A kind of long-material large bottle glass and preparation method thereof

A technology for glass products and bottles, which is applied in the field of large bottle glass and its preparation, can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, low cost, and avoiding physical stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The raw materials used are composed of 74.30 parts of quartz sand, 3.09 parts of aluminum hydroxide, 26.72 parts of sodium carbonate, 2.48 parts of magnesium oxide and 11.87 parts of calcium carbonate.

[0037] The specific steps of the manufacturing method are as follows:

[0038] (1) According to the above chemical composition, accurately weigh the weight of the corresponding raw materials of each composition and mix them uniformly to make a batch, melt and homogenize the batch in a kiln at 1803K;

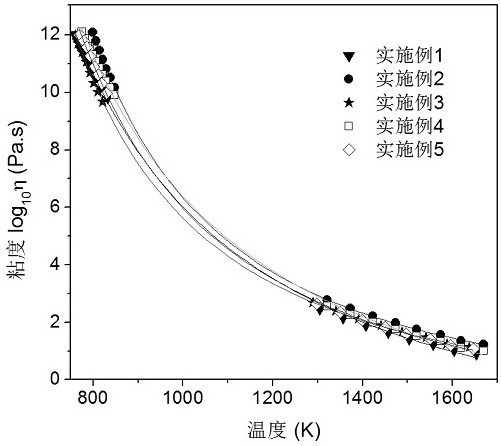

[0039] (2) The temperature of the molten glass obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1396K, and the viscosity is 10 2 Pa s;

[0040] (3) Use the picking rod of the glass picking robot to pick out enough glass liquid at one time, drop it into the 1# cast iron mold, and use compressed air for initial blowing;

[0041] (4) After the initial blowing in step (3), the mouth of the bottle has been hardened, and the...

Embodiment 2

[0045] The raw materials used are composed of 75.05 parts of quartz sand, 4.64 parts of aluminum hydroxide, 21.42 parts of sodium carbonate, 2.51 parts of magnesium oxide, 1.49 parts of potassium carbonate and 12.41 parts of calcium carbonate.

[0046] The specific steps of the manufacturing method are as follows:

[0047] (1) According to the above chemical composition, the weight of the corresponding raw materials of each composition is accurately weighed and mixed evenly to make a batch, and the batch is melted and homogenized in a kiln at 1823K;

[0048] (2) The temperature of the molten glass obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1451K, and the viscosity is 10 2 Pa s;

[0049] (3) Use the picking rod of the glass picking robot to pick out enough glass liquid at one time, drop it into the 1# cast iron mold, and use compressed air for initial blowing;

[0050] (4) After the initial blowing in step (3), the mo...

Embodiment 3

[0054] The raw materials used are composed of 73.74 parts of quartz sand, 3.55 parts of aluminum hydroxide, 24.36 parts of sodium carbonate, 2.01 parts of magnesium oxide, 2.24 parts of potassium carbonate and 12.96 parts of calcium carbonate.

[0055] The specific steps of the manufacturing method are as follows:

[0056] (1) According to the above chemical composition, accurately weigh the weight of the corresponding raw materials of each composition and mix them uniformly to make a batch, melt and homogenize the batch in a kiln at 1813K;

[0057] (2) The temperature of the molten glass obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1398K, and the viscosity is 10 2 Pa s;

[0058] (3) Use the picking rod of the glass picking robot to pick out enough glass liquid at one time, drop it into the 1# cast iron mold, and use compressed air for initial blowing;

[0059] (4) After the initial blowing in step (3), the mouth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com