A kind of alkali-containing aluminosilicate glass and its product, strengthening method and application

A technology of silicate glass and glass products, applied in the field of flat glass manufacturing, can solve problems such as affecting the display effect of display products, damage to the surface of the screen, endangering the service life, etc. melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

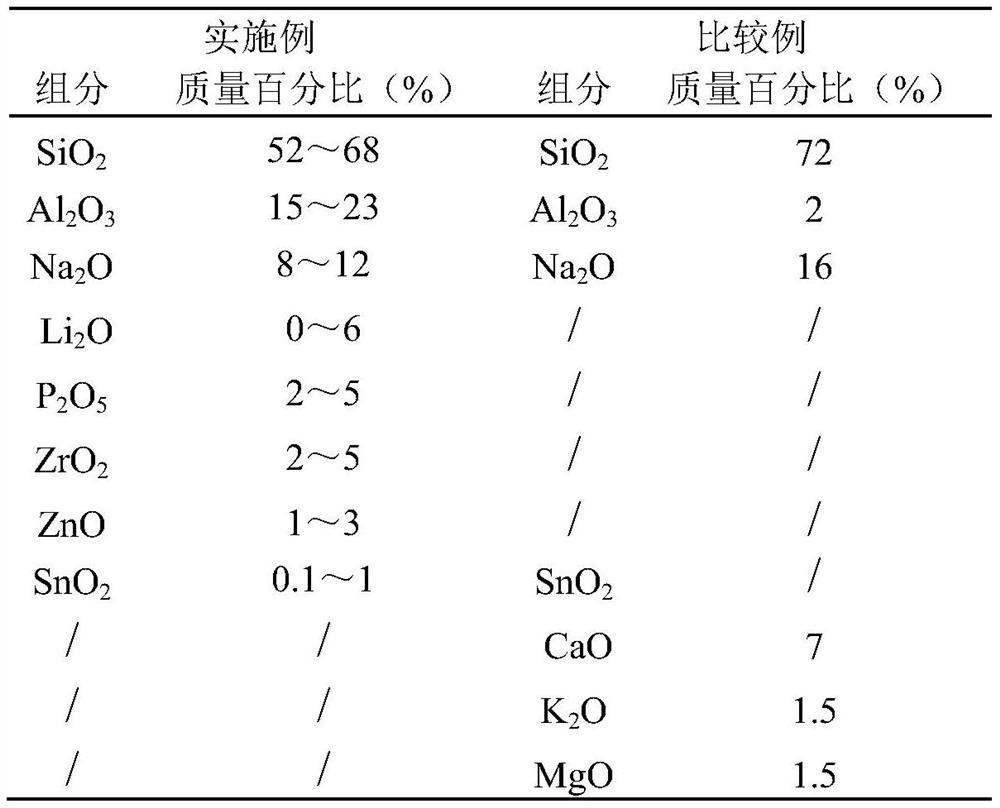

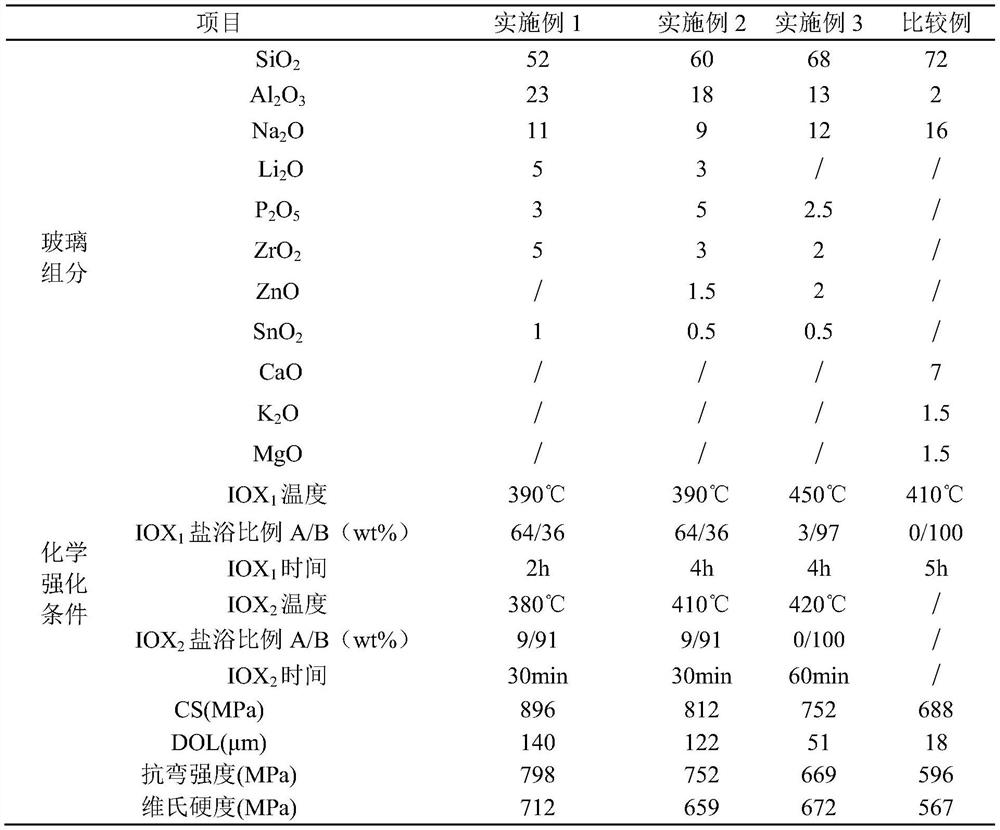

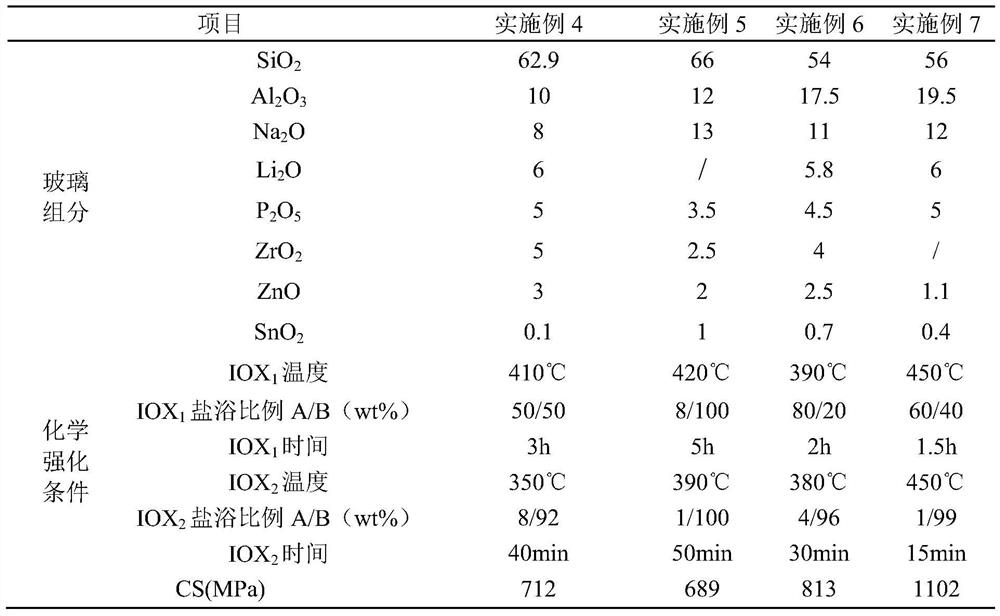

[0025] A chemically strengthenable alkali-containing aluminosilicate glass of the present invention, including flat glass and glass products, including SiO in mass percentage 2 52%~68%, Al 2 o 3 10%~23%,Na 2 O 8%~13%, Li 2 O 0~6%, P 2 o 5 2%~5%, ZrO 2 0~5%, ZnO 0~3%; addition of SnO can also be included 2 , by mass percent SnO 2 0.1% to 1%.

[0026] The function and specific content of each component in the above-mentioned alkali-containing aluminosilicate glass are discussed below, and the unit of content is mass percent.

[0027] SiO 2 : 52% to 68%.

[0028] SiO 2 It is a necessary component to constitute the glass skeleton. The higher the content, the better the chemical durability of the glass and the higher the mechanical strength of the glass. In addition, since SiO 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com