Green tea powder capsule and preparation method thereof

A technology for green tea powder and capsules is applied in the directions of pre-extraction tea treatment, food ingredients as taste modifiers, and functions of food ingredients, etc. problems, to avoid surface hardening, better taste, and reduce the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

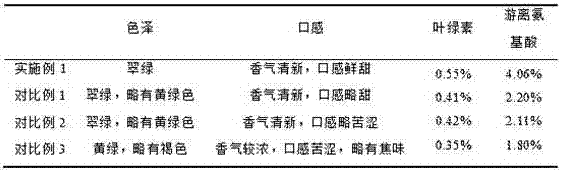

Examples

Embodiment 1

[0010] Spray 50g of steamed green tea with a concentration of 0.3% mannitol aqueous solution, adding 2% of the weight of the steamed green tea, then place it at 10°C for 1 hour, and then pre-freeze it in a fluidized liquid nitrogen quick-freezing equipment , the temperature is -50°C, and then the pre-frozen tea leaves are put into a vacuum freeze-drying box with a vacuum degree of 15 Pa, and the temperature is raised to 35°C at a step temperature of 0.5°C per minute, and the temperature is maintained for 4 hours, and then freeze-dried The tea leaves are pulverized into 1500-2000 mesh powders at low temperature with ultrafine powder grinding equipment, and packed into capsules made of plant starch to obtain a green tea powder capsule.

Embodiment 2

[0012] Spray 50g of steamed green tea leaves with a concentration of 0.5% mannitol aqueous solution, the addition amount is 5% of the weight of the steamed green tea leaves, and then place it at 10°C for 1 hour, and then pre-freeze it in a fluidized liquid nitrogen quick-freezing equipment , the temperature is -50°C, and then the pre-frozen tea leaves are put into a vacuum freeze-drying box with a vacuum of 10 Pa, and the temperature is raised to 30°C at a step temperature of 0.5°C per minute, and the temperature is maintained for 5 hours, and then the freeze-dried The tea leaves are pulverized into 1500-2000 mesh powders at low temperature with ultrafine powder grinding equipment, and packed into capsules made of plant starch to obtain a green tea powder capsule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com