Tea Tower Light Wave Fixing Device

A de-enzyming device and light wave technology, which is applied in tea processing before extraction, etc., can solve problems such as low energy saving, high power consumption, and difficult control of de-enzyming temperature, so as to reduce the space occupied by equipment, reduce the area occupied by equipment, and avoid surface hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

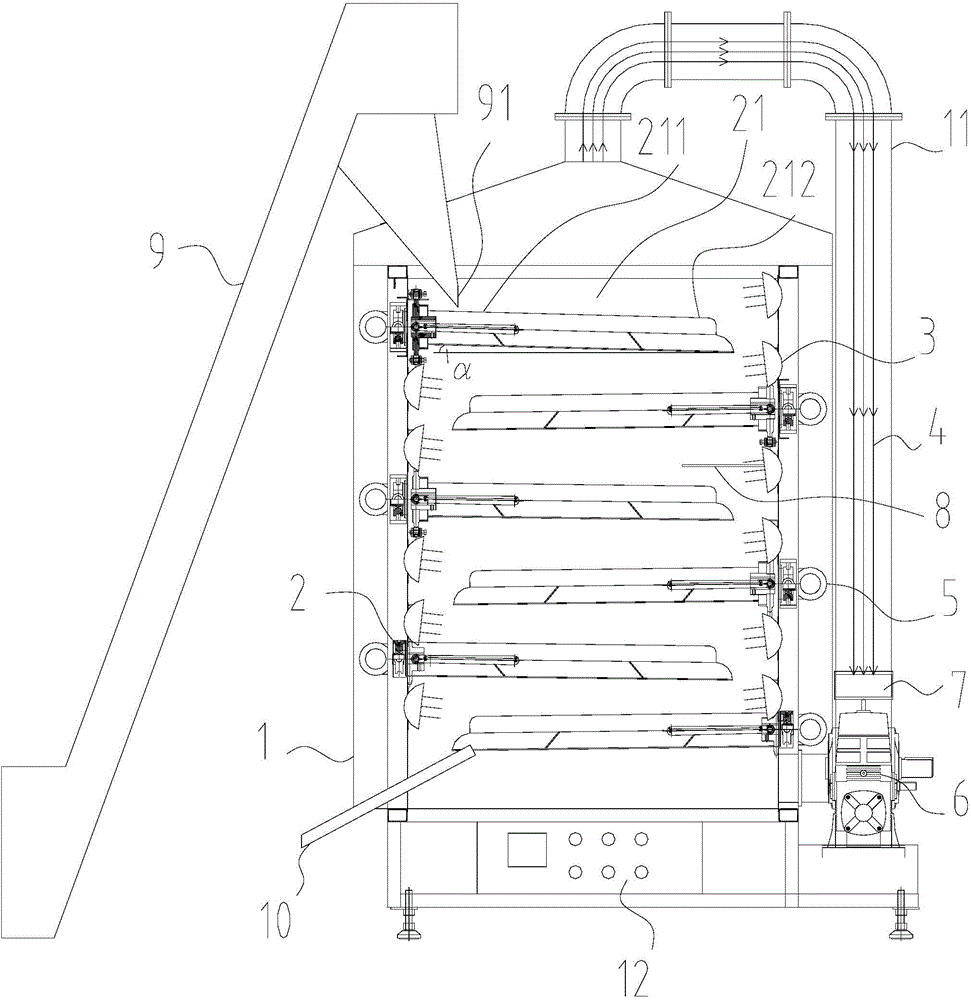

[0020] Such as figure 1 The tea tower-type light wave cleaning device shown includes a tower body 1, a hoist 9, and at least one vibrating conveying device 2 fixedly arranged on the inner wall of the tower body 1. The vibrating conveying plate 21 of the vibrating conveying device 2 exists relative to the horizontal plane. An inclination angle α, and the position of the fixed end 211 of the vibrating conveying plate 21 is higher than the suspended end 212 of the vibrating conveying plate 21 , and the discharge port 91 of the elevator 9 is set above the tower body 1 . During actual transportation, the tea leaves to be processed are lifted to the outlet 91 by the hoist 9, and then the tea leaves enter the vibrating conveying plate 21 in the tower body 1 through the top of the tower body 1. Since the vibrating conveying device 2 has provided Vibration source of vibration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com