Heater and picture foring device containing heater

A heating device and technology to be heated, applied in the direction of drum heating device, induction heating device, electric heating device, etc., can solve the problems of uneven heating, uneven gloss, heating roller failure, etc., and achieve good heat resistance and high gloss characteristics , the effect of preventing surface hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

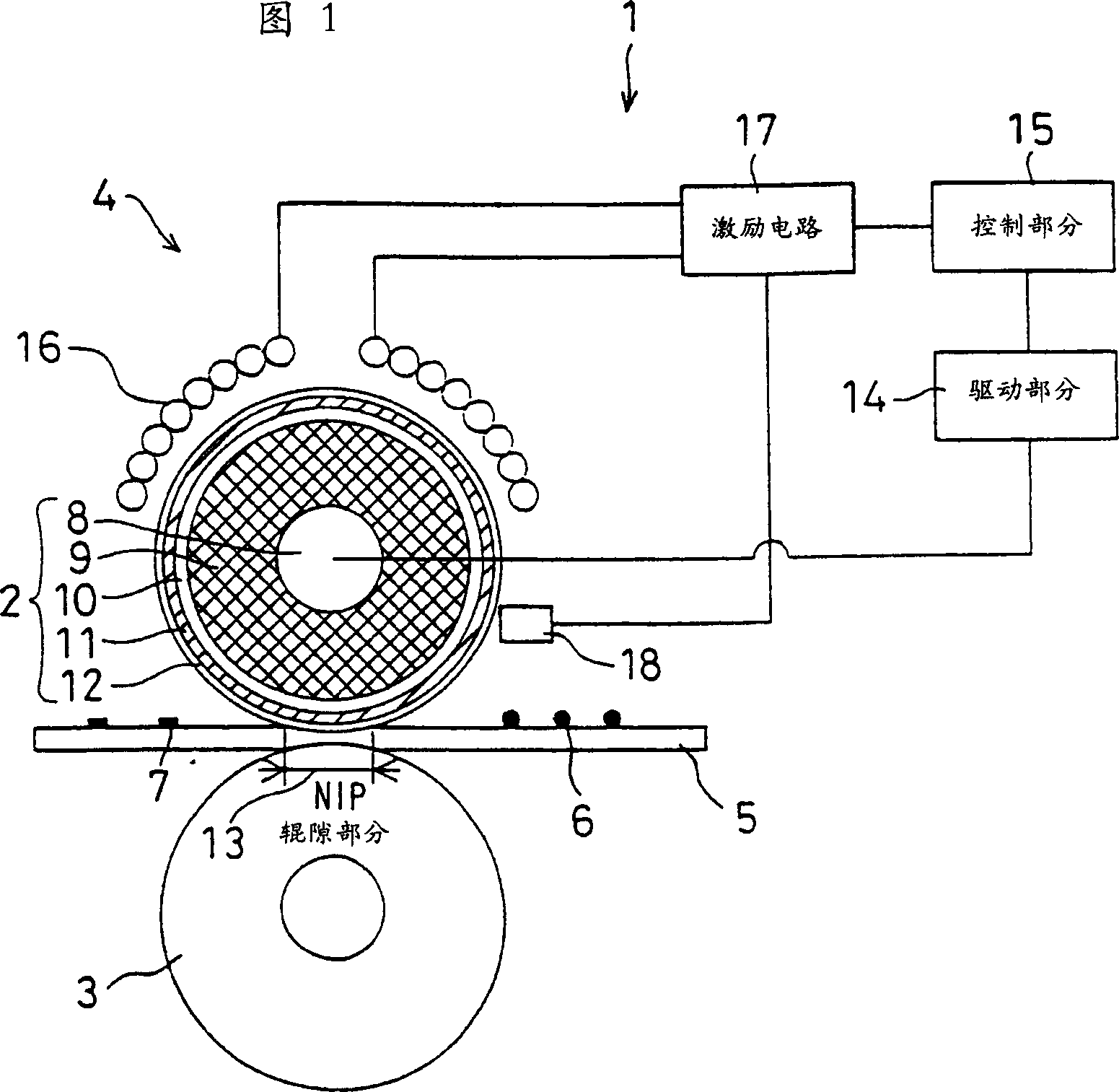

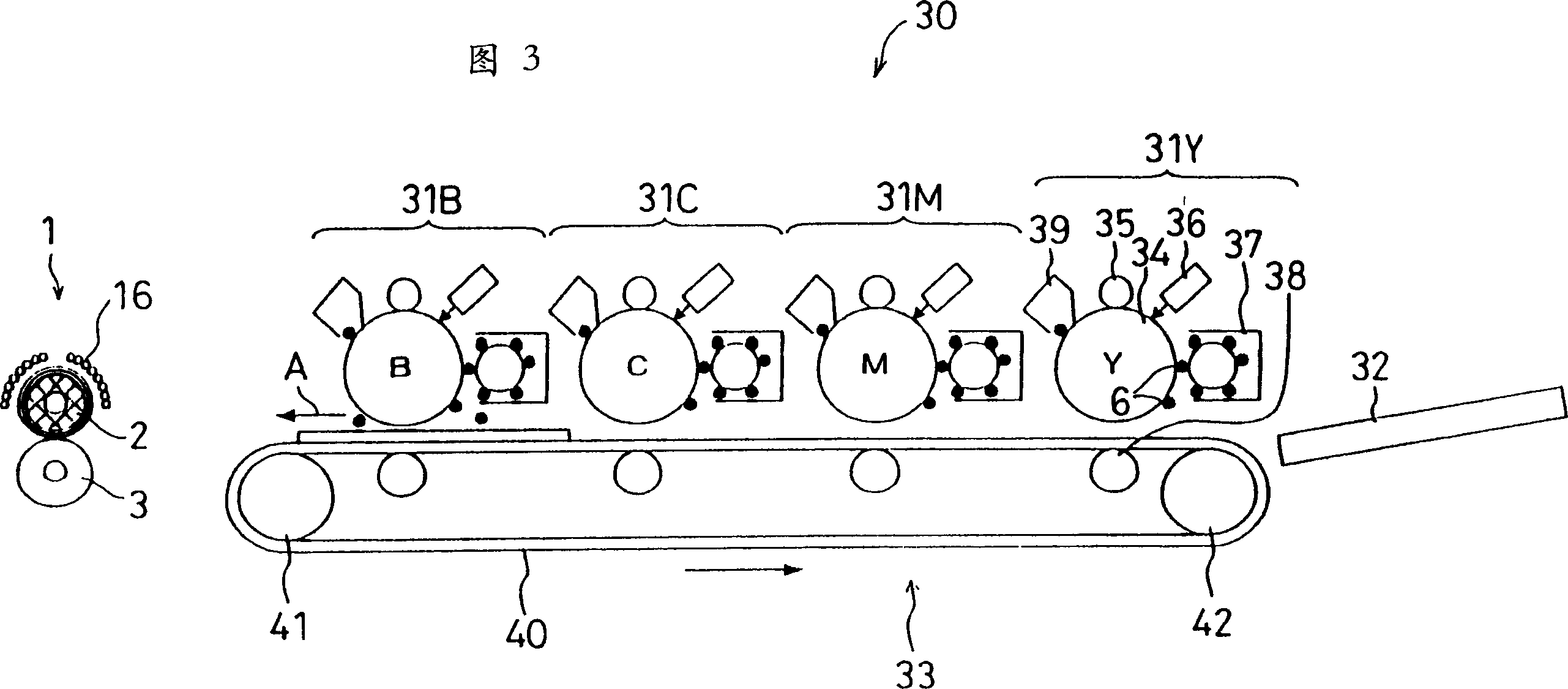

[0067] The heating roller 2 includes a second elastic layer 11 sandwiched between a conductive layer 10 and a release layer 12 . Here, the color fixing performance was examined for the action of the second elastic layer 11 formed in the heating roller 2 .

[0068] Stated below are the conditions satisfied by the elements constituting the color fixing device 1 under the evaluation regarding the color fixing performance. Here, the heat roller 2 is configured as follows. On the core body 8 made of hollow metal made of aluminum with an outer diameter of 28 mm, a first elastic layer 9 is formed, which is a 6 mm thick sponge elastic layer obtained from foamed silicone rubber. The conductive layer 10 is located on the outer periphery of the first elastic layer 9 and is composed of a 40 μm thick nickel metal sleeve. The following is an evaluation of three different types of heated rollers:

[0069] (1) In the heating roller, only a peeling layer 12 with a thickness of 30 μm is form...

Embodiment 2

[0081] In Example 1, the appropriate thickness of the second elastic layer 11 was checked. In Example 2, the elongational modulus of elasticity of the peeling layer 12 related to obtaining a high-quality image was examined.

[0082] In the heat roller 2, the thickness of the second elastic layer 11 was set to 150 μm, and the thickness of the release layer 12 was set to 30 μm. Here, the elongation modulus of elasticity of the release layer 12 is set to three different levels: 1.96×10 8 Pa(0.2×10 4 kg / cm 2 );5.88×10 8 Pa(0.6×10 4 kg / cm 2 );9.8×10 8 Pa(1.0×10 4 kg / cm 2 ). That is, three different heating rollers are prepared, each installed in the color fixing device 1, respectively. Then, the color fixing performance of the heat roller 2 and its effect on the fixed image were examined. In Example 2, the color fixing temperature was set at 170°C. An unfixed color toner image composed of a single-layer color toner image is formed on the recording paper 5 . The viscous...

Embodiment 3

[0091] Next, the effect of the surface roughness of the peeling layer 12 on the color fixing performance was examined. In this embodiment, two different heating rollers 2 are prepared. In one of them, the surface roughness of the peeling layer 12 is set to 0.3 μm based on the average surface roughness Ra on the center line, or 1.0 μm based on the ten-point average surface roughness Rz. In another of these, the surface roughness of the peeling layer 12 is set to 0.4 μm based on Ra, or 2.0 μm based on Rz. In the color fixing device 1 including each heating roller 2, the color fixing performance was evaluated on the basis of an area without shift. Also, in the present embodiment, the thickness of the second elastic layer 11 of the heating roller 2 is set to 150 μm, and the thickness of the release layer 12 is set to 30 μm. Here, the elongation modulus of elasticity of the release layer 12 is 5.88×10 8 Pa. The color fixing temperature was set at 170°C. Other conditions are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com