Drying method of flower materials in peony flower tea preparation technology

A preparation process and peony tea technology are applied in the field of drying flower materials in the preparation process of peony tea, can solve the problems of low fiber content and affect the quality of peony petal tea, improve product quality, shorten drying time, and realize comprehensive utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

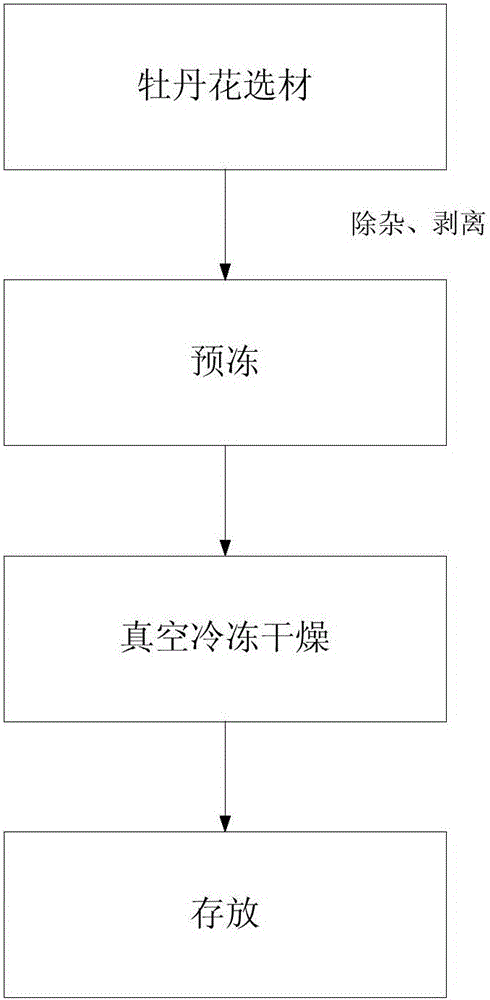

Method used

Image

Examples

Embodiment 1

[0038] Quickly peel off the outermost petals of the peonies "Yinhongqiaopair" (rose type, pink) collected in April at the early blooming stage of the peony to remove the mud. Carefully peel off the petals with tweezers, keeping the petals intact. Put the processed peony petals in the best shape into -80°C refrigerator for 12 hours, without squeezing or stacking. Put the pre-cooled peony flowers into the vacuum freeze dryer quickly, set the cold step temperature of -70°C, the vacuum degree of the drying chamber of 0.1MPa, the temperature of the heating plate of 15°C, the material thickness of 10mm, and dry for 36h (petals) . The dried petals were crushed and sieved, and 2g of dry powder was extracted with acidified methanol to extract its phenolic substances. The total phenolic content was determined by Folin-Schoka method to be 4753.95GAEmg / 100g, NaNO 2- AlCl 3 The total flavonoid content determined by the method was 674.00REmg / 100g, the DPPH free radical scavenging ability...

Embodiment 2

[0040] Quickly peel off the outermost petals of the peonies "big brown and purple" (rose type, deep red) collected in April at the early blooming stage, remove the mud and dirt, keep the 3cm stems, and dry the whole flower. Put the treated peony flowers in the best form into -60°C refrigerator for 24 hours, without squeezing or stacking. Put the pre-cooled peony flowers into the vacuum freeze dryer quickly, set the cold step temperature of -60°C, the vacuum degree of the drying chamber of 0.08MPa, the heating plate temperature of 25°C, the material thickness of 15mm, and dry for 96h (whole flower ). The dried whole flower was crushed and sieved, and 2g of the dry powder was extracted with acidified methanol to extract its phenolic substances. The total phenolic content was determined to be 4442.55GAEmg / 100g, NaNO 2- AlCl 3 The total flavonoid content is 966.06REmg / 100g, the DPPH free radical scavenging ability is 59.41%, and the ABTS+·scavenging ability is 41.97%.

Embodiment 3

[0042] Quickly peel off the outermost petals of the peony "Jingyu" (crown type, white) collected in April at the early blooming stage to remove the mud. Carefully peel off the petals with tweezers, keeping the petals intact. Put the processed peony petals in the best shape into the -40°C refrigerator for 24 hours, without squeezing or stacking. Put the pre-cooled peony flowers into the vacuum freeze dryer quickly, set the cold step temperature of -60°C, the vacuum degree of the drying chamber of 0.09MPa, the temperature of the heating plate of 16°C, the material thickness of 9mm, and dry for 48h (petals) . The dried petals were crushed and sieved, and 2g of the dry powder was extracted with acidified methanol to extract its phenolic substances. The total phenolic content was determined by Folin-Schoka method to be 3425.62GAEmg / 100g, NaNO 2- AlCl 3 The total flavonoid content determined by the method was 440.15REmg / 100g, the DPPH free radical scavenging ability was 64.87%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com