A kind of large bottle glass suitable for artificial molding and preparation method thereof

A bottle and artificial technology, applied in the field of large bottle glass and its preparation, to achieve the effect of low cost and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw materials used are composed of 76.77 parts of quartz sand, 3.09 parts of aluminum hydroxide, 26.72 parts of sodium carbonate, 2.48 parts of magnesium oxide and 7.41 parts of calcium carbonate.

[0035] The specific steps of the manufacturing method are as follows:

[0036] (1) Accurately weigh and mix the raw materials according to the above, and melt and homogenize the batch materials in the kiln at 1823K;

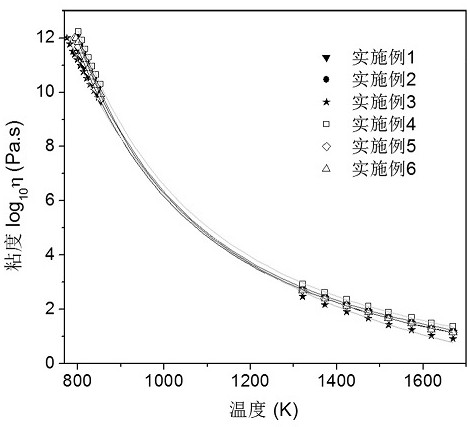

[0037] (2) The glass melt obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1448K, and the viscosity is 10 2 Pa s;

[0038] (3) Pick out an appropriate amount of glass liquid through the blowing rod, and blow it into small bubbles with a wall thickness of about 5mm;

[0039] (4) Repeat step (3) several times, and when enough glass liquid (such as 5.5 kg) is dipped in the blowing rod, blow it up to the finished product specification in the mold at one time;

[0040] (5) Put the glass product obtained in ...

Embodiment 2

[0042] The raw materials used are composed of 78.79 parts of quartz sand, 4.64 parts of aluminum hydroxide, 24.18 parts of sodium carbonate, 2.51 parts of magnesium oxide, 2.24 parts of potassium carbonate and 1.83 parts of calcium carbonate.

[0043] The specific steps of the manufacturing method are as follows:

[0044] (1) Accurately weigh and mix the raw materials according to the above, and melt and homogenize the batch materials in the kiln at 1833K;

[0045] (2) The temperature of the glass melt obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1468K, and the viscosity is 10 2 Pa s;

[0046] (3) Pick out an appropriate amount of glass liquid through the blowing rod, and blow it into small bubbles with a wall thickness of about 5mm;

[0047] (4) Repeat step (3) several times, and when enough glass liquid (such as 5.5 kg) is dipped in the blowing rod, blow it up to the finished product specification in the mold at one ...

Embodiment 3

[0050] The raw materials used are composed of 73.74 parts of quartz sand, 2.32 parts of aluminum hydroxide, 27.64 parts of sodium carbonate, 2.01 parts of magnesium oxide, 2.24 parts of potassium carbonate and 10.95 parts of calcium carbonate.

[0051] The specific steps of the manufacturing method are as follows:

[0052] (1) Accurately weigh and mix the above-mentioned raw materials evenly, melt and homogenize the batch materials in the kiln at 1813K;

[0053](2) The glass melt obtained from step (1) flows to the working part through the forehearth, and the temperature drops to 1416K, and the viscosity is 10 2 Pa s;

[0054] (3) Pick out an appropriate amount of glass liquid through the blowing rod, and blow it into small bubbles with a wall thickness of about 5mm;

[0055] (4) Repeat step (3) several times, and when enough glass liquid (such as 5.5 kg) is dipped in the blowing rod, blow it up to the finished product specification in the mold at one time;

[0056] (5) Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com