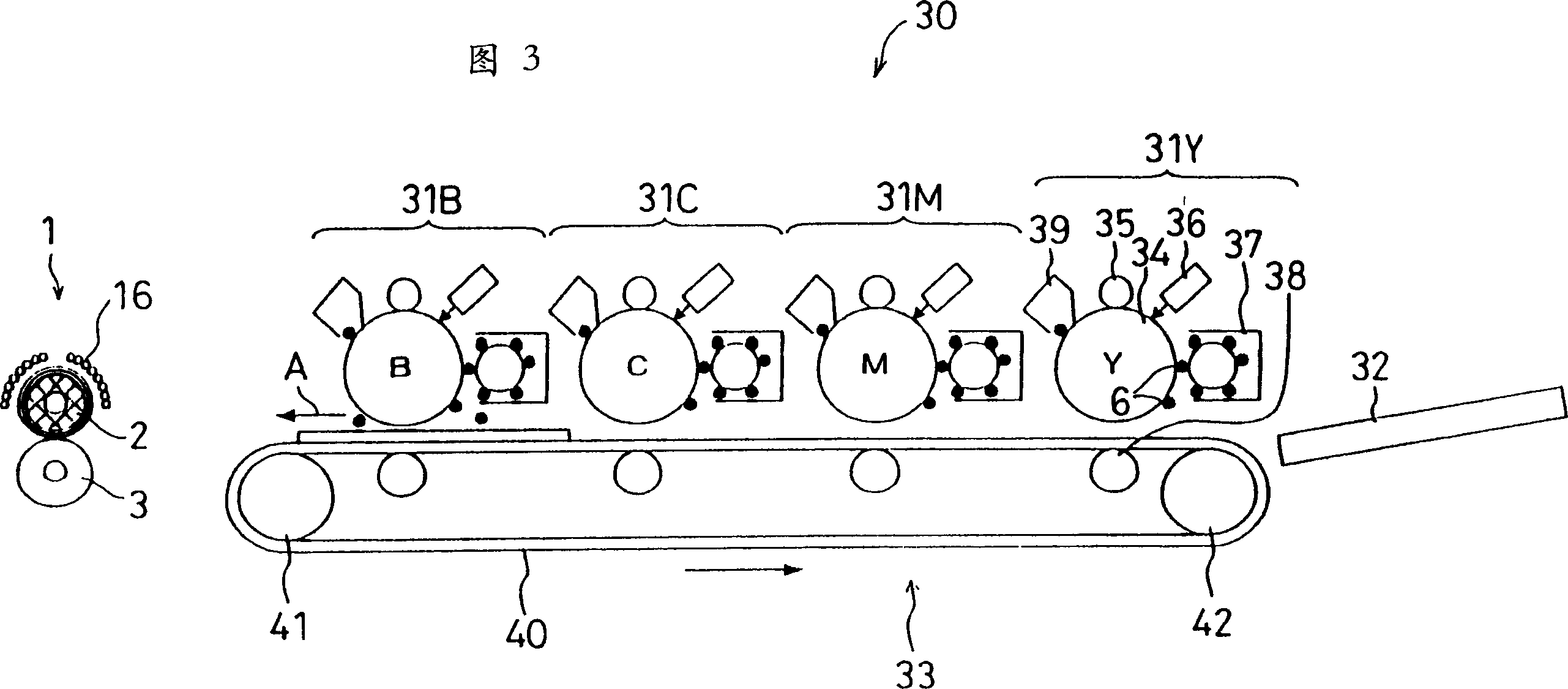

Heater and picture foring device containing heater

InactiveCN1410848AAvoid surface hardeningFully meltedShaft and bearingsElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:SHARP KK

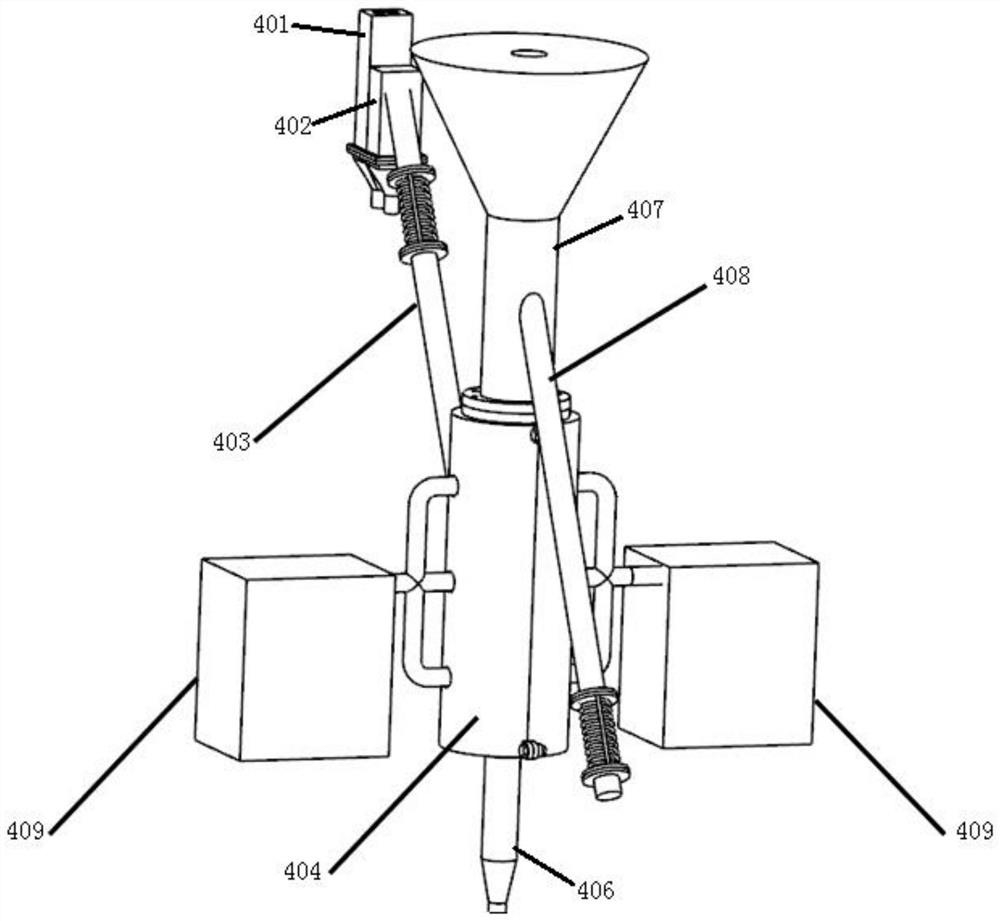

Device and method for microwave-enhanced fluidized phosphogypsum dehydration

The invention discloses a device and method for microwave-enhanced fluidized ardealite dehydration. The method comprises the following steps: ardealite is added into a system through a screw feeder; hot air provided by a hot blast stove is subjected to venturi drying, attached water in phosphogypsum is removed by a cyclone preheater, and then the hot air enters a wave-transparent heating section of the fluidized bed together with a wave-absorbing powder substance for mixing fluidization; and microwaves penetrate through the wave-transparent heating section in the resonant cavity and are absorbed by the wave-absorbing powder substance and the ardealite, and the removal of ardealite crystal water is simultaneously realized in solid-solid, gas-solid and microwave heating modes by utilizing heat generated by high-speed movement of molecules. Due to the change of the fluidization height of the ardealite without crystal water, the ardealite is separated from the wave-absorbing powder substance. The method and the device are wide in applicability, can realize continuous production of two products by one set of device, and are high in heat efficiency, high in heating speed, uniform in material heating, high in product stability, enhanced in polar component on the surface of hemihydrate gypsum molecules, reduced in contact angle, low in tail gas temperature and small in heat loss.

Owner:云南云天化环保科技有限公司

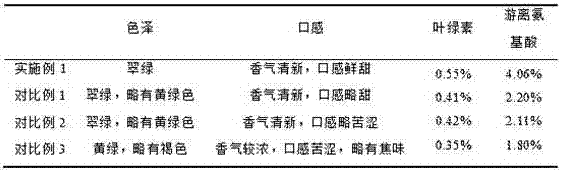

Green tea powder capsule and preparation method thereof

InactiveCN105433381AAvoid damageReduce churnPre-extraction tea treatmentFood shapingFreeze-dryingLiquid nitrogen

The invention provides a green tea powder capsule and a preparation method thereof, and in particular, tea leaves after steaming are subjected to vacuum freeze drying and then are loaded into a capsule. The preparation method comprises the steps: pre-freezing the tea leaves after steaming in a liquid nitrogen quick-freezing device, then loading the pre-frozen tea leaves into a vacuum freeze drying box, heating up to 30+ / -5 DEG C at the step temperature of 0.5 DEG C per minute, drying, then crushing the freeze-dried tea leaves at low temperature into a powder, loading the powder into the capsule prepared from plant starch, and thus obtaining the green tea powder capsule.

Owner:HUNAN ER KANG PHARMA

Preparation method of washing power for rapidly cleaning food oil stains

InactiveCN107129888AGood decontamination effectSimple processSurface-active detergent compositionsDetergent mixture composition preparationMicrowaveSodium dodecylbenzenesulfonate

A preparation method of washing powder capable of quickly cleaning food grease stains comprises the following steps: mixing and stirring 10 to 30 parts of sodium dodecylbenzene sulfonate, 5 to 10 parts of sodium alkylbenzene sulfonate and 2 to 3 parts of water, Then add 40~50 parts of sodium carbonate, 10~20 parts of sodium sulfate, 5~10 parts, 5~10 parts of 4A zeolite, 1~2 parts of carboxymethyl cellulose sodium, 0.5~1 part of enzyme preparation, 1~2 parts Stir with water, and finally add 0.5 to 1 part of soap grains and stir to obtain a paste product. After ultrasonic treatment, microwave drying is carried out. The process of the present invention is simple, no spray drying is required, equipment investment is small, energy consumption is low, and the obtained preparation The obtained washing powder has good decontamination effect, has no adverse effect on the environment after washing and drainage, has low water content, is not easy to agglomerate, and has high activity.

Owner:孔晓静

A preparation method for brewing ready-to-eat tremella polysaccharide health tea

ActiveCN103999987BGuaranteed not to be oxidizedPreserve flavor and nutrientsTea substituesTremellaFreeze-drying

The invention relates to a preparation method of instant-brewing type tremella polysaccharide health tea. The tremella polysaccharide health tea comprises the following components in percentage by weight: tremella and auxiliary materials, wherein tremella accounts for more than 80%, and the rest is the auxiliary materials. The preparation method disclosed by the invention has the beneficial effects that the preparation method is implemented under low temperature, is in a high-vacuum state, and can be used for ensuring that each component in the tremella polysaccharide health tea can not be oxidized, thus maintaining the color, fragrance, taste and nutritional components to the highest extent. The components of the tremella polysaccharide health tea subjected to vacuum freeze drying are respectively spongy, can not cause air shrinkage, are good in re-hydration ratio, and are more close to the original shape of fresh materials after re-hydration. After the tremella polysaccharide health tea is brewed by using boiled water, polysaccharide can be rapidly precipitated, rapidly dissolved into hot water, and directly absorbed by a human body.

Owner:古田县恒惠食用菌开发有限公司

Ginkgetin-containing brine and preparation method thereof

InactiveCN108771188AAdd flavorReduce astringencyFood freezingLipidic food ingredientsFlavorLicorice roots

The invention discloses ginkgetin-containing brine and a preparation method thereof, and belongs to the technical field of seasonings. The ginkgetin-containing brine is prepared from the following components in parts by weight: 4-6 parts of cortex cinnamoni, 5-7 parts of anise, 13-17 parts of cooking wine, 5-9 parts of fennel, 2-4 parts of licorice roots, 1-3 parts of radix et rhizoma nardostachyos, 30-36 parts of rock candies, 8-10 parts of edible oil, 3-5 parts of pericarpium zanthoxyli, 20-26 parts of ginger, 36-40 parts of refined salt, 16-20 parts of gingko powder, 0.6-0.8 part of resveratrol, 0.4-0.6 part of tea polyphenol, 0.2-0.4 part of tannin, 0.3-0.5 part of monascuspurpureus and 0.7-0.9 part of soya bean lecithin. The preparation method includes the following steps: (1) preparing caramel, (2) preparing spices, and (3) preparing the brine. The obtained brine has the advantages of capability of enhancing health-care function of food, improving the viscosity of blood fat and preventing hyperlipidemia, unique flavor and high market value at the same time.

Owner:ANHUI WANGJIABA ECOLOGICAL AGRI

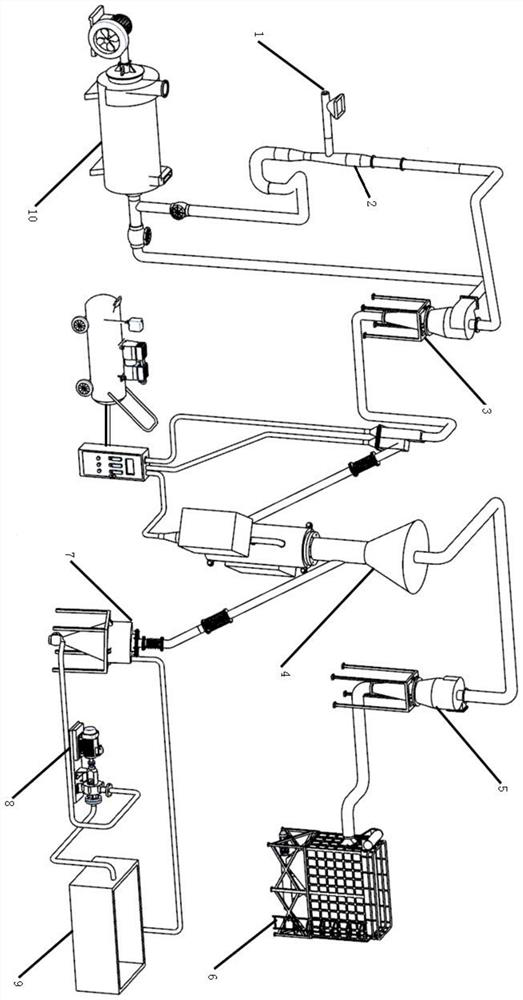

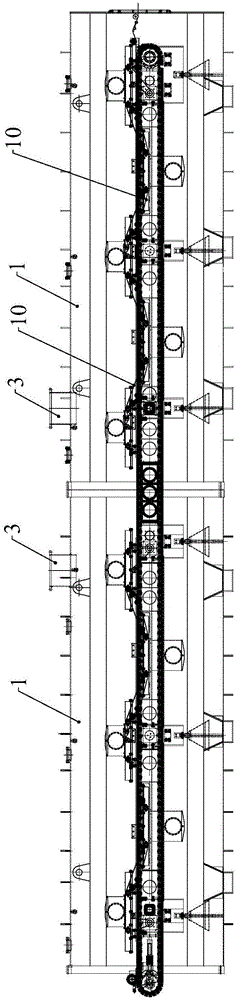

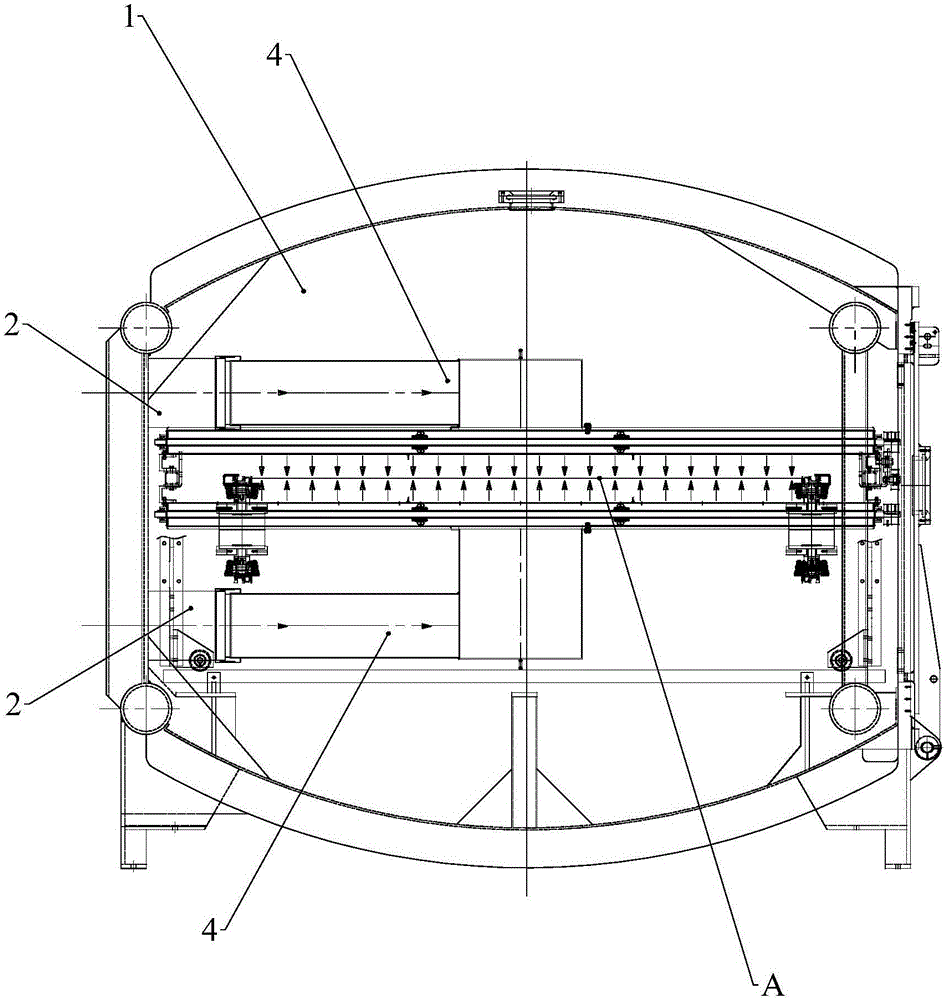

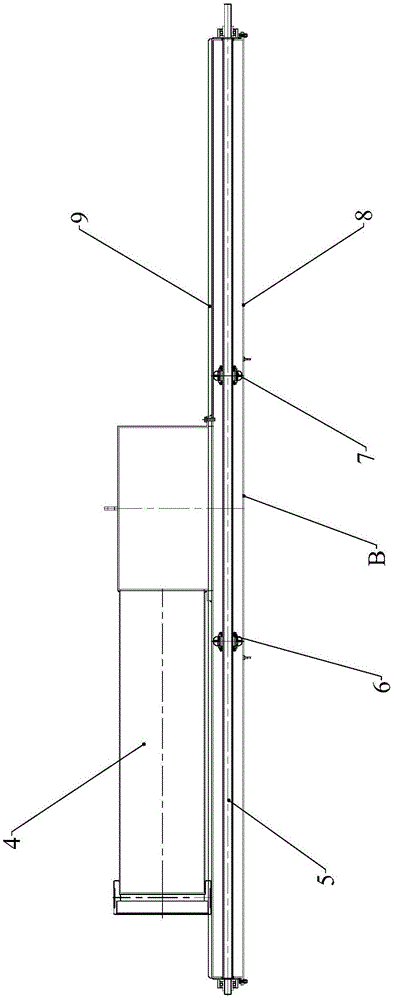

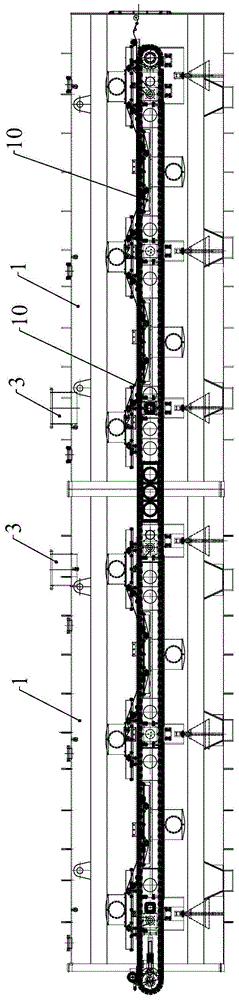

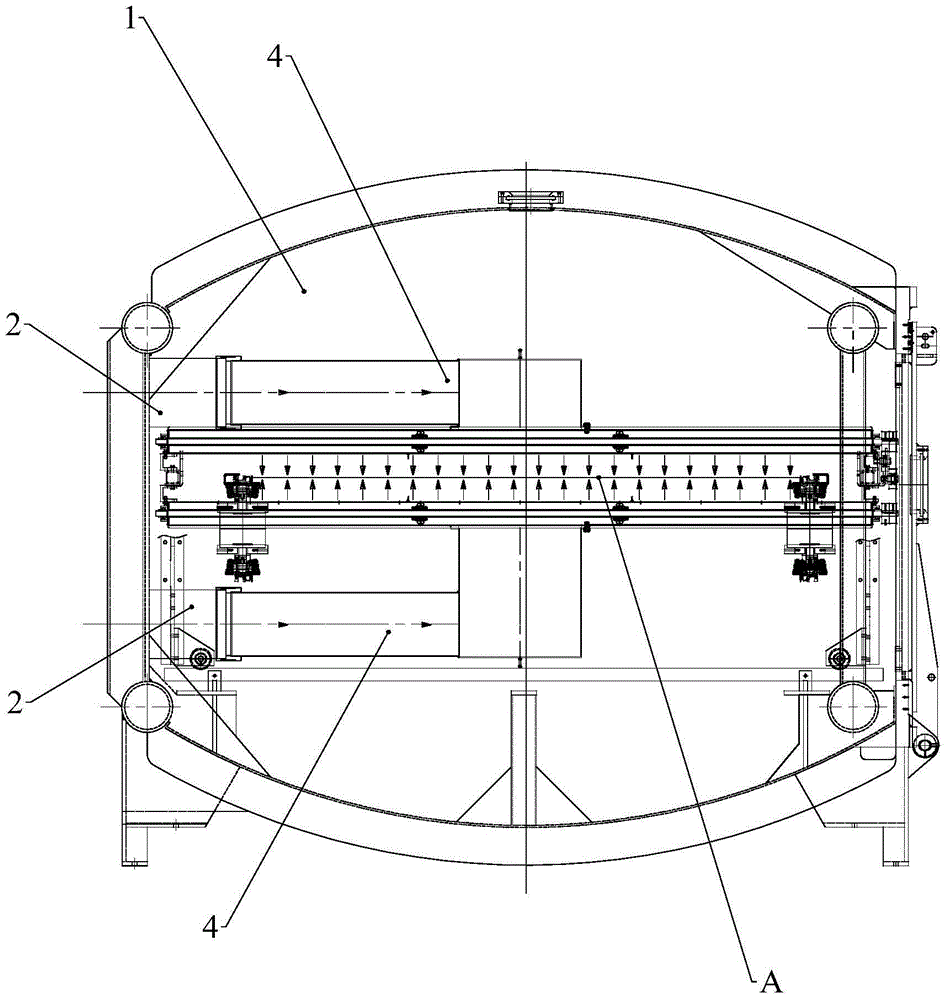

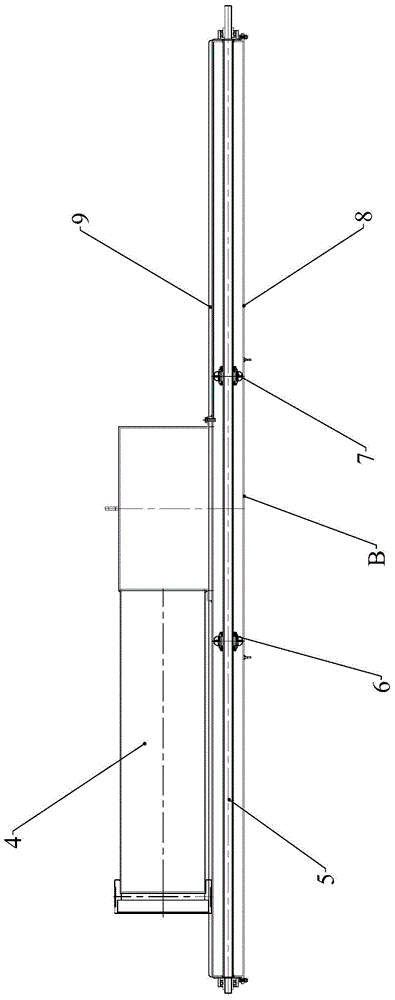

Ammonia gas drying system for liquid ammonia mercerizing machine

ActiveCN105063933AReduce wasteReduce the burden onLiquid/gas/vapor removalMercerisingAmmonia gasHeating system

The invention relates to an ammonia gas drying system for a liquid ammonia mercerizing machine. The ammonia gas drying system comprises a plurality of upper ammonia gas heating systems and lower ammonia gas heating systems arranged in a drying tank in a staggered mode in the fabric conveying direction. The drying tank is provided with high-temperature ammonia gas inlets and exhaust openings for exhausting heated ammonia gas. Each ammonia gas heating system comprises a high-temperature ammonia gas conveying channel, an adjusting screw rod, an adjusting beam and a breathable plate. The adjusting beams are arranged between the breathable plates and supporting hoods of the high-temperature ammonia gas conveying channels. The upper sides and the lower sides of the adjusting beams make seal contact with the breathable plates and the supporting hoods. The adjusting screw rods in all the ammonia gas heating systems conduct synchronous transmission through synchronous belts. The interval distance between the adjusting beams is adjusted through the adjusting screw rods so that the ventilation portions of the breathable plates can be matched with the size of the fabric for heating so as to form a heating area adjusting structure. The ammonia gas drying system has the advantages that the heating range can be adjusted according to the size of the fabric, the utilization rate of ammonia is increased, and the cost is reduced.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

Herba dendrobii decoction pieces and processing method thereof

InactiveCN109498750AImprove the effect of clearing away heat and nourishing yinStrengthen the effect of clearing away heat and nourishing yinPlant ingredientsMicrowaveWater content

The invention belongs to the technical field of traditional Chinese medicine, and relates to herba dendrobii decoction pieces and a processing method thereof. The processing method of the herba dendrobii decoction pieces comprises the following steps: (1) clean selection: taking clean and fresh herba dendrobii and slicing the herba dendrobii; (2) infiltration: adding rice wine for infiltration andtaking the herba dendrobii out; (3) steaming: steaming the herba dendrobii obtained in step (2); (4) covered moistening: adding honey to the steamed herba dendrobii for covered moistening; (5) drying: drying the herba dendrobii obtained in step (4) by microwaves until water content of the herba dendrobii is lower than or equal to 12%. Through the adoption of the processing method, dissolution ofactive constituents in the herba dendrobii decoction pieces is improved, and the effects of the herba dendrobii for clearing heat and nourishing yin are enhanced.

Owner:江西景德中药股份有限公司

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

Flexible structure with strain gauge, application to electrochemical lithium-ion batteries in a flexible packaging

ActiveUS10170733B2Avoid surface hardeningNot to minimize attenuation of signalFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrochemistry

The present invention relates to a flexible structure (6) comprising a strain gauge (7) that is elongate along a longitudinal axis X1, and intended to measure the deformation of the flexible structure in a direction X parallel to the axis X1, the strain-gauge support (71) being bonded to the flexible structure only via the lateral ends (75, 76) thereof. One particularly targeted application is the bonding of strain tool gauges to the packaging of a flexible lithium battery, such as an Li-ion battery.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

A liquid ammonia mercerizing machine ammonia drying system

ActiveCN105063933BReduce wasteReduce the burden onLiquid/gas/vapor removalMercerisingAmmonia gasHot Temperature

The invention relates to an ammonia gas drying system for a liquid ammonia mercerizing machine. The ammonia gas drying system comprises a plurality of upper ammonia gas heating systems and lower ammonia gas heating systems arranged in a drying tank in a staggered mode in the fabric conveying direction. The drying tank is provided with high-temperature ammonia gas inlets and exhaust openings for exhausting heated ammonia gas. Each ammonia gas heating system comprises a high-temperature ammonia gas conveying channel, an adjusting screw rod, an adjusting beam and a breathable plate. The adjusting beams are arranged between the breathable plates and supporting hoods of the high-temperature ammonia gas conveying channels. The upper sides and the lower sides of the adjusting beams make seal contact with the breathable plates and the supporting hoods. The adjusting screw rods in all the ammonia gas heating systems conduct synchronous transmission through synchronous belts. The interval distance between the adjusting beams is adjusted through the adjusting screw rods so that the ventilation portions of the breathable plates can be matched with the size of the fabric for heating so as to form a heating area adjusting structure. The ammonia gas drying system has the advantages that the heating range can be adjusted according to the size of the fabric, the utilization rate of ammonia is increased, and the cost is reduced.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

A kind of preparation method of dried shrimp

ActiveCN109549134BImprove qualityExtended shelf lifeFood freezingMeat/fish preservation using chemicalsPhenolic content in teaFreeze-drying

The invention discloses a preparation method of dried shrimps. Shrimp is soaked in tea polyphenol solution at low temperature, boiled in water, soaked in antistaling agent, soaked in osmotic dehydration liquid and ultrasonically dehydrated, vacuum freeze-dried and packaged to obtain dried shrimp products. The preparation method of the present invention can maintain the color and luster of shelled shrimps and inhibit the oil oxidation process, thereby improving the storage stability of dried shrimp products and inhibiting browning; the yellowness value and volatile base nitrogen value of the obtained dried shrimps are obviously reduced, and the storage Astaxanthin has a good protective effect during the process, and astaxanthin in shrimp is a natural antioxidant, which plays an important role in inhibiting oil oxidation and protecting color. Therefore, the dried shrimp prepared by the present invention is obviously better than the dried shrimp currently on the market in terms of color protection, oxidation inhibition and shelf life extension, and the operation steps are practical.

Owner:DALIAN POLYTECHNIC UNIVERSITY

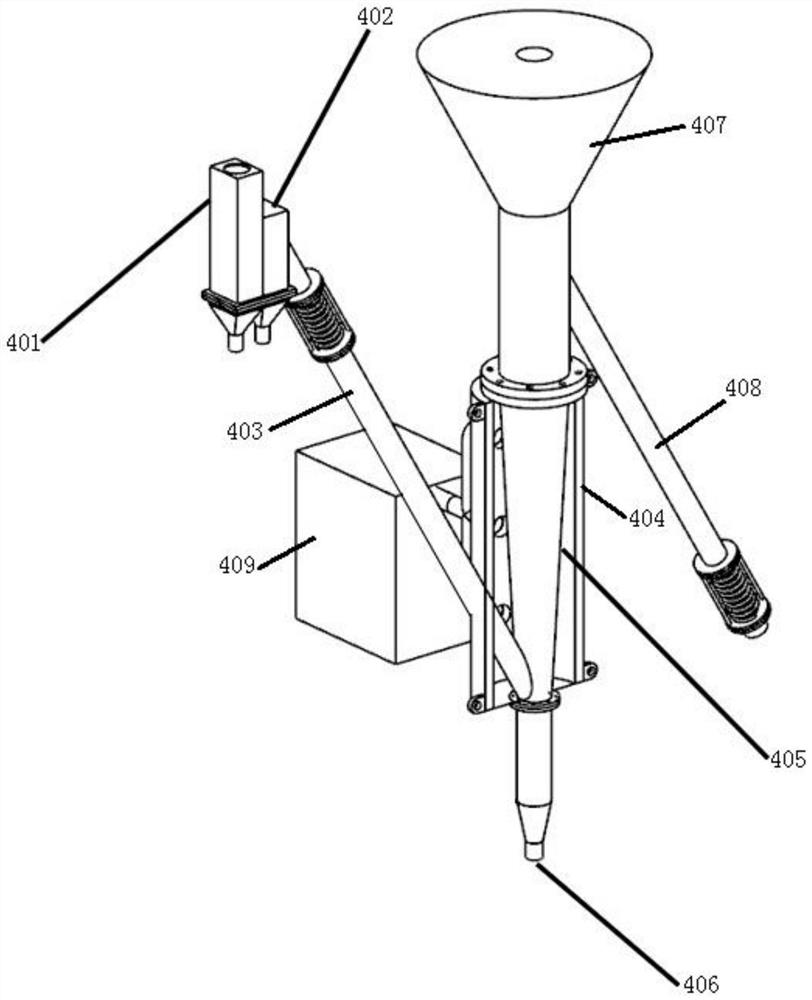

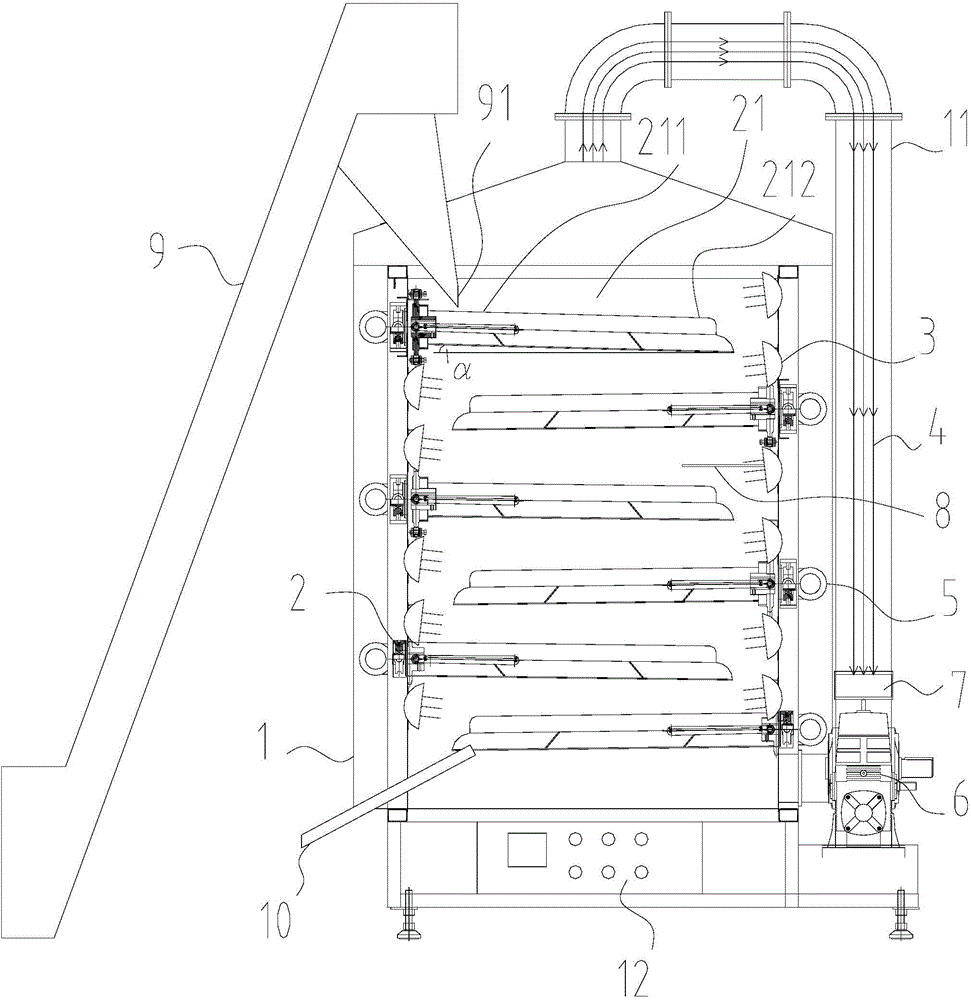

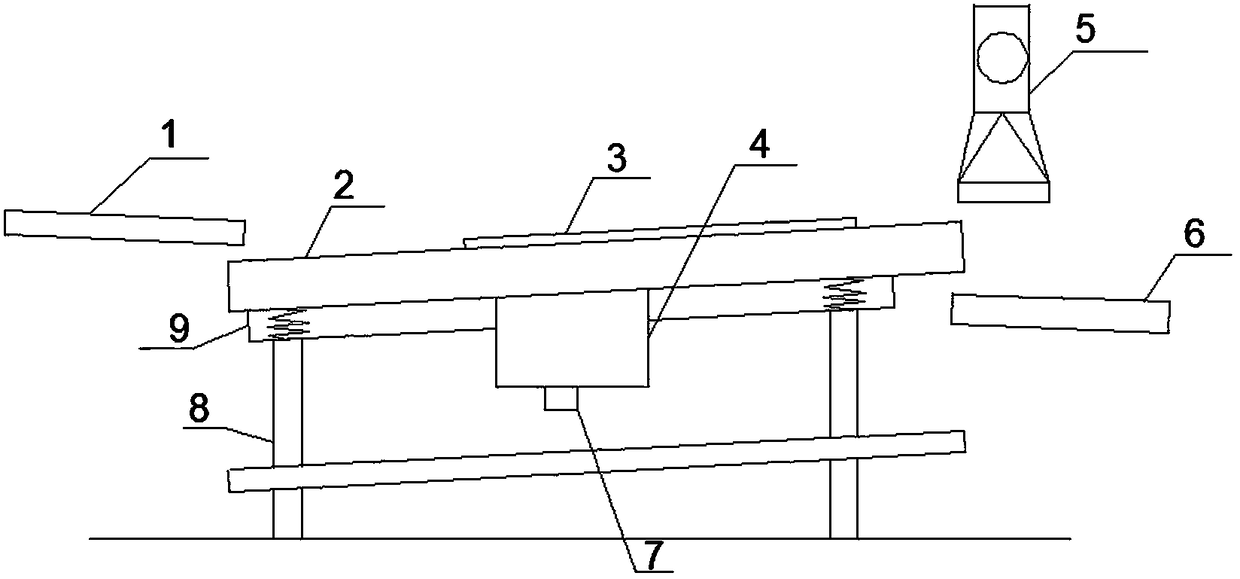

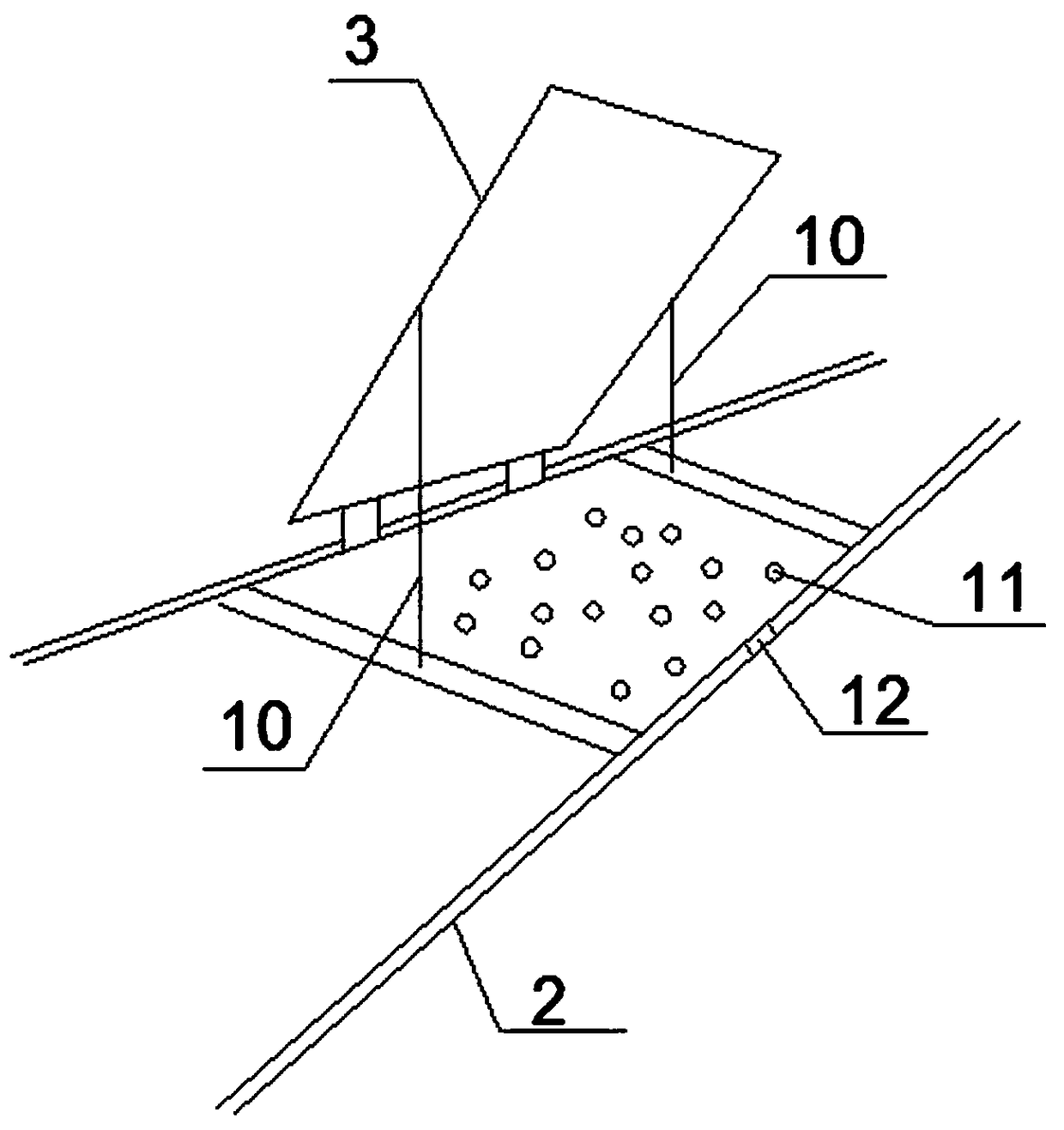

Tea Tower Light Wave Fixing Device

InactiveCN103815068BEvenly heatedAvoid surface hardeningPre-extraction tea treatmentTowerMechanical engineering

The invention relates to the field of tea leaf production equipment and in particular relates to a tower type tea leaf light wave fixation device capable of effectively improving the tea leaf fixation quality and reducing the production energy consumption. The device comprises a tower body, a lifting machine and at least one vibration conveying device, wherein each vibration conveying plate has a tilt angle, the fixed end of the vibration conveying plate is higher than the suspension end of the vibration conveying plate, and a discharging hole is formed above the tower body; a light wave irradiator is fixedly arranged on the inner wall of the tower body and is positioned above the corresponding vibration conveying plate; a hot air circulation system is arranged outside the tower body, the two ends of an air pipe of the hot air circulation system are communicated with the top and the bottom of the tower body respectively, and the air pipe is used for conveying hot air at the top in the tower body to the bottom in the tower body. The device overcomes the defects of scorch edges, burnt points and the like in the whole fixation process and is suitable for the tea leaf fixation process.

Owner:SICHUAN NAT TEST MEASURING INSTR TECH

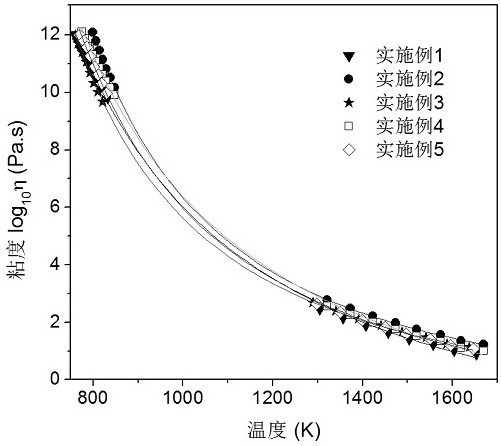

A kind of long-material large bottle glass and preparation method thereof

ActiveCN110282873BSolve the problem that cannot be mechanically formed at one timeLong materialBlow machinesPolymer scienceManufactured material

Owner:QILU UNIV OF TECH +1

Frozen dry jujube and preparation thereof

InactiveCN1176592CAvoid breaking downReduce lossesFruit and vegetables preservationAdditive ingredientFreeze-drying

A freeze dried jujube is prepared from fresh jujube through removing kernel, pre-freezing and freeze drying in vacuum freeze drier where water is directly sublimated. Its advantages are less loss of nutrients, and original color and taste.

Owner:FOOD INST LULIANG DISTRICT SHANXI PROV

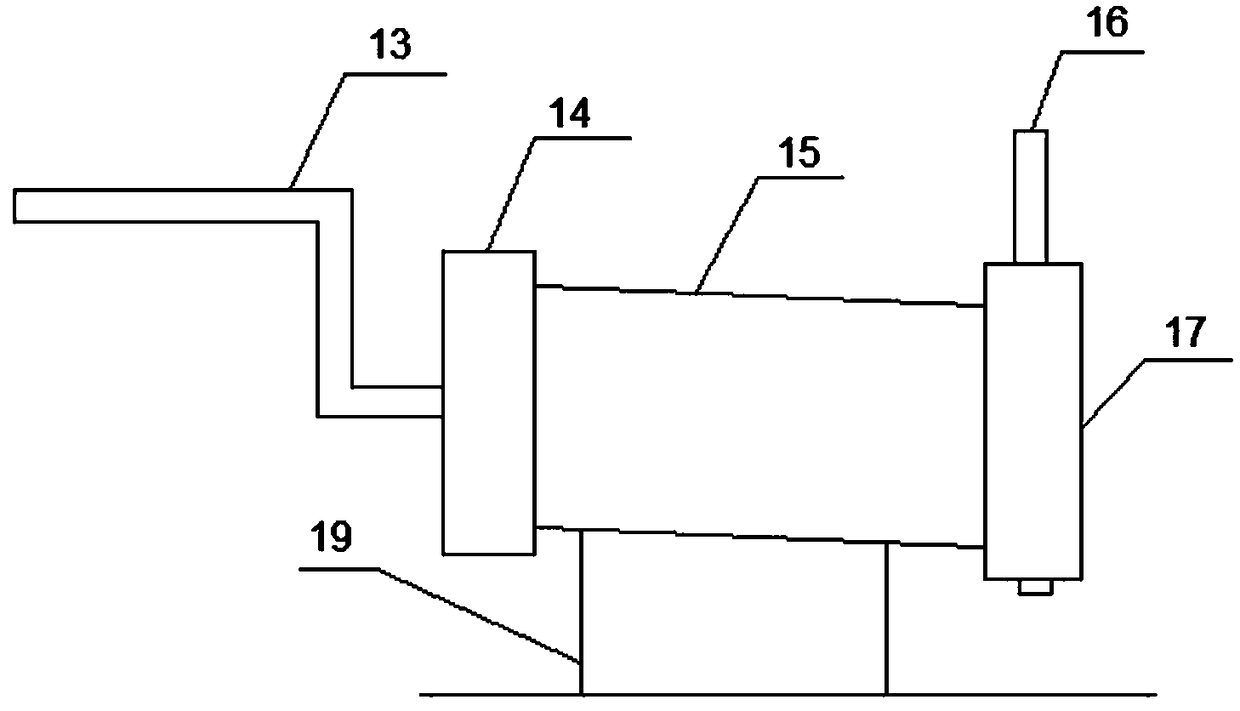

A technology for drying shredded tobacco combined with high frequency and thin plate

The invention discloses a device and process for drying shredded tobacco in combination with high frequency and thin plate, which comprises a shredded tobacco HT moisture resurfacing system, a high frequency dryer, a shredded tobacco feeding system and a thin plate low temperature shredded drying machine. Feeding device, the shredded tobacco HT moisture regain system is connected with the high-frequency dryer through the homogenizing device. A feeder and a vibrating trough are arranged at the end in turn, and the discharge end of the shredded tobacco feeding system is connected with the thin-plate low-temperature shred drying machine through the feeder and the vibrating trough in turn. The invention not only can effectively improve the drying efficiency of shredded tobacco, but also has short drying time and high effective utilization rate of energy, thereby greatly improving the quality of shredded tobacco, increasing the filling capacity of shredded tobacco, and reducing the miscellaneous gas and irritation in shredded tobacco , improves the purity of cut tobacco, significantly improves the sensory quality of cut tobacco, and is suitable for large-scale industrial use.

Owner:CHINA TOBACCO HENAN IND

Processing method for vacuum freeze drying of Hemerocallis fulva L.

ActiveCN103283819BYellow-green colorCrisp and tenderFruit and vegetables preservationVitamin CAdditive ingredient

The invention discloses a processing method for vacuum freeze drying of Hemerocallis fulva L. The processing method comprises the following steps: S1, pre-freezing pretreated fresh Hemerocallis fulva L. at a temperature of -40 DEG C for more than 10 h; and S2, freeze drying the prefrozen Hemerocallis fulva L. at a temperature of -40 to -50 DEG C in a high vacuum state for 12 to 16 h. The invention has the following beneficial effects: pretreated Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and is safe to eat since colchicine is inactivated; the process of vacuum freeze drying is employed, so the processed Hemerocallis fulva L. maintains good appearance, intact flower buds and the original color, fragrance, flavor and shape of Hemerocallis fulva L., water content in the processed Hemerocallis fulva L. is low, a loss late of nutritional ingredients like protein, vitamin C, a dietary fiber and the like is low, and a storage life of the processed Hemerocallis fulva L. is long; rehydration of the processed Hemerocallis fulva L. is easy, and the processed Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and retains original delicate fragrance after rehydration.

Owner:四川省宕府王食品有限责任公司

Drunken tilapia snack food and processing method thereof

The invention discloses a drunken tilapia snack food and a processing method thereof. Tilapia fillets are prepared into semi-dried drunken fillets through the steps of picking, inebriating, vacuum microwave drying and the like. By controlling the drying conditions, the flavoring material and original chewiness of the drunken fish are well maintained while the water content of the drunken fish is improved, and thus the drunken fish is good in flavor and taste. The process is capable of shortening the production period, reducing the production cost, and facilitating production. The drunken tilapia snack food processed by the method disclosed by the invention is natural in flesh color, compact, fresh and tender in meat, proper in salt taste, hardness and moisture, free from intermuscular fishbone, and suitable for people of all ages. The method is further suitable for small and medium freshwater fish, such as colussoma brachypomum, without or with less intermuscular fishbone.

Owner:GUANGDONG YUJIA AQUATIC FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com