Patents

Literature

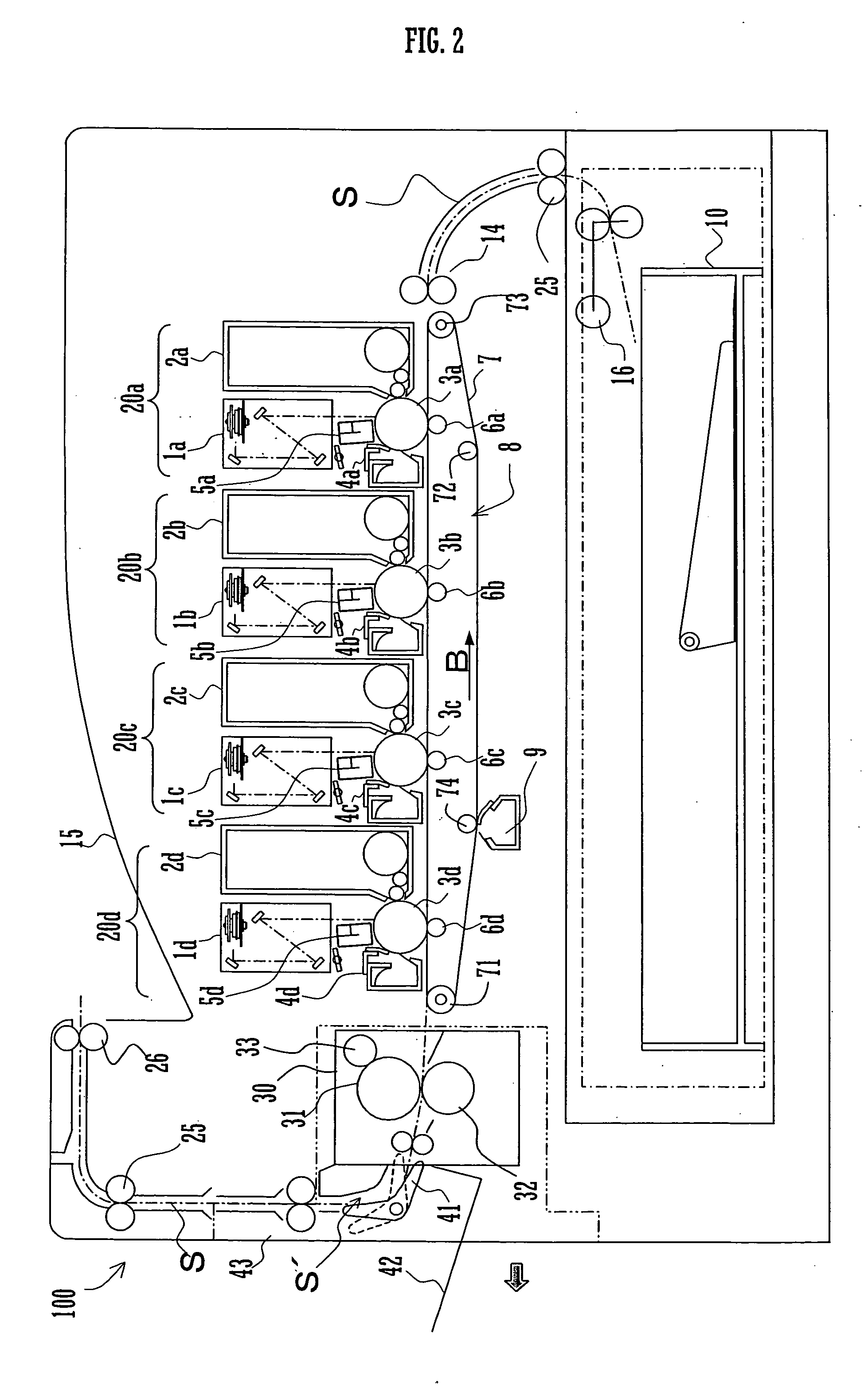

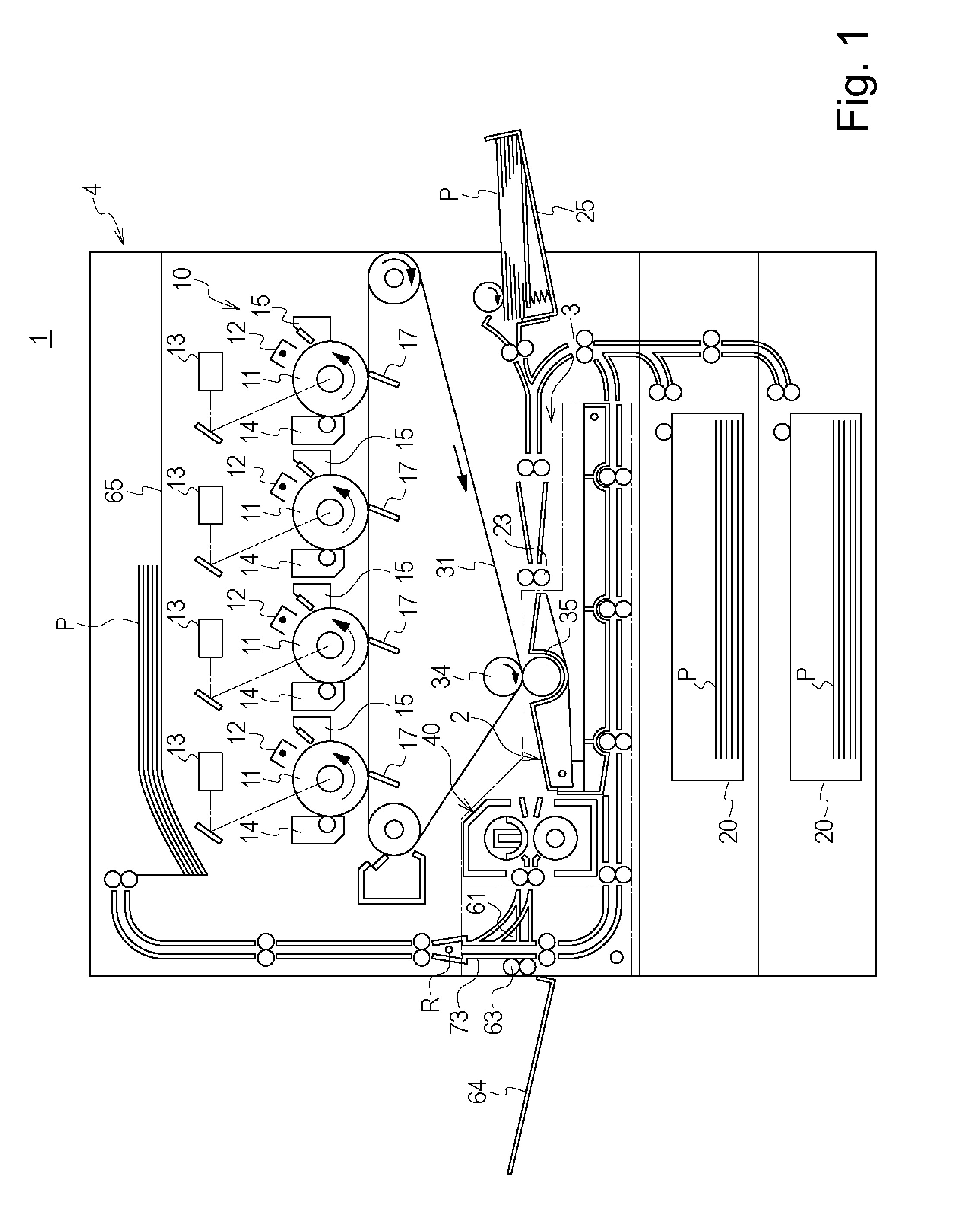

147results about "Roller heating devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heater and image heating device mounted with heater

ActiveUS20140076878A1Avoid temperature riseOhmic-resistance electrodesElectrographic process apparatusElectrical resistance and conductanceMechanical engineering

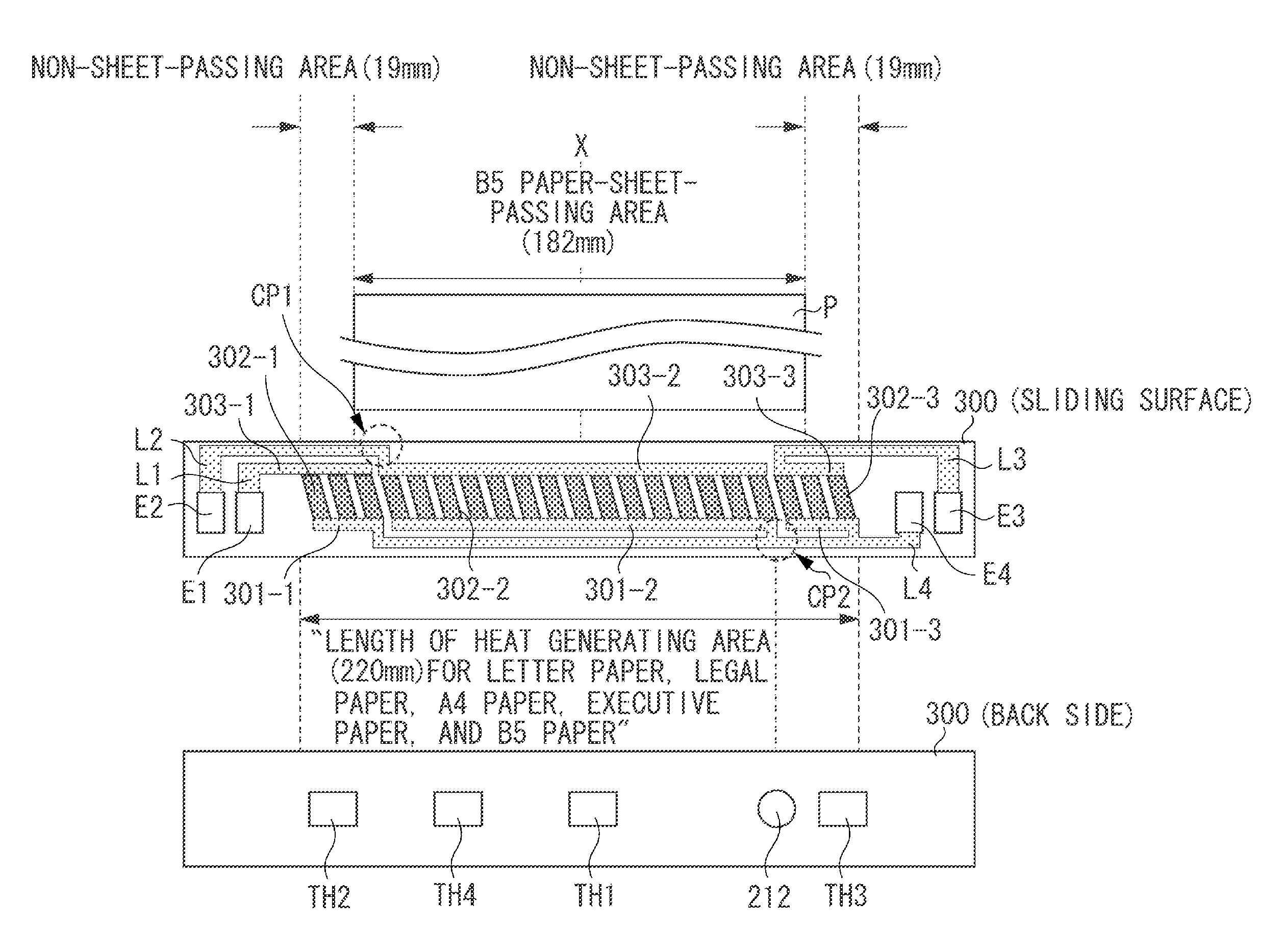

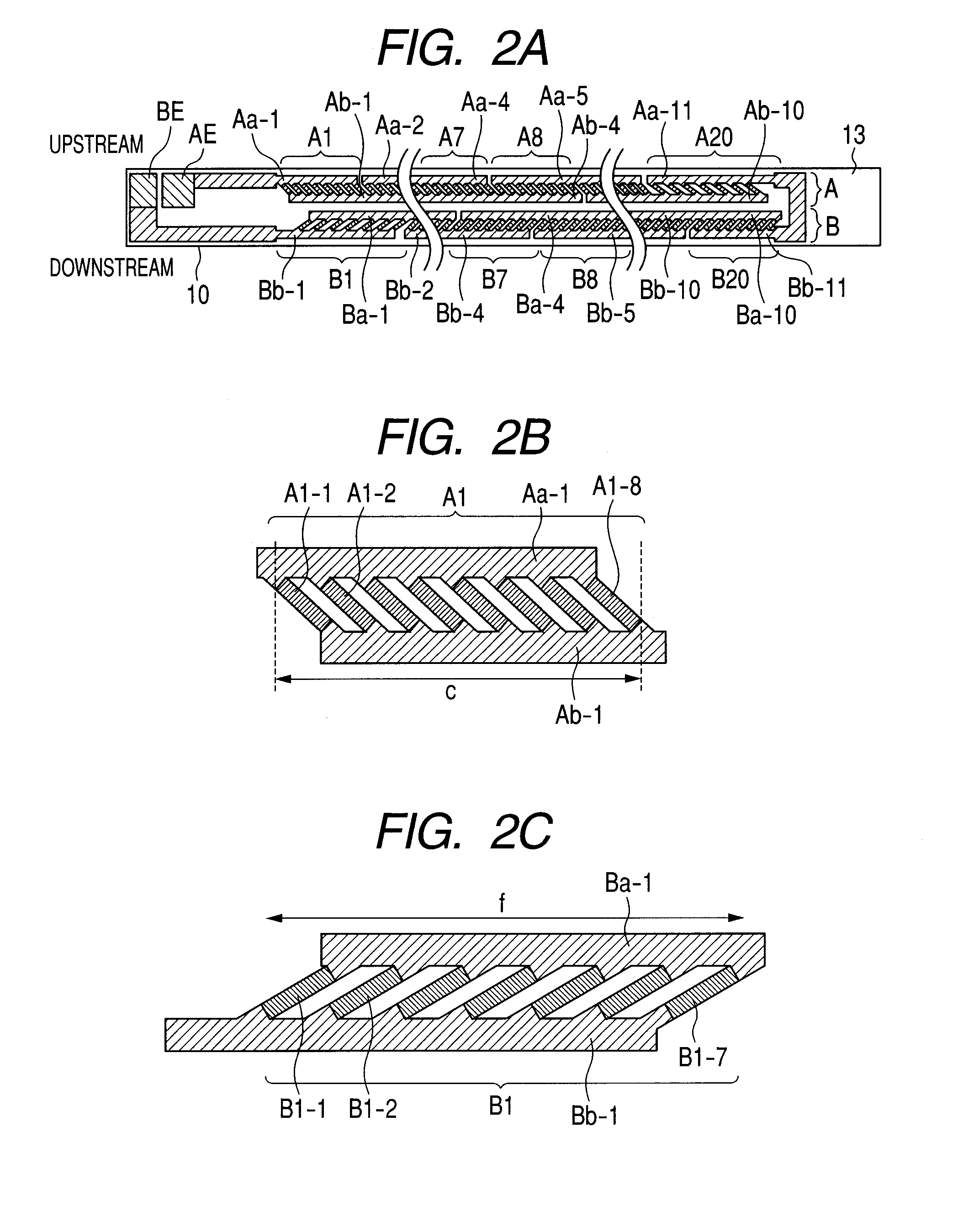

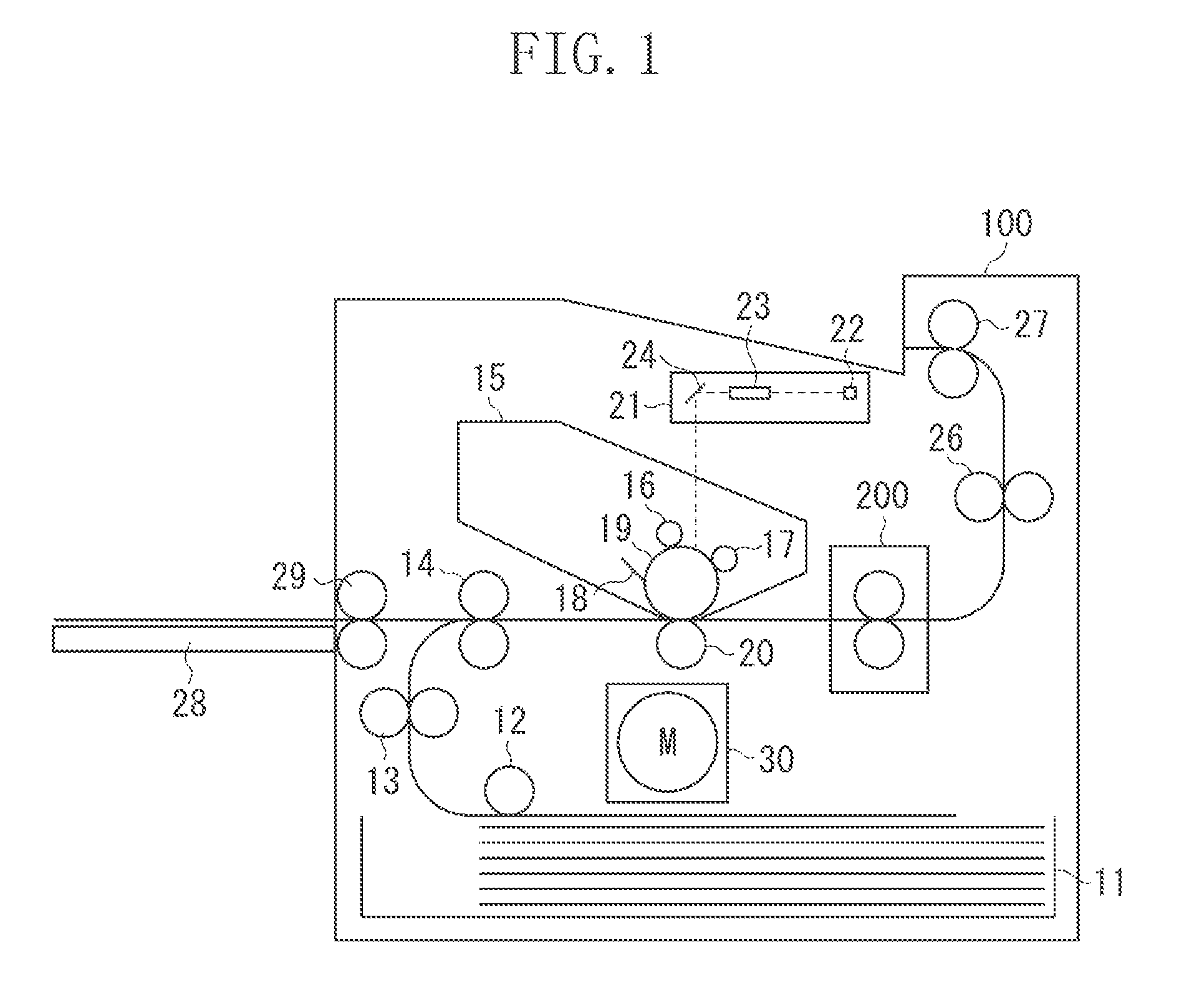

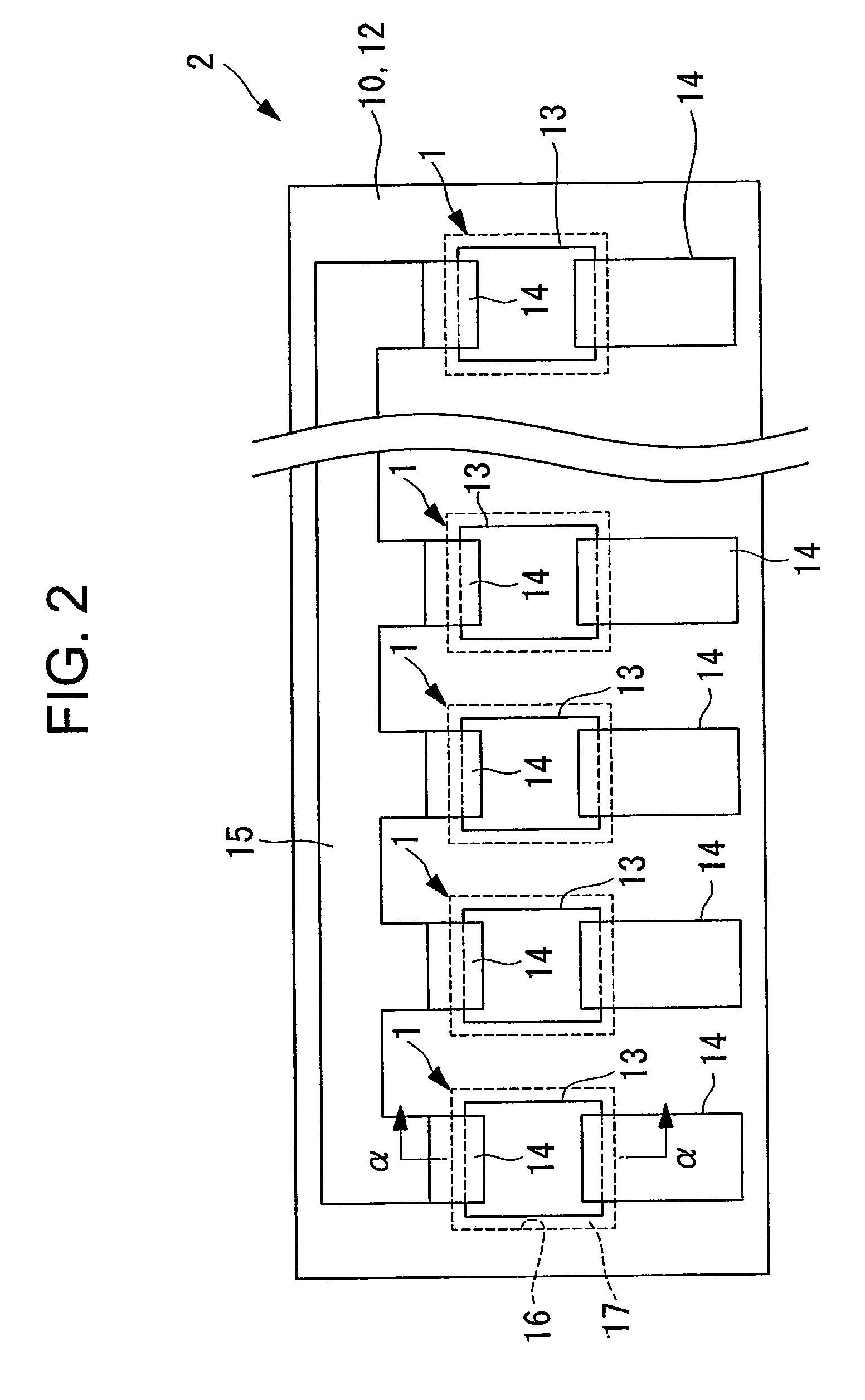

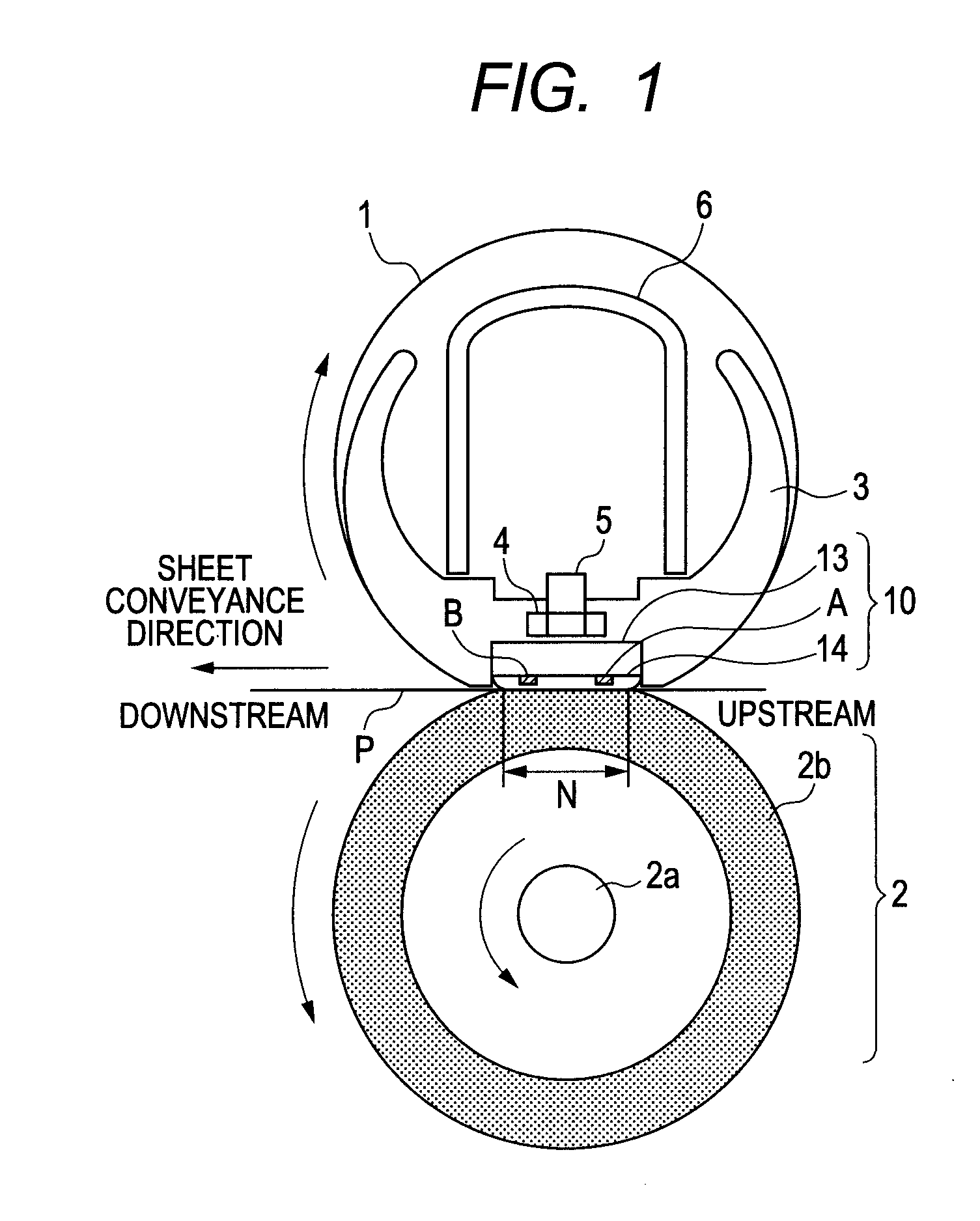

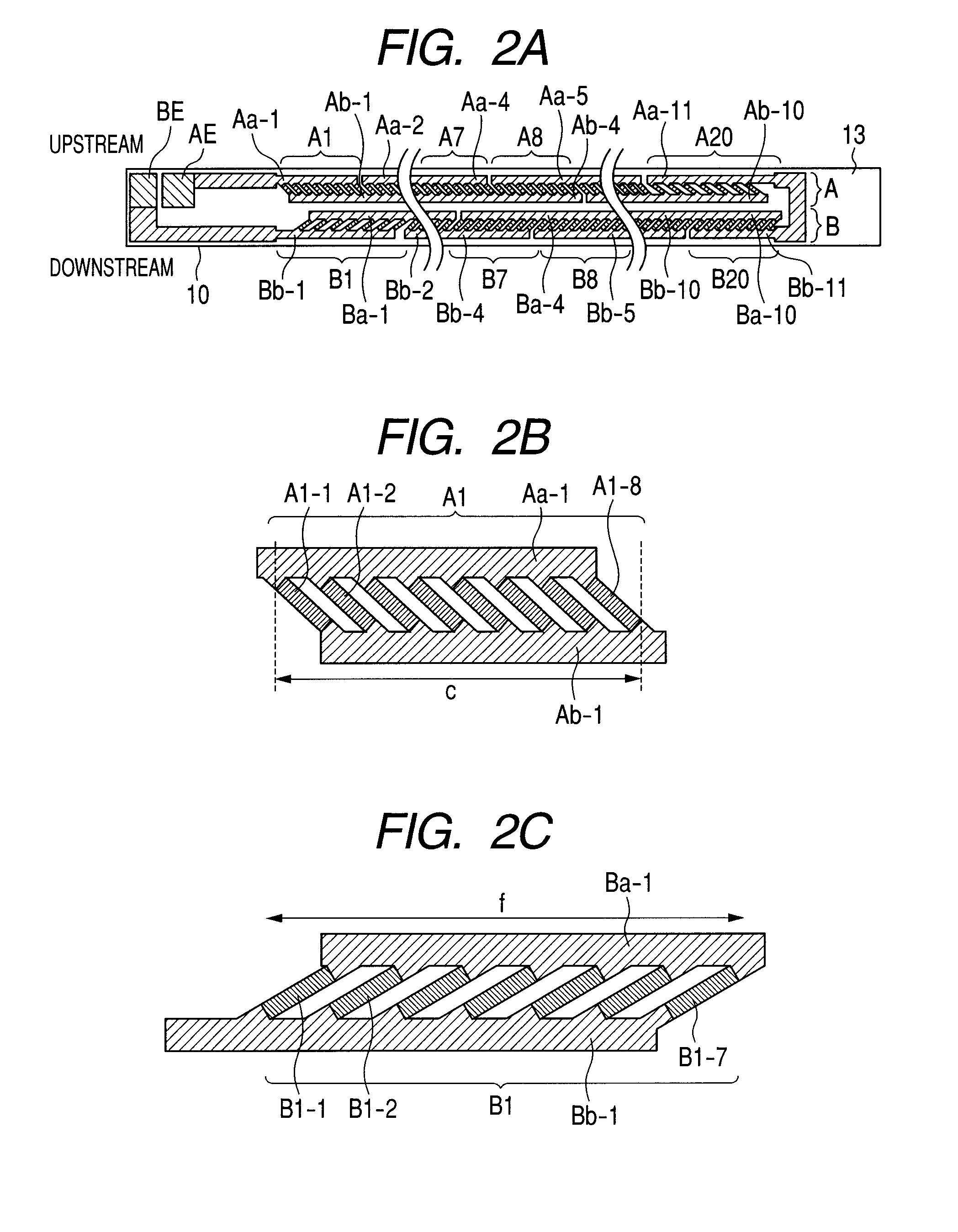

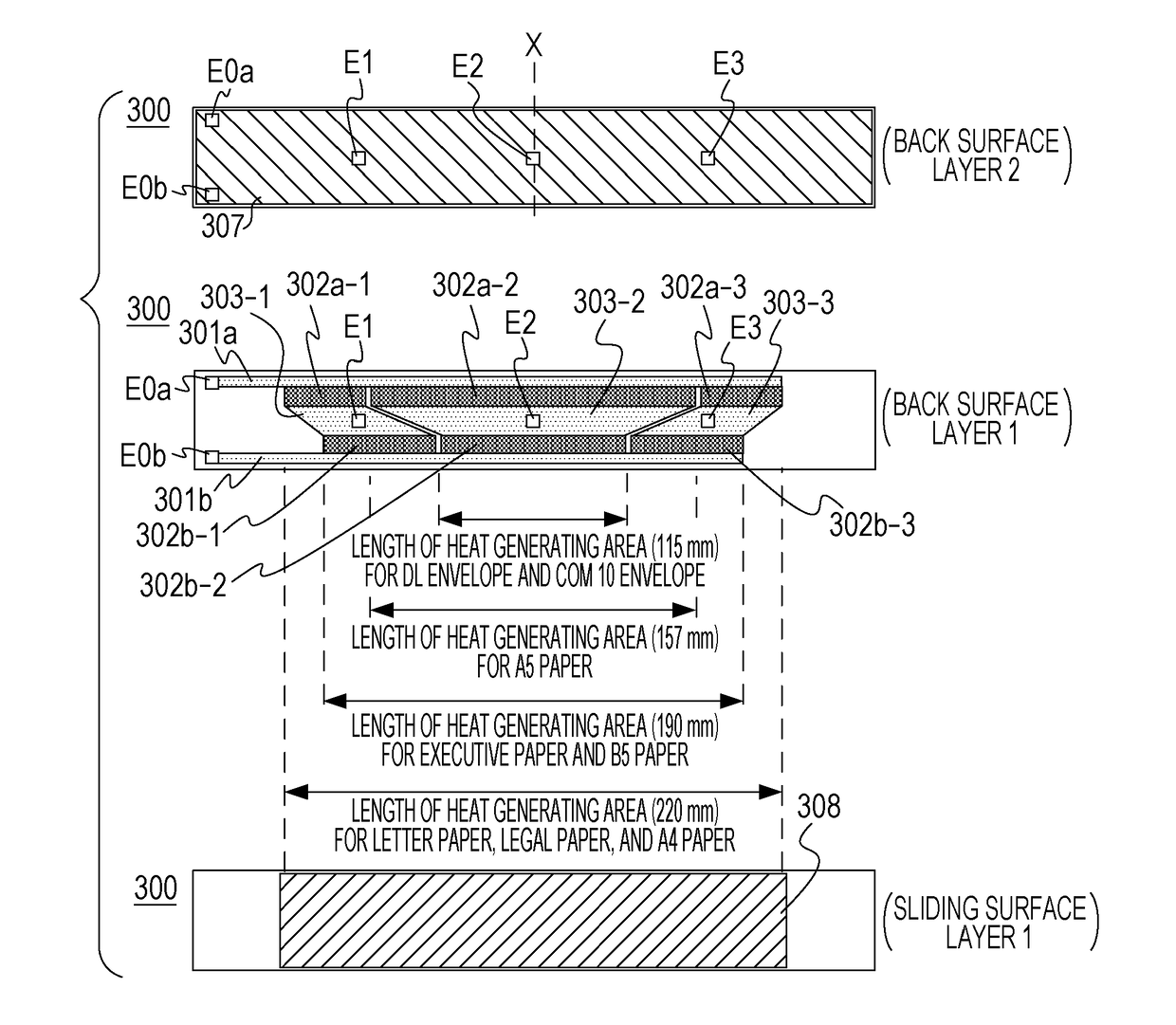

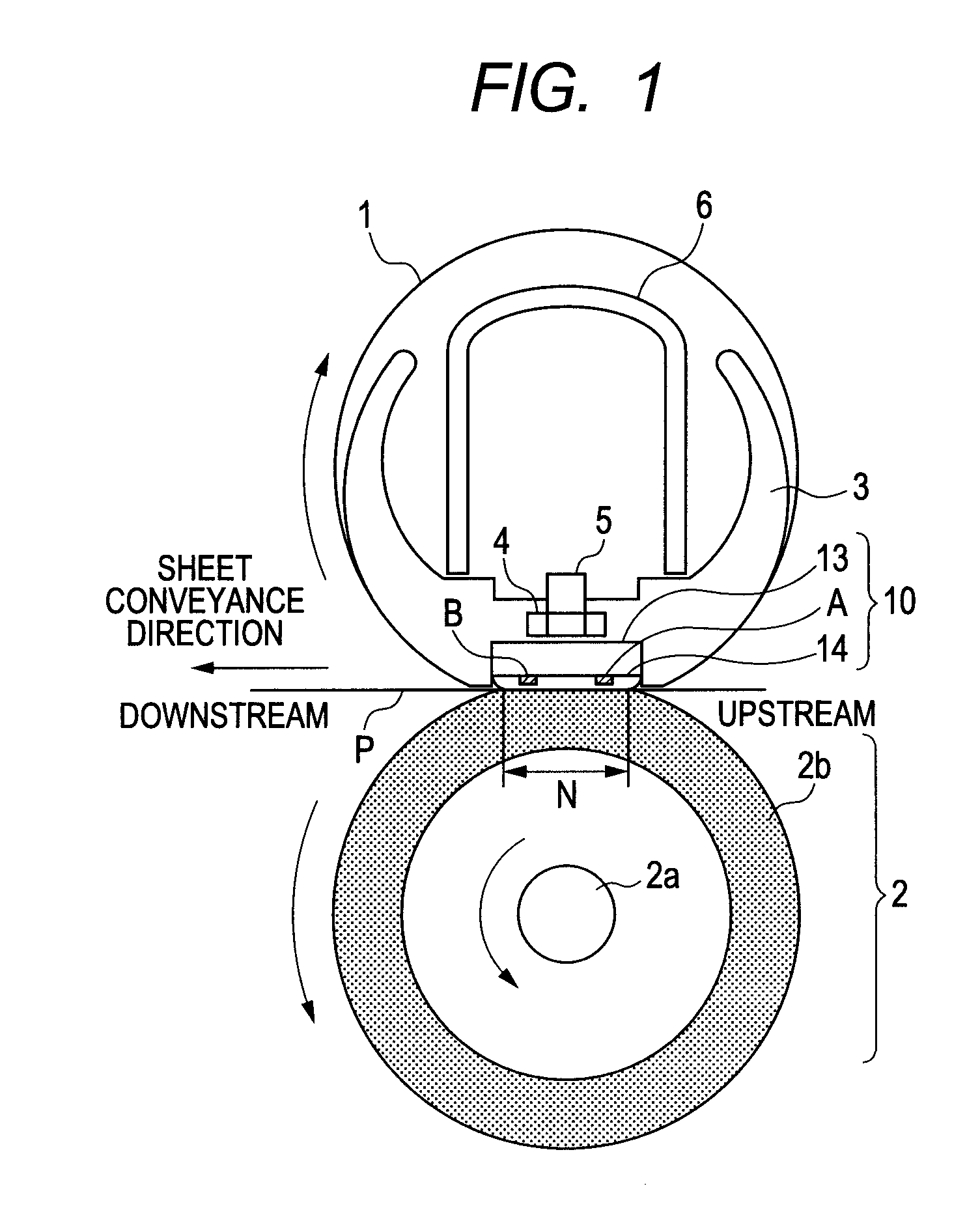

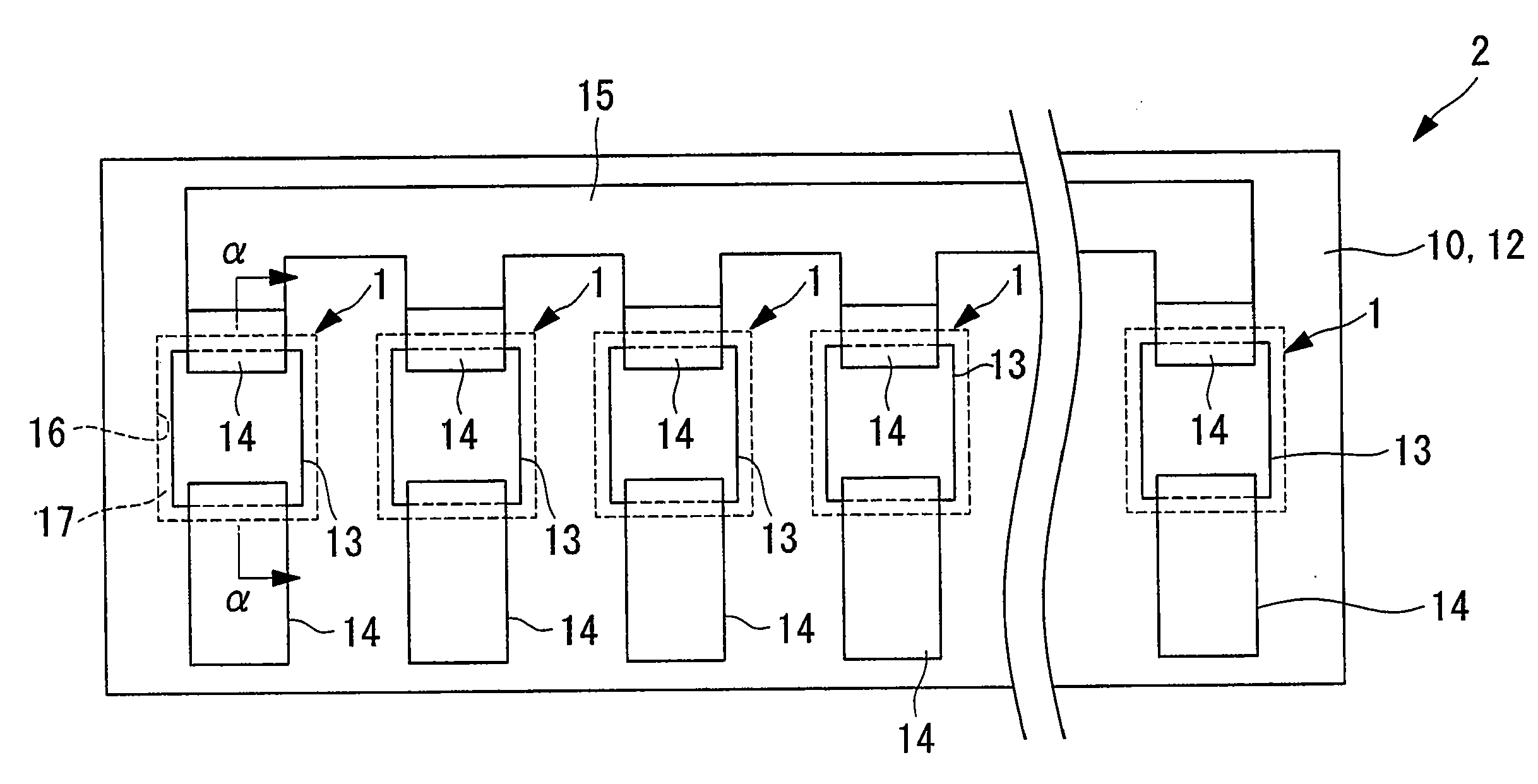

A heater of the present invention includes jointed heat generating resistors having a positive temperature characteristic of resistance and provided between a first conductive element and a second conductive element on a substrate in a longitudinal direction of the substrate, and a plurality of heating blocks provided in the longitudinal direction, each of which is a set of the first conductive element, the second conductive element, and the heat generating resistor, and power supplied to at least one of the plurality of heating blocks can be controlled independent of other heating blocks.

Owner:CANON KK

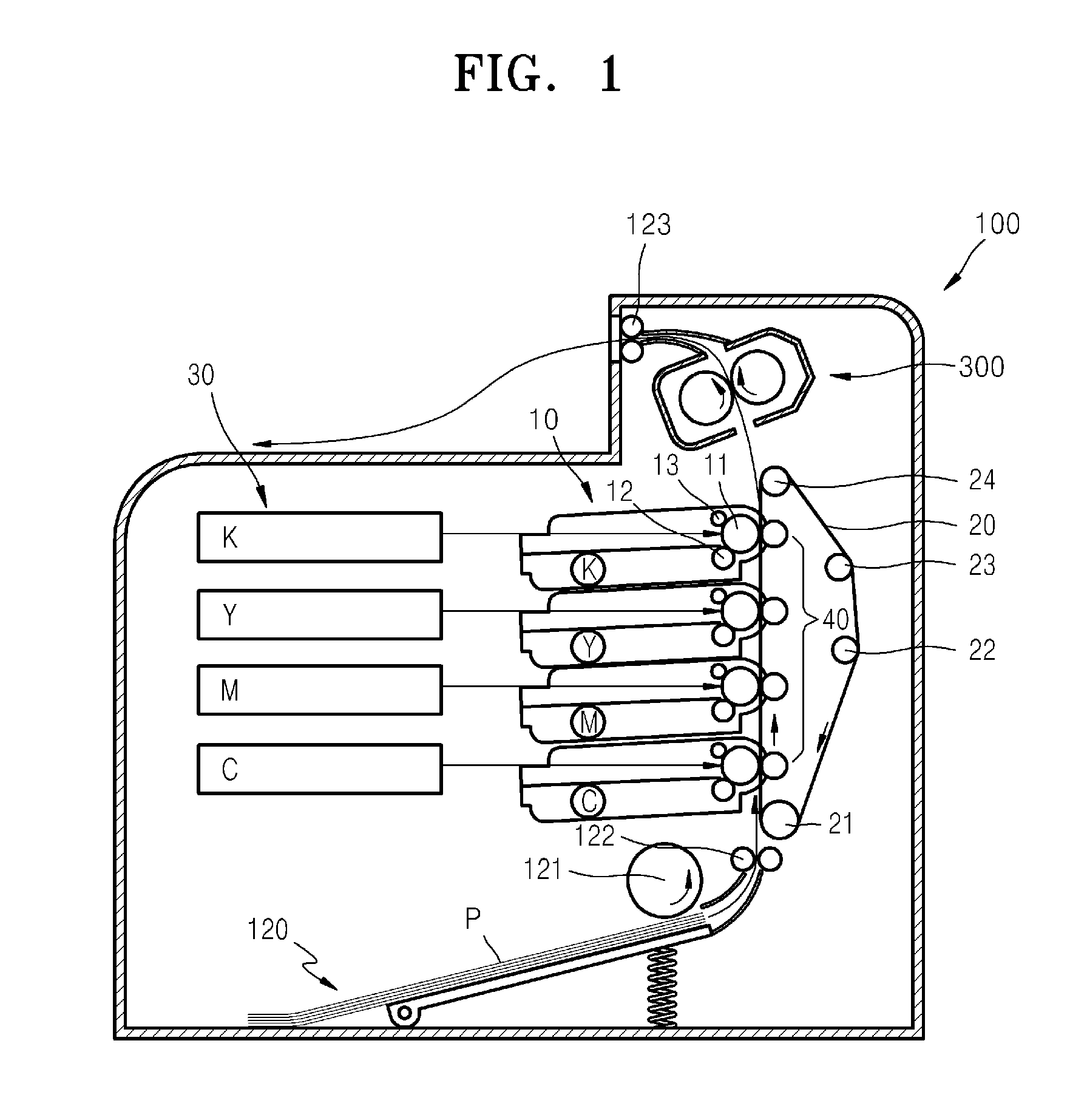

Fixing device for an image forming apparatus and fixing roller for the same

InactiveUS6122479AReduce power consumptionIncreased durabilityShaft and bearingsOhmic-resistance heating detailsElectricityImage formation

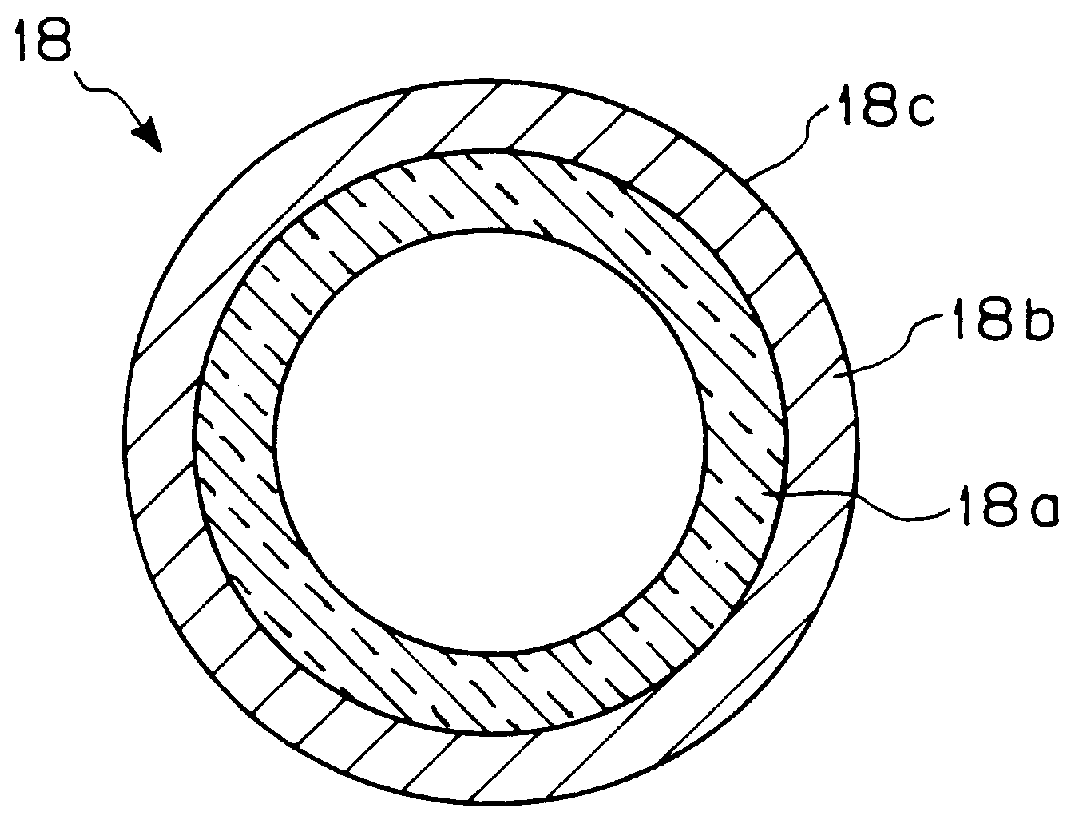

In a fixing device for an image forming apparatus, a heat roller includes a hollow cylindrical base, a heating layer formed of strip-like fibers implementing desired power consumption, and a parting layer provided on the outer periphery of the heating layer with the intermediary of an electrical insulating layer. The strip-like fibers of the heating layer are wound on the base and provided with a preselected resistance.

Owner:RICOH KK

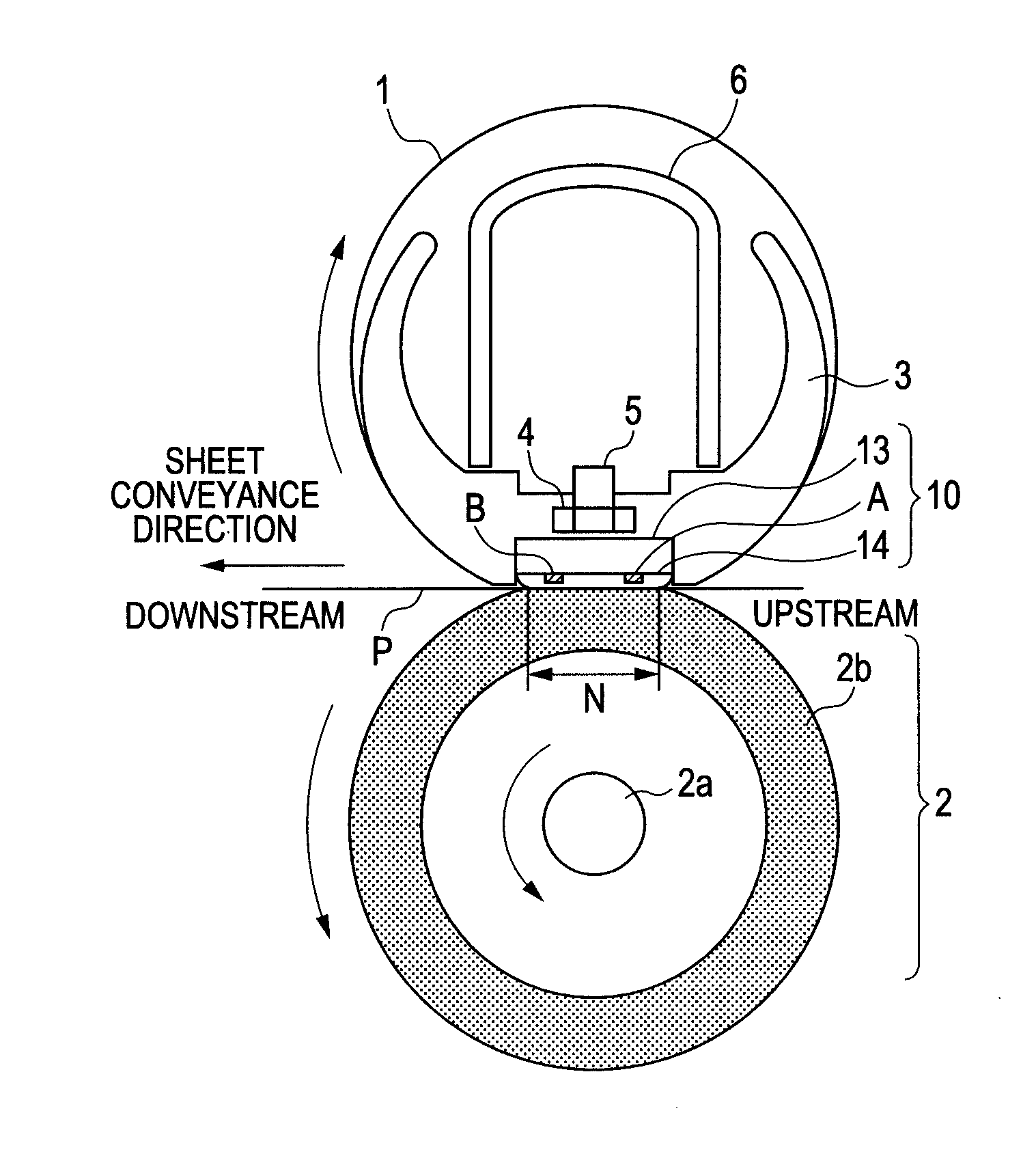

Image heating apparatus and heater for use therein

ActiveUS7203438B2Decrease in numberSuppress uneven temperature distributionOhmic-resistance electrodesElectrographic process apparatusElectrical resistance and conductanceElectricity

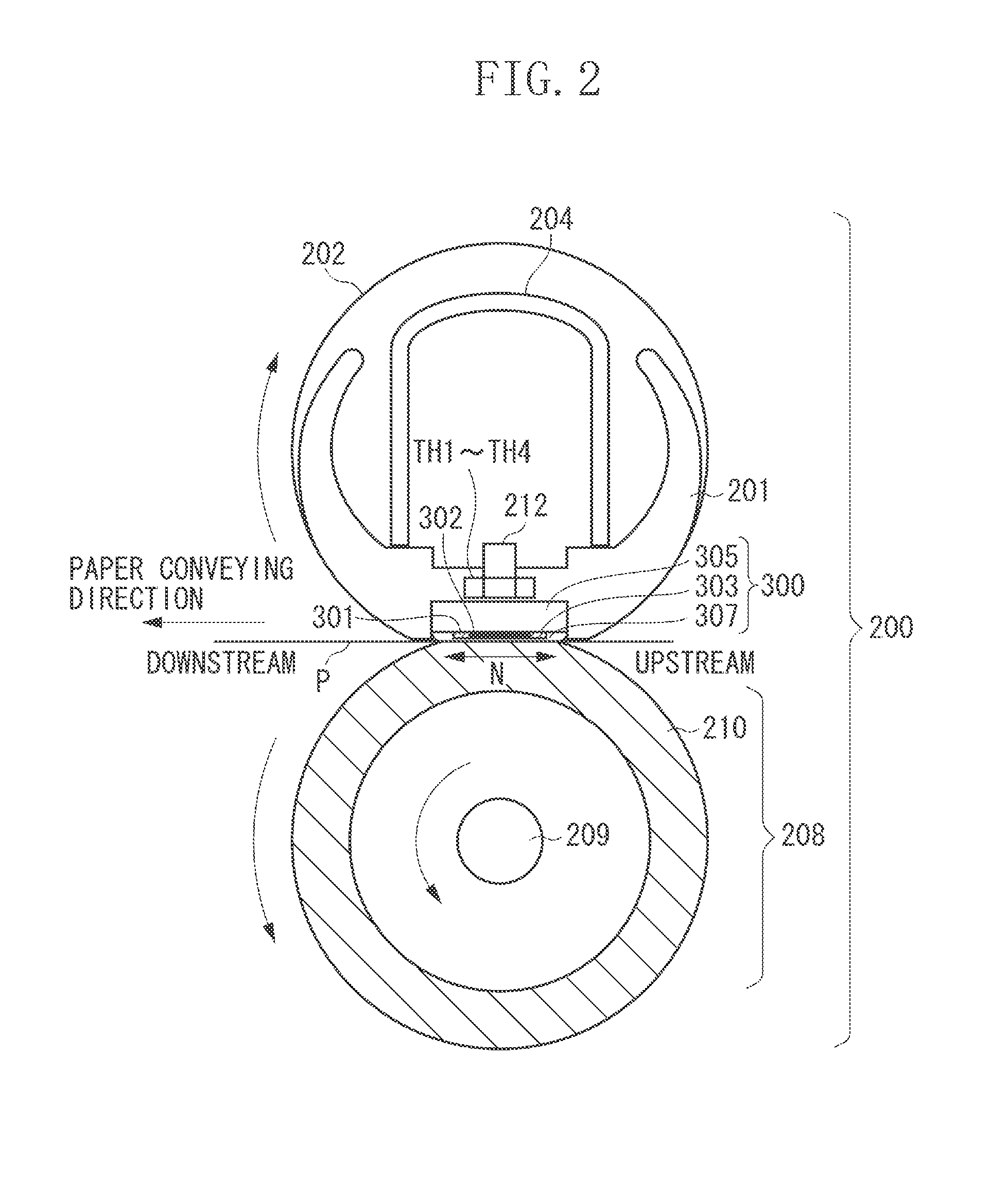

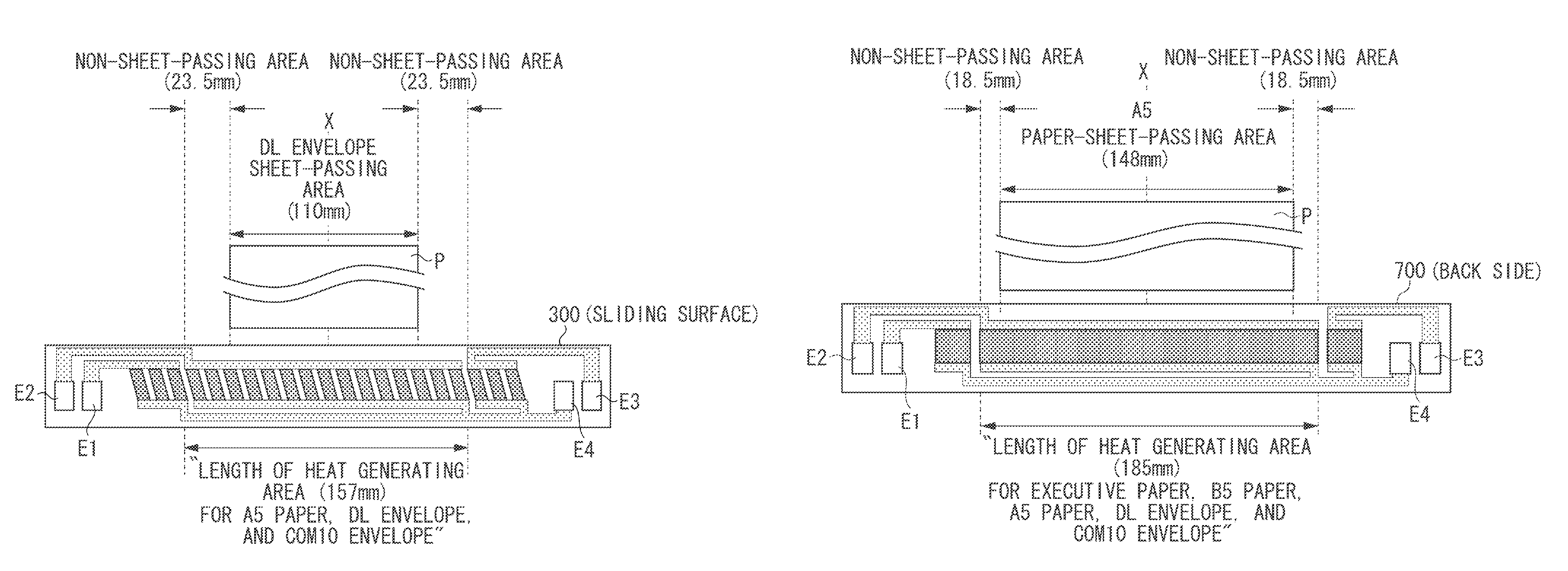

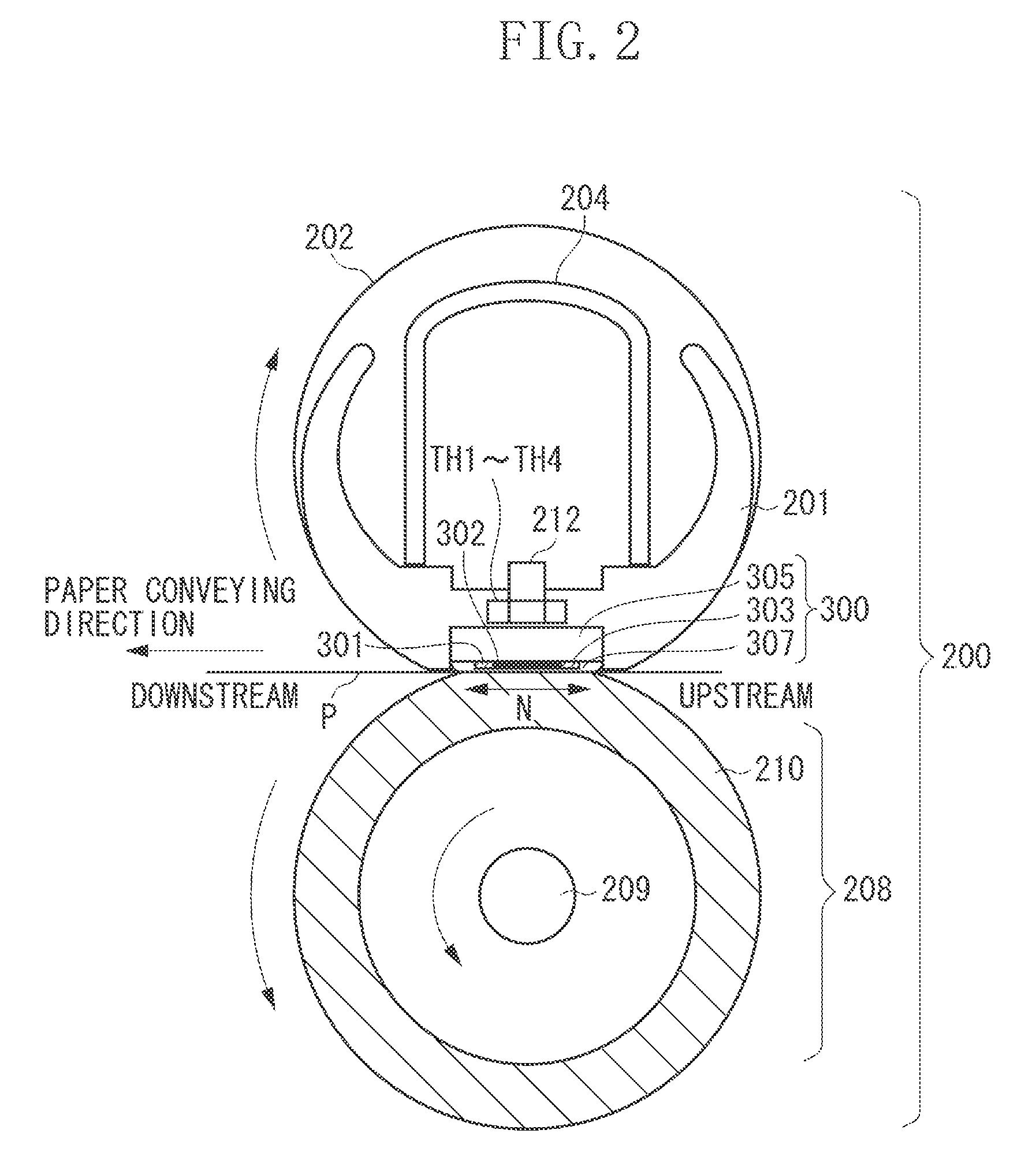

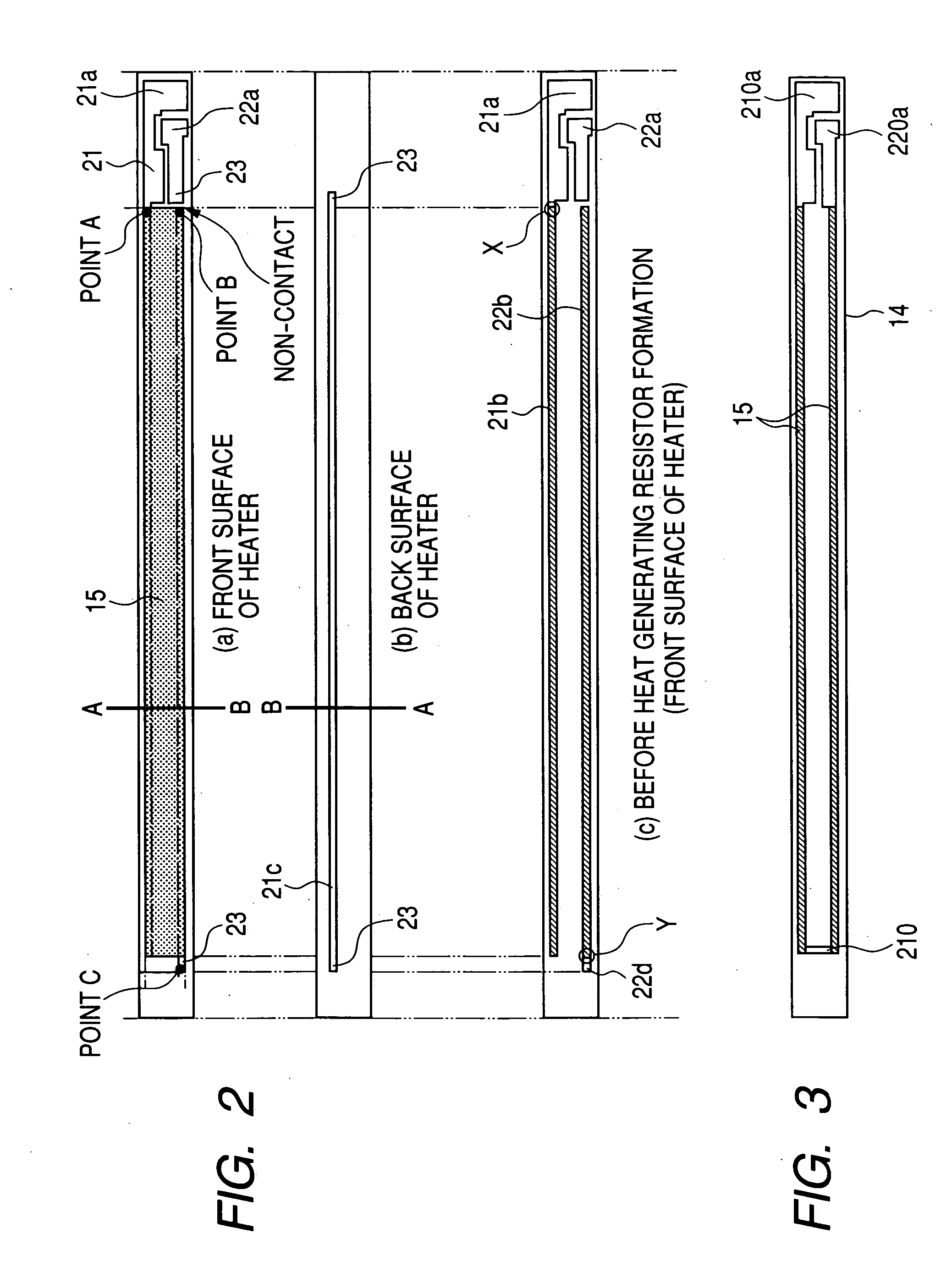

Image heating apparatus capable of preventing an excessive temperature increase in a sheet non-passing area and heater for use in the image heating apparatus including: a substrate, a heat generating resistor formed on the substrate, and first and second electrodes for supplying an electric power to the heat generating resistor. Each of the first and second electrodes has a first area to contact a power supplying connector and a second area provided at an end portion electrically opposite to the first area along a longitudinal direction of the substrate, and the heat generating resistor is provided to electrically connect the second area of the first and second electrode so that when the heater is at a set temperature for an image heating operation a resistance value Rc of the second area, and a resistance value Rt between a portion within the second area of the first and second electrode and electrically closest to the first area satisfy a relation Rc / Rt<=1 / 30.

Owner:CANON KK

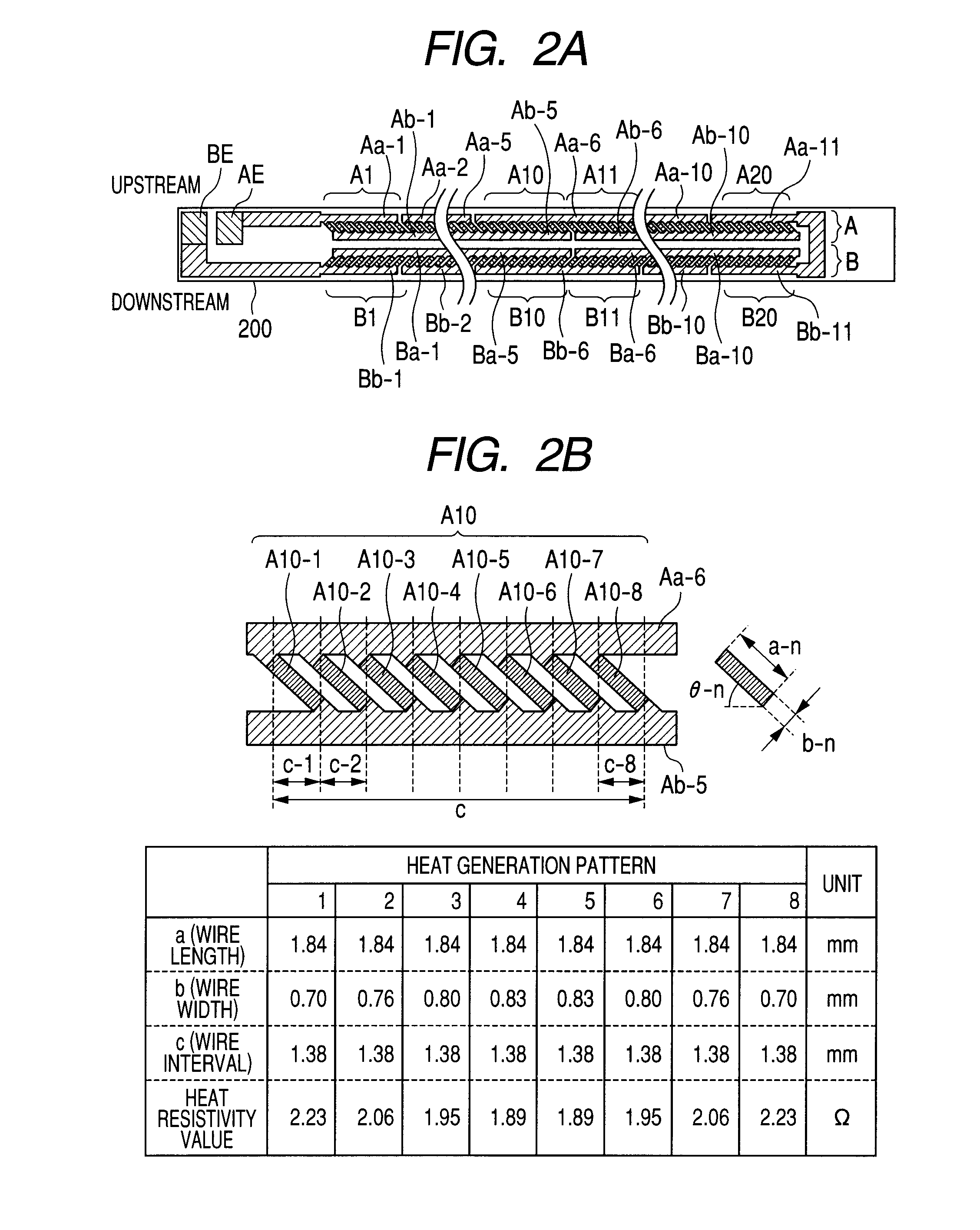

Heater and image heating apparatus including same

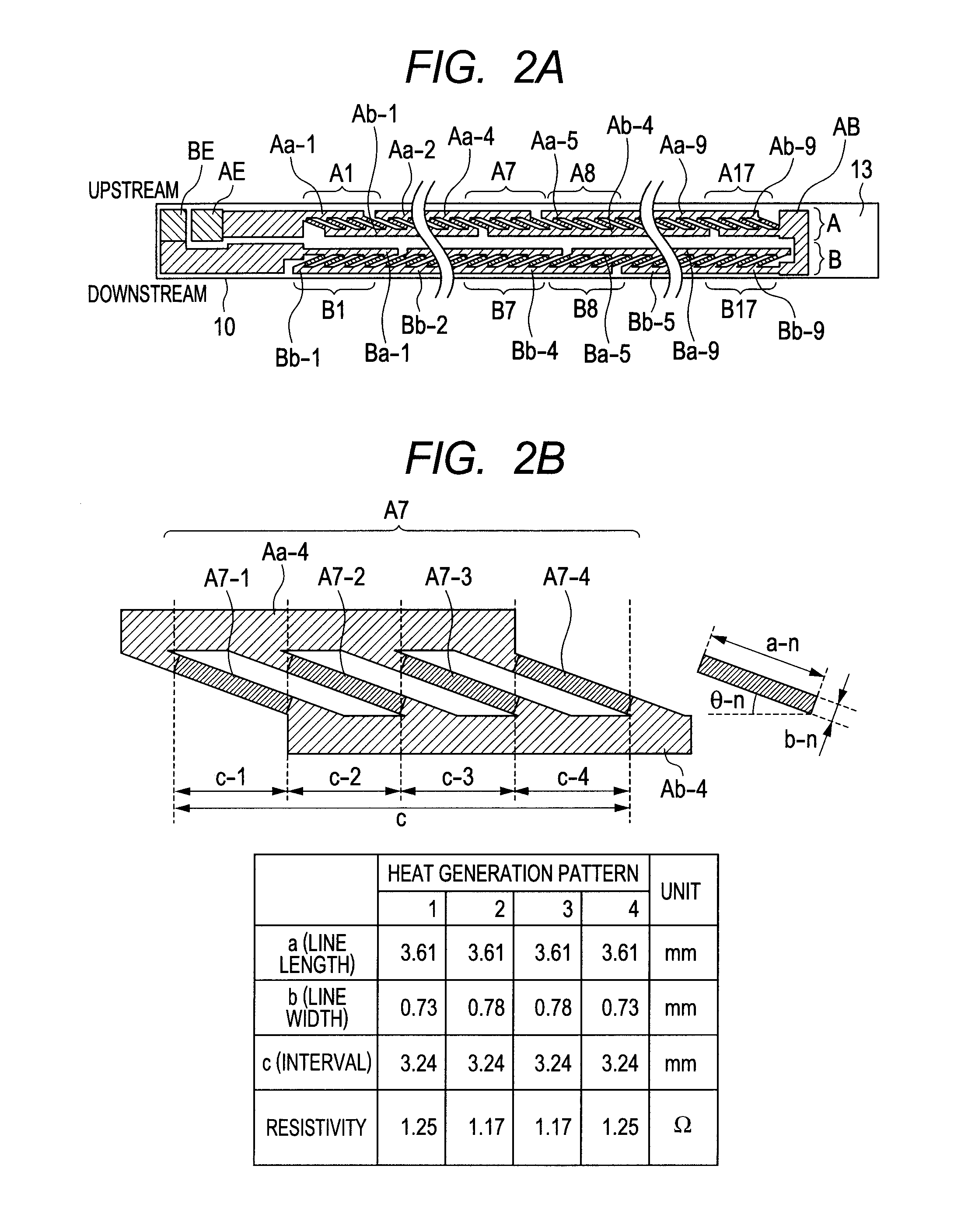

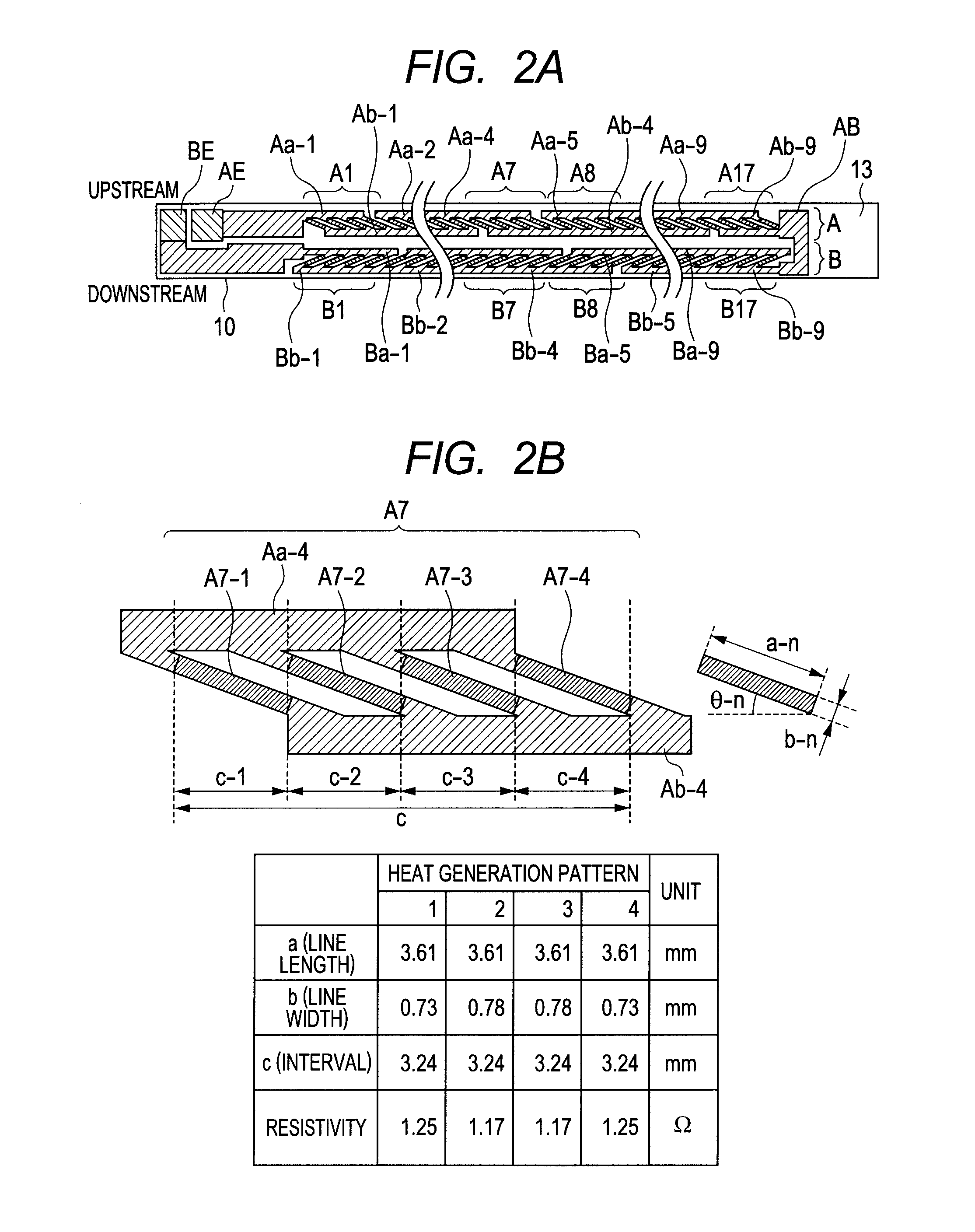

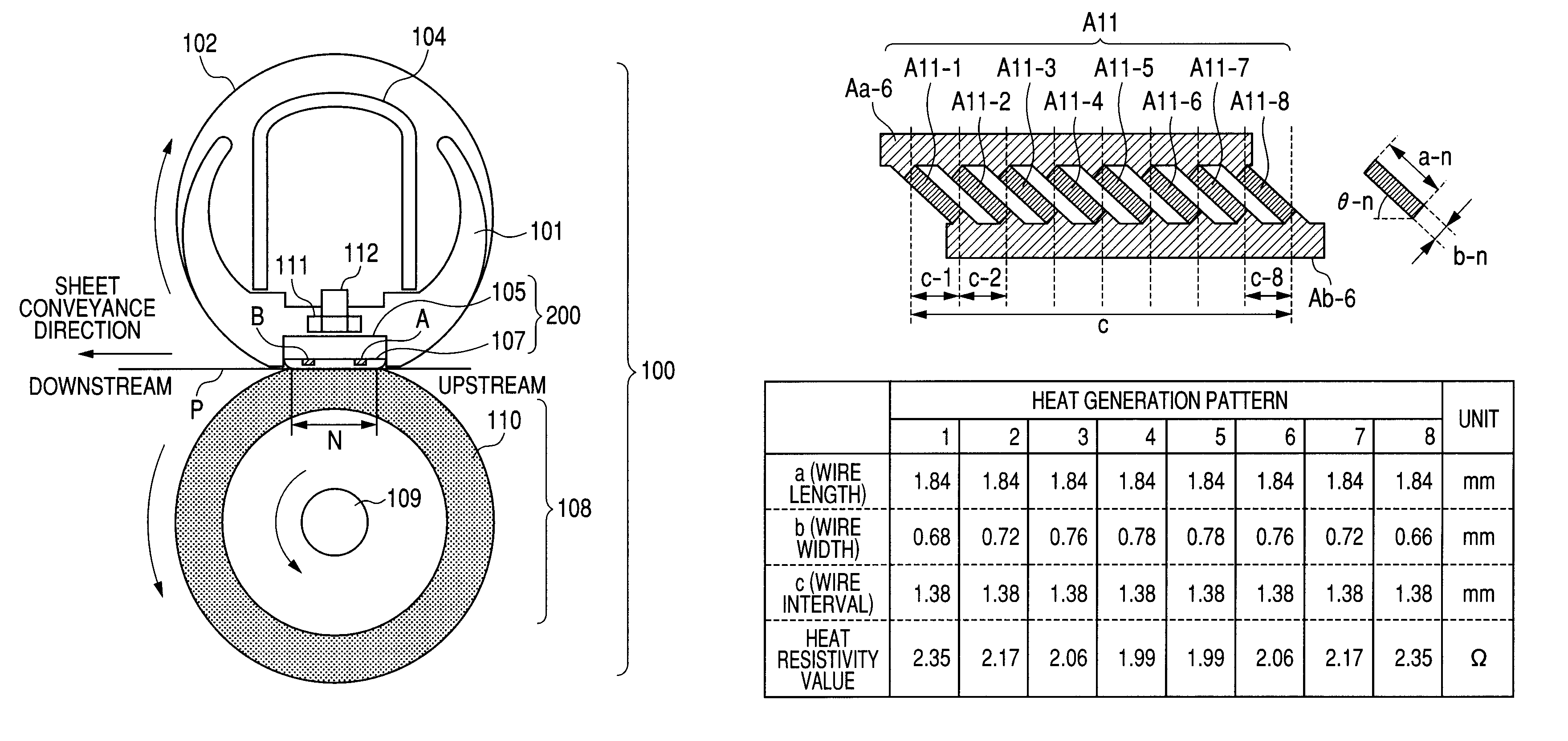

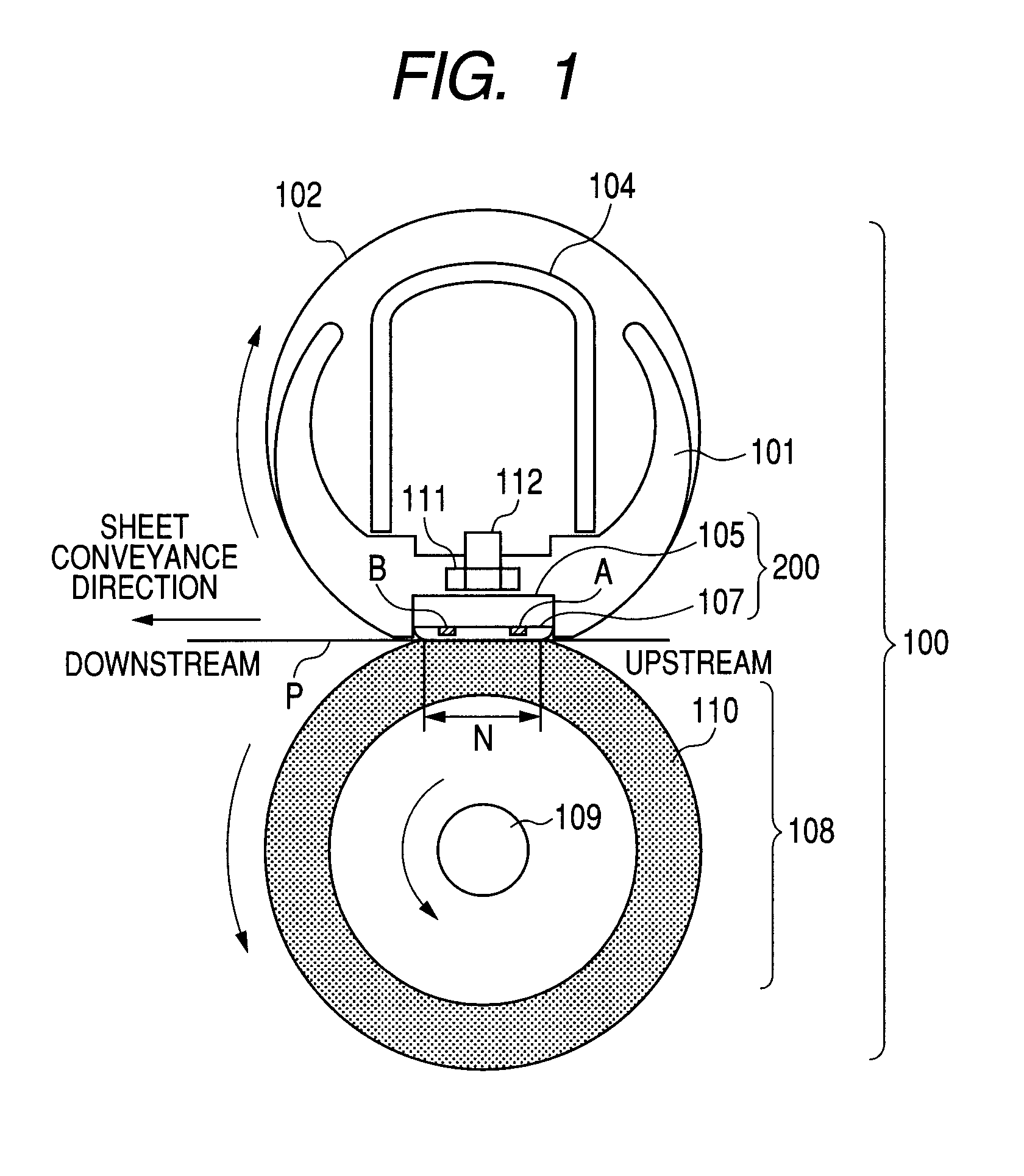

ActiveUS20120201582A1Suppression of heat generation distribution unevennessHeat suppressionOhmic-resistance heating detailsHeating element shapesEngineeringMaximum size

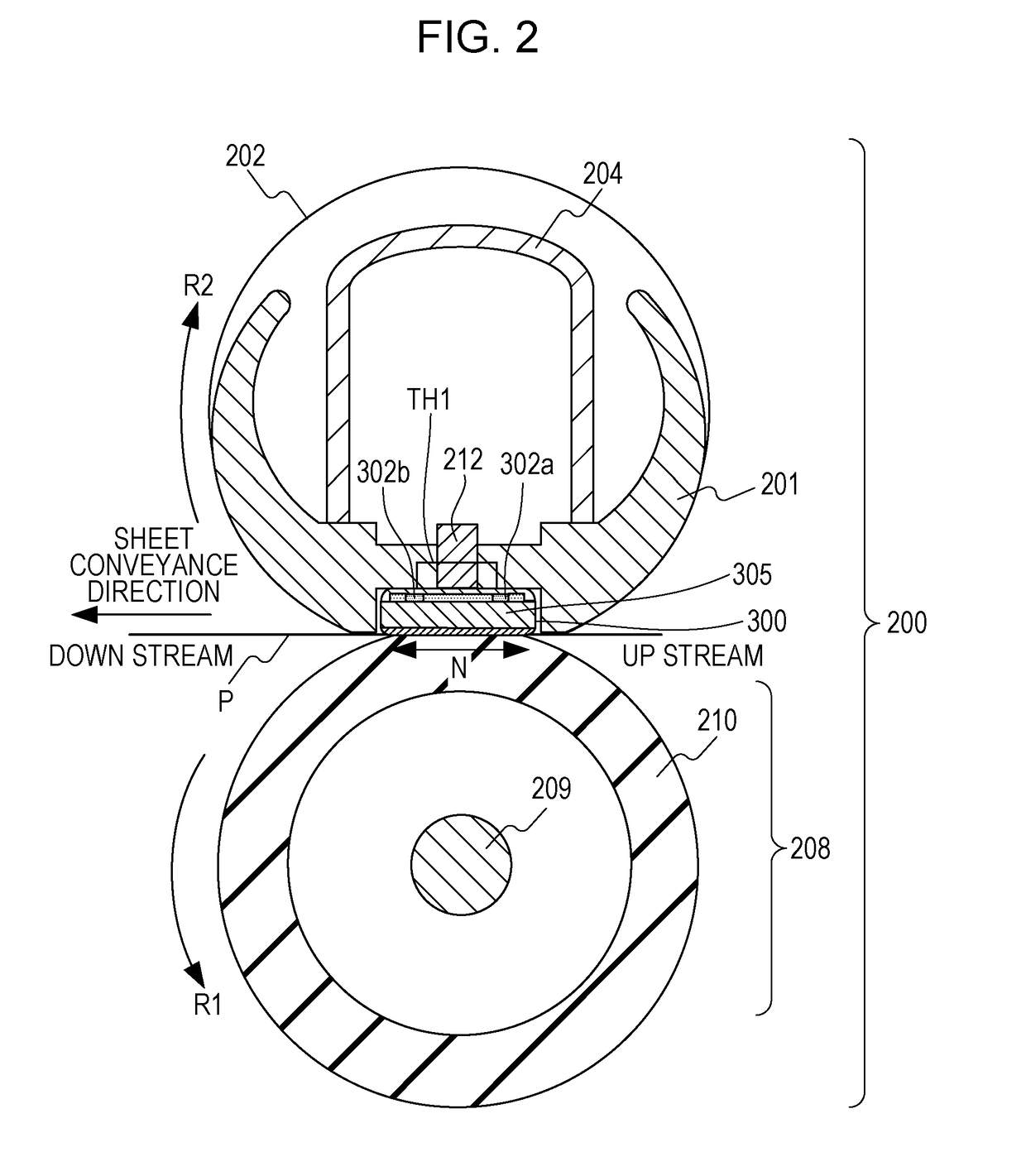

The image heating apparatus includes a heater that achieves even heat-generation distribution and suppression of a non-sheet feeding portion temperature increase when an image is printed on a sheet whose size is smaller than a maximum size for the apparatus, and an endless belt, wherein plural heat-generation resistive members having positive temperature coefficients are connected in parallel are provided between first and second conductive members provided along a longitudinal direction of a substrate; plural heat-generation blocks including the plural heat-generation resistive members connected in parallel, are arranged in series along the longitudinal direction; and in the plural heat-generation resistive members included in one of the heat-generation blocks, a heat-generation resistive member arranged at an end portion in the longitudinal direction has a resistivity value higher than that of a heat generation resistive member arranged at a center in the longitudinal direction, or an interval between heat generation resistive members is larger in the end portion.

Owner:CANON KK

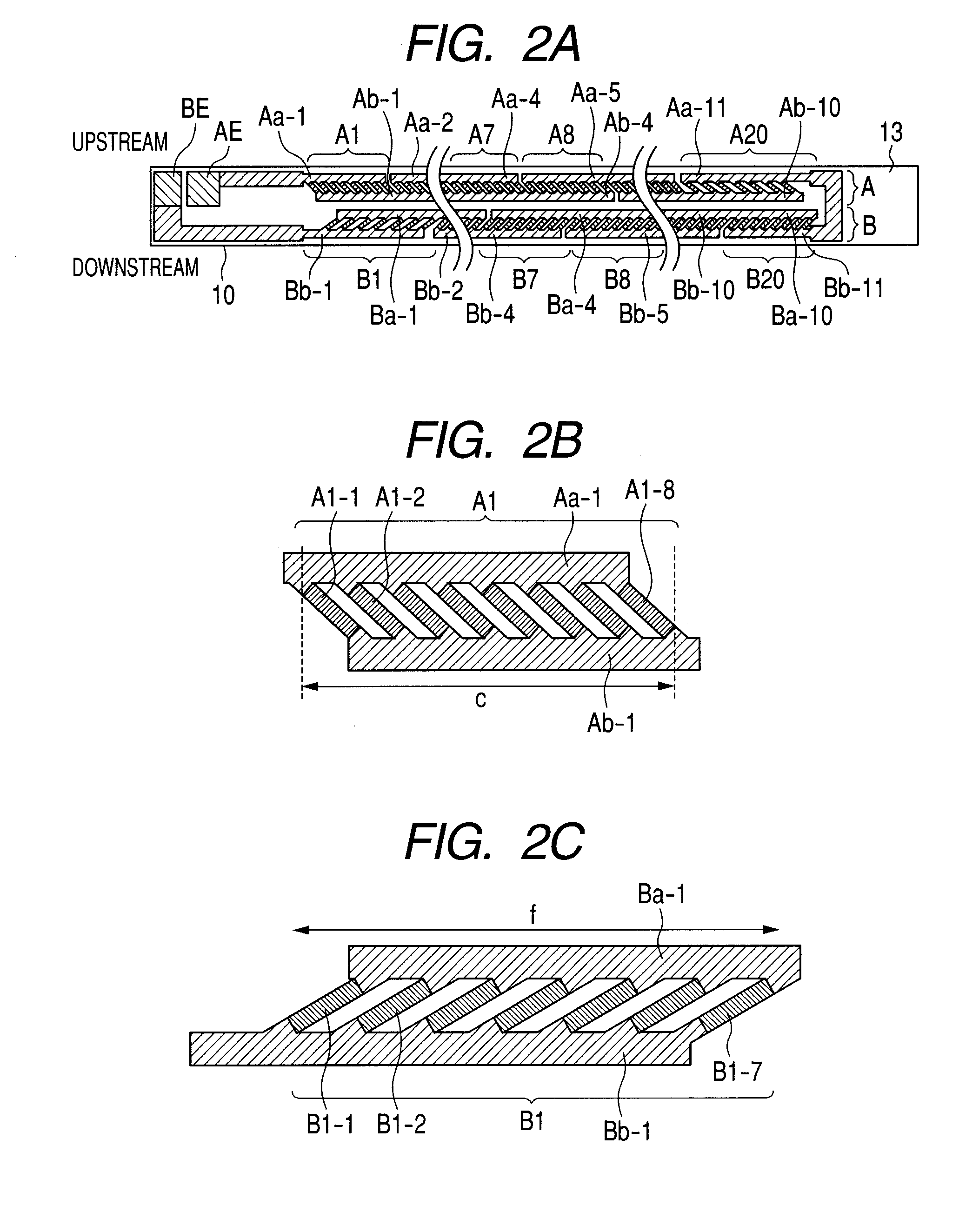

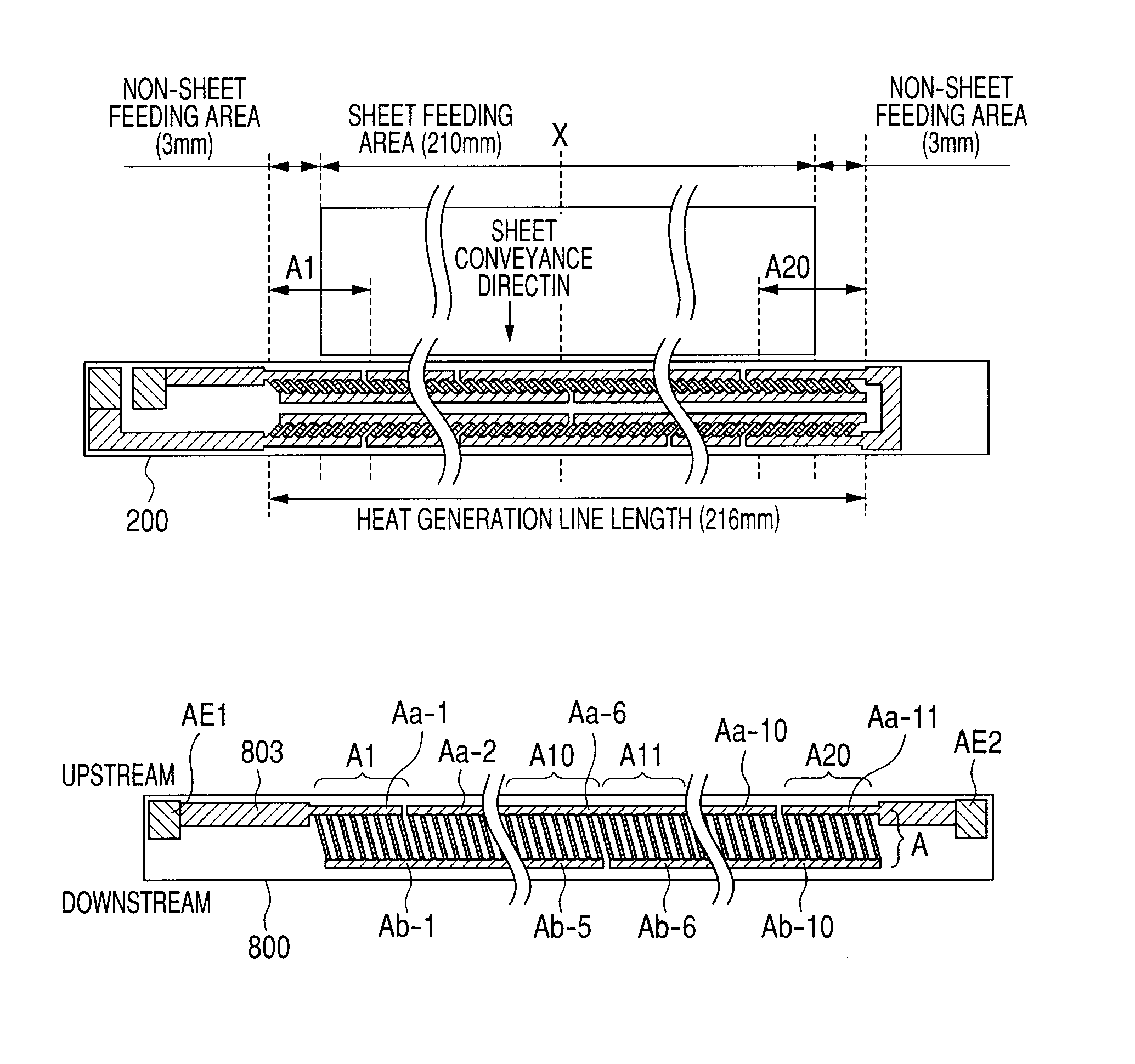

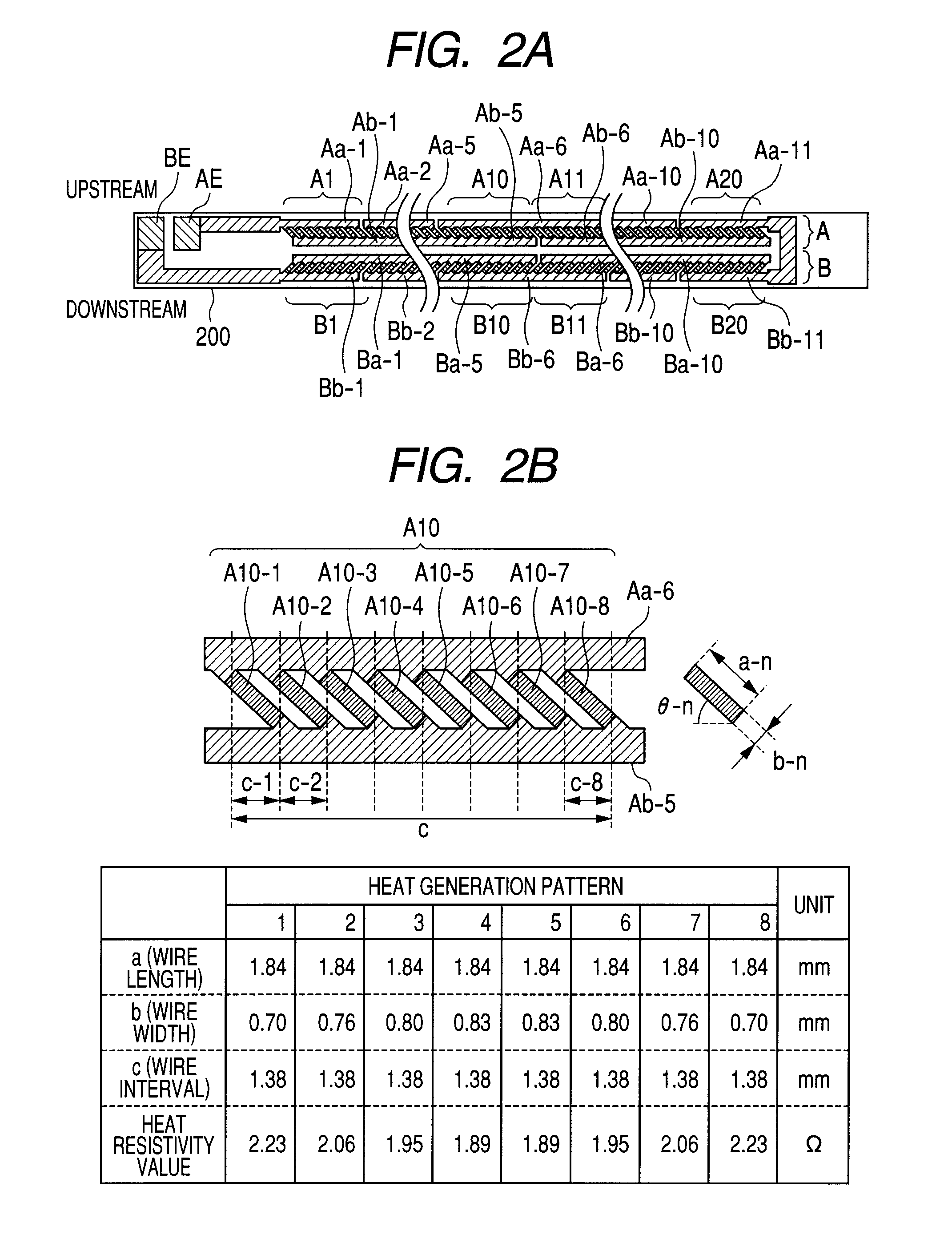

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS20120121306A1Uneven heat generationInhomogeneous suppressionOhmic-resistance heating circuitsHeater elementsElectricityHotline

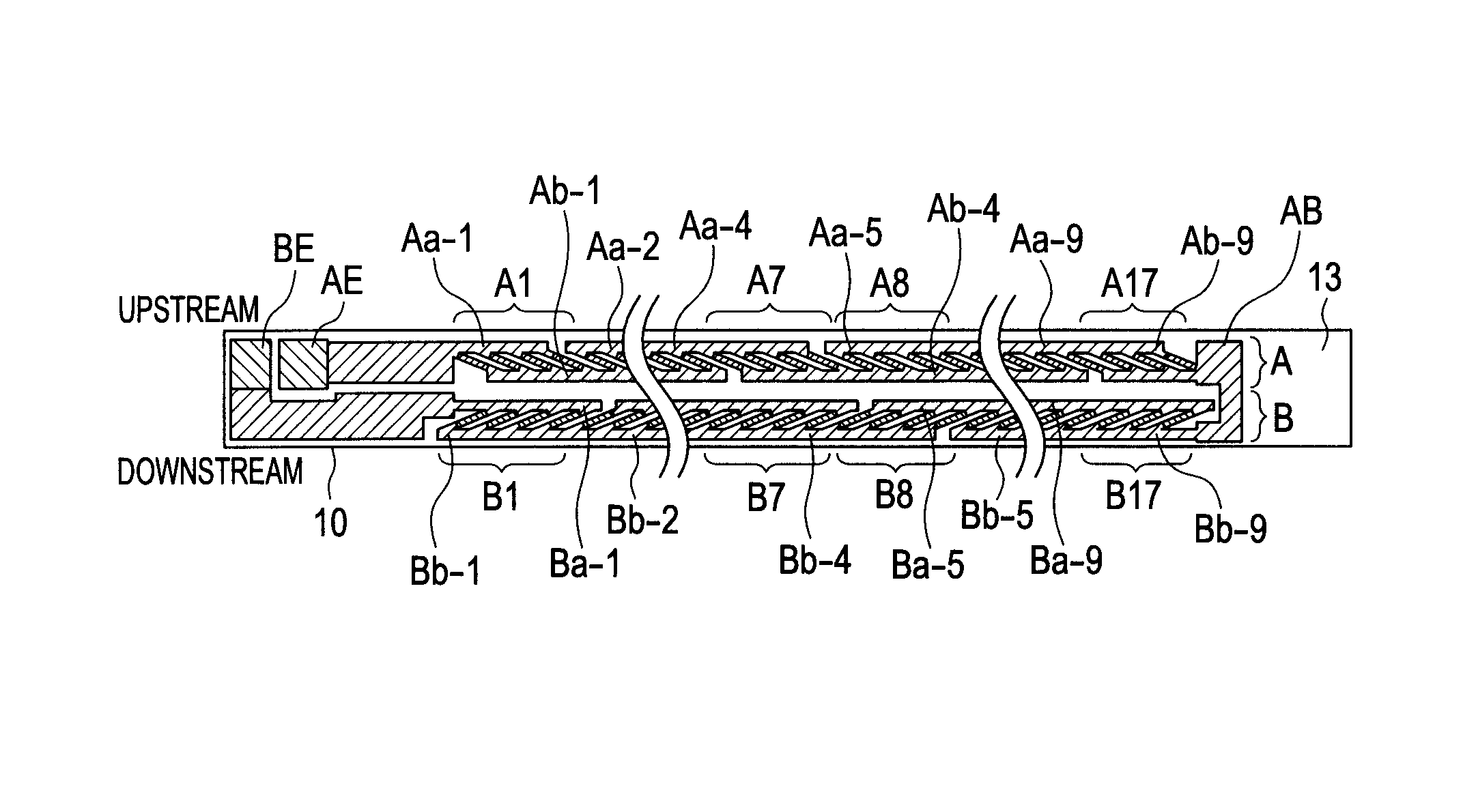

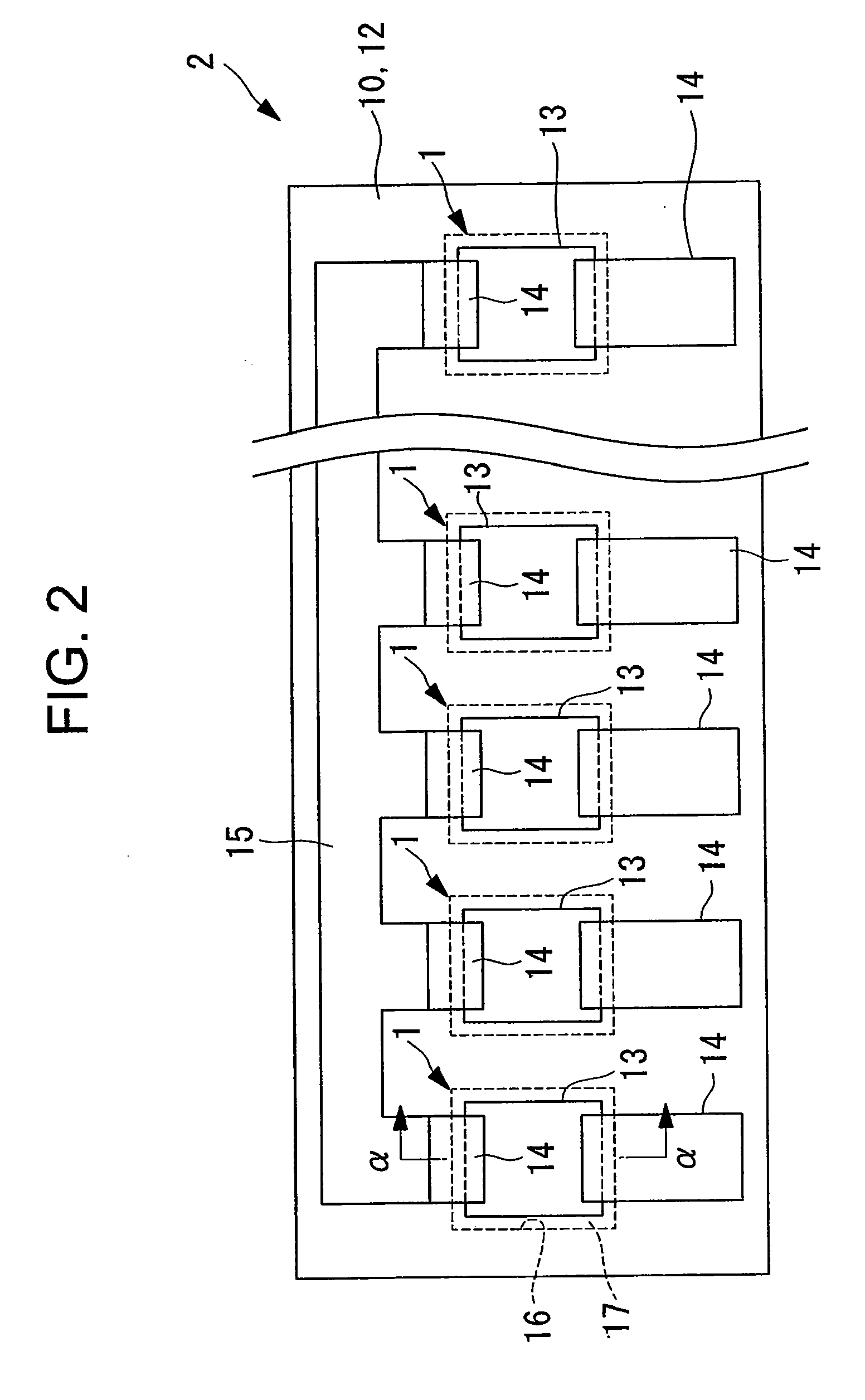

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

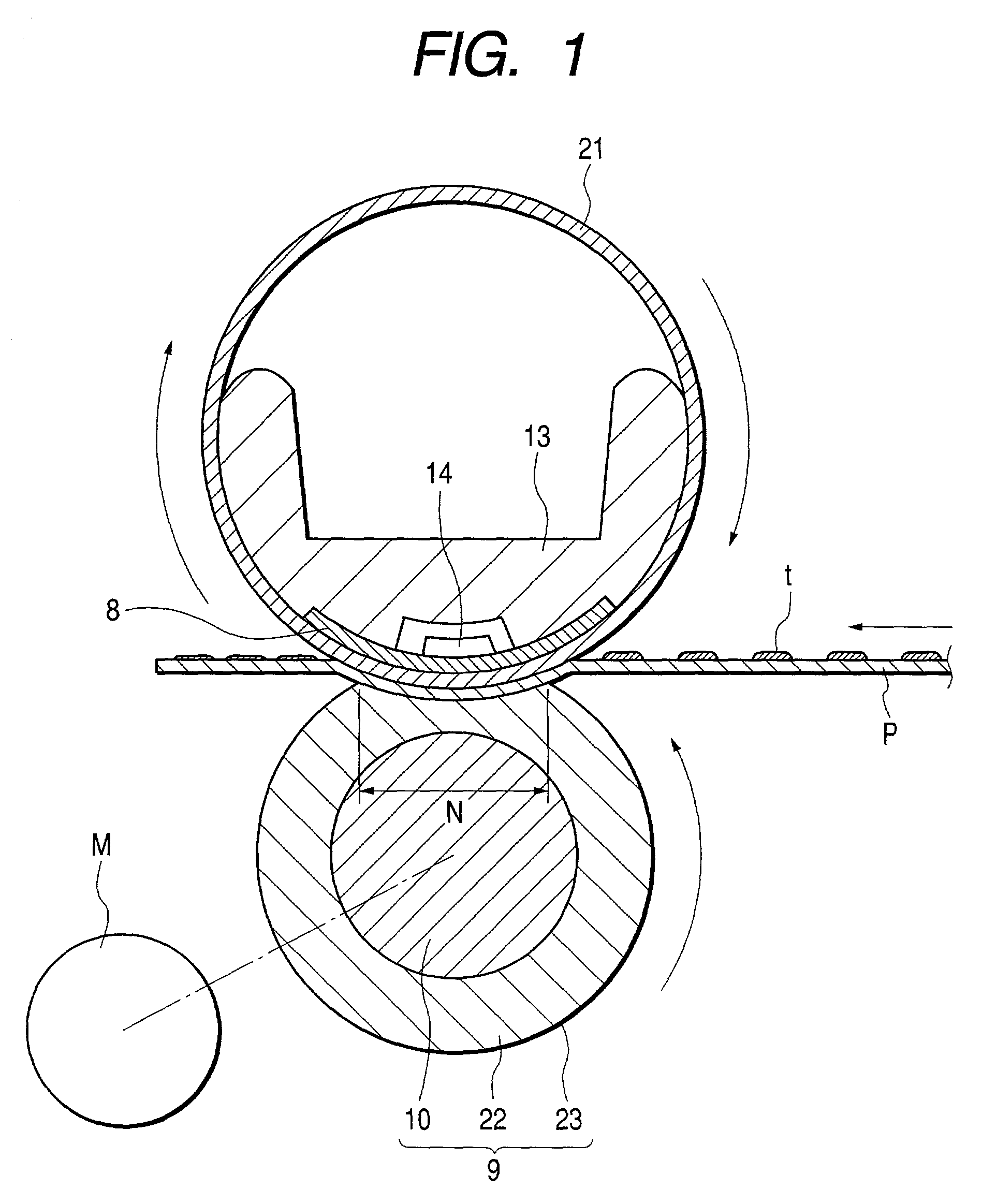

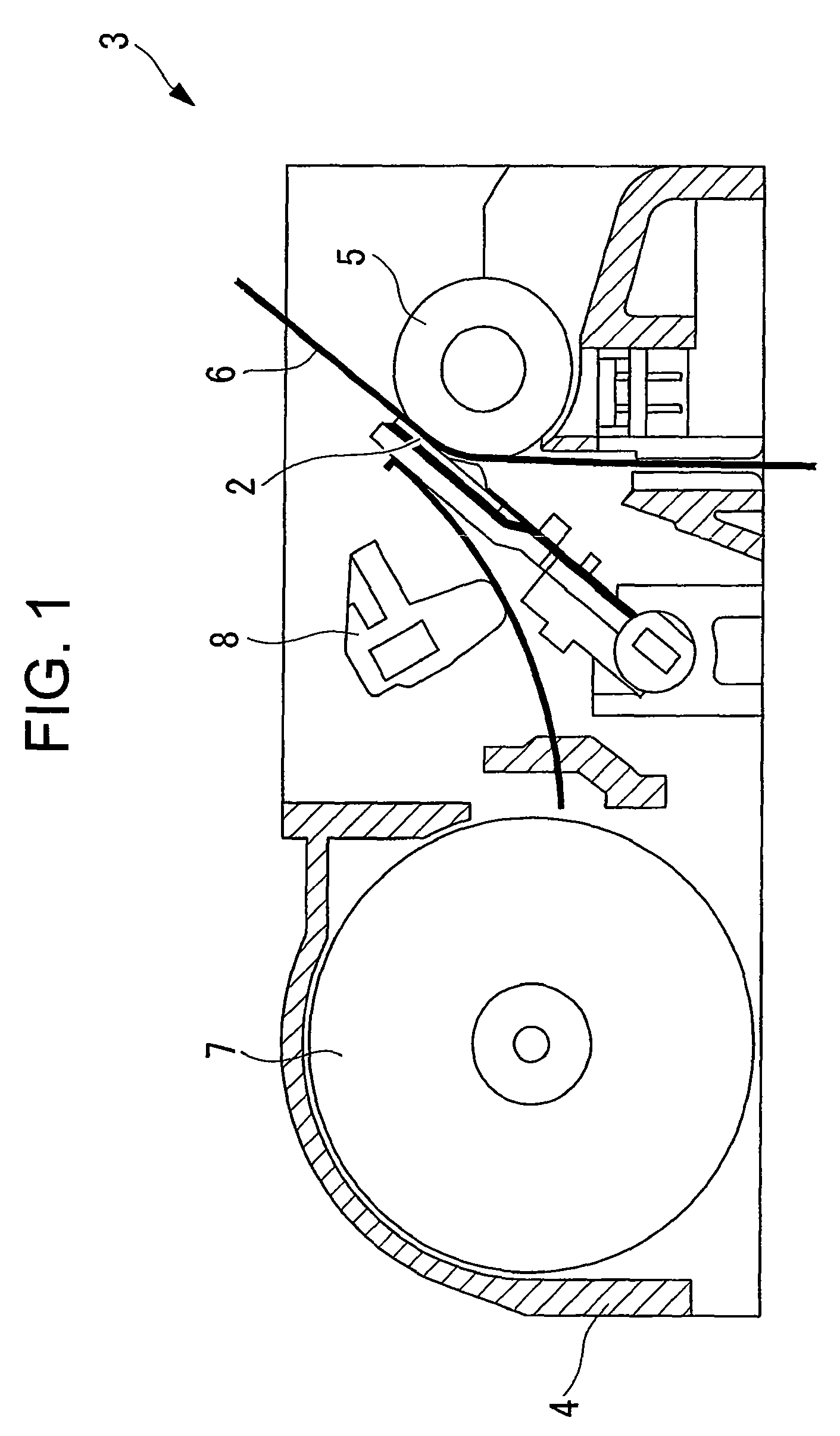

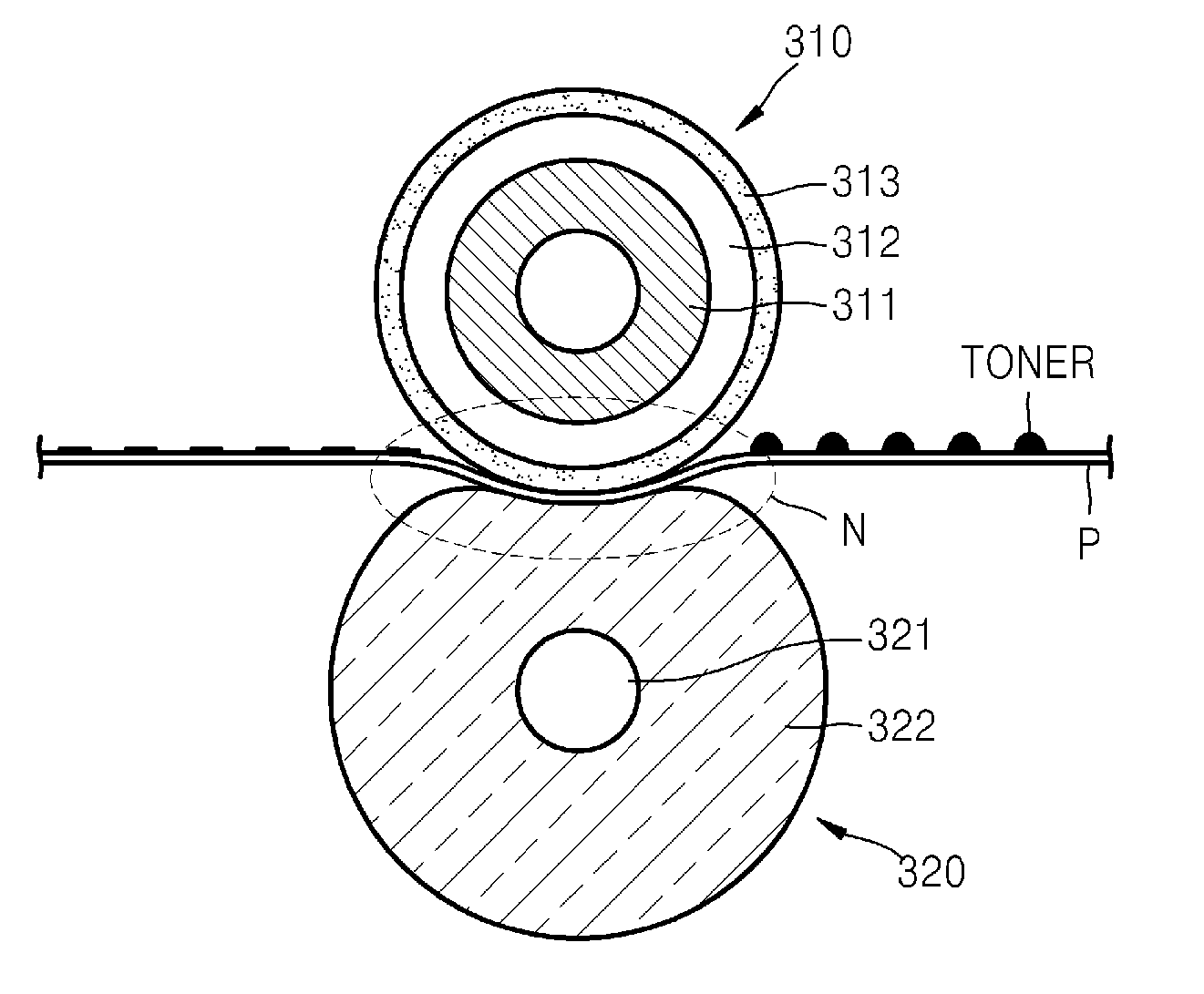

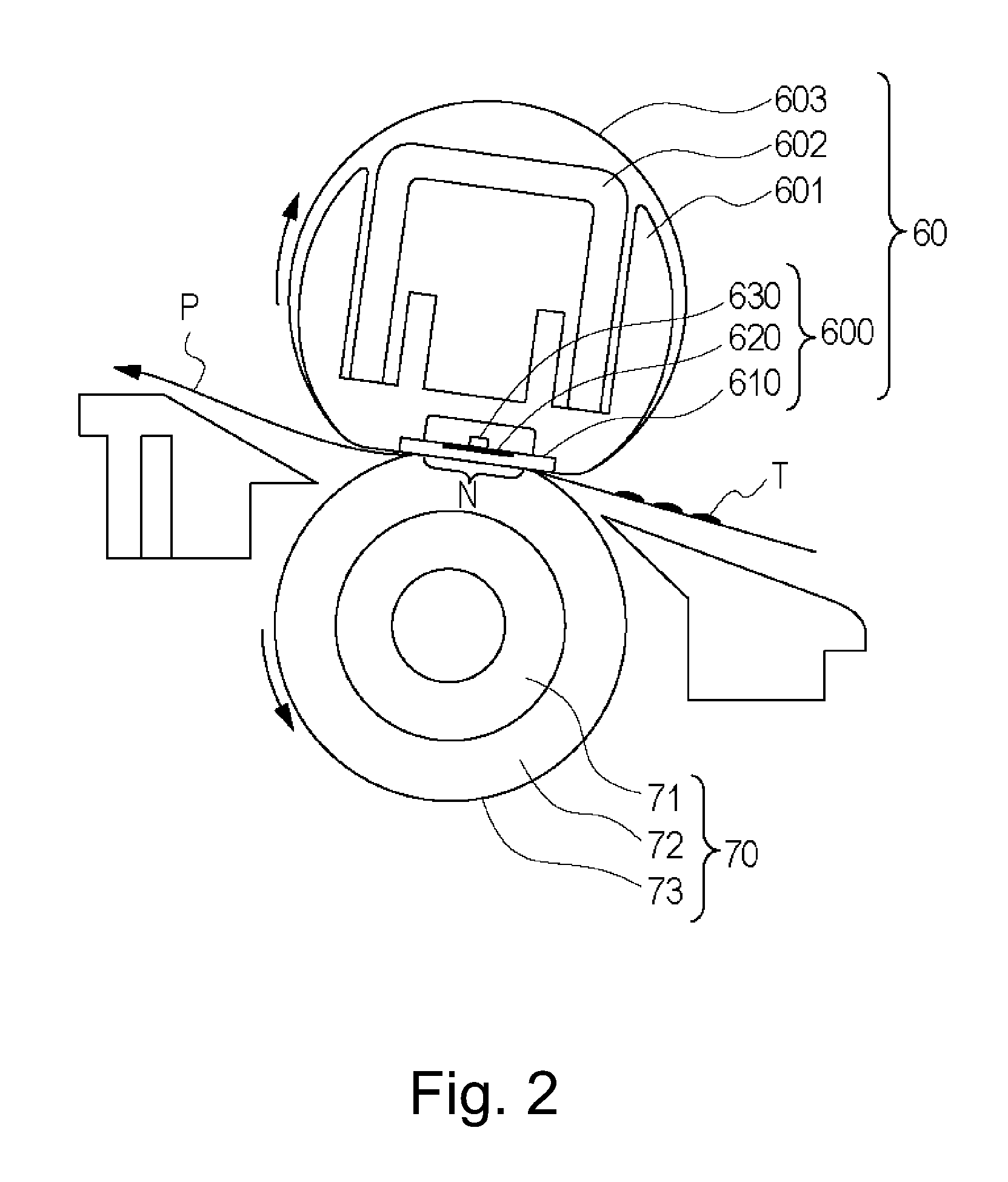

Heating device, image forming apparatus including the device and induction heating member included in the device

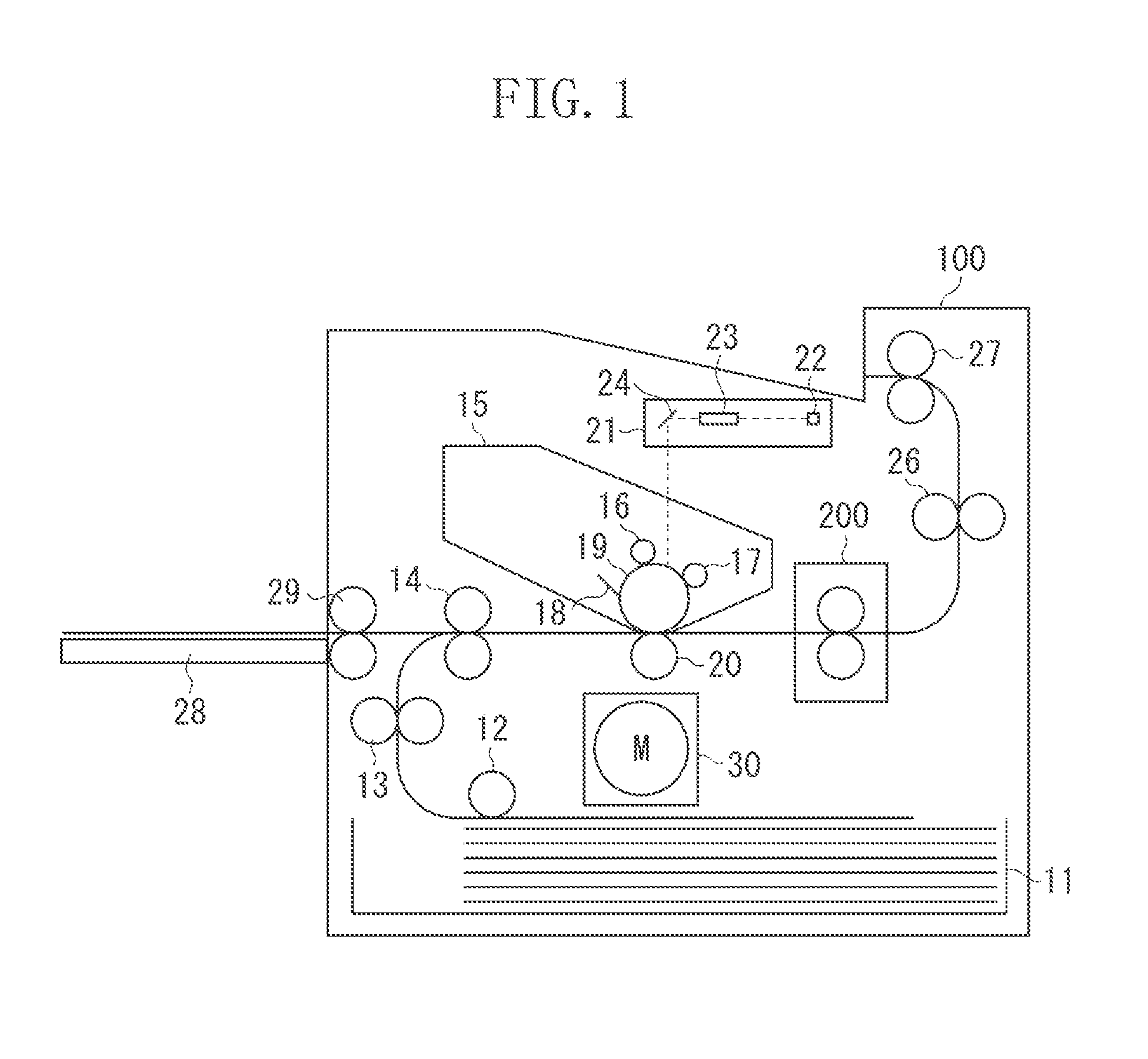

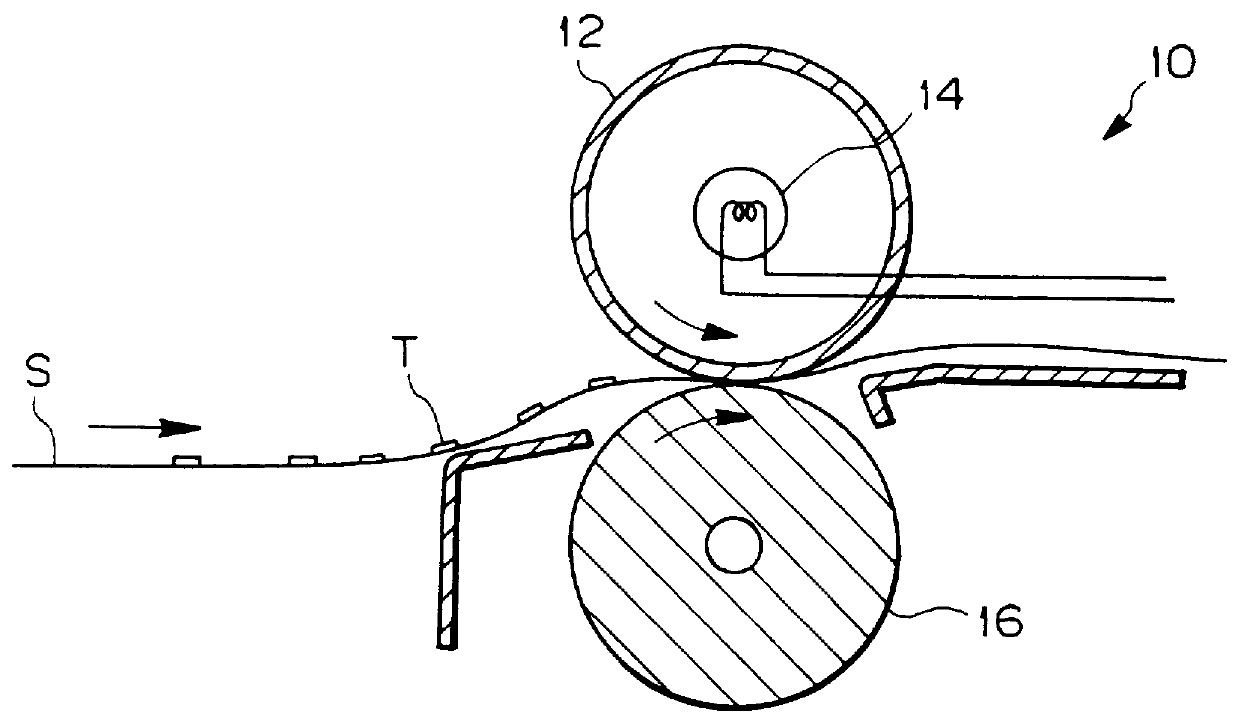

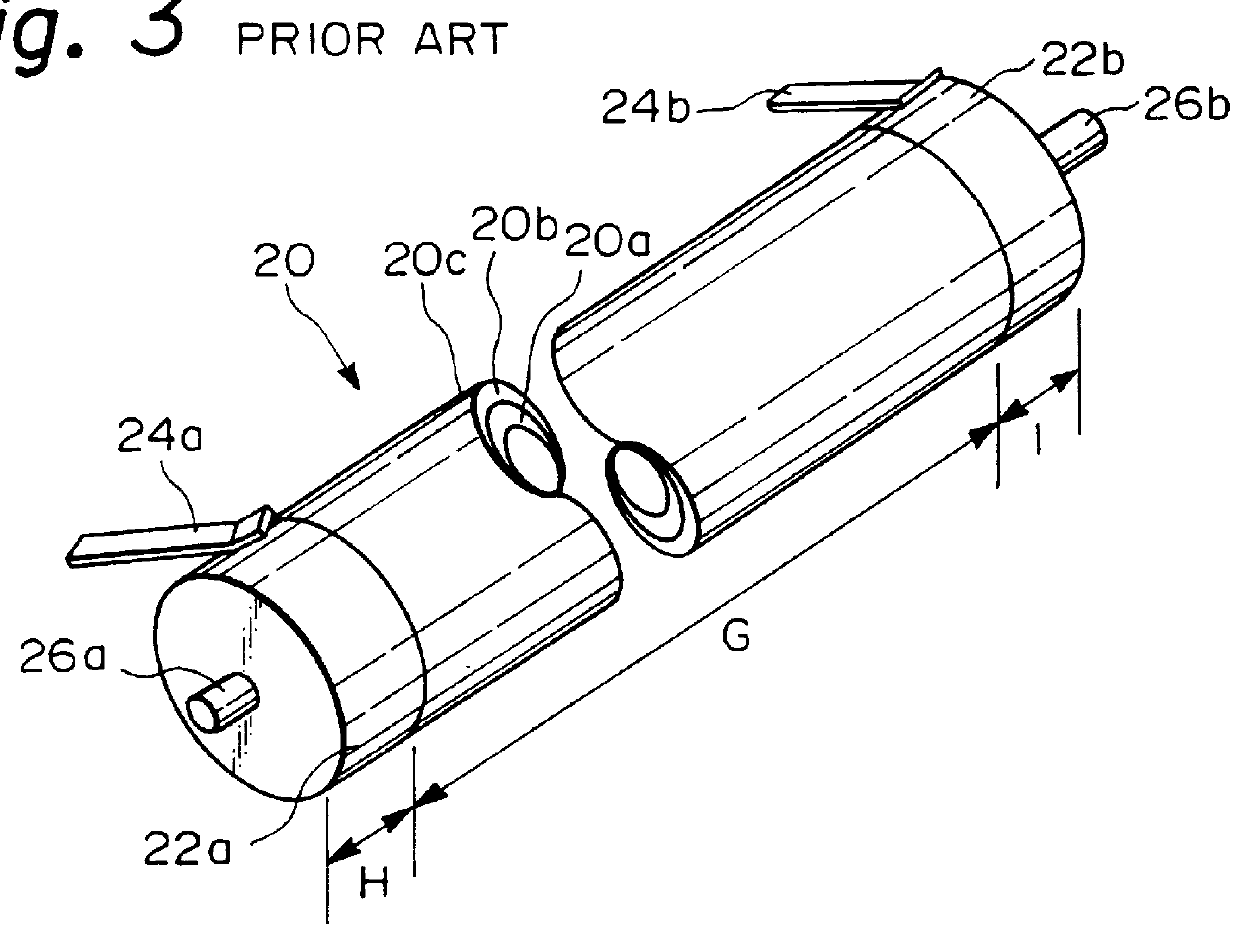

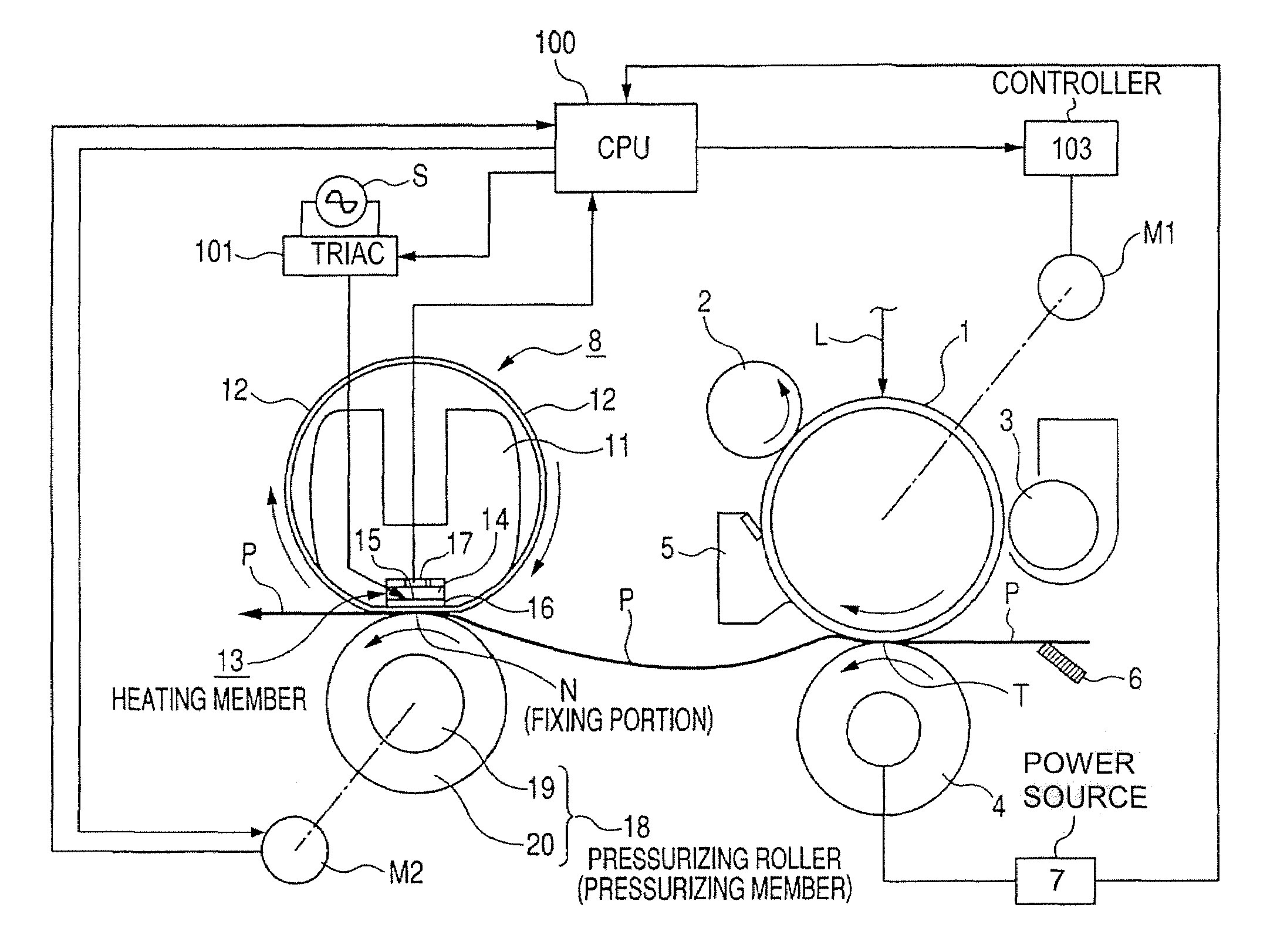

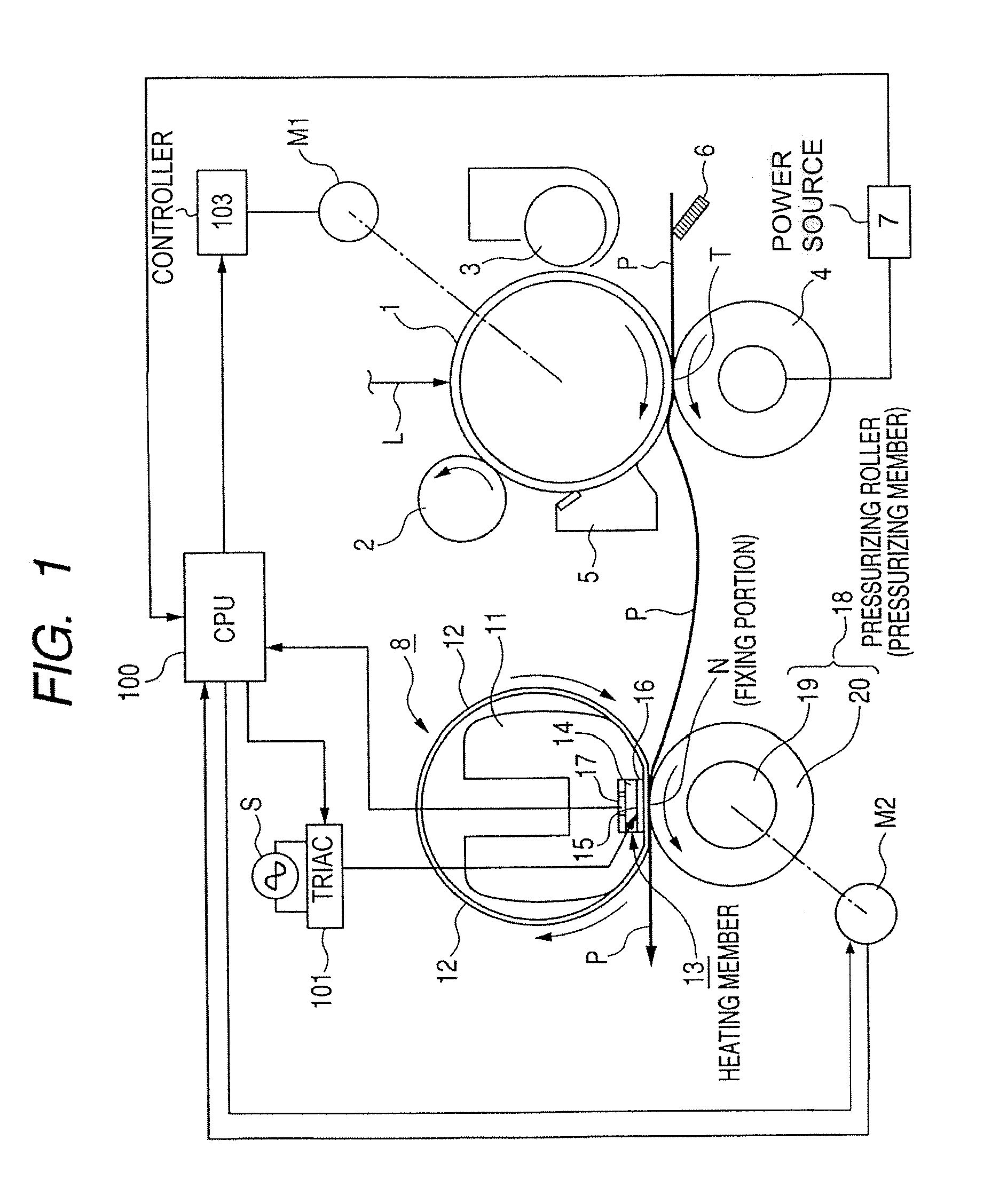

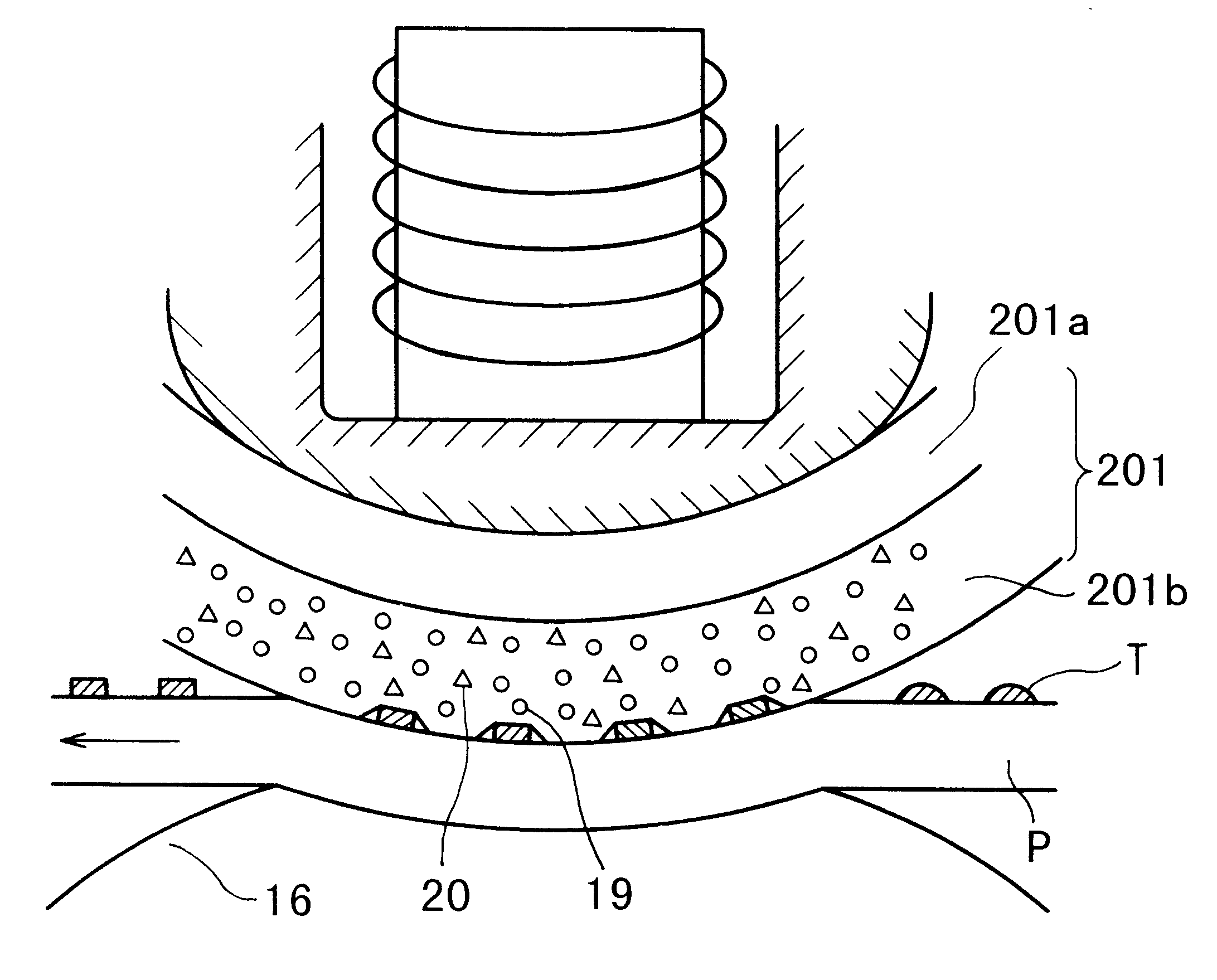

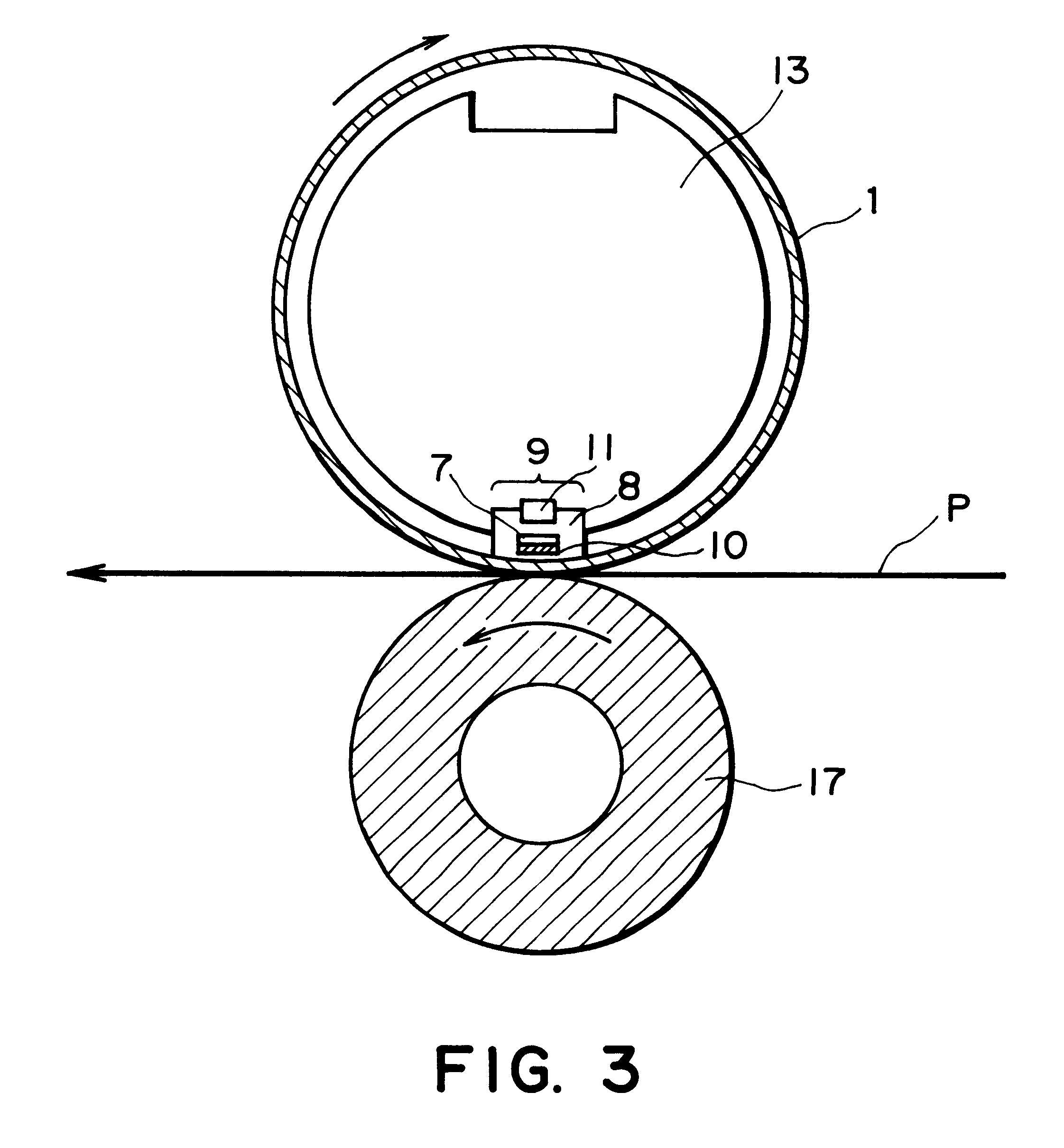

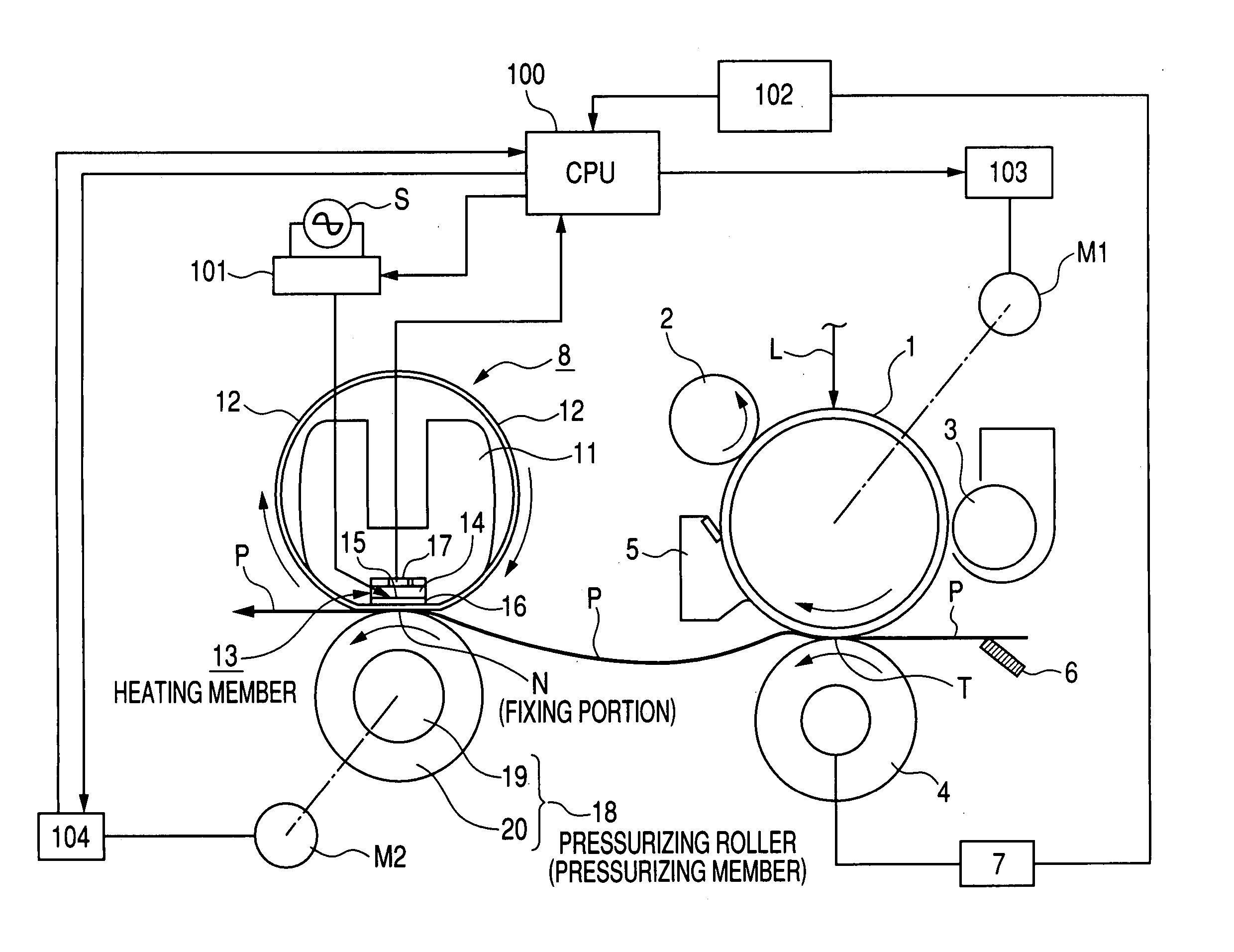

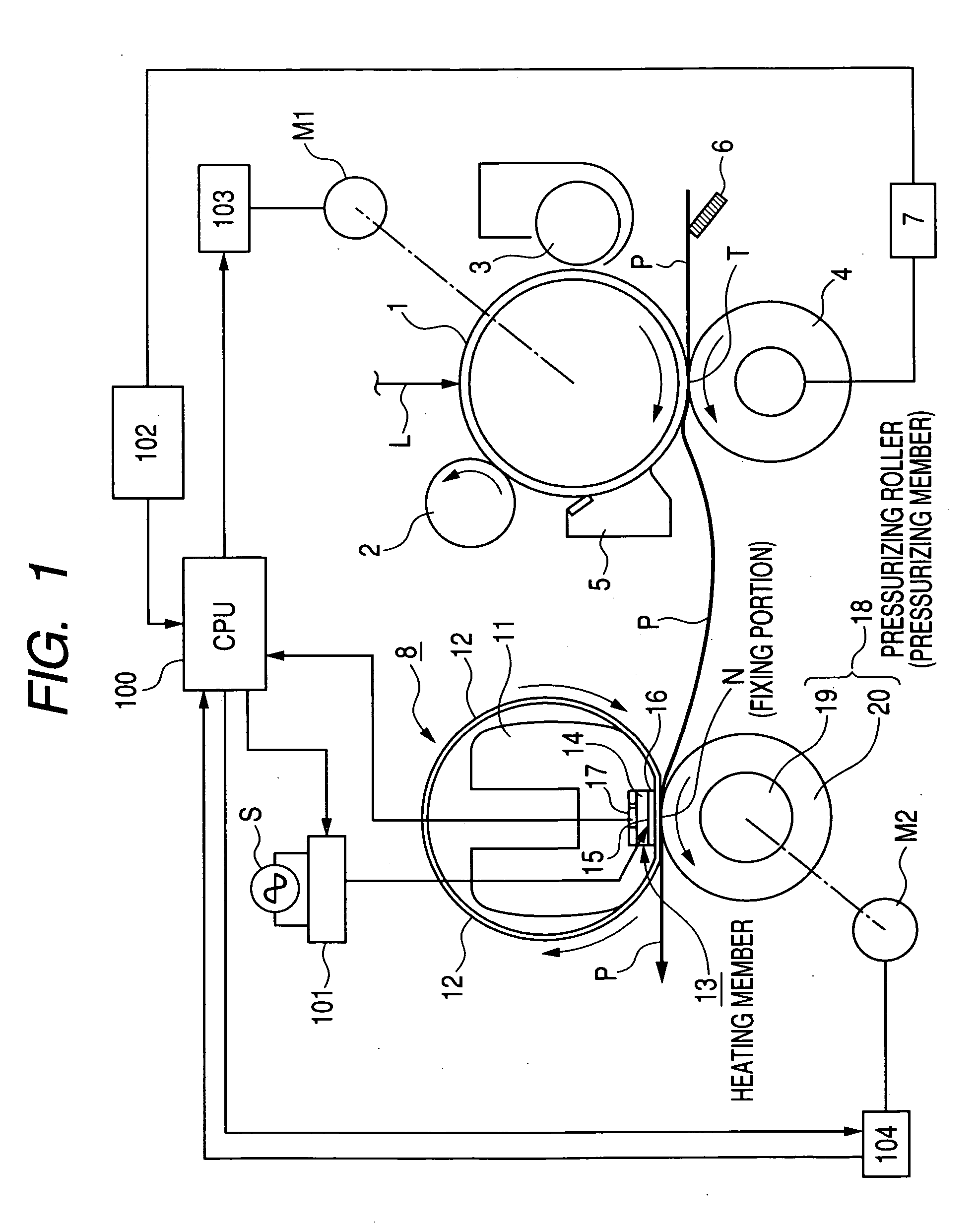

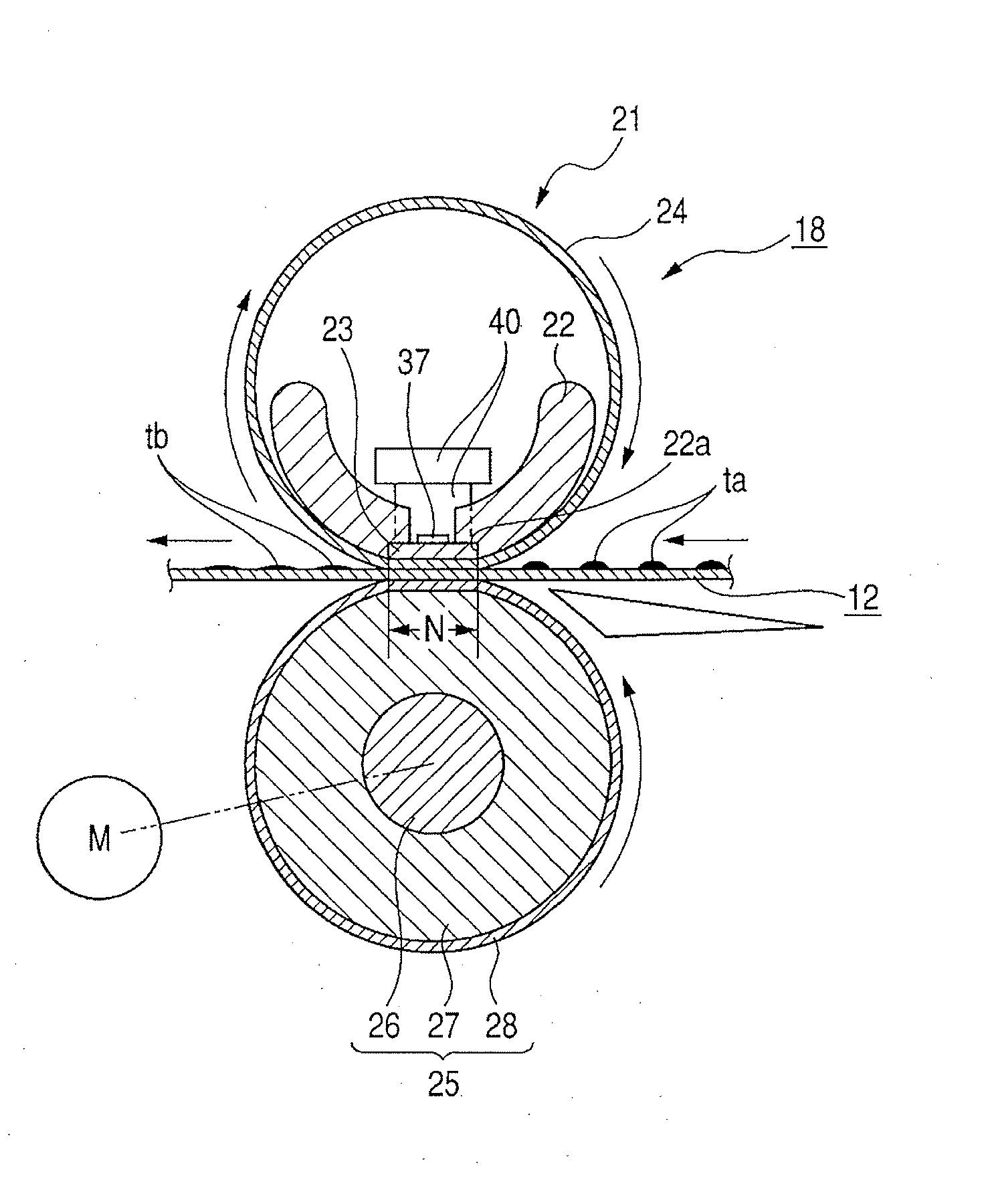

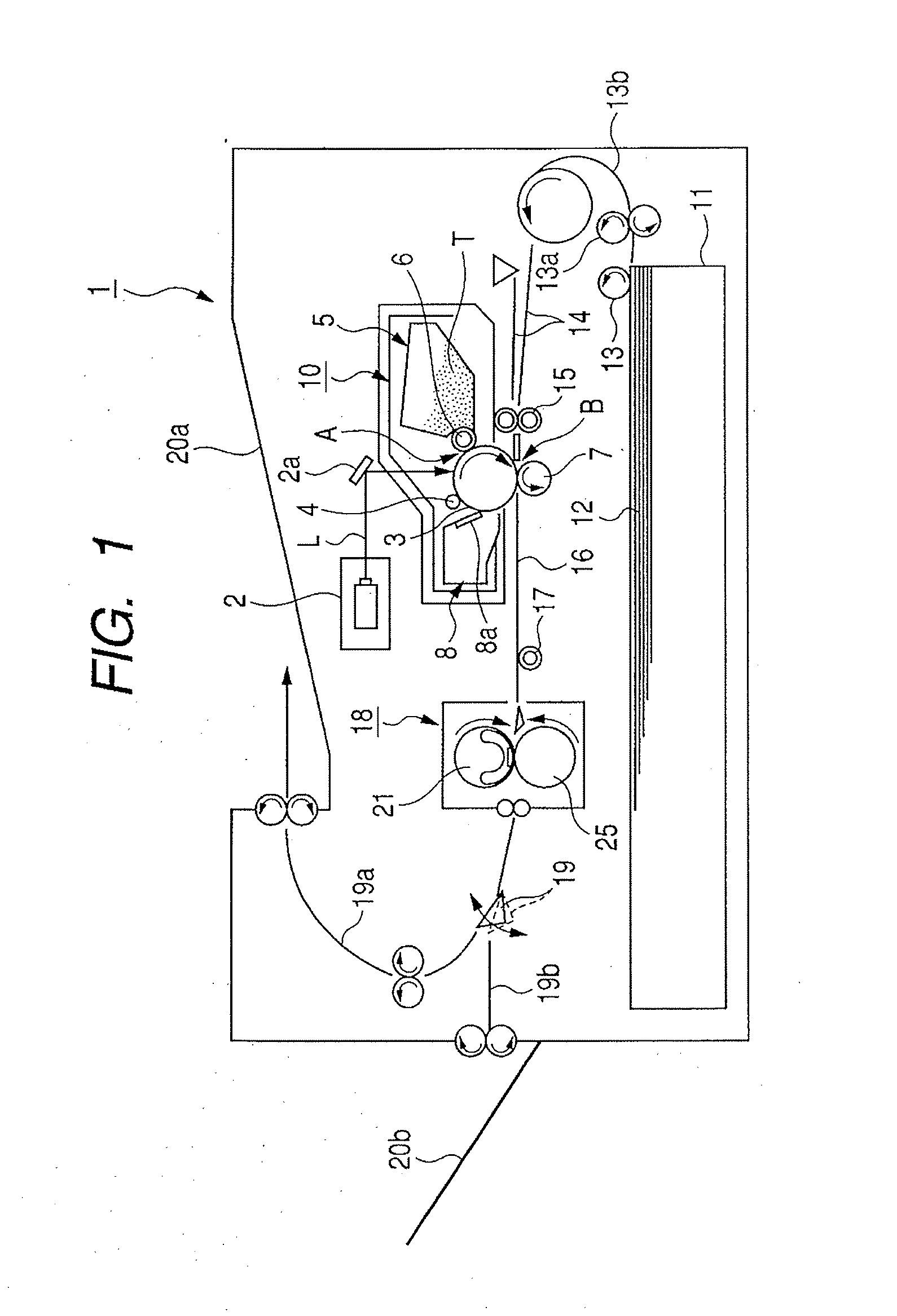

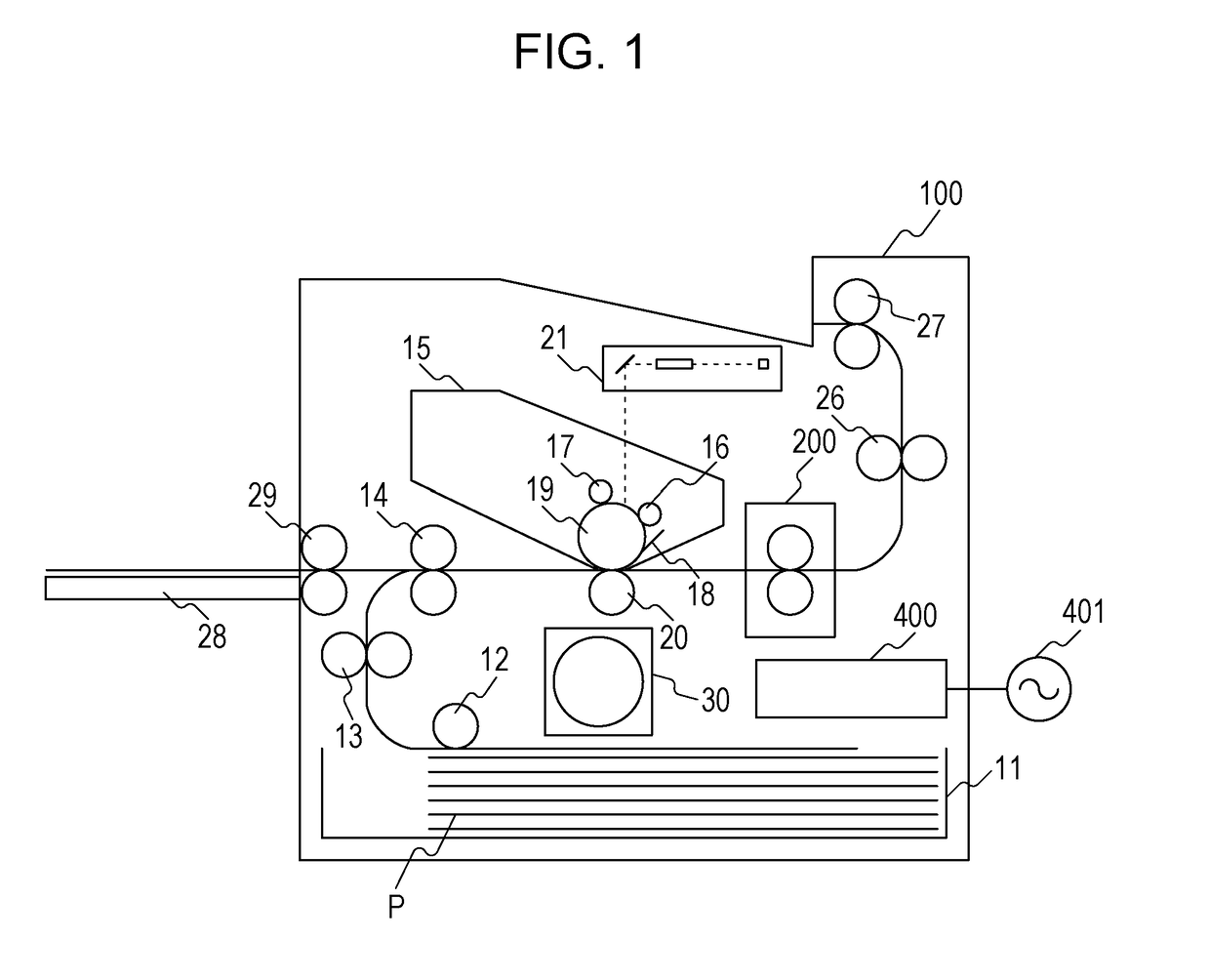

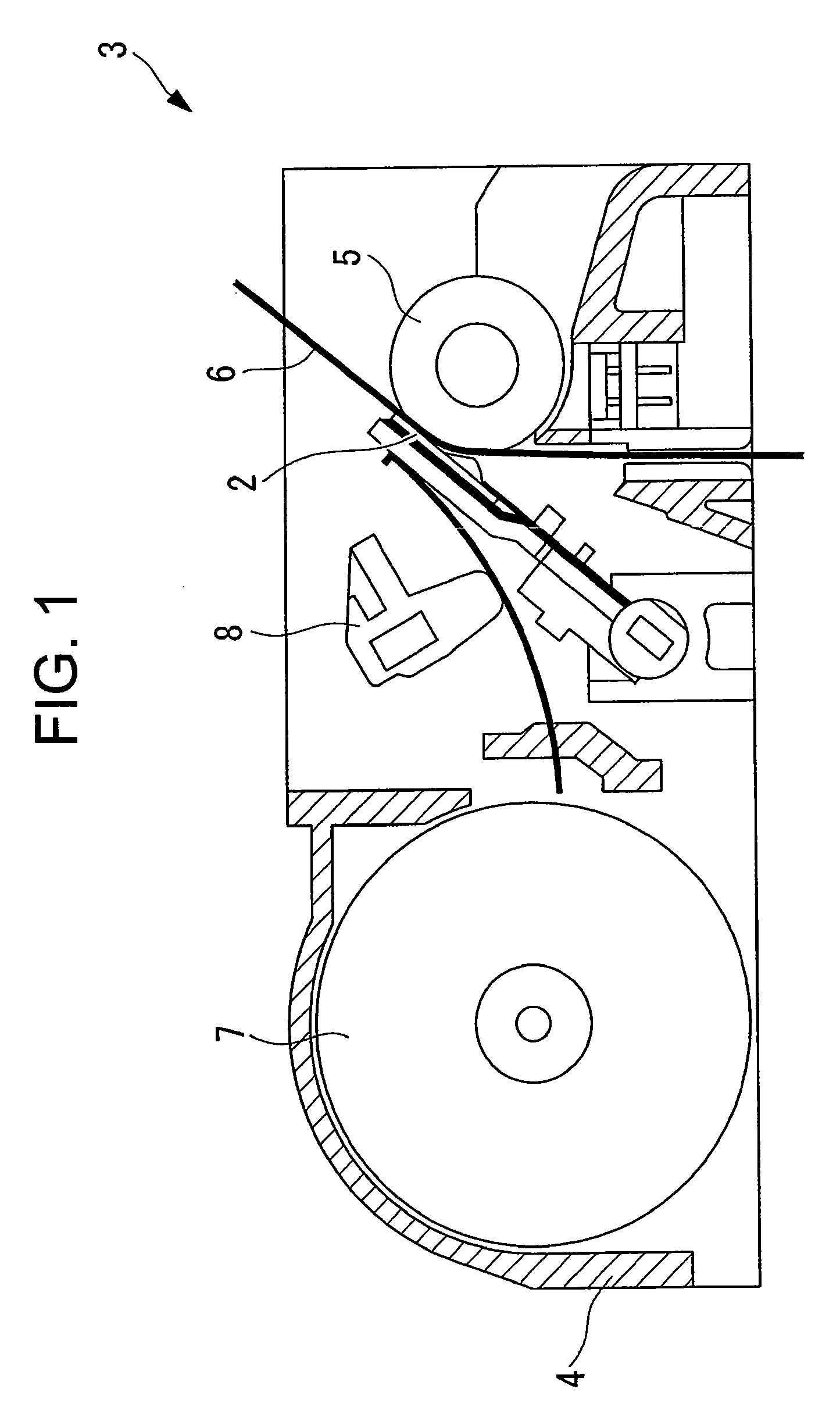

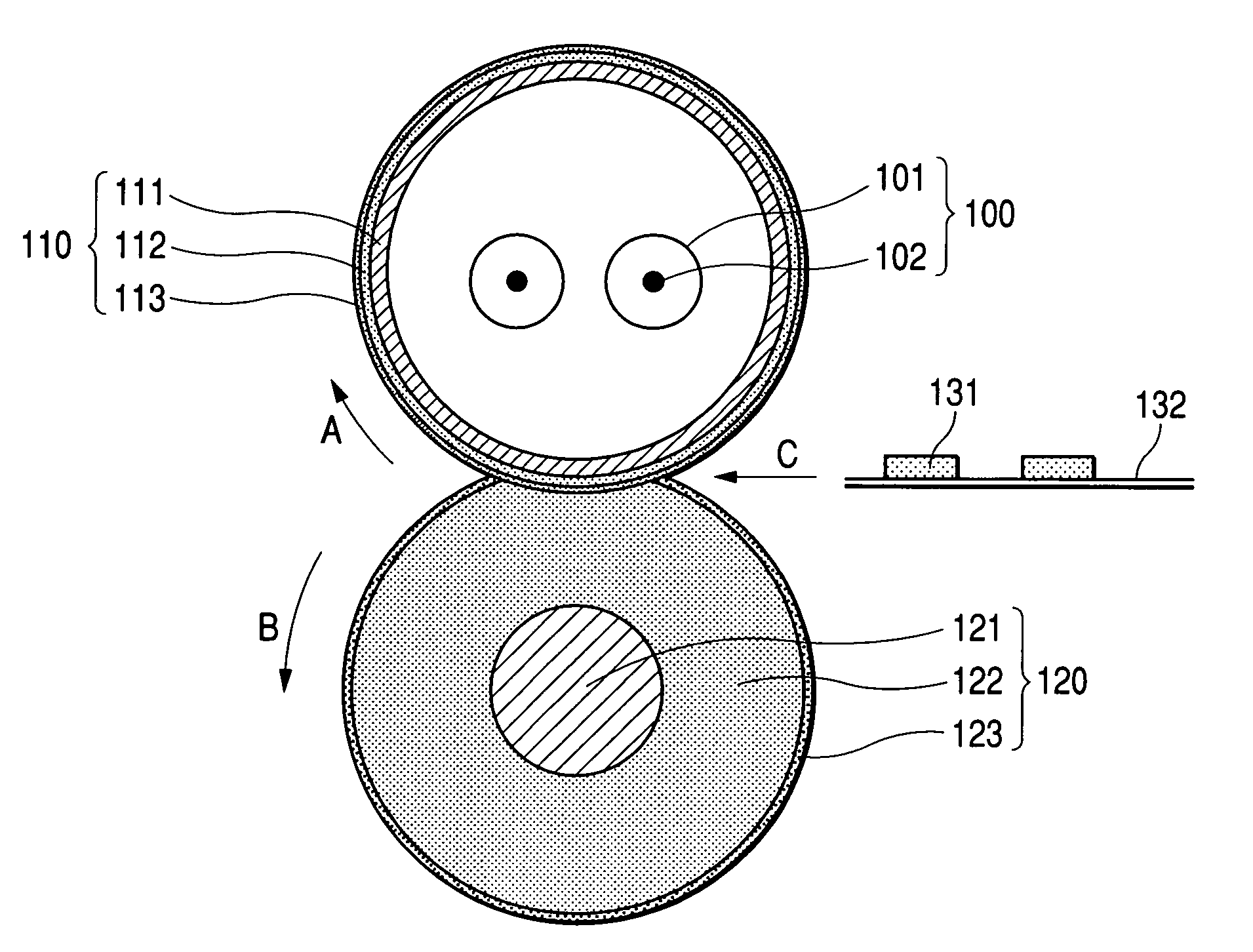

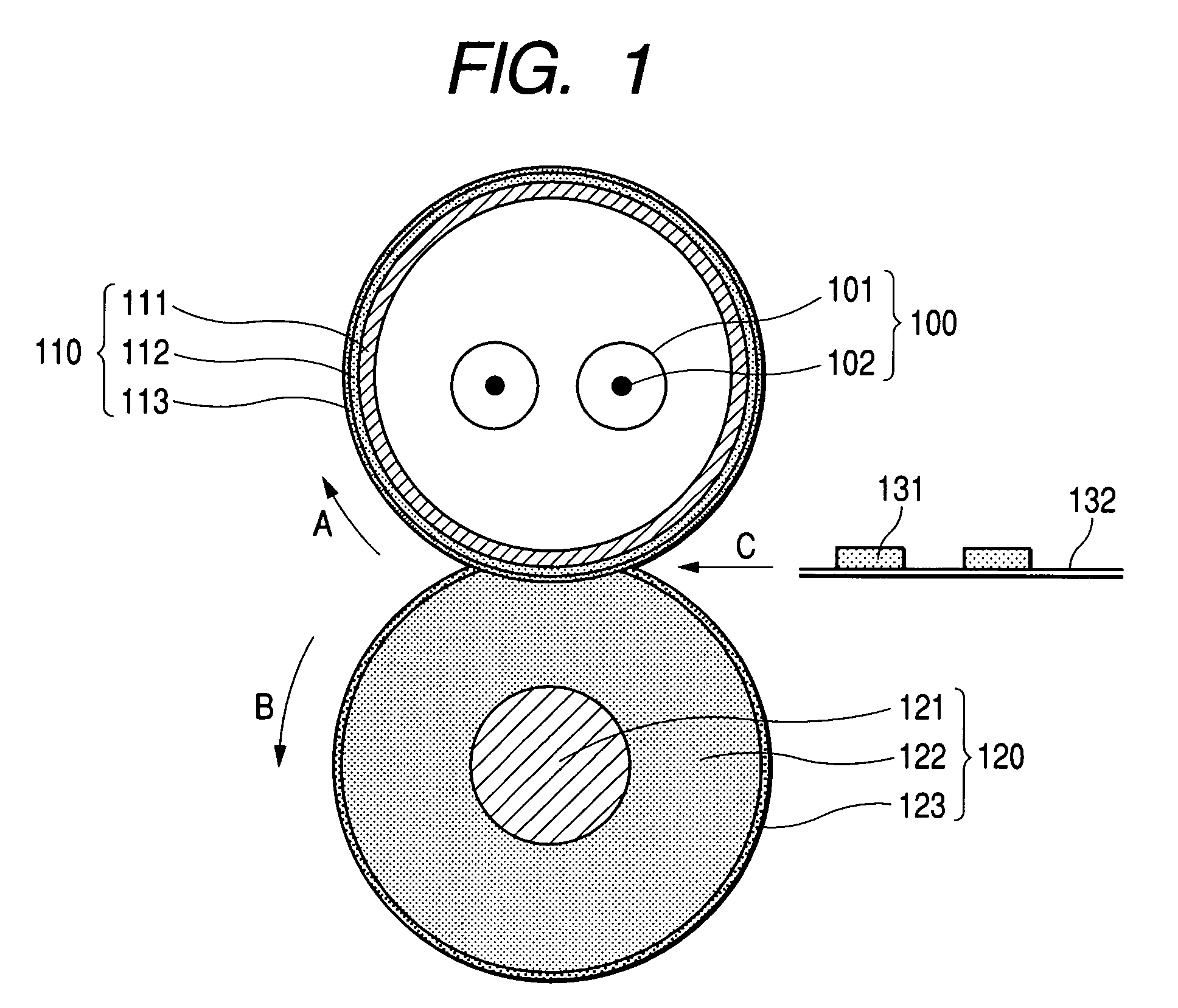

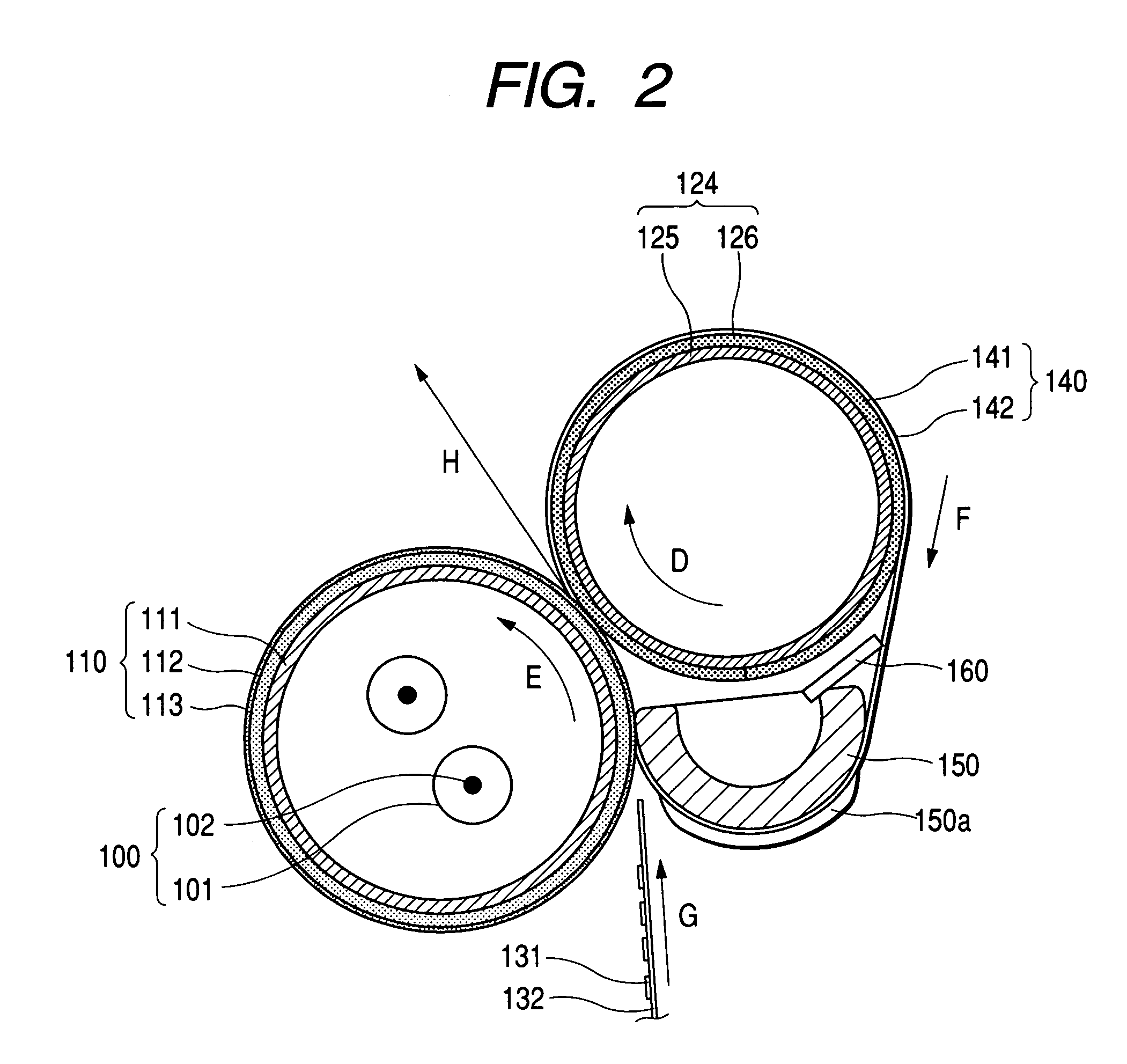

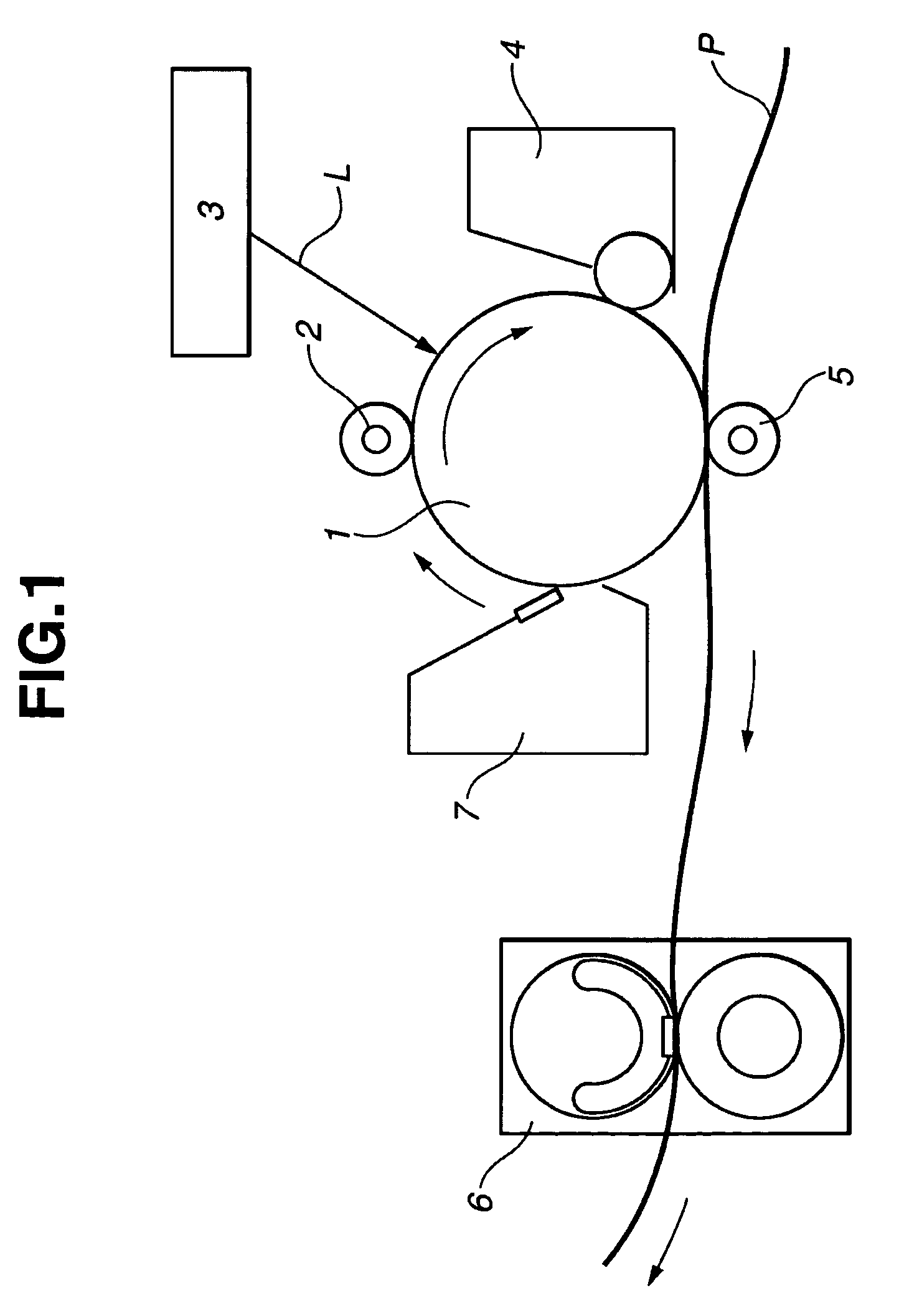

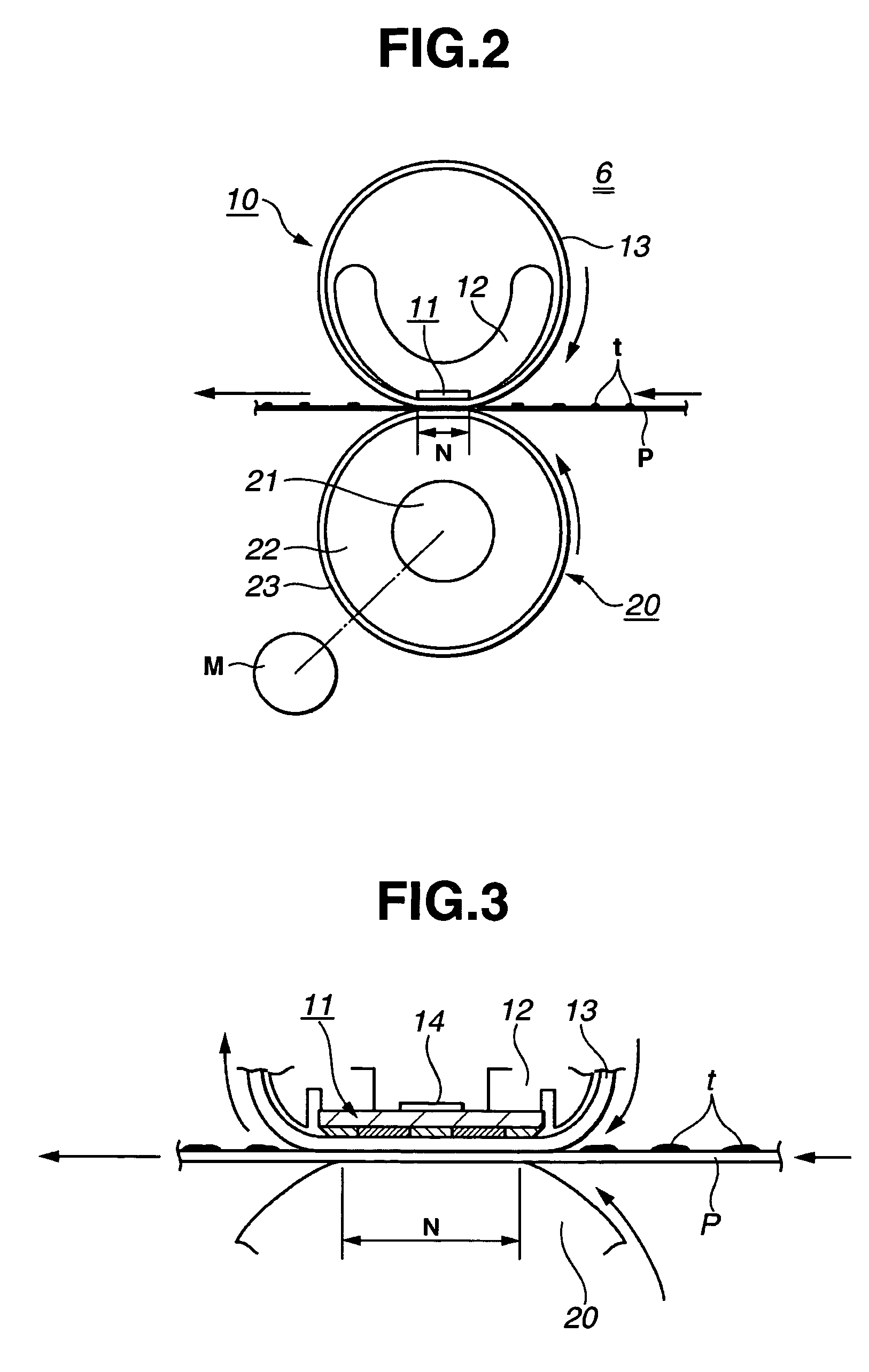

InactiveUS6246035B1Easy to fixEffectively fixing the toner image without causing image aberration or blurringElectrographic process apparatusInduction heating apparatusImage formationThermal transmittance

A heating device suitable for use as a fixing means for fixing a toner image onto a recording medium in, e.g., an electrophotographic image forming apparatus is provided so as to provide images free from image blurring or fixing failure while improving the anti-offset performance. The heating device includes a heating member, and a heat-resistant film having a first surface to be moved relative to and in contact with the heating member and a second surface to be in contact with a member to be heated, so that the member to be heated and the heat-resistant film are moved together over the heating member to heat the member to be heated. The heat-resistant film comprises at least a base layer and an elastic layer, wherein the elastic layer contains a filler exhibiting a thermal conductivity of at least 0.04 cal / cm.sec. °C.

Owner:CANON KK

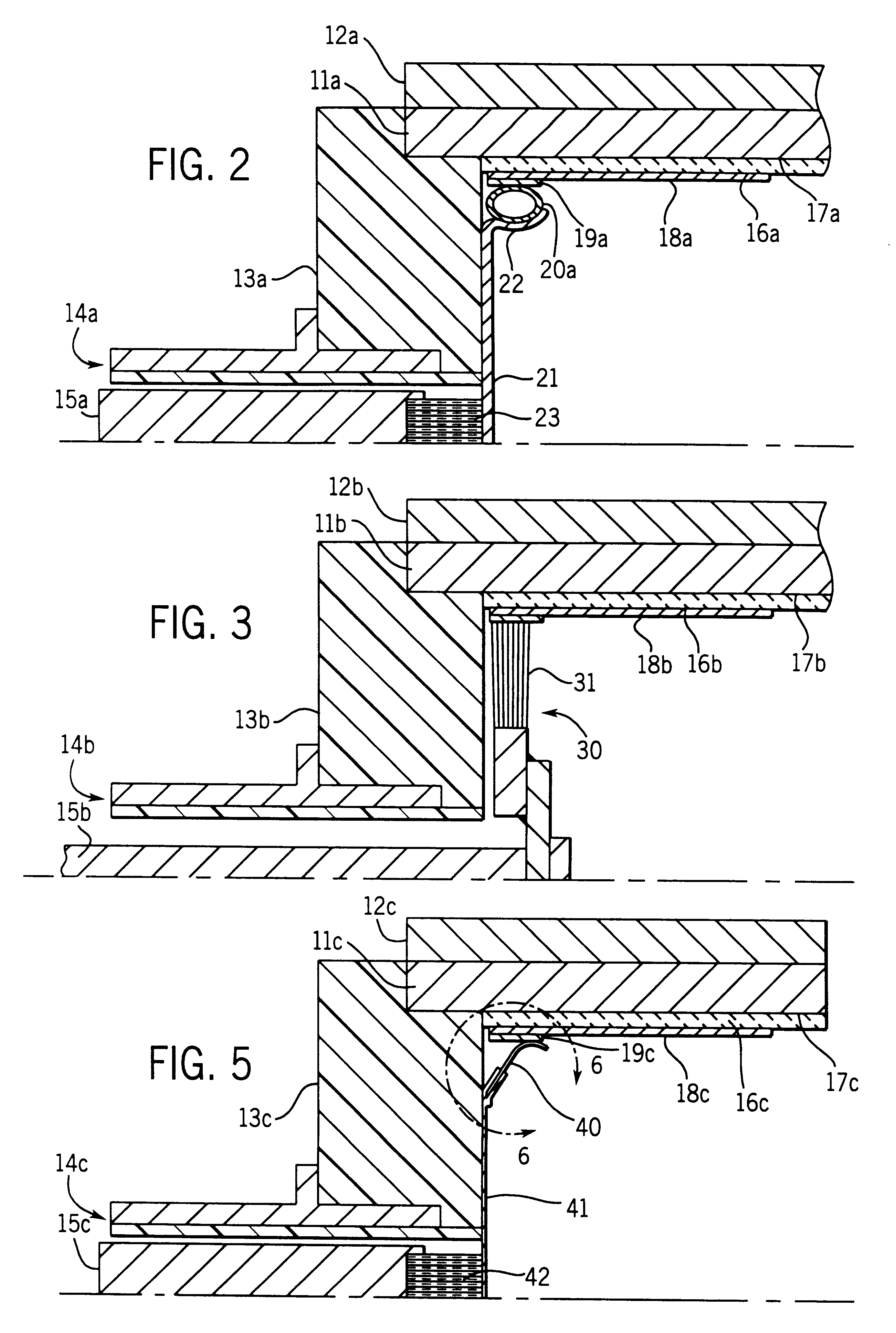

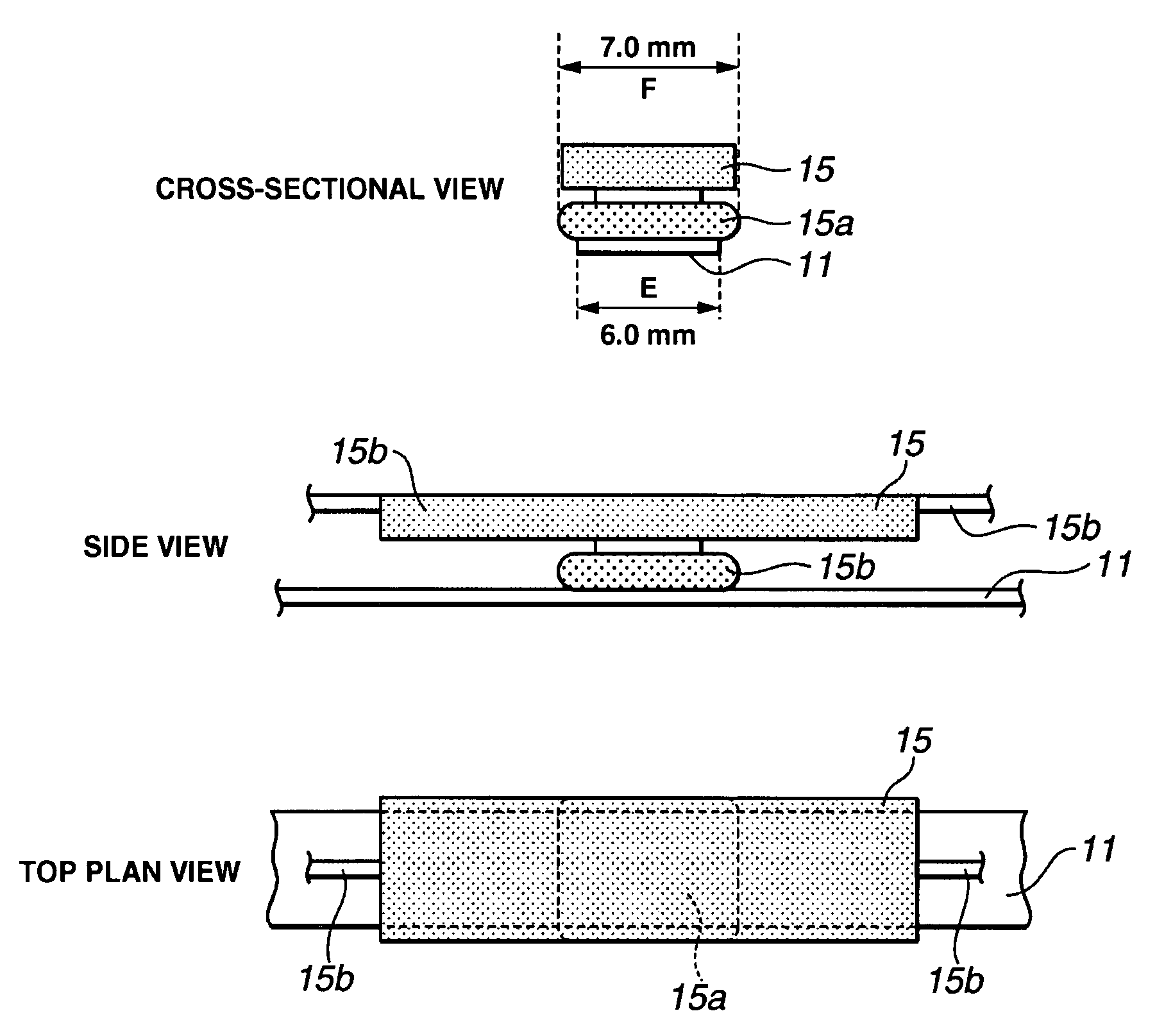

Ceramic heater/fuser roller with internal heater

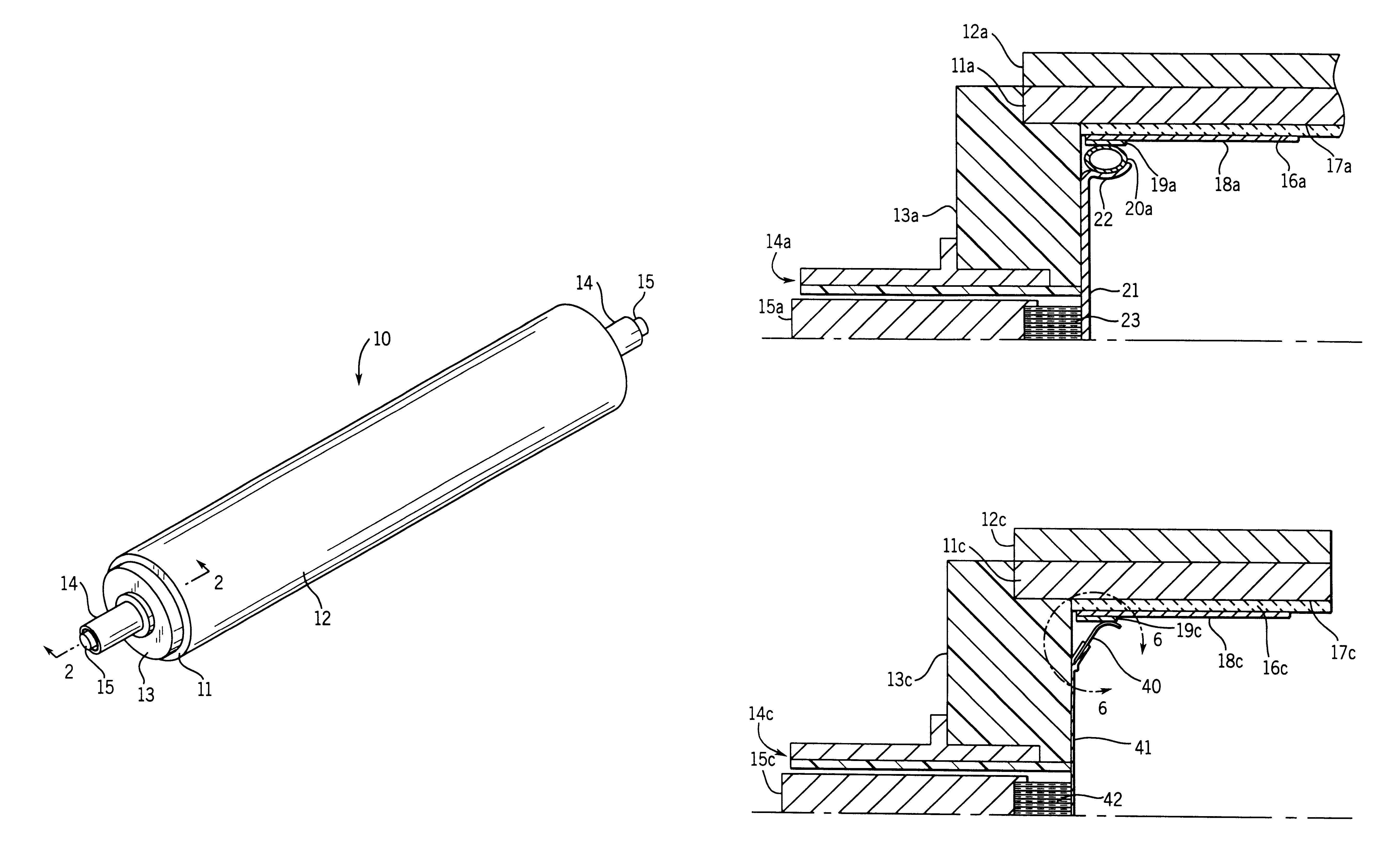

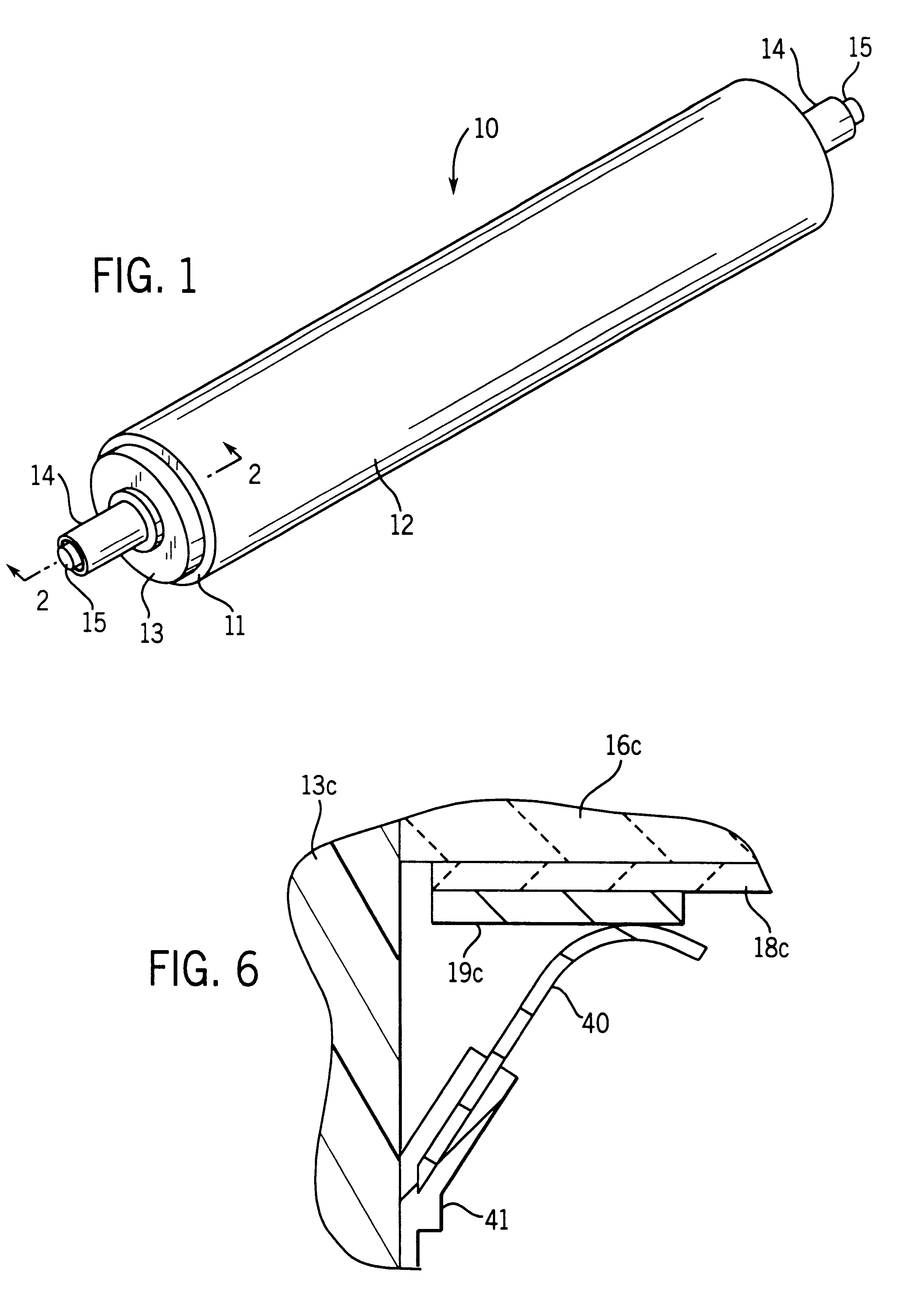

InactiveUS6285006B1Easy and more straightforward to bondReduced risk of damageOhmic-resistance heating detailsRollsElectricityThree-phase

A thermal conduction roller (10) has a tubular roller core (11) with an inside surface; and an electrical insulator coat (16) primarily of zirconia on the inside surface, a heater coat (18) of titania or a titania blend is disposed over the insulator coat (16), and at least two electrical contact assemblies that are disposed inside the roller and electrically connect to the heater coat (18) as the roller (10) is being rotated. One embodiment utilizes an electrical insulator coat (16) in a range of thickness from about ten mils to about twenty mils. A thinner coat may not have sufficient dielectric strength, while a thicker coat decreases thermal conduction. A release material (12) is applied to the outside of the roller (10). Various contact structures according to the present invention are also described in detail, including one especially adapted to connect to a three-phase power supply.

Owner:AMERICAN ROLLER

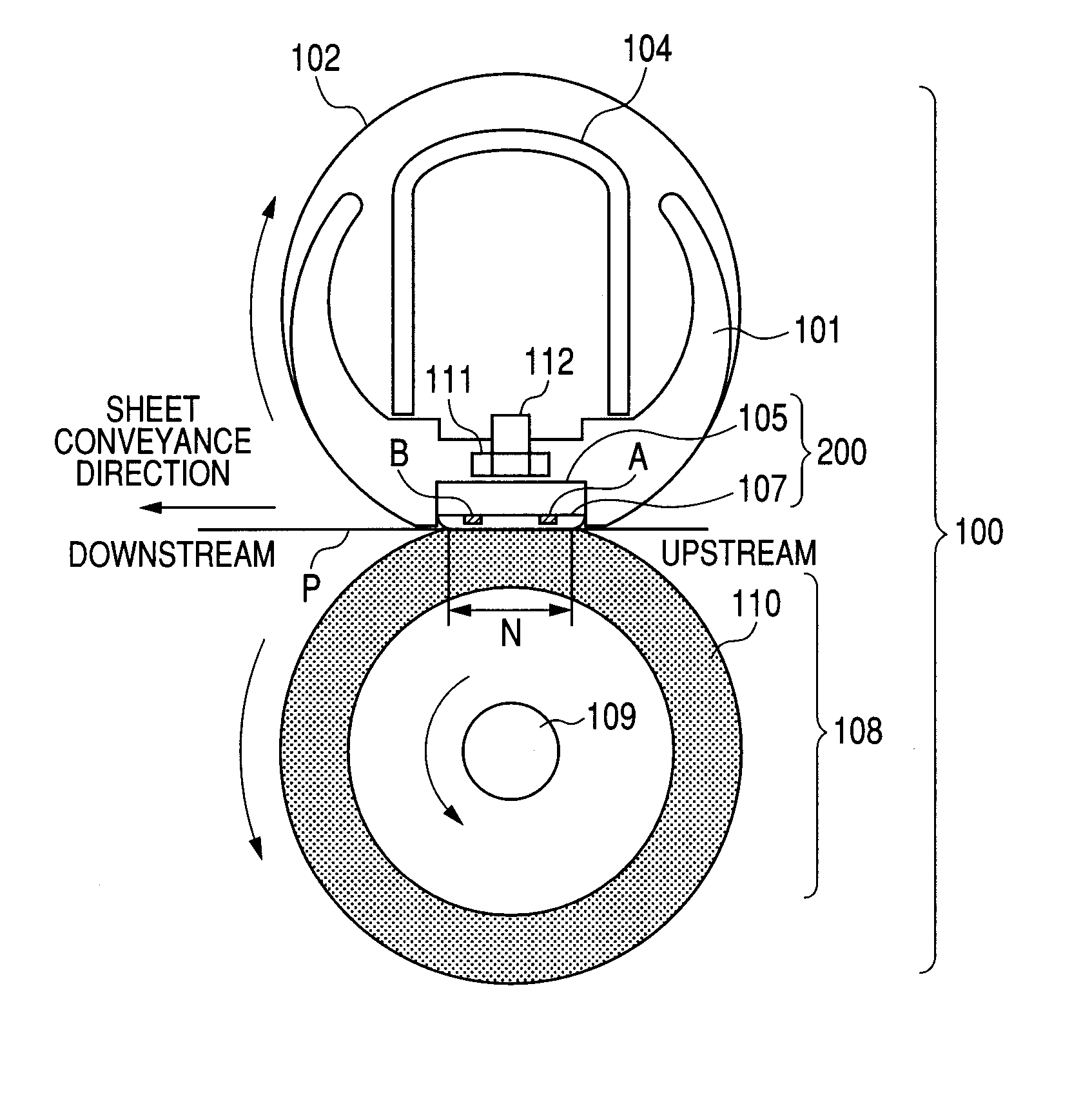

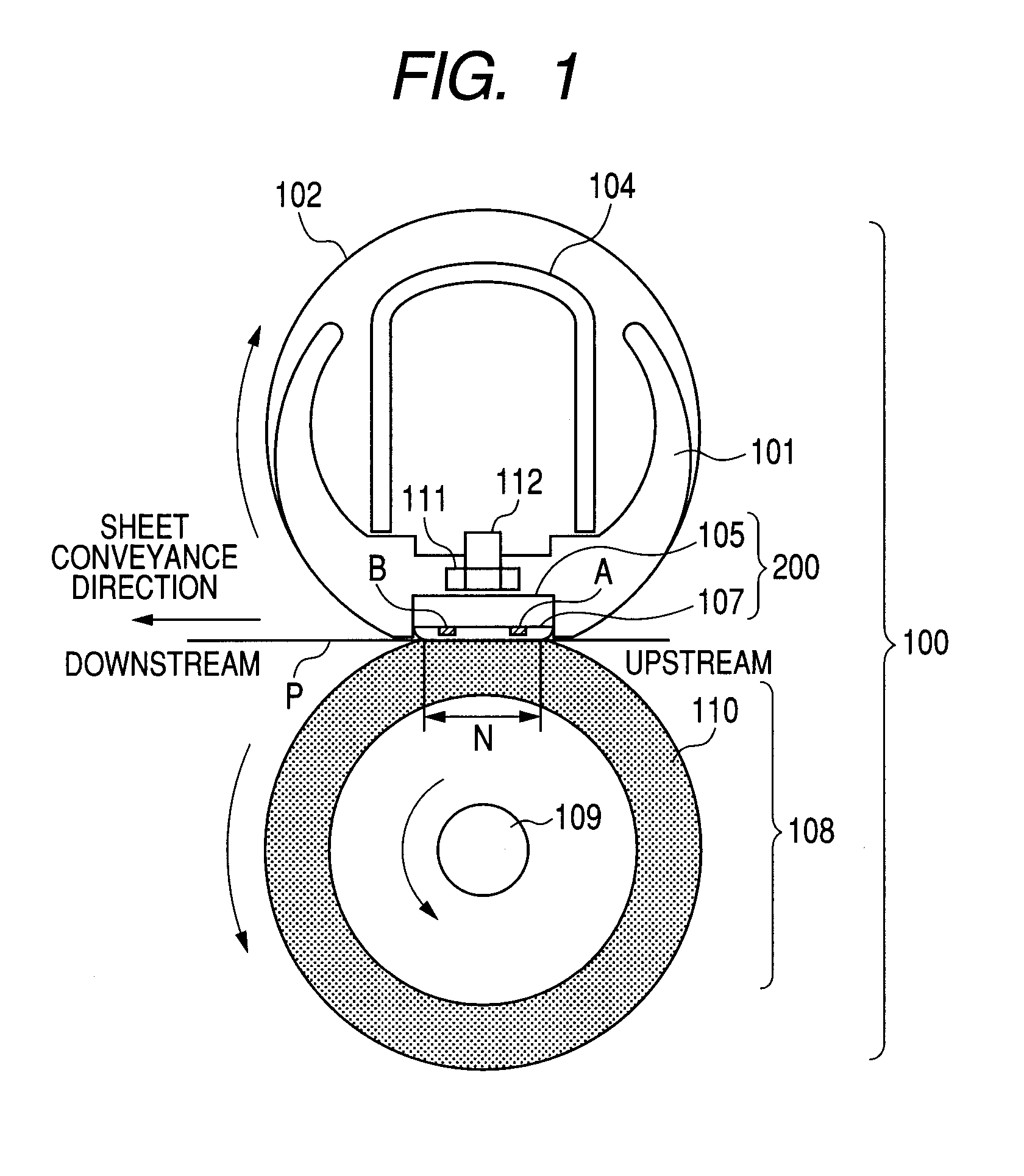

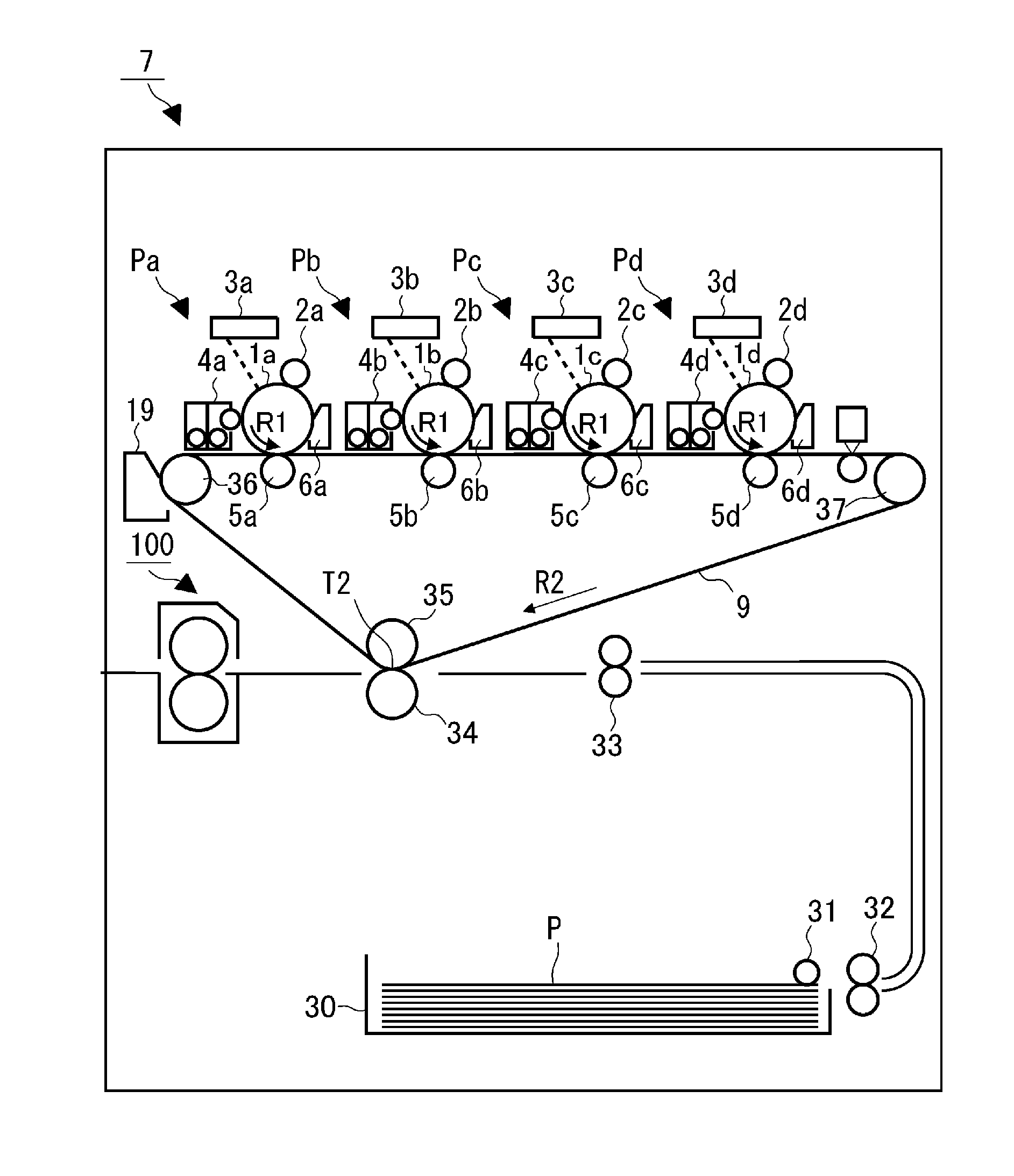

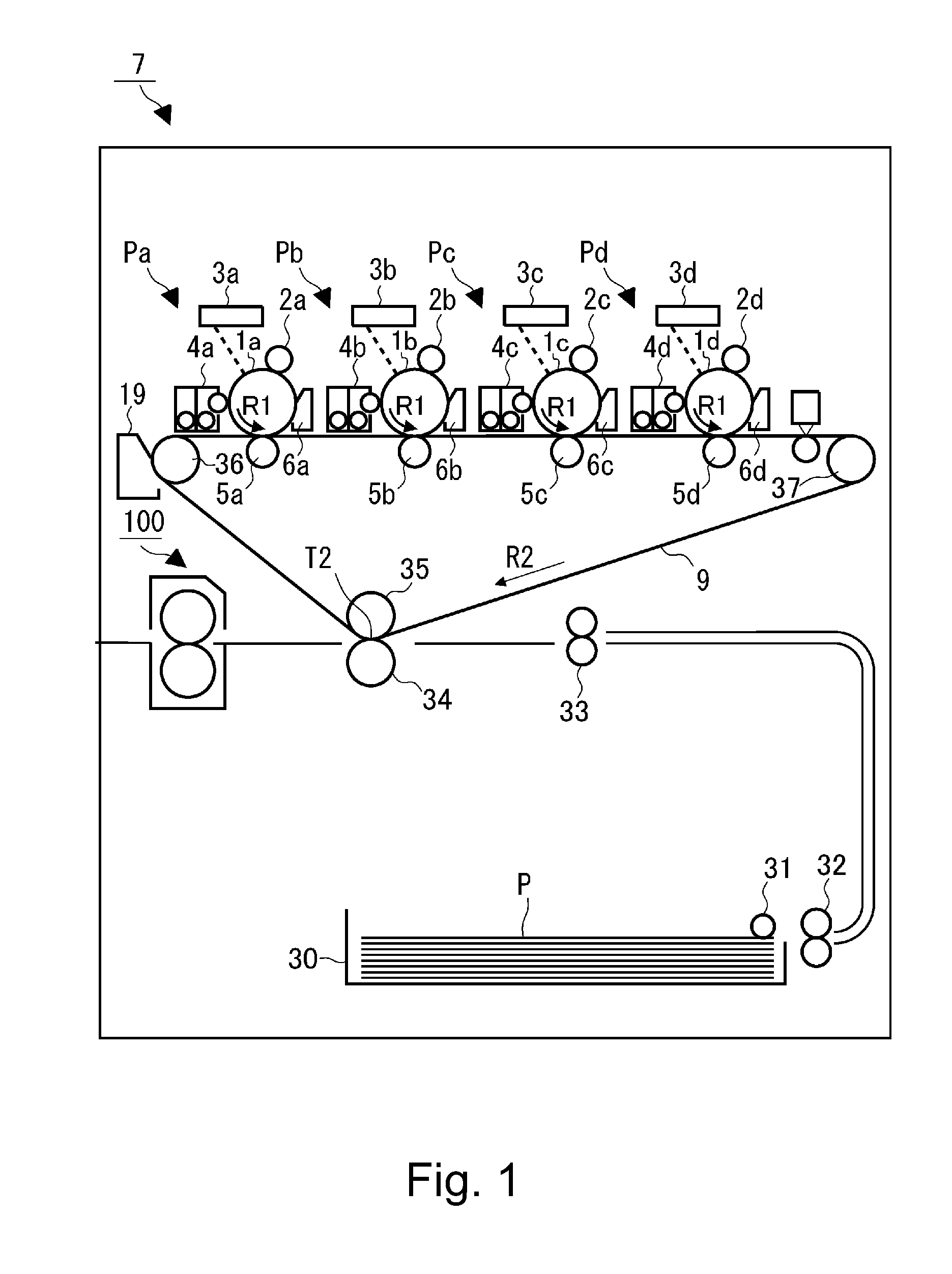

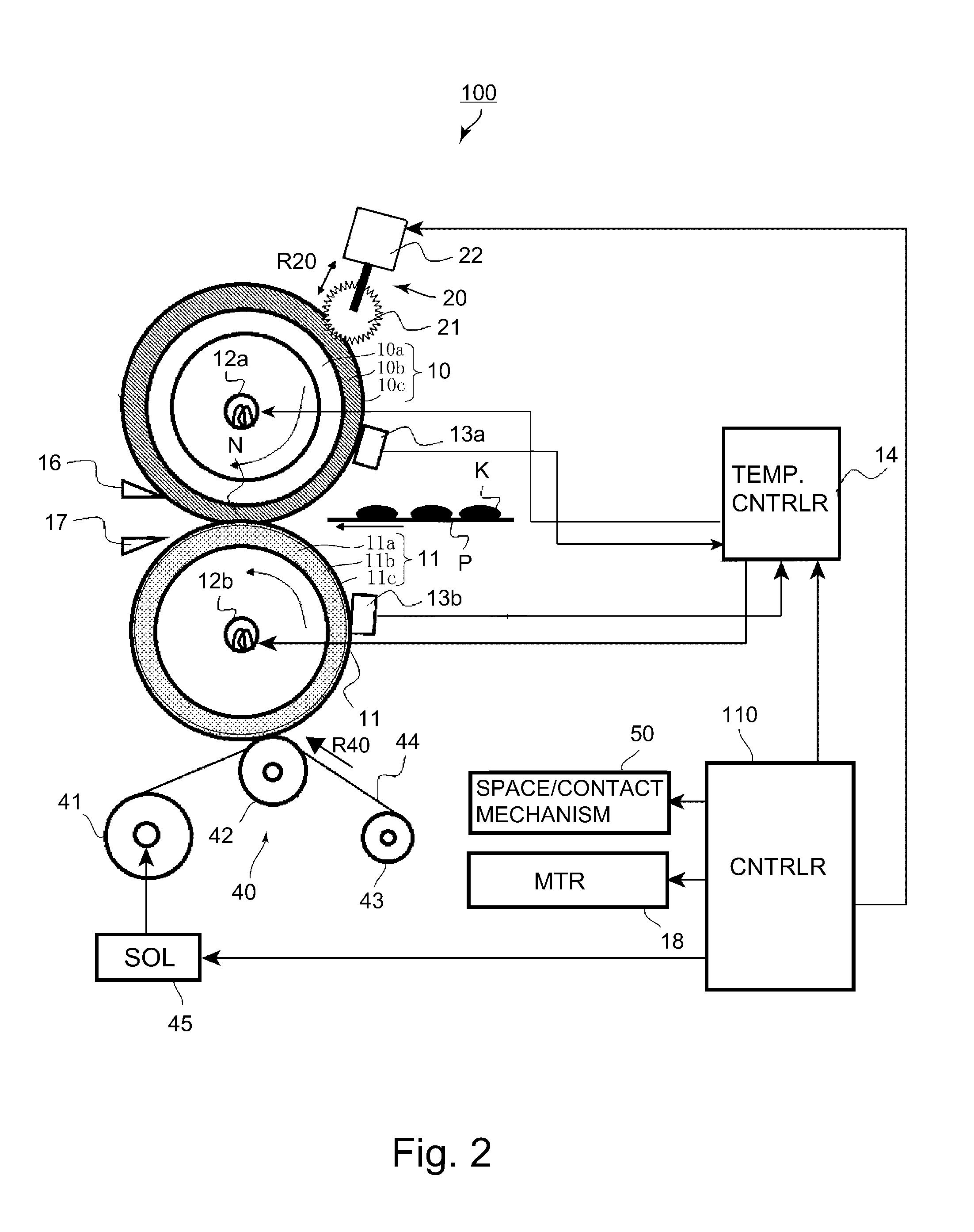

Image heating apparatus

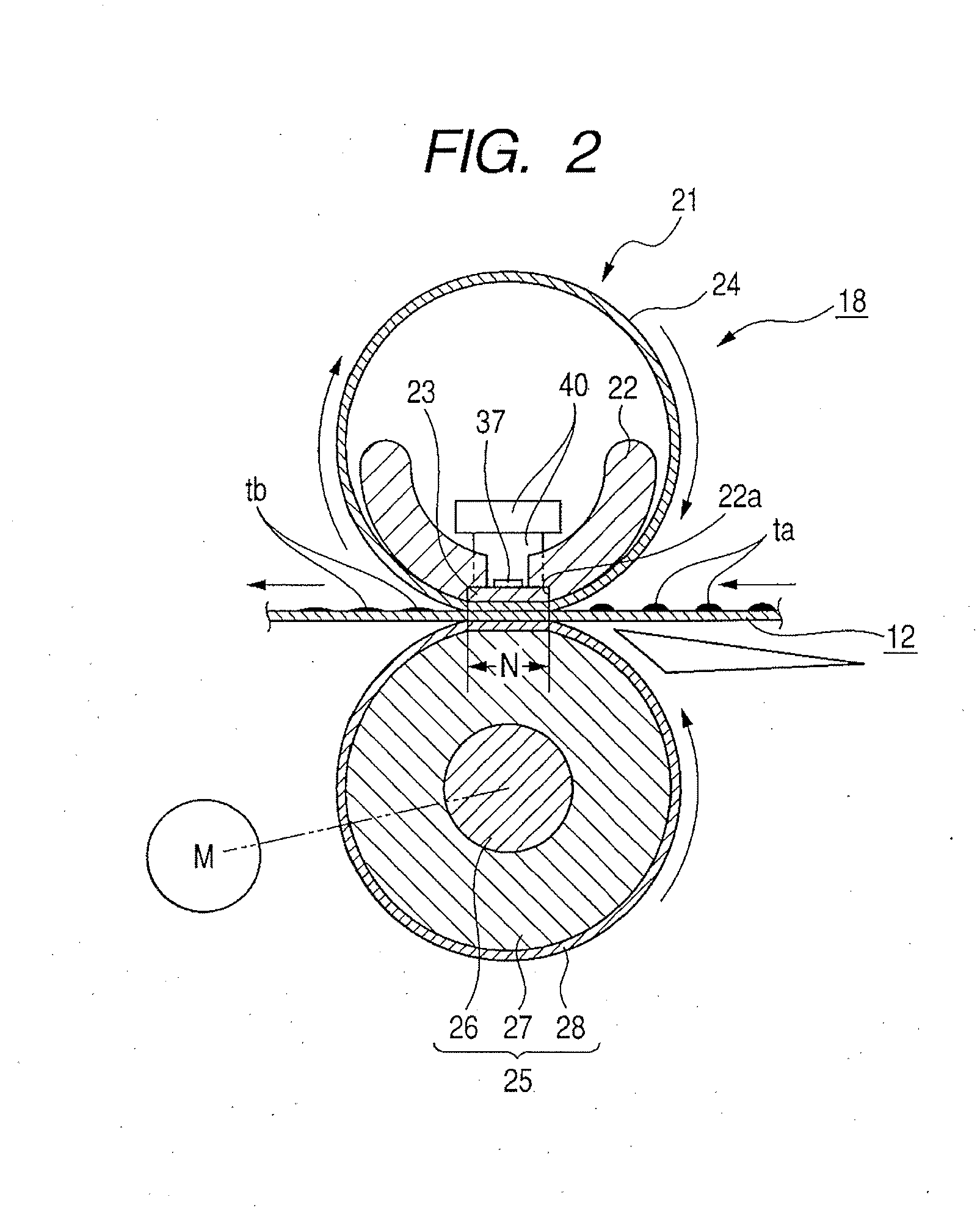

ActiveUS20130206745A1Inhibit transferOhmic-resistance heating detailsRollsTemperature differenceRubbing

An image heating apparatus includes a image heating roller in a nip; a nip forming member; a heating roller rubbing roller; a moving mechanism for moving the rubbing roller between a spaced position and a rubbing position; and a controller for executing operations in first and second modes. In the first mode, the heating roller is rotated with the rubbing roller in the spaced position and the heating roller in contact with the nip forming member with a target temperature of the heating roller higher than that of the nip forming member. In the second mode, the rubbing roller is contacted with the heating roller rubbing the surface of the heating roller. The temperature difference in the first mode between the target temperature of the heating roller and that of the nip forming member is larger than the temperature difference when the toner image is heated by the nip.

Owner:CANON KK

Heater and image heating device mounted with heater

ActiveUS9235166B2Avoid temperature riseOhmic-resistance electrodesElectrographic process apparatusElectrical resistance and conductanceJoint heat

A heater of the present invention includes jointed heat generating resistors having a positive temperature characteristic of resistance and provided between a first conductive element and a second conductive element on a substrate in a longitudinal direction of the substrate, and a plurality of heating blocks provided in the longitudinal direction, each of which is a set of the first conductive element, the second conductive element, and the heat generating resistor, and power supplied to at least one of the plurality of heating blocks can be controlled independent of other heating blocks.

Owner:CANON KK

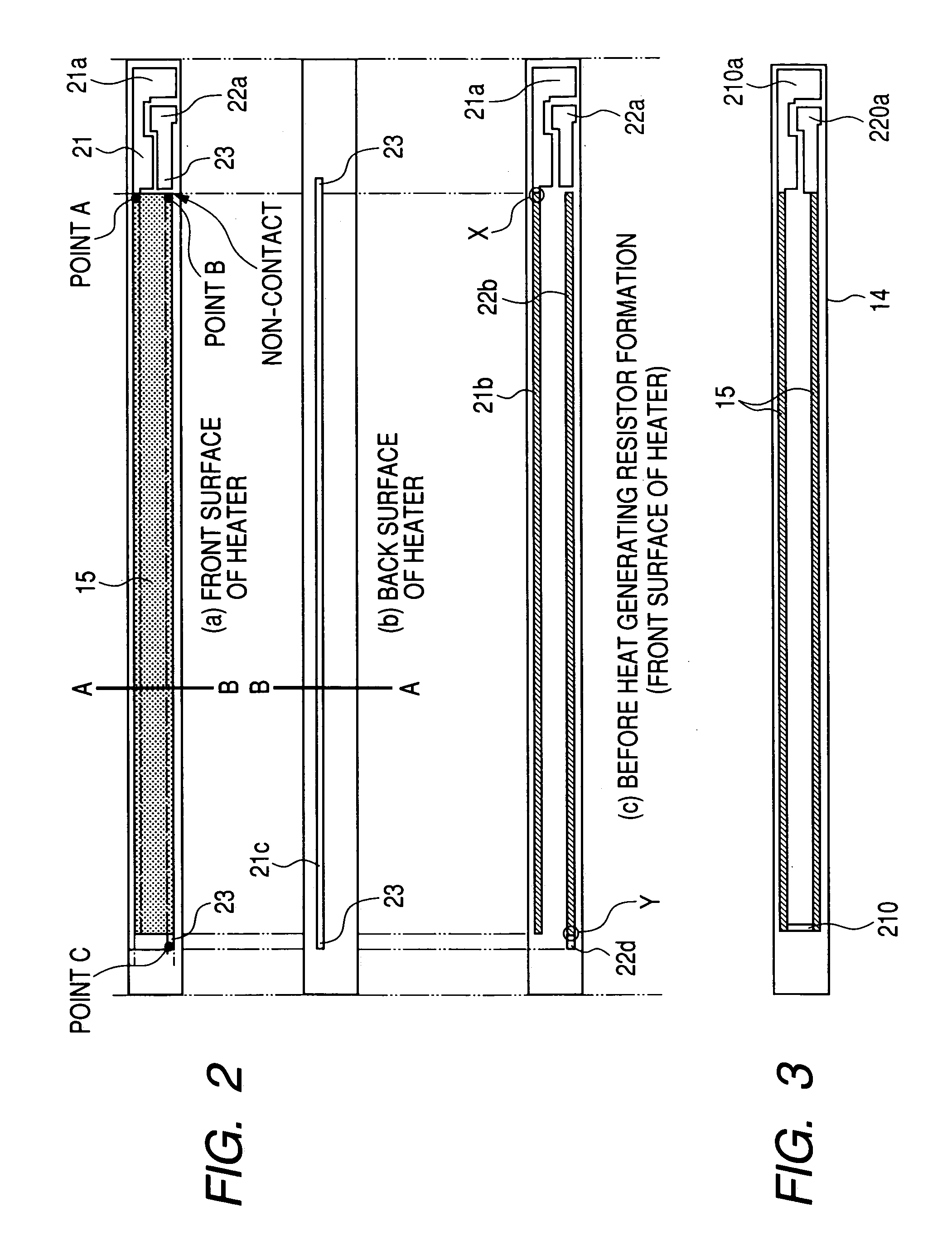

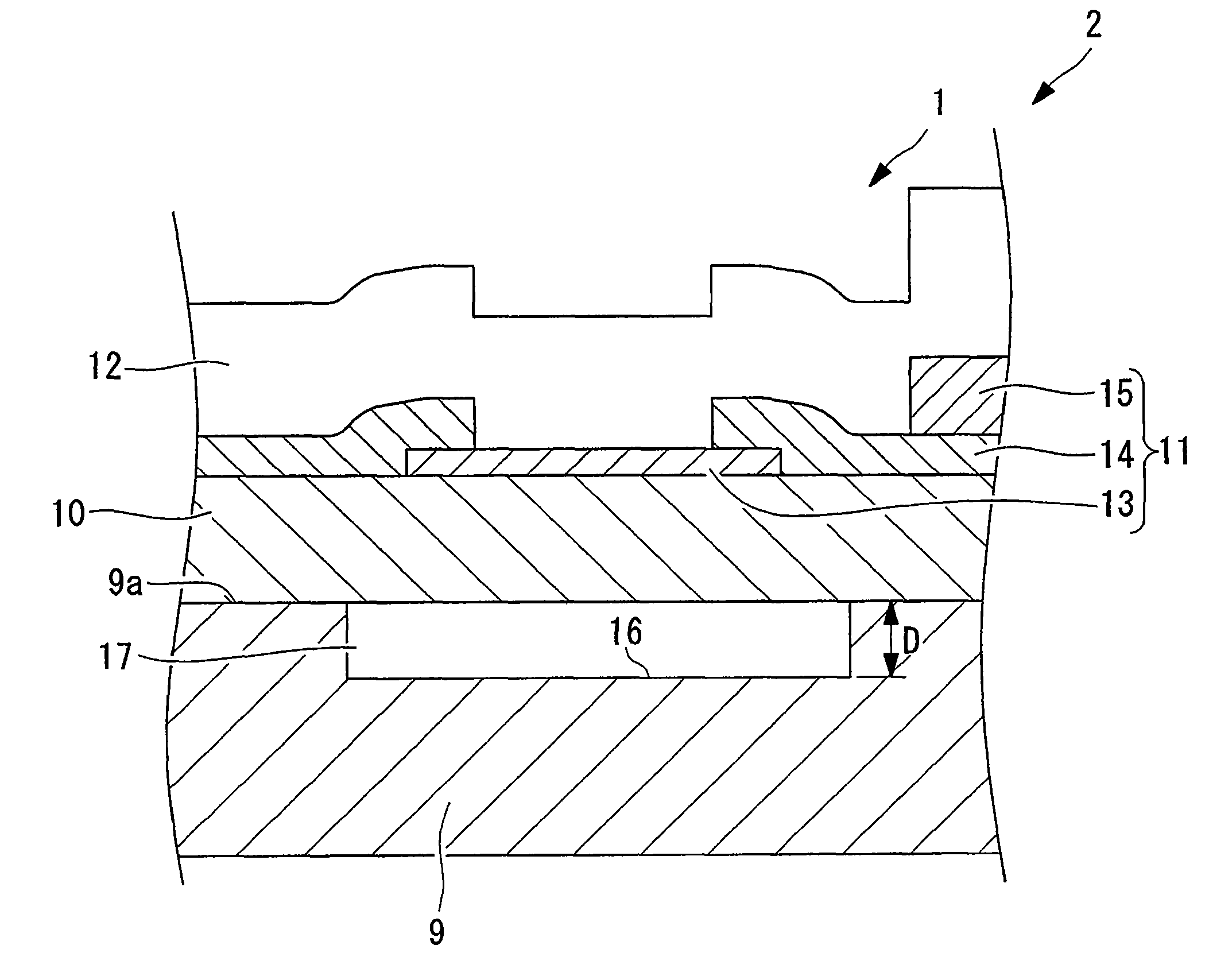

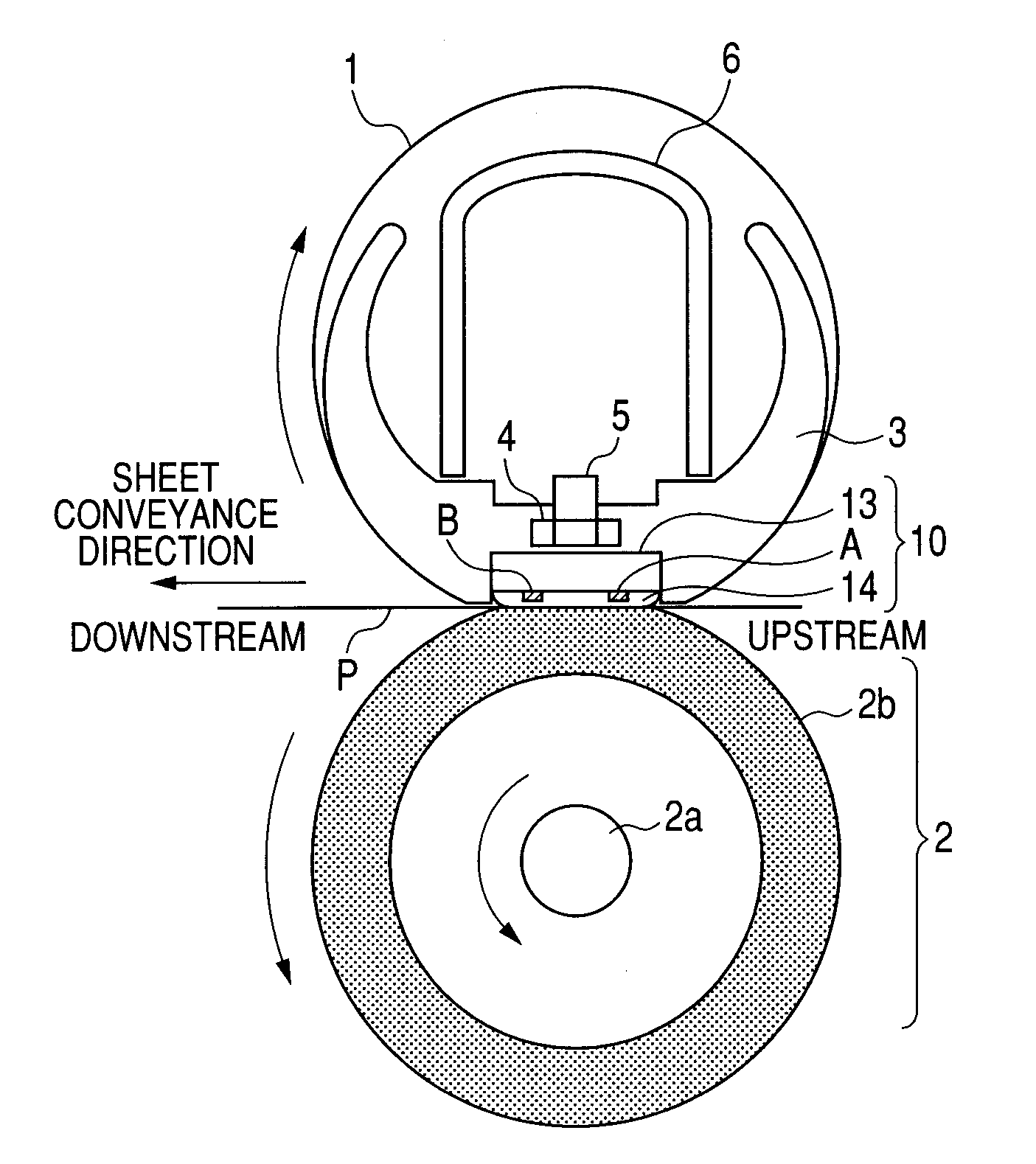

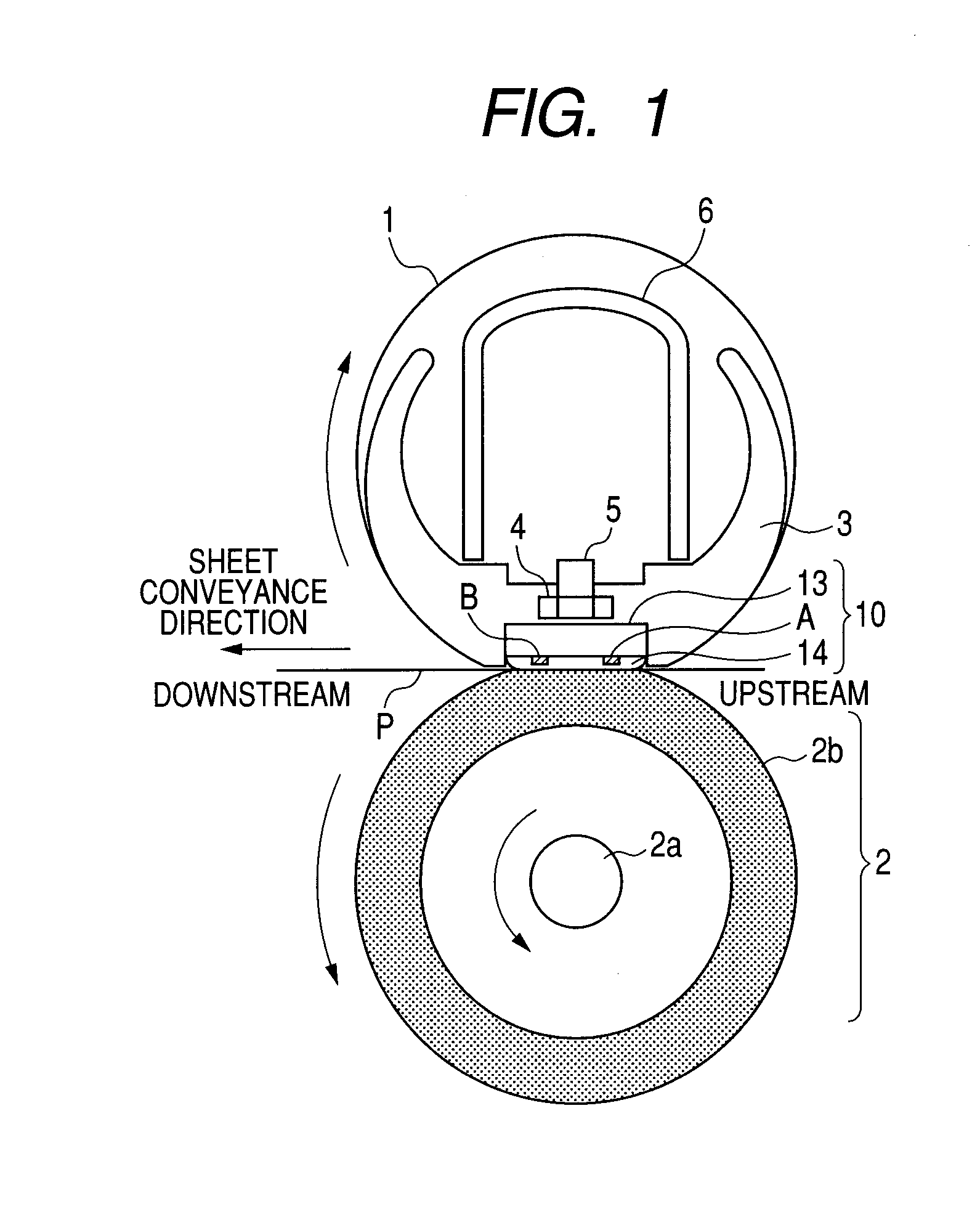

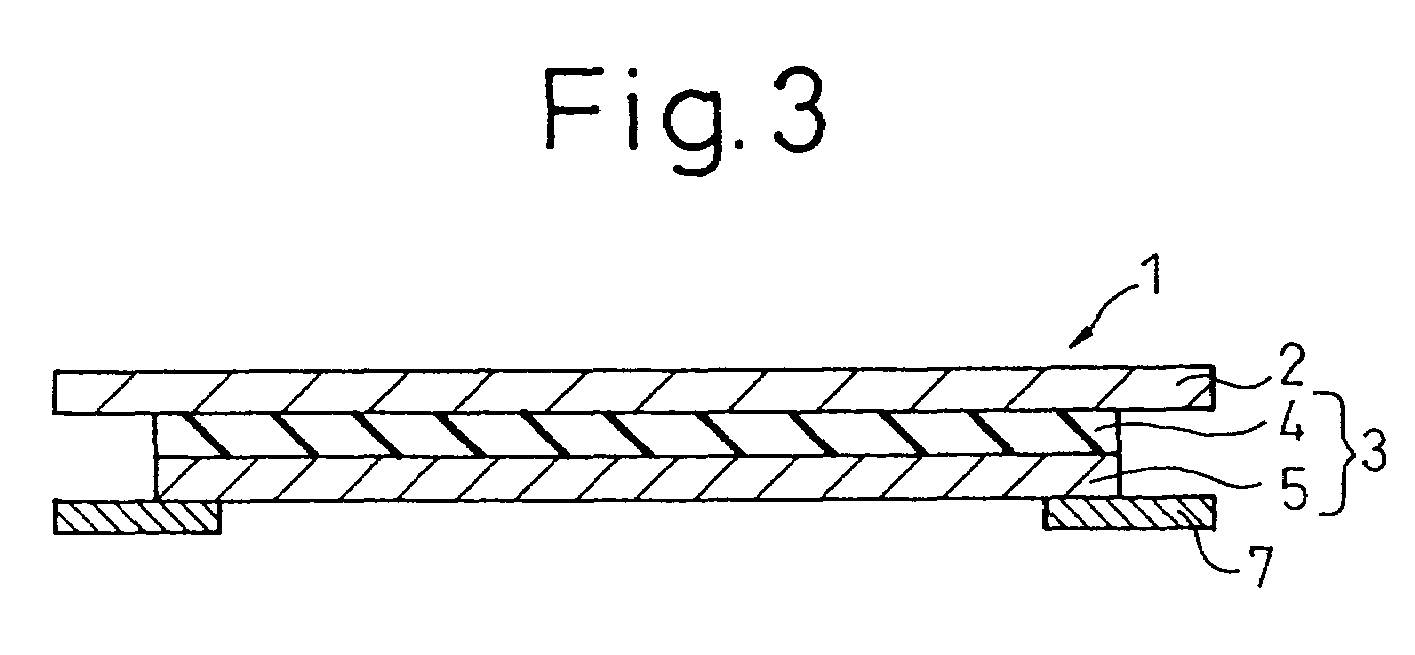

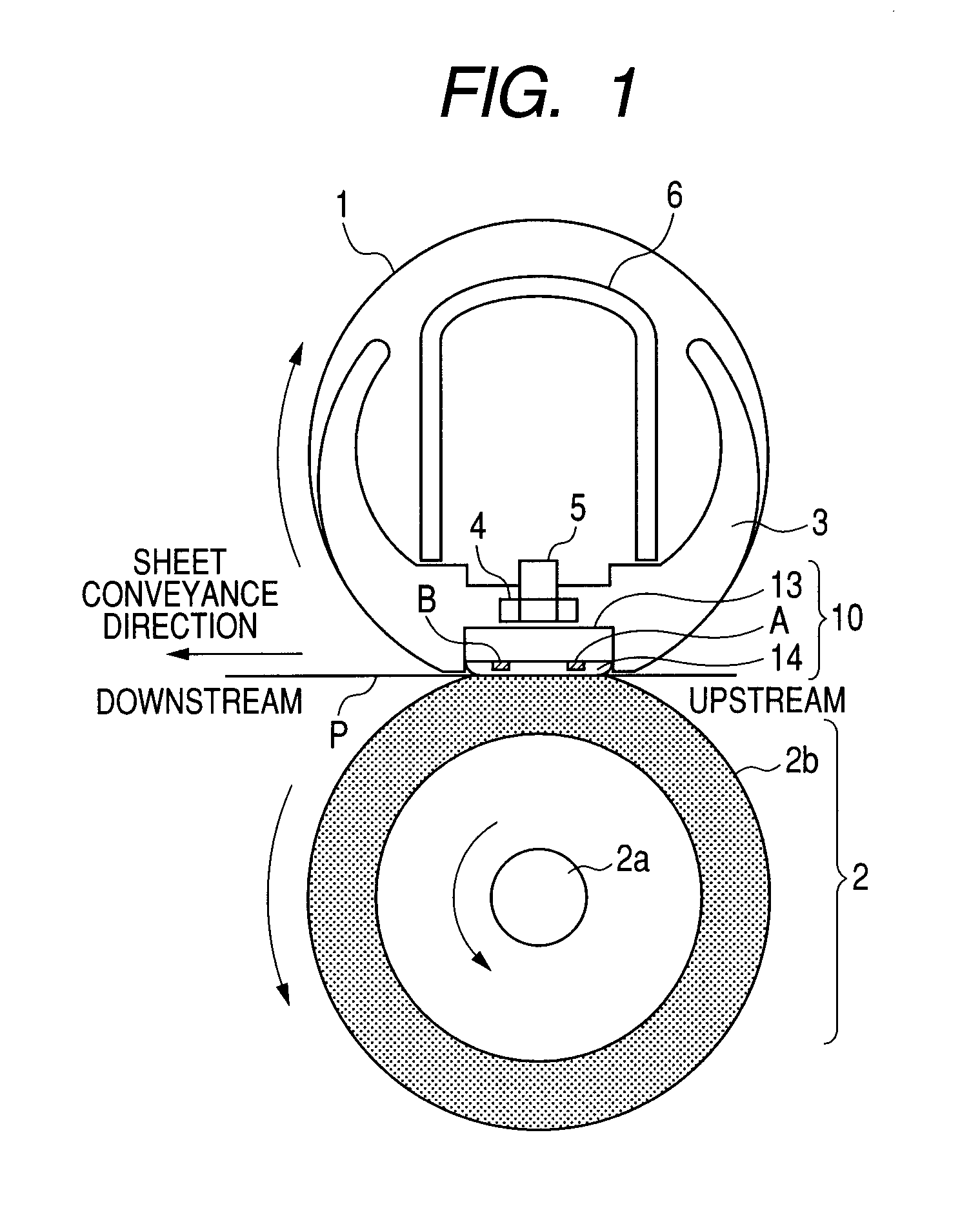

Heater having metallic substrate and image heating apparatus using heater

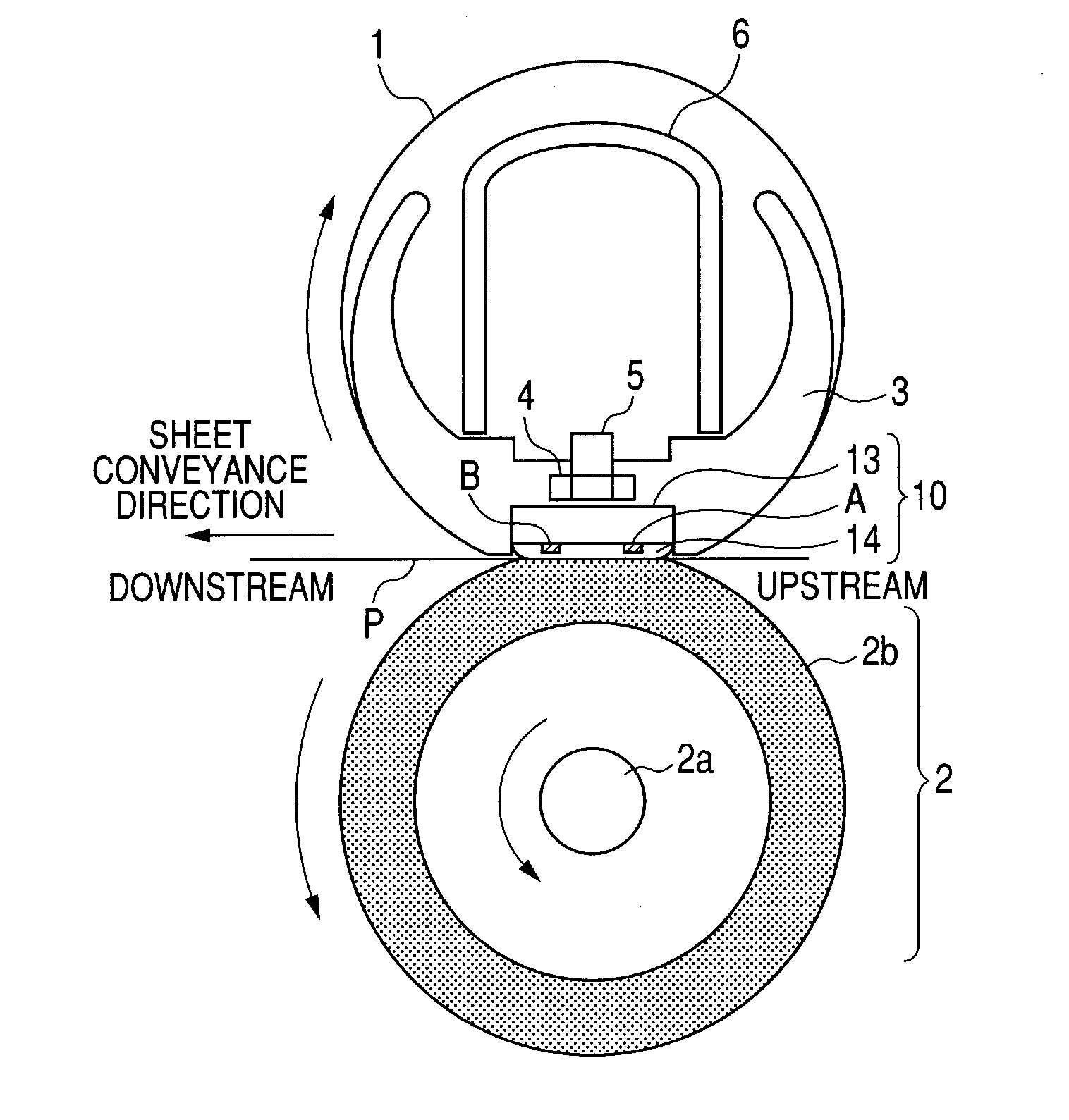

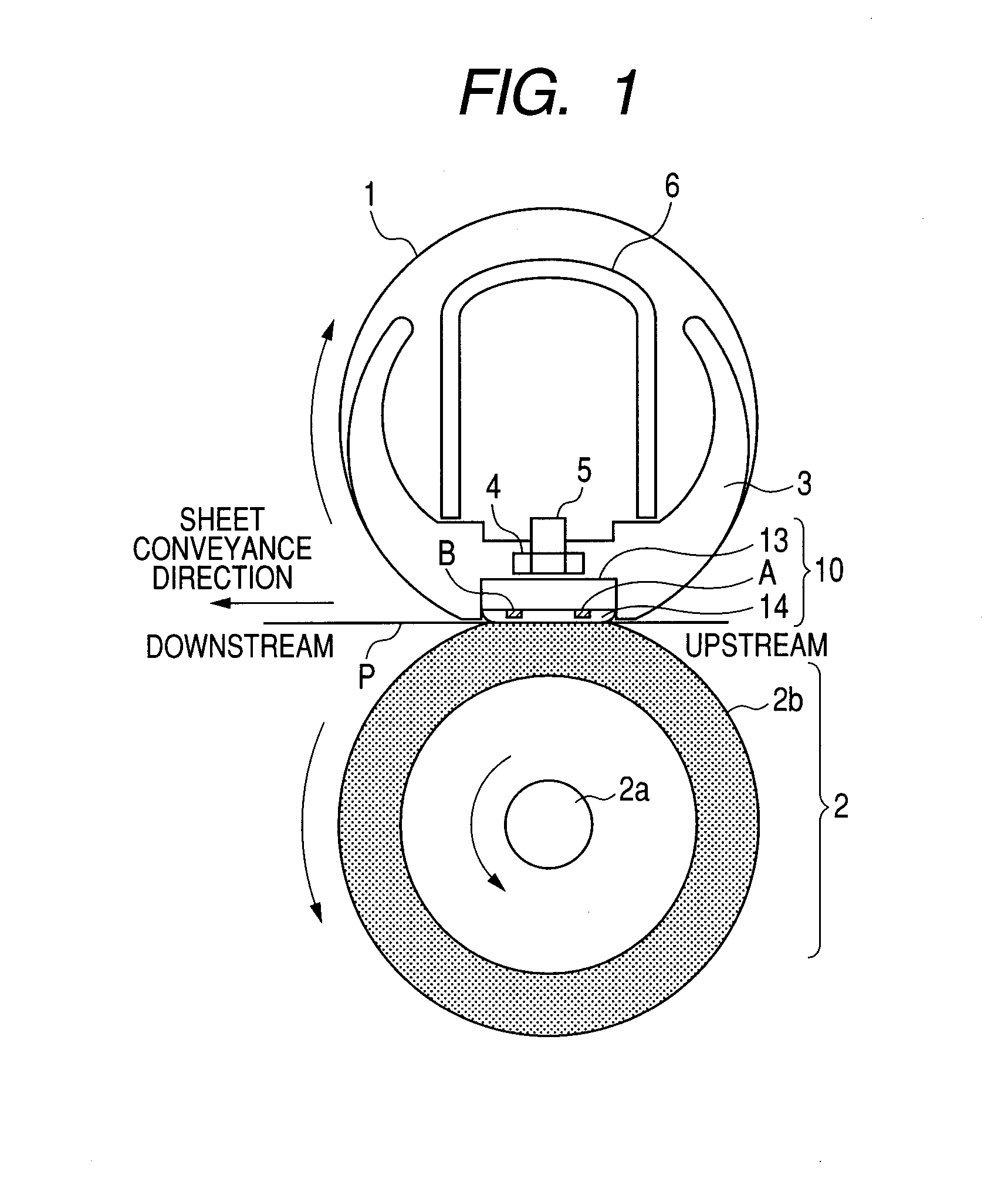

InactiveUS20020127035A1Suppress a driving torque of a filmLow costElectrographic process apparatusRoller heating devicesConvex sideEngineering

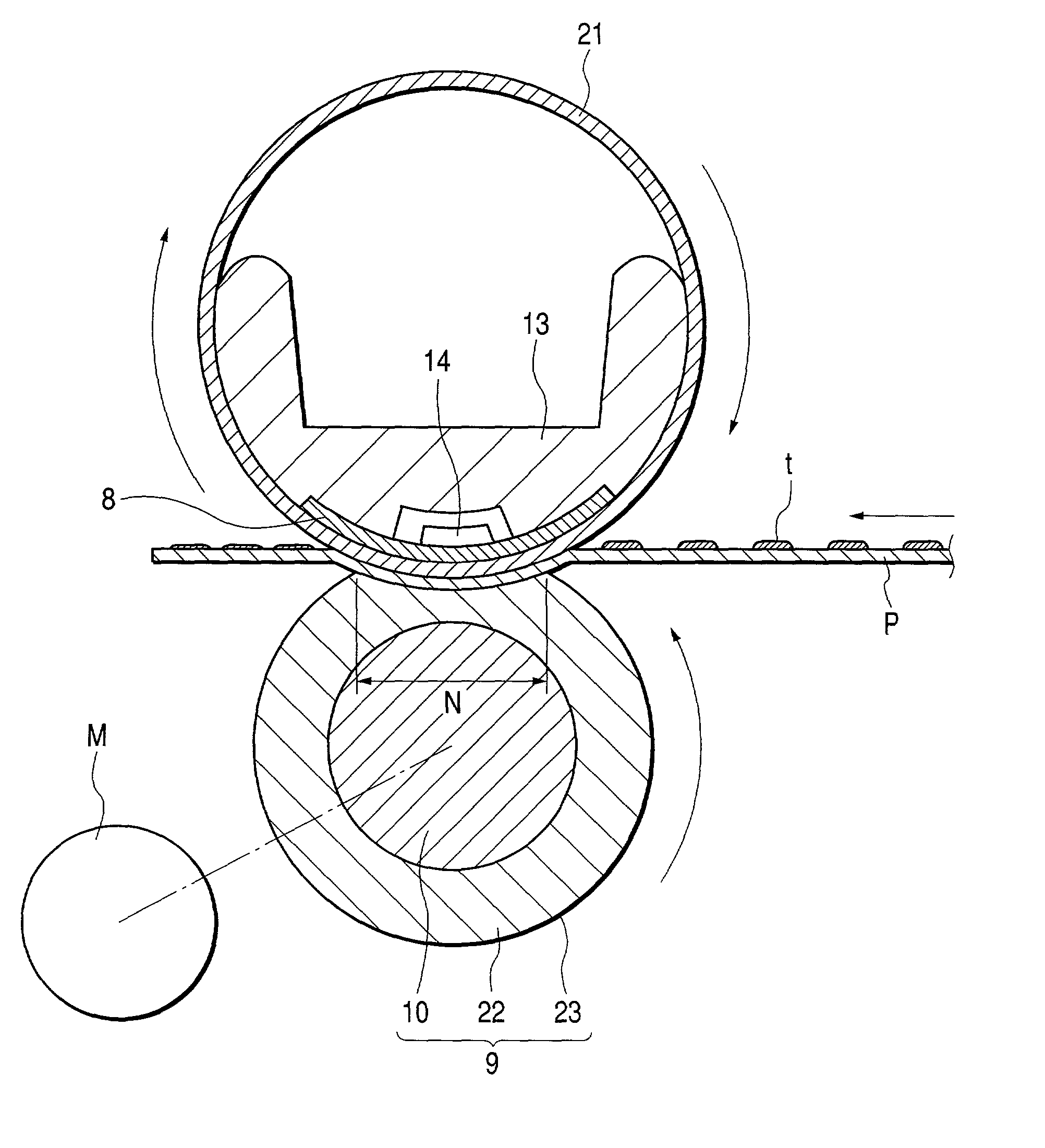

The image heating apparatus for heating an image formed on a recording material has a heater, a film moving in contact with the heater, and a back-up roller for defining a nip with the heater via the film. In the image heating apparatus, the heater includes a metallic substrate, and the metallic substrate has a convex surface on a side of the nip and a concave surface on an opposite surface.

Owner:CANON KK

Thermally sprayed resistive heaters and uses thereof

InactiveUS20170258268A1Low resistivityStable resistivityMolten spray coatingHeater elementsBorideThermal spraying

A heater is provided having at least one thermally sprayed resistive heating layer, the resistive heating layer comprising a first metallic component that is electrically conductive and capable of reacting with a gas to form one or more carbide, oxide, nitride, and boride derivative; one or more oxide, nitride, carbide, and boride derivative of the first metallic component that is electrically insulating; and a third component capable of stabilizing the resistivity of the resistive heating layer. In some embodiments, the third component is capable of pinning the grain boundaries of the first metallic component deposited in the resistive heating layer and / or altering the structure of aluminum oxide grains deposited in the resistive heating layer.

Owner:THERMOCERAMIX +1

Image heating apparatus and heater for use therein

ActiveUS20050163523A1Decrease in numberSuppress uneven temperature distributionOhmic-resistance electrodesElectrographic process apparatusElectricityElectrical resistance and conductance

The invention is to provide an image heating apparatus capable of preventing an excessive temperature increase in a sheet non-passing area and a heater for use in such apparatus, and the heater for use in the image heating apparatus of the invention is constructed by including: a substrate; a heat generating resistor formed on the substrate; and first and second electrodes for supplying an electric power to the heat generating resistor; wherein each of the first and second electrodes has a first area to be contacted with a power supplying connector and a second area provided at an end portion electrically opposite to the first area, the second areas are provided along a longitudinal direction of the substrate, and the heat generating resistor is so provided as to electrically connect the second area of the first electrode and the second area of the second electrode; wherein, within the second area of the first electrode, a portion electrically closest to the first area of the first electrode is provided in the vicinity of an end portion of the substrate in the longitudinal direction thereof, and within the second area of the second electrode, a portion electrically closest to the first area of the second electrode is provided in the vicinity of the other end portion of the substrate in the longitudinal direction thereof; and wherein, when the heater is at a set temperature for an image heating operation in the image heating apparatus, a resistance value Rc of the second area of either of the first and second electrodes and a resistance value Rt between a portion within the second area of the first electrode electrically closest to the first area of the first electrode and a portion within the second area of the second electrode electrically closest to the first area of the second electrode satisfy a relation: Rc / Rt≦1 / 30.

Owner:CANON KK

Heating resistor element, manufacturing method for the same, thermal head, and printer

InactiveUS7768541B2Avoid deformationImprove printing qualityElectrographic process apparatusPrintingEngineeringHeat sensitive

Owner:SEIKO INSTR INC

Heater and image heating apparatus having the heater installed therein

InactiveUS20120201581A1Avoid feverHeating element shapesElectrographic process apparatusEngineeringMaximum size

The image heating apparatus includes first and second lines having a first and second heat generation blocks, the first and second lines being disposed at different positions in a transverse direction, wherein the first and second lines are arranged so that a whole of first heat generation block in the first line and a whole of second heat generation block in the second line overlap with each other in the longitudinal direction, and a whole of second heat generation block in the first line and a whole of first heat generation block in the second line overlap with each other in the longitudinal direction. By the virtue of the present invention, it achieves to be capable of suppressing a temperature rise in a non-sheet feeding area in a case of printing a sheet smaller in size than a maximum size supported by the image heating apparatus.

Owner:CANON KK

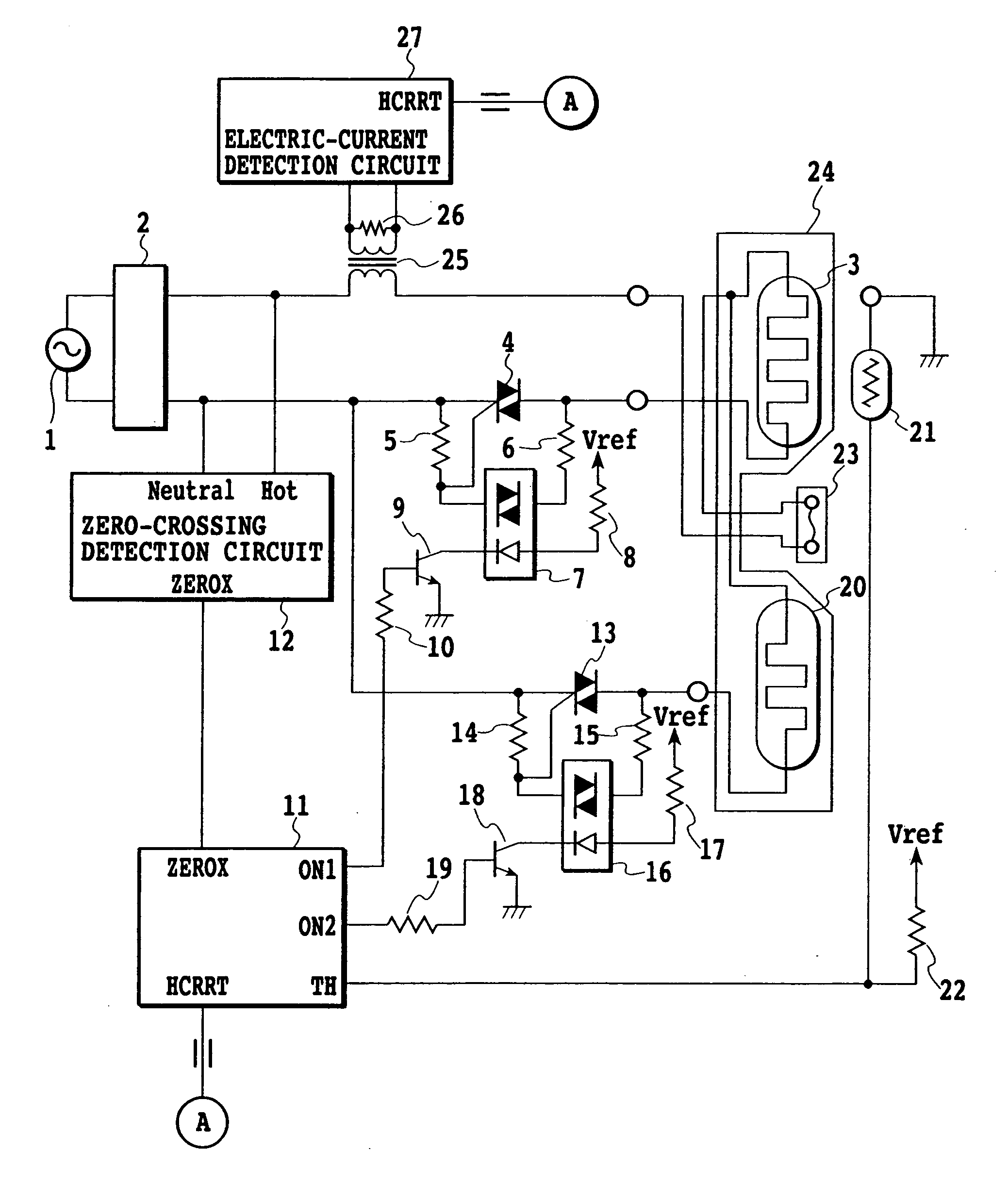

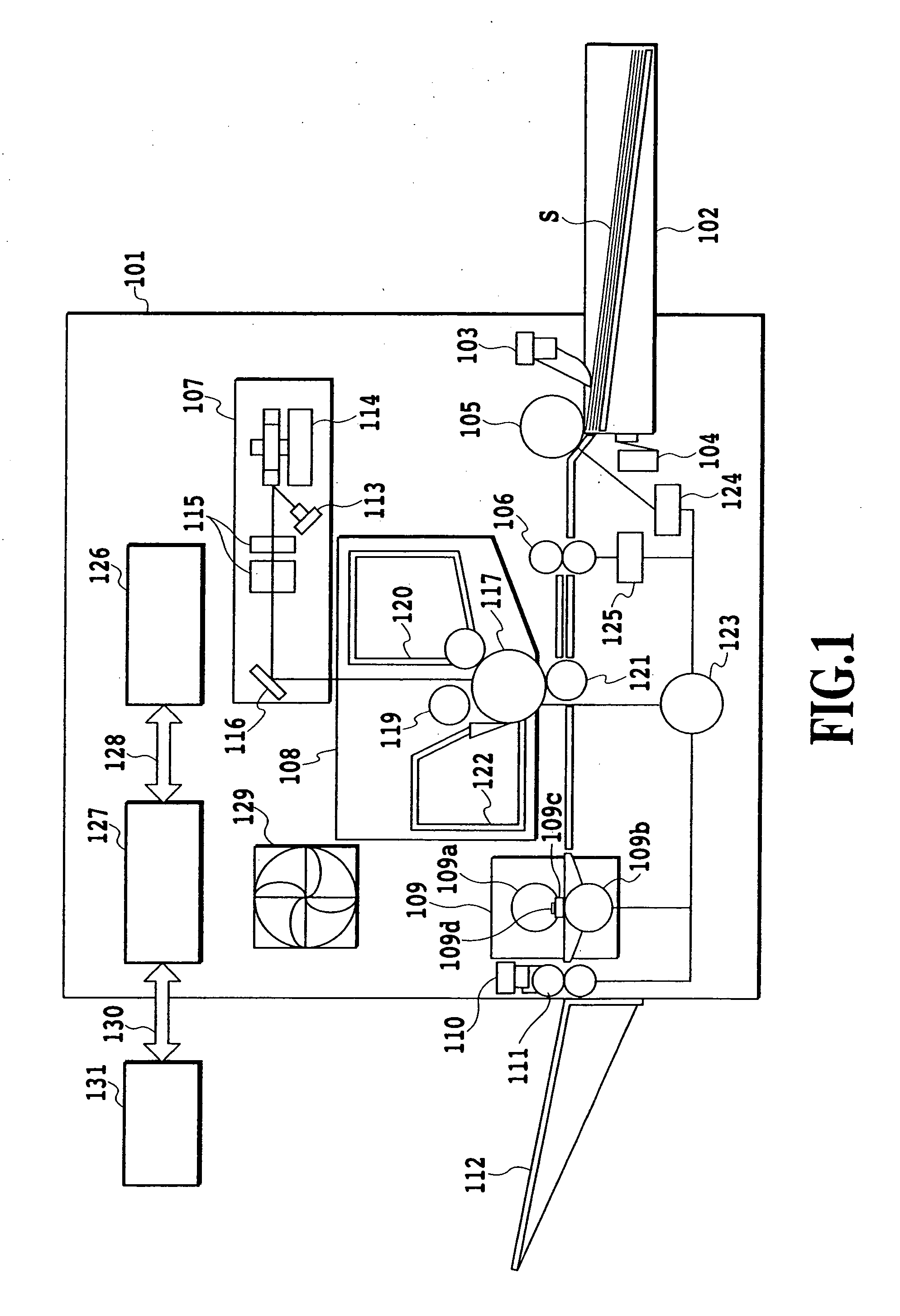

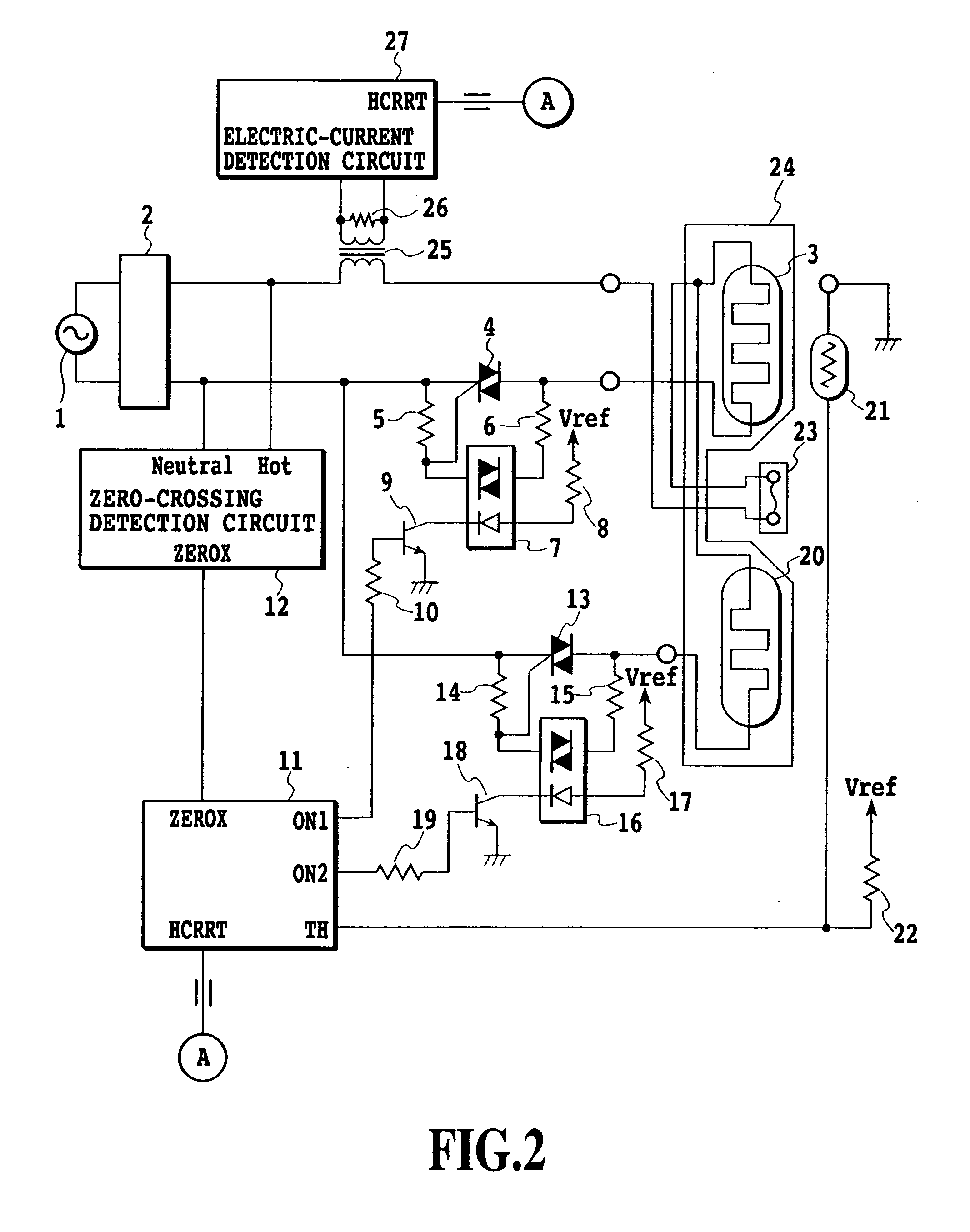

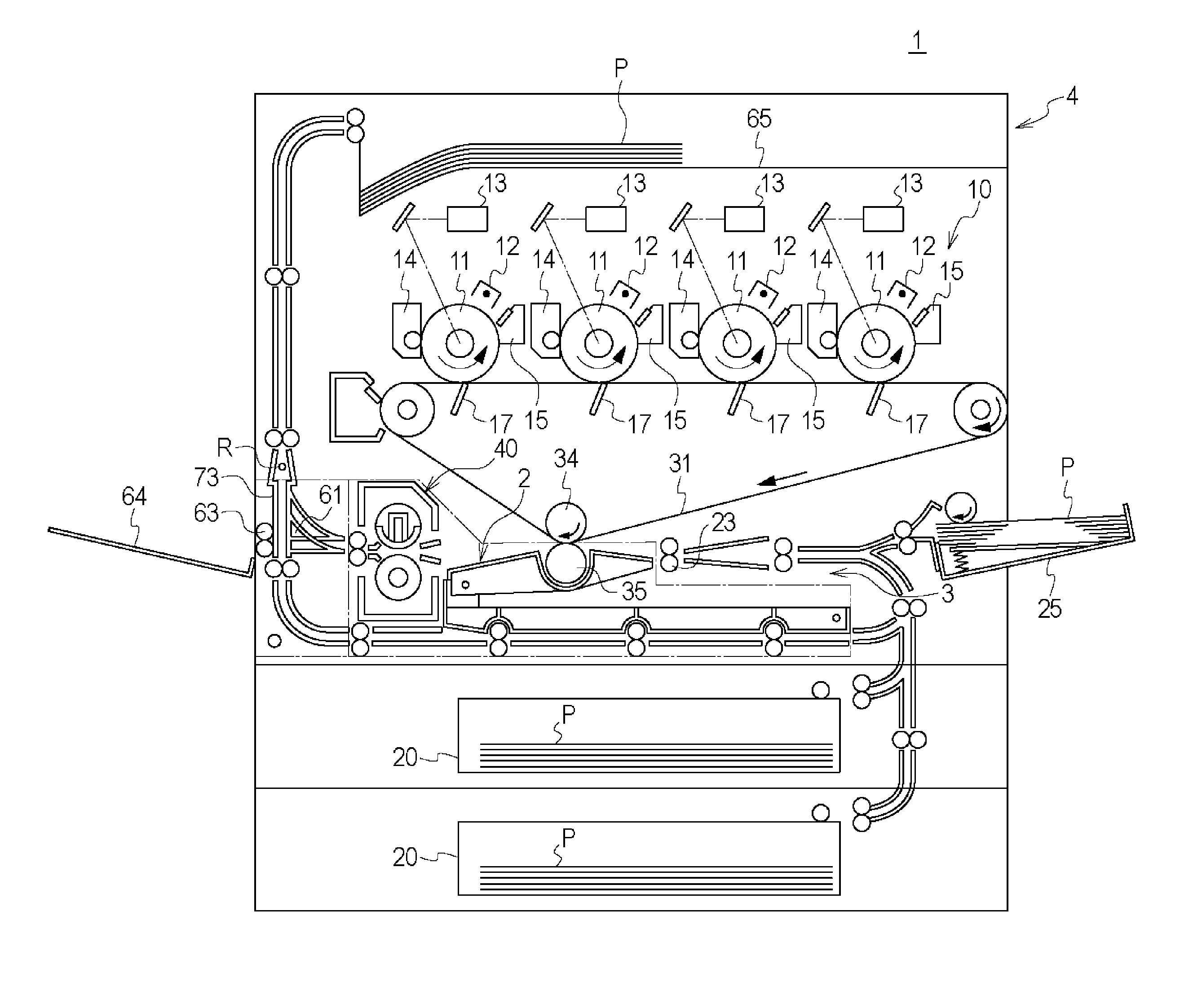

Image forming apparatus and electric-power control method

ActiveUS20070193998A1Increase the burdenOhmic-resistance heating detailsHigh frequency current welding apparatusImage formationEngineering

An electric power supply is controlled below a maximum suppliable current value by detecting the applied current of a heater. The image forming apparatus includes a heater which includes heating elements that generate heat when electric power is supplied, a current detector for detecting a current value supplied to the heater, a temperature detector for detecting the temperature of the fixing device, and an electric power controller for supplying electric power to the heater with a current application duty based on the temperature detected by the temperature detector within a range below a maximum current application duty. The maximum current application duty can be reset based on a current application duty to the heater and based on a current value detected by the current detector.

Owner:CANON KK

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS20140169846A1Inhomogeneous suppressionSolve even heatingOhmic-resistance heating circuitsHeater elementsElectricityImage formation

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

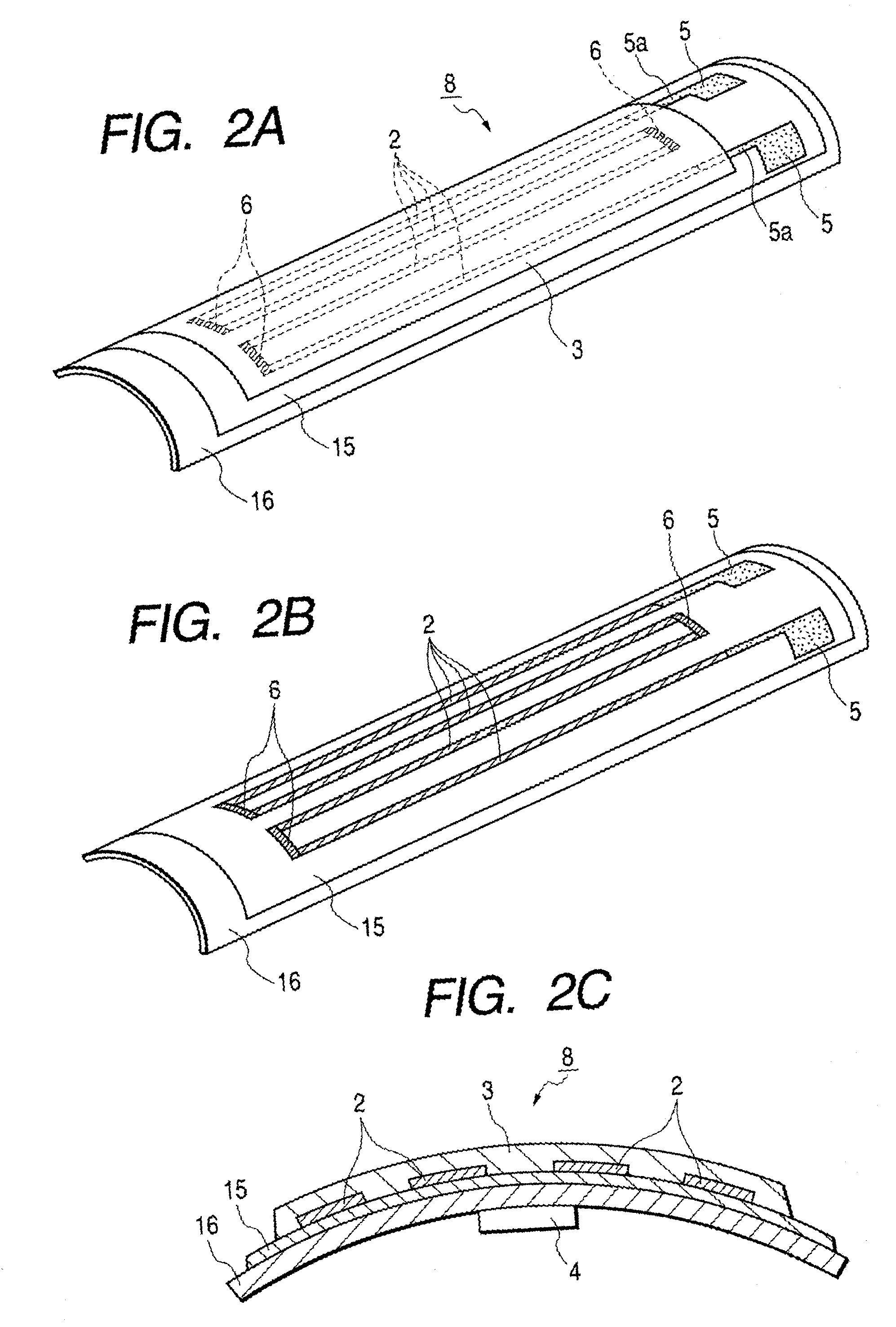

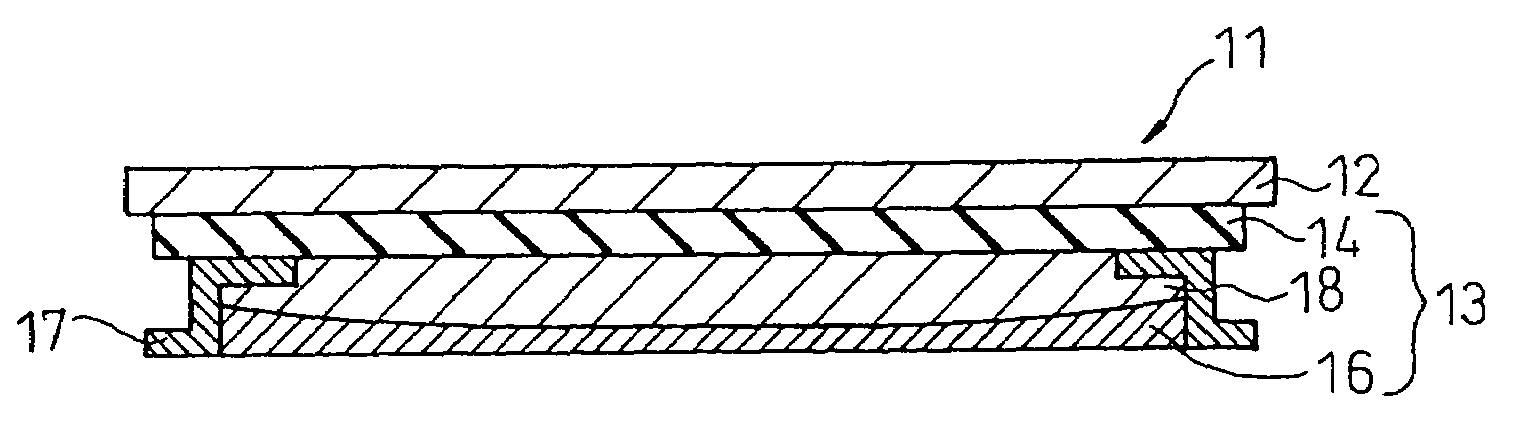

Heat plate, heating element, belt type fixing device and image forming apparatus

InactiveUS6987245B2Heating fastFast timeElectrographic process apparatusHeating element materialsConvex sideElectron

A heat plate for fixation comprising: a metallic base plate; and a heating resistor arranged on a reverse face of the metallic base plate, the heating resistor being formed by laminating, at least, an electric insulating layer and heating resistor layer in this order on the metallic base plate, wherein the heat plate is capable of raising the temperature of the metallic base plate to a fixing temperature when the heating resistor layer is energized and heated. A semicircular heating member for fixation comprises the heat plate which is curved so that the metallic base plate has a convex surface, a belt type fixing device is provided with the semicircular heating member, and an electrophotographic image forming apparatus is provided with the belt type fixing device comprising the semicircular heating member.

Owner:TAKAO KAWAMURA +1

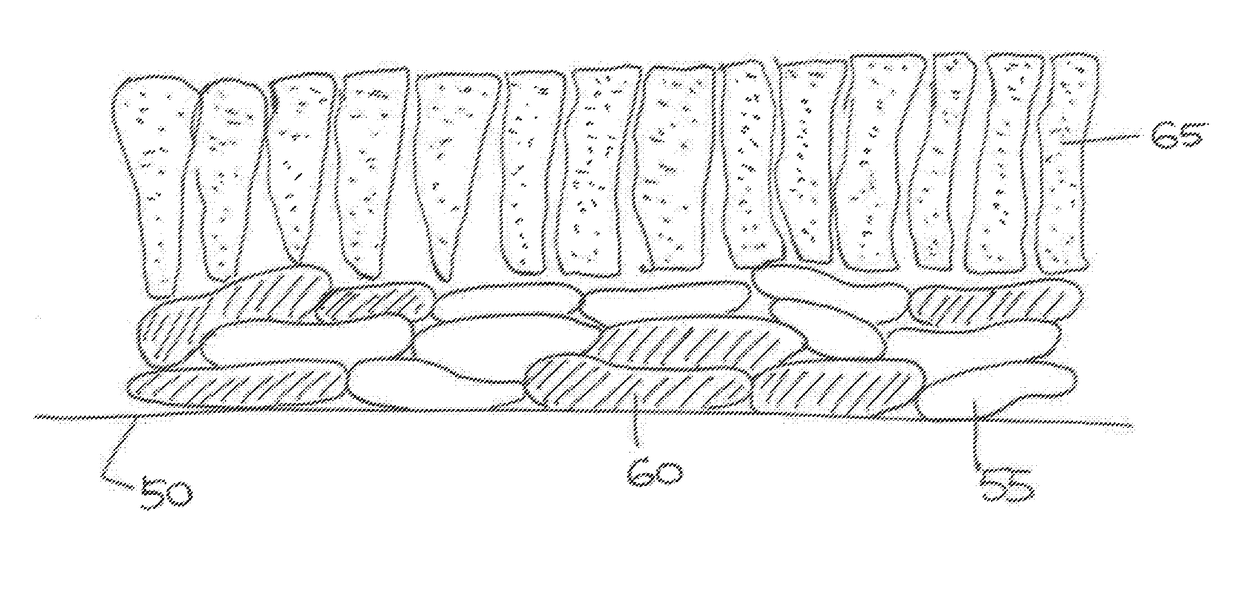

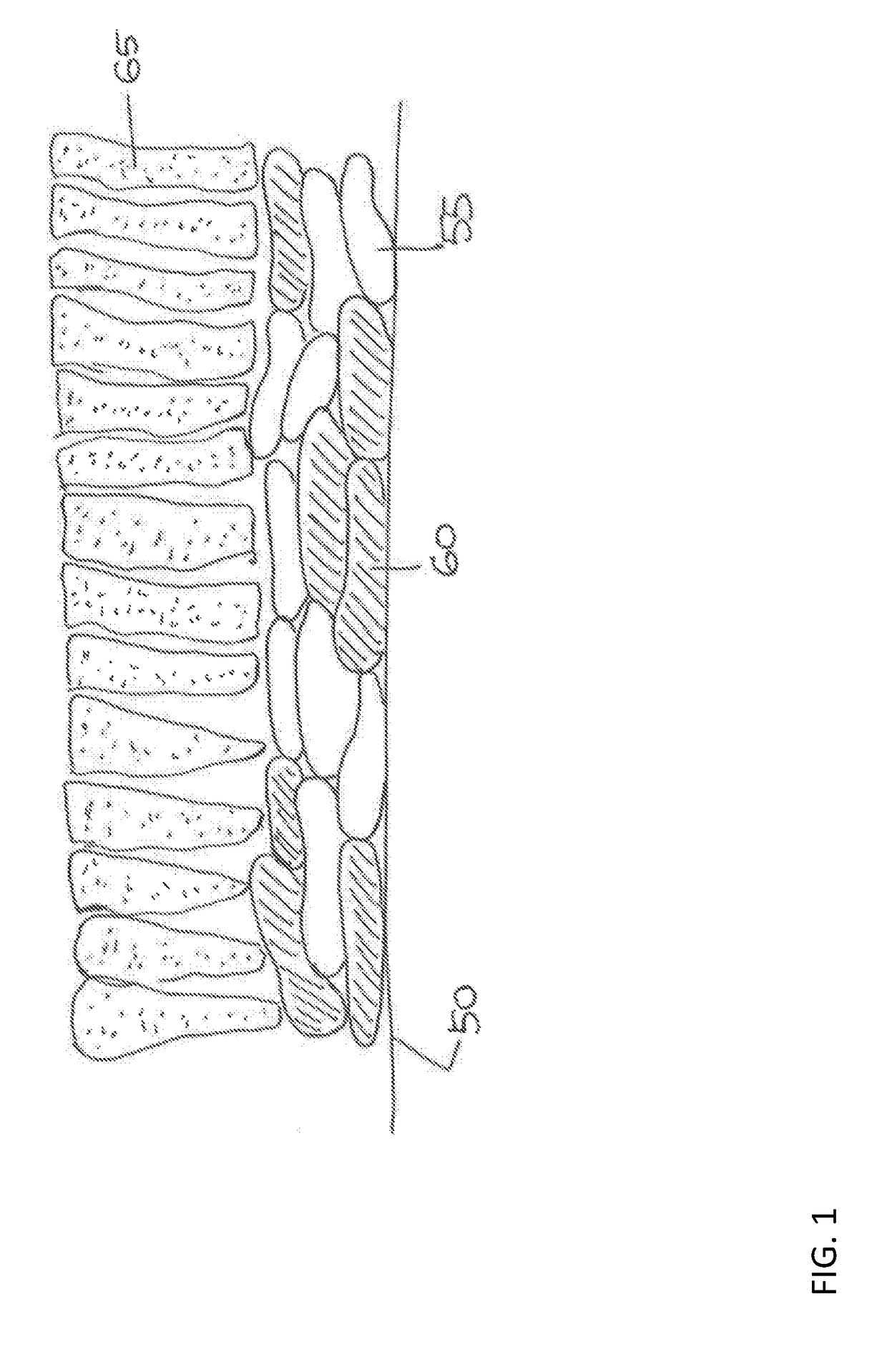

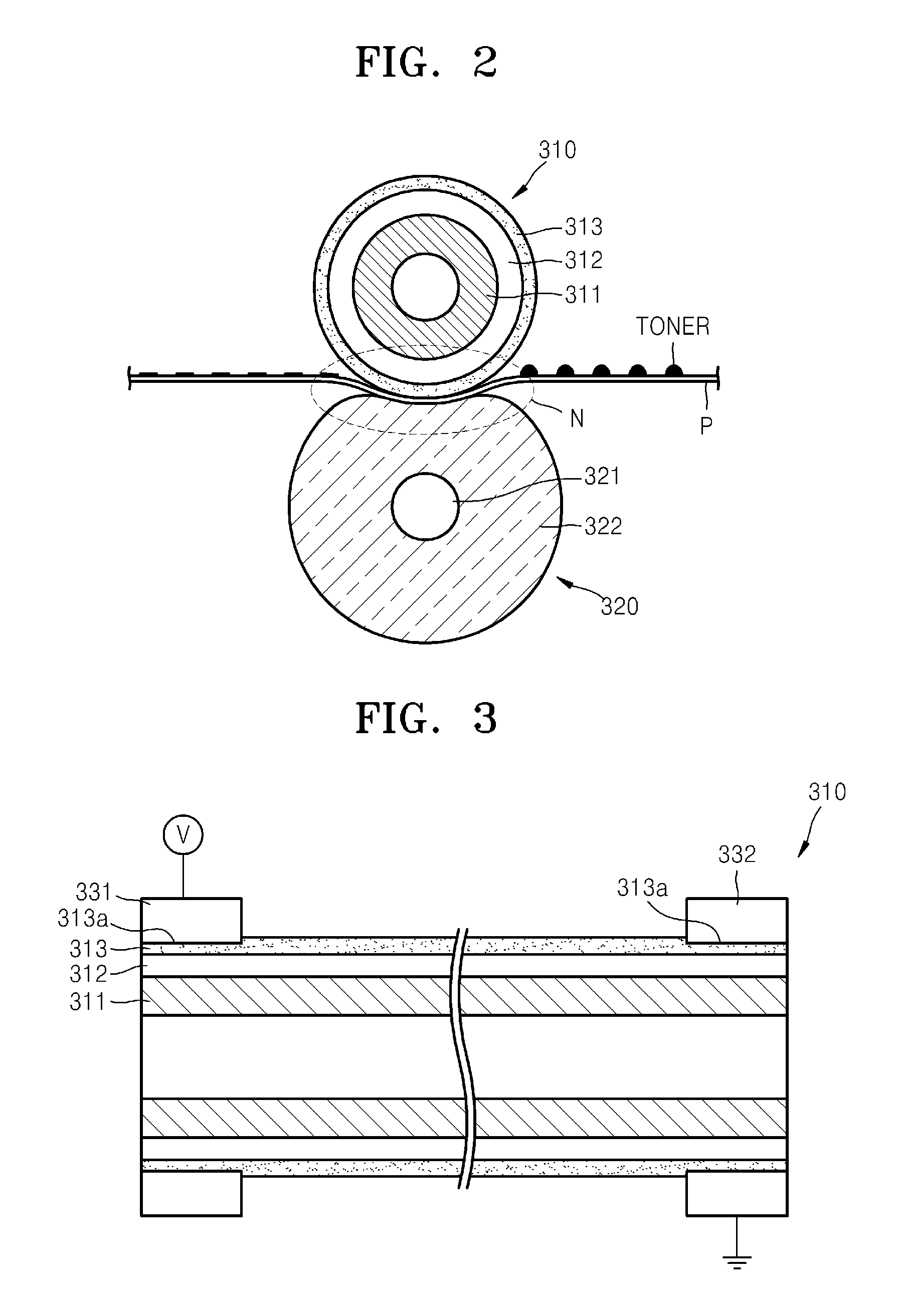

Heating member including resistive heating layer, and fusing apparatus and image forming apparatus including the heating member

ActiveUS20110116850A1Reduce contact resistanceOhmic-resistance heating detailsElectrographic process apparatusContact elementImaging equipment

A heating member includes a resistive heating layer disposed on an outermost layer of the heating member, where the resistive heating layer comprises a conductive filler distributed in a base material and where the resistive heating layer emits heat when supplied with an electric current from an electrode, and a contacting unit which exposes the conductive filler of the resistive heating layer and contacts the electrode..

Owner:HEWLETT PACKARD DEV CO LP

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS8653422B2Inhomogeneous suppressionSolve even heatingOhmic-resistance heating circuitsOhmic-resistance electrodesElectricityHotline

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

Heater having heat generating resistor on substrate and image heating apparatus mounting heater thereon

ActiveUS20070182798A1Stress resistantLow costElectrographic process apparatusPrintingHeat generationResistor

The heating apparatus comprises a substrate extending in one direction and a plurality of heat generating members provided on one surface of the substrate along a longitudinal direction thereof and wherein at least one of the plural heat generating members has heat generating regions having different heat generation amount per unit length in the longitudinal direction, substrate reinforcing members are provided on the other surface of the substrate in correspondence to the high heat generating regions provided on one surface of the substrate. By the virtue of the invention, cost can be reduced, emergency safety upon occurrence of overrun of a CPU can be achieved, and increase in temperature of a sheet non-passing portion can be suppressed.

Owner:CANON KK

Heater and image heating apparatus mounted with the same

ActiveUS20170075266A1Electrographic process apparatusRoller heating devicesEngineeringElectrical and Electronics engineering

Owner:CANON KK

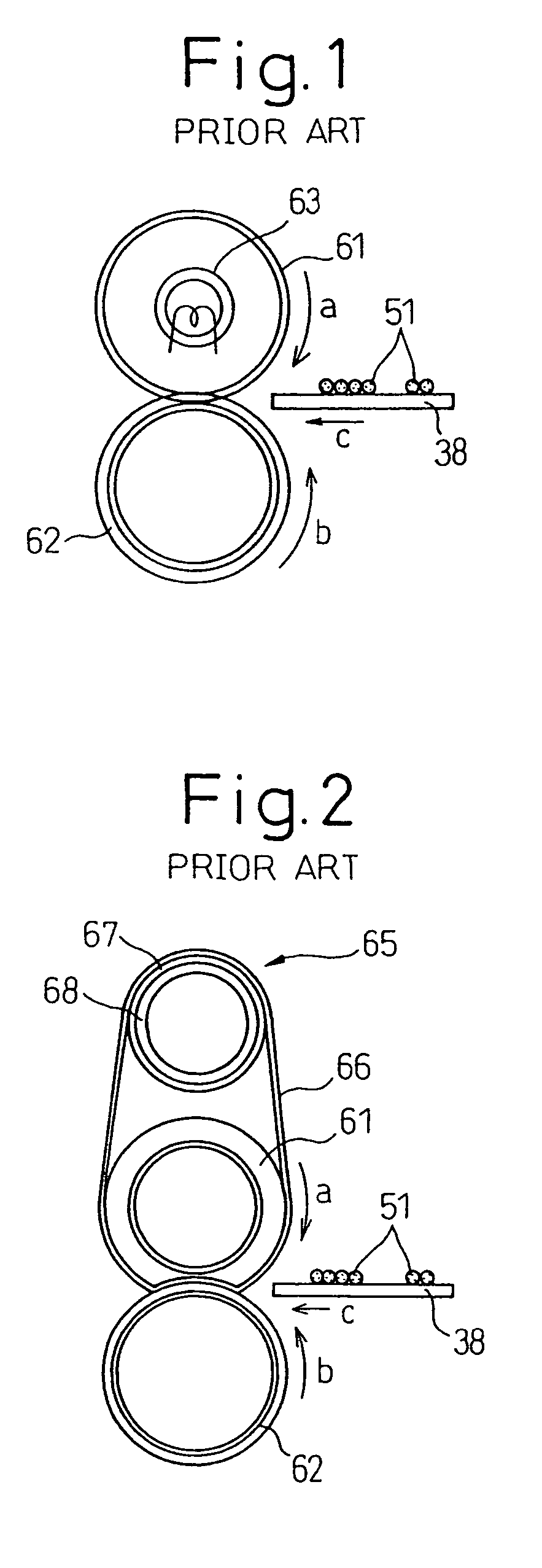

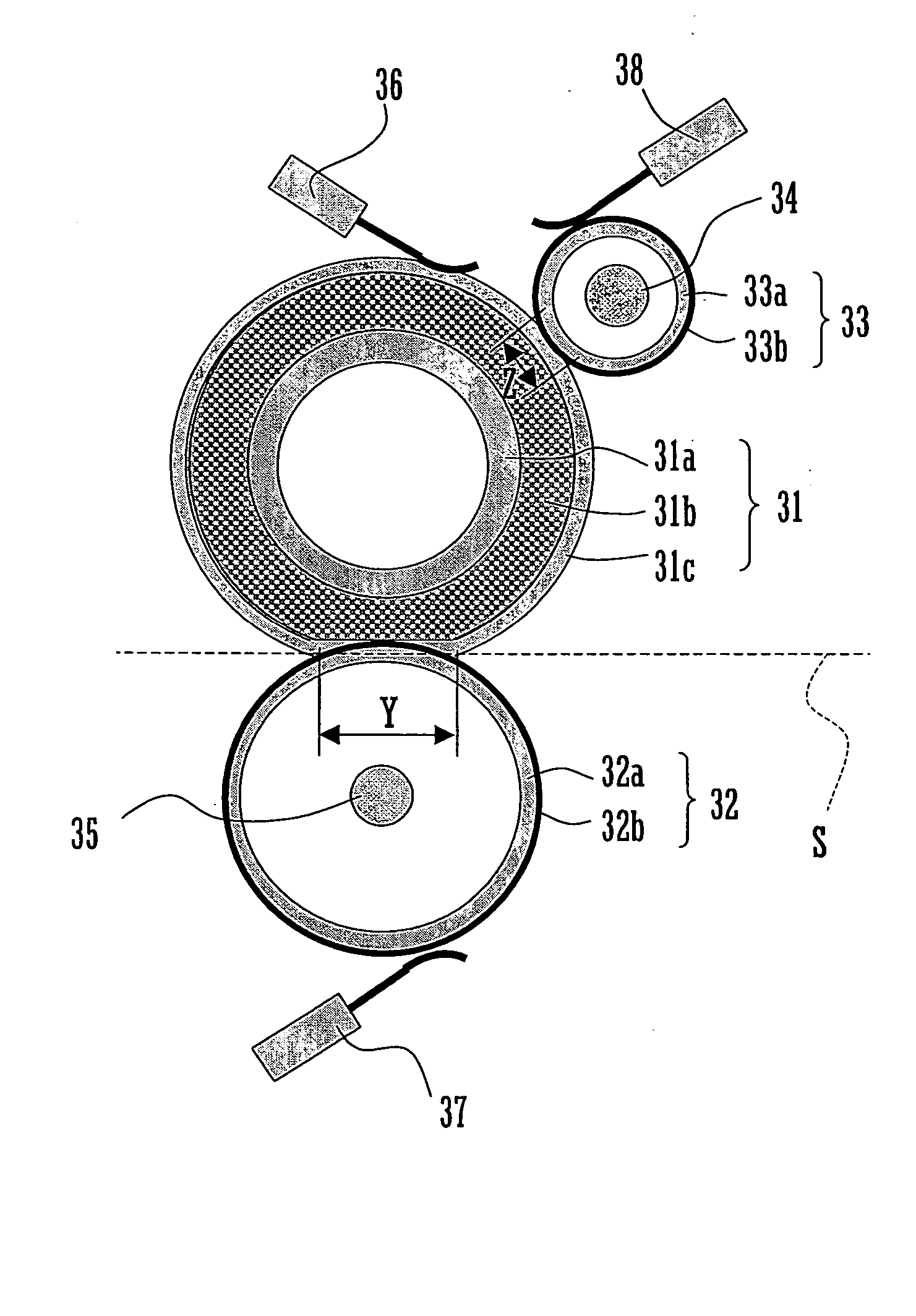

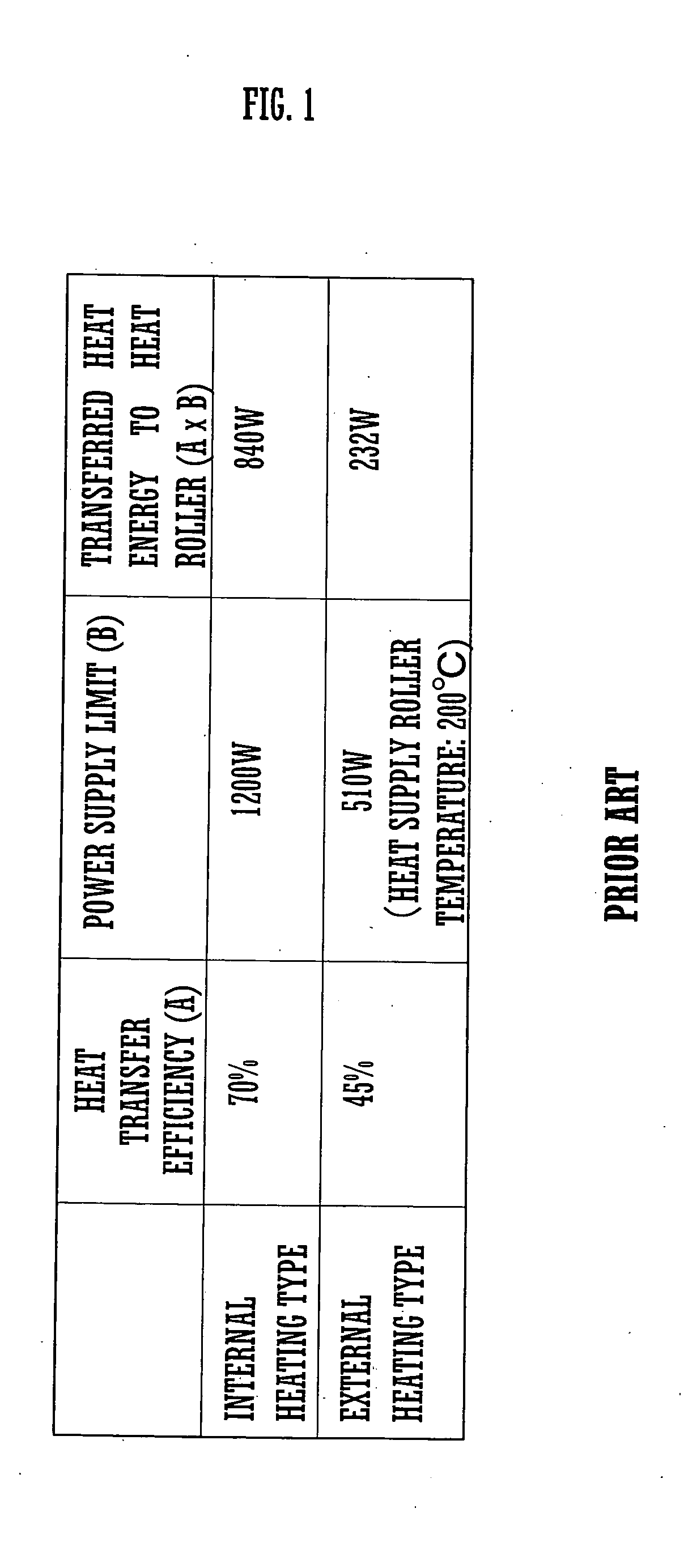

Heating device and heating method

InactiveUS20050061792A1Short warm-up timeReduce standby power consumptionWave amplification devicesOhmic-resistance heating detailsEngineeringPaper sheet

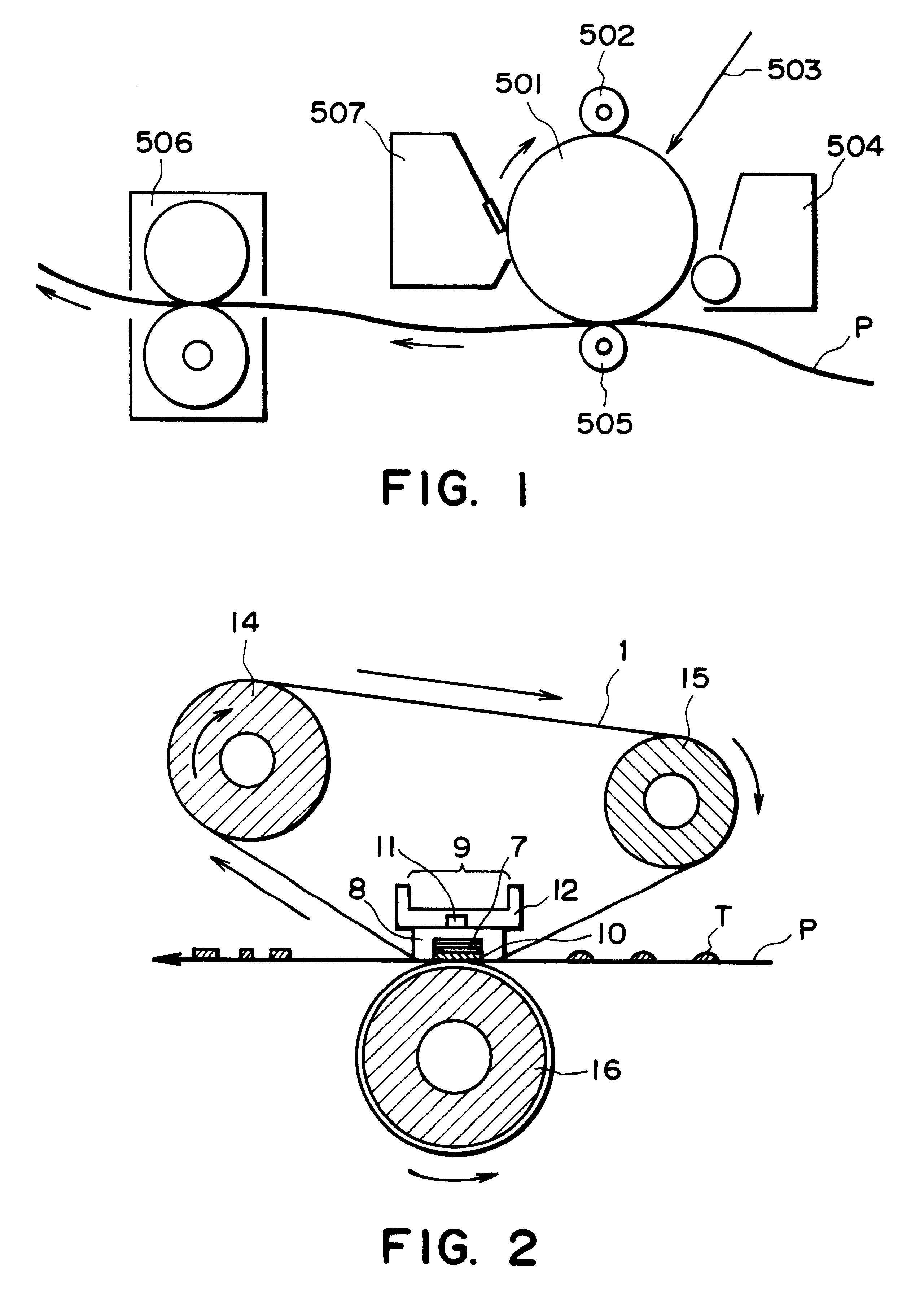

An upper heat roller with an external heat source and a lower heat roller with an internal heat source are arranged with a paper transport path therebetween, in such a manner as to be pressed against each other. The lower heat roller is heated sufficiently, thereby supplying a paper sheet with sufficient heat when the paper sheet is transported through a contact region between the upper and lower heat rollers to be heated.

Owner:SHARP KK

Heater and image heating apparatus including same

ActiveUS8698046B2Heat suppressionOhmic-resistance electrodesHeater elementsElectrical resistance and conductanceMaximum size

The image heating apparatus includes a heater that achieves even heat-generation distribution and suppression of a non-sheet feeding portion temperature increase when an image is printed on a sheet whose size is smaller than a maximum size for the apparatus, and an endless belt, wherein plural heat-generation resistive members having positive temperature coefficients are connected in parallel are provided between first and second conductive members provided along a longitudinal direction of a substrate; plural heat-generation blocks including the plural heat-generation resistive members connected in parallel, are arranged in series along the longitudinal direction; and in the plural heat-generation resistive members included in one of the heat-generation blocks, a heat-generation resistive member arranged at an end portion in the longitudinal direction has a resistivity value higher than that of a heat generation resistive member arranged at a center in the longitudinal direction, or an interval between heat generation resistive members is larger in the end portion.

Owner:CANON KK

Heating resistor element, manufacturing method for the same, thermal head, and printer

InactiveUS20090102911A1Easy to useReduce power consumptionElectrographic process apparatusPrintingEngineeringThermal expansion

Provided is a heating resistor element including: an insulating substrate including a glass material; a heat accumulating layer bonded to the insulating substrate through heating to temperature ranging from an annealing point to a softening point in a state of being adhered to a surface of the insulating substrate, and including the same material as the glass material of the insulating substrate; and a heating resistor provided on the heat accumulating layer, in which, on at least one of bonded surfaces between the insulating substrate and the heat accumulating layer, at least one of the insulating substrate and the heat accumulating layer is provided with a concave portion in a region opposed to the heating resistor to form a hollow portion. Accordingly, deformation caused by a difference in coefficient of thermal expansion is suppressed to improve printing quality.

Owner:SEIKO INSTR INC

Heater and image heating apparatus including the same

ActiveUS20150341985A1Increase widthOhmic-resistance electrodesHeater elementsEngineeringElectrical and Electronics engineering

A heater usable with an image heating apparatus including first and second terminals includes electrodes including first and second electrodes connectable the first and second terminals, respectively, the first electrodes and the second electrodes extend longitudinally; heat generating portions between adjacent electrodes; a first electric line connected with the first electrodes, the first line being extending with a gap between the heat generating portions, a second electric line connected with the second electrode connected with the heat generating portions in a first heat generating region, a third electric line connected with the second electrode connected with the heat generating portions in a second heat generating region, the second electric line being extended adjacent to the second electric line, wherein a gap between the second and third electric lines in the widthwise direction is smaller than the gap between the first and second electrodes in the widthwise direction.

Owner:CANON KK

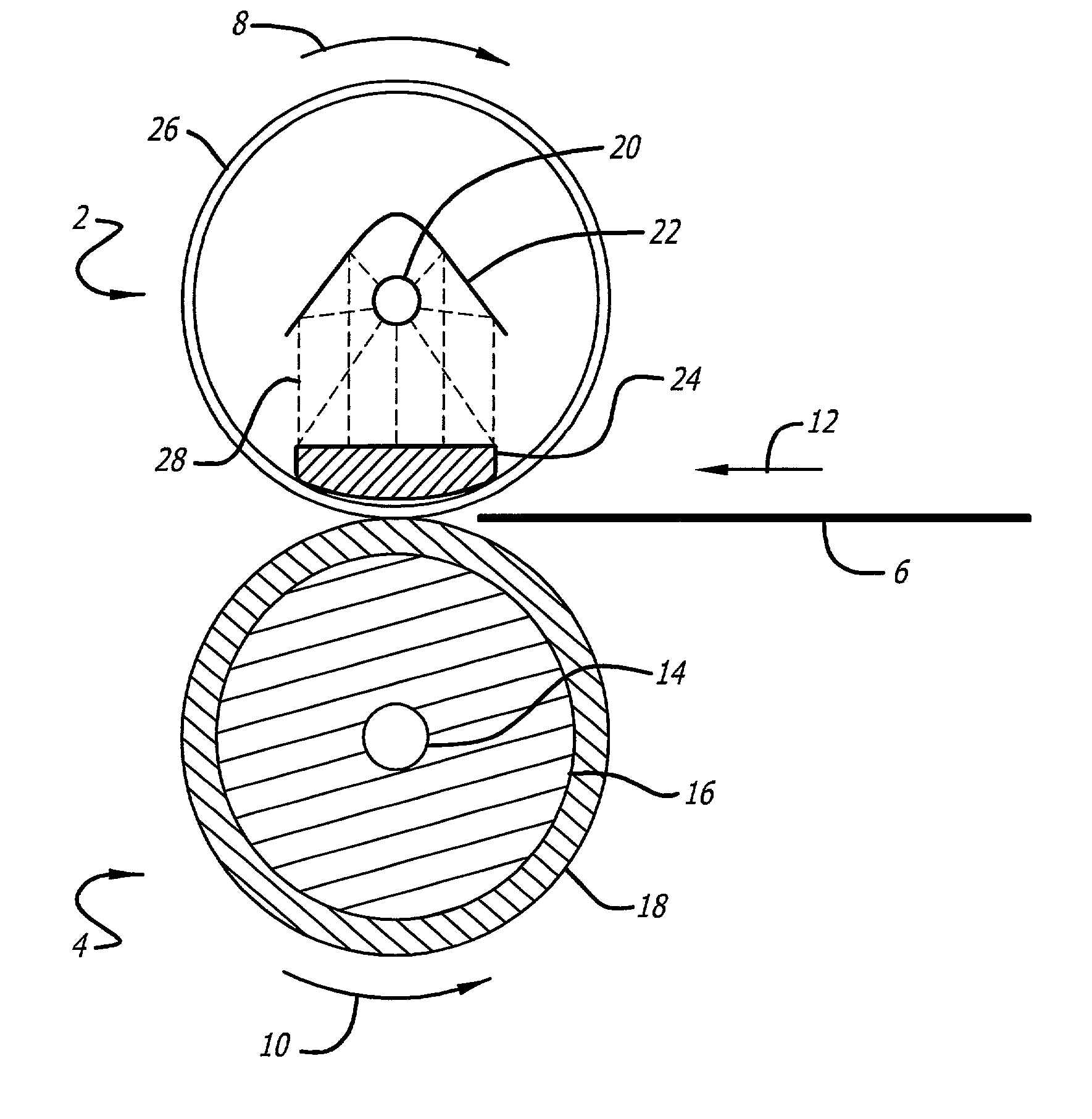

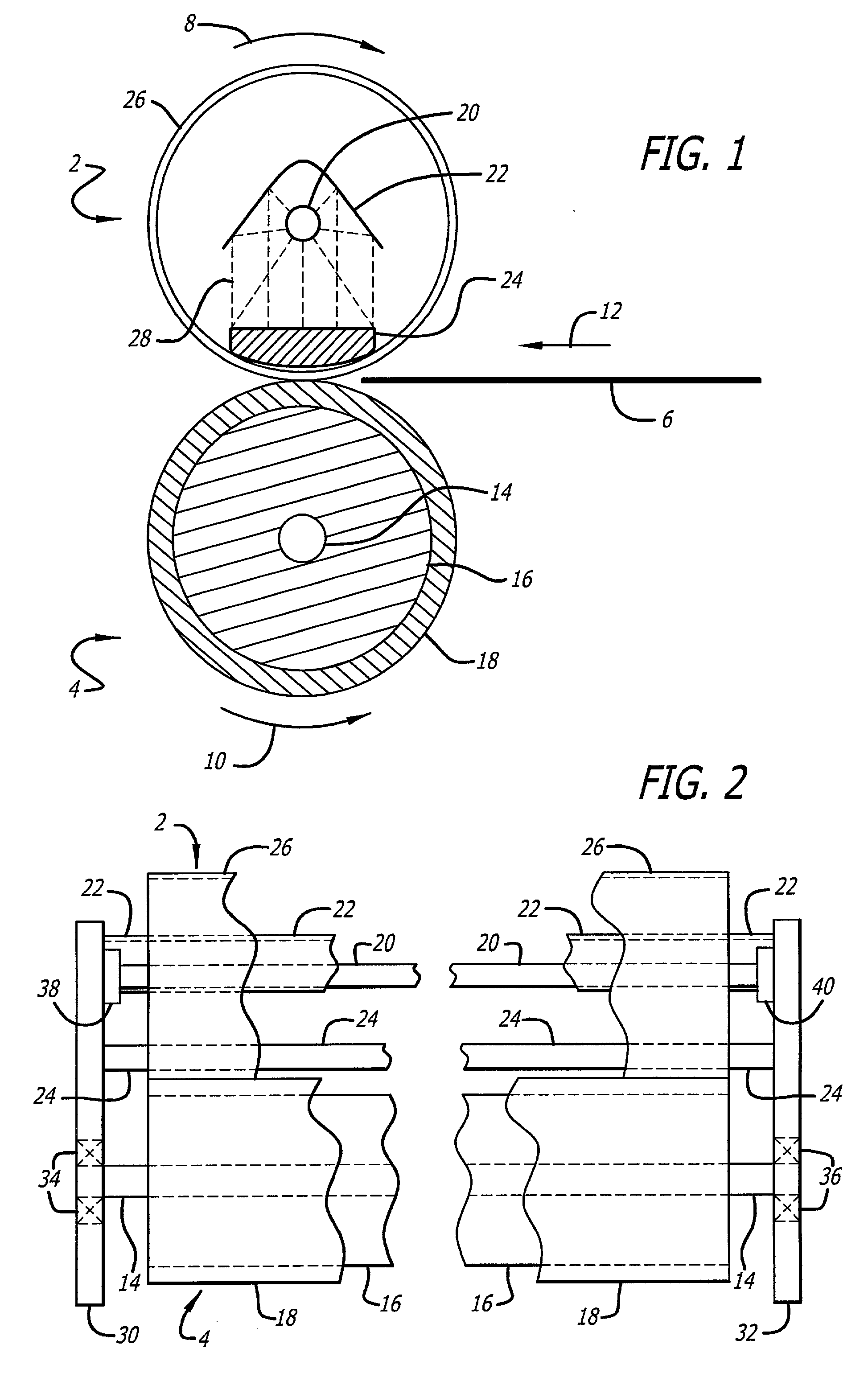

System and method for utilizing a user non-perceivable light source in a machine

InactiveUS20030160039A1Electrographic process apparatusRoller heating devicesLaser imagingEngineering

A apparatus and method for fusing toner to media in a laser imaging device. A paraboloidal trough reflector is positioned about a linear heating element to focus and concentrate radiant energy emitted from the heating element onto a thermal spreader. The thermal spreader absorbs the radiant energy and converts it to heat. A thermoplastic fusing roller is rotatably supported about the bulb heater, the reflector and the thermal spreader. A pressure roller is supported to urge media against the fusing roller at the position of the thermal spreader. Fusing heat is conducted from the thermal spreader, through the fusing roller and to the media. The pressure roller is driven to rotate, thereby advancing the media through the fusing unit to fuse the toner thereto. Additionally, the present teachings disclose a printing device having a fusing unit with a bulb heater that emits user non-perceivable light. A mechanism is included for conveying light from the bulb heater to a location within the printing device. Also, a component positioned to receive the light and to utilize the light for illumination thereof in a user perceivable manner.

Owner:HEWLETT PACKARD DEV CO LP

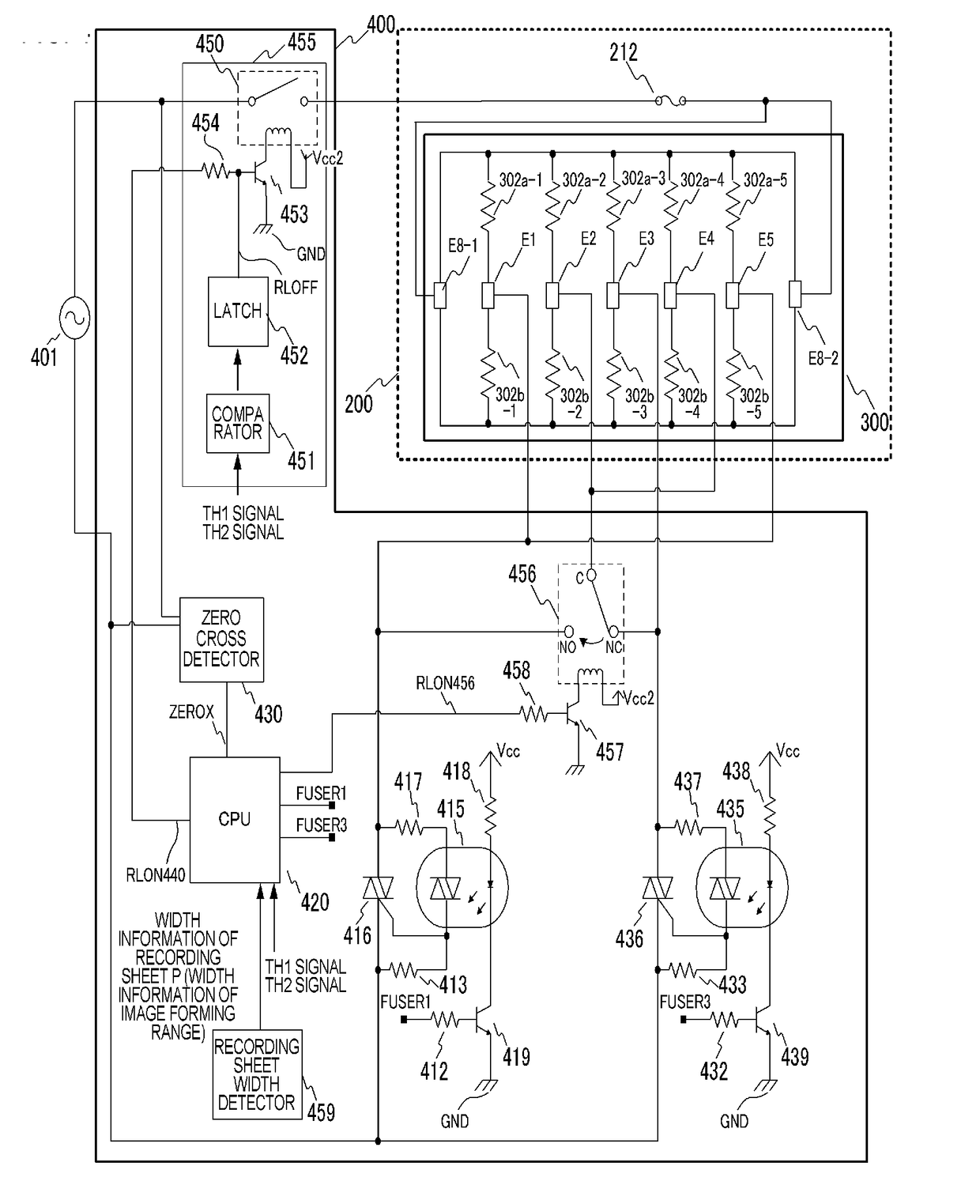

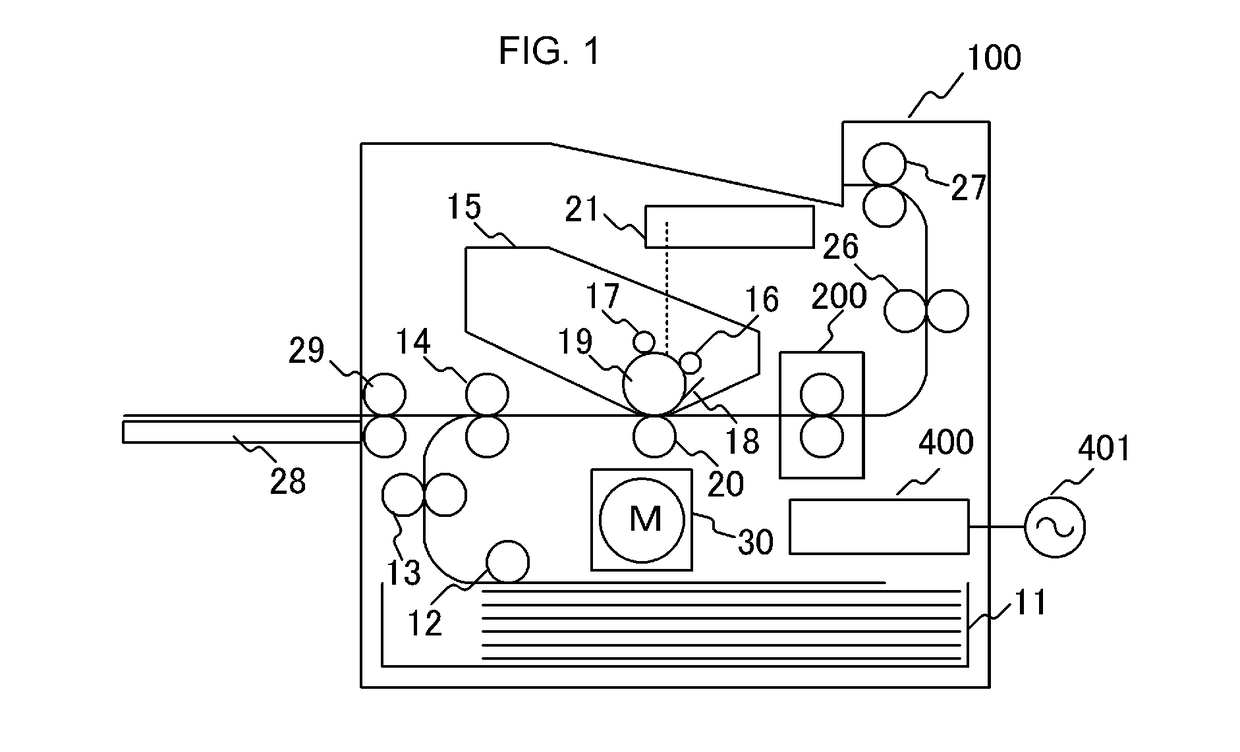

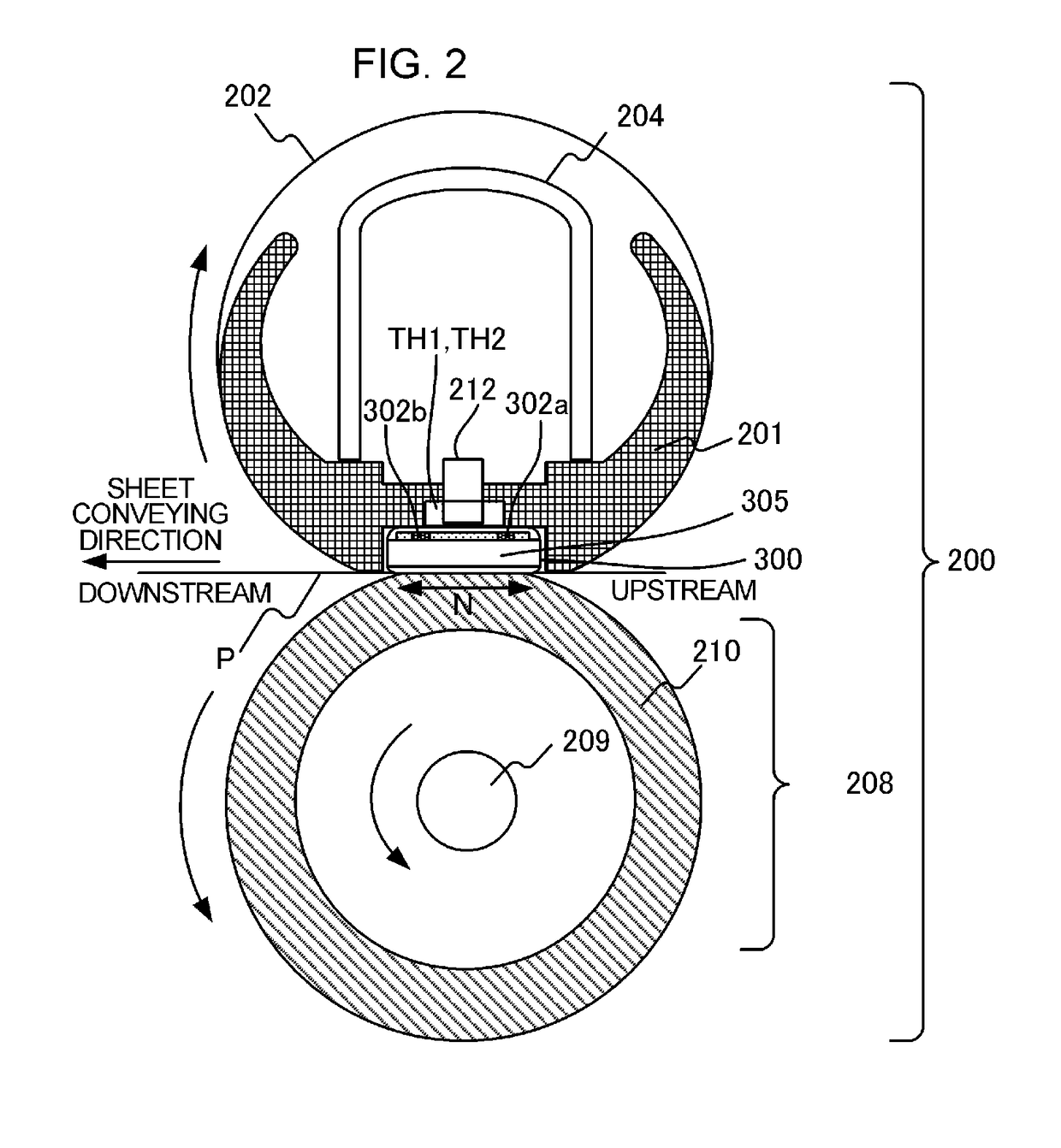

Image heating apparatus and image forming apparatus

ActiveUS20180032009A1Ensure safetySecuring safety of an apparatusElectrographic process apparatusRoller heating devicesDriving circuitElectrical and Electronics engineering

An apparatus includes a first and second driving circuits that energize a first and third heat generating blocks; a first and second temperature detection members that detect each temperature of the first and third heat generating blocks; a control portion that controls the first and second driving circuits according to at least one of the temperatures detected by the first and second temperature detection members; and a connection switching portion that selectively connects any one of the first and second driving circuits to a second heat generating block according to a switching instruction from the control portion. The control portion controls energization of the second heat generating block together with a heat generating block which is energized by the driving circuit connected to the second heat generating block.

Owner:CANON KK

Fixing device and image forming apparatus including a heating roller with multiple heaters

InactiveUS7406286B2Inhibit deteriorationPrevent image unevennessOhmic-resistance heating detailsRollsImage formationPeak value

In a fixing device for causing a pressurizing roller to come in pressure contact with a heating roller including a central region heating heater for heating a central region and a side end region heating heater for heating a side end region on an outside of the central region, thereby fixing an unfixed toner, or an image forming apparatus comprising the fixing device, an outside of an image region of the heating roller is caused to have a peak of heat distribution of the central region heating heater and heat radiated from both side ends of the heating roller is compensated to flatten the temperature distribution of the image region, thereby preventing a deterioration in an image.

Owner:SEIKO EPSON CORP

Image heating apparatus

ActiveUS7002105B2Suppress failure in heatingSuppression temperatureElectrographic process apparatusRoller heating devicesElectrical and Electronics engineeringEngineering

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com