Ammonia gas drying system for liquid ammonia mercerizing machine

A liquid ammonia mercerizing and drying system technology, applied in mercerizing, removing liquid/gas/vapor, textiles and papermaking, etc., can solve the problems of mixing danger, easy hardening of fabric surface, waste of energy, etc., and improve utilization rate , enhance conversion, and reduce burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

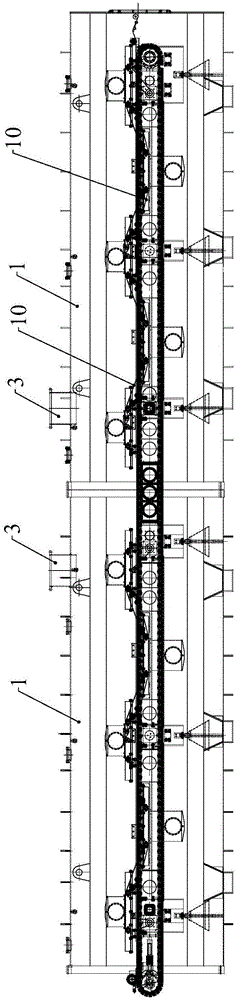

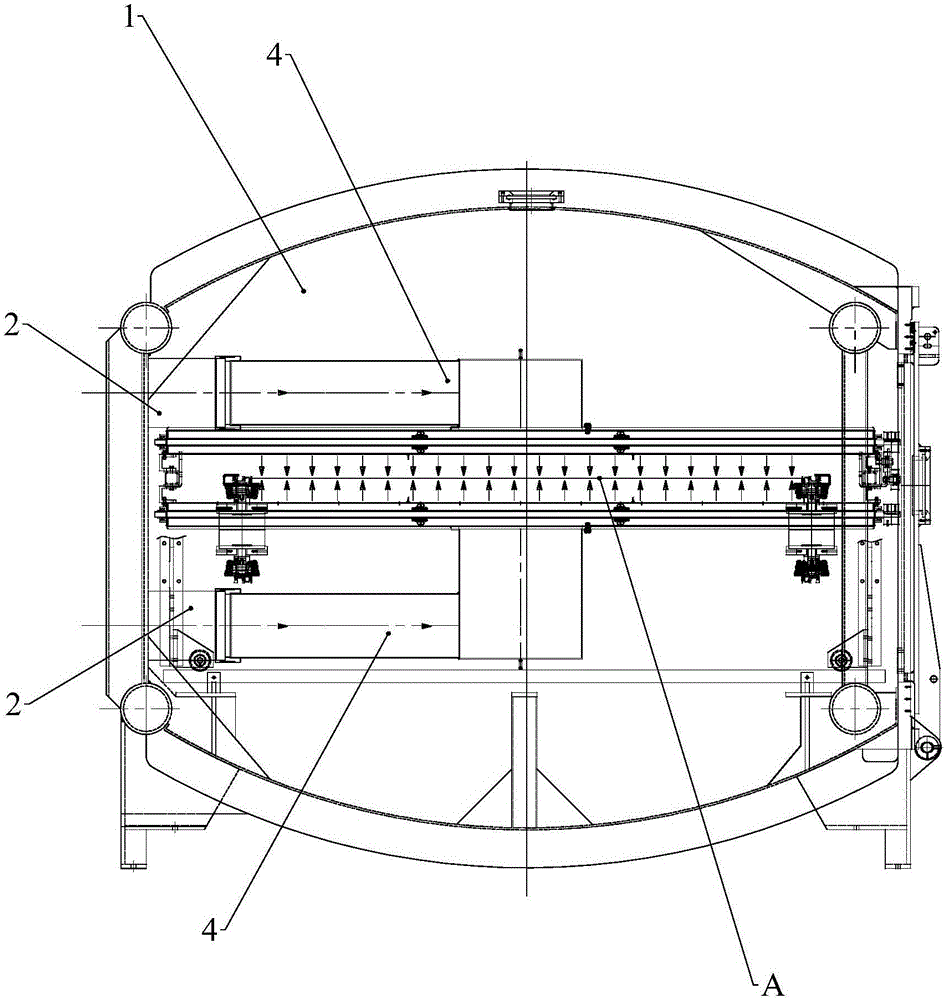

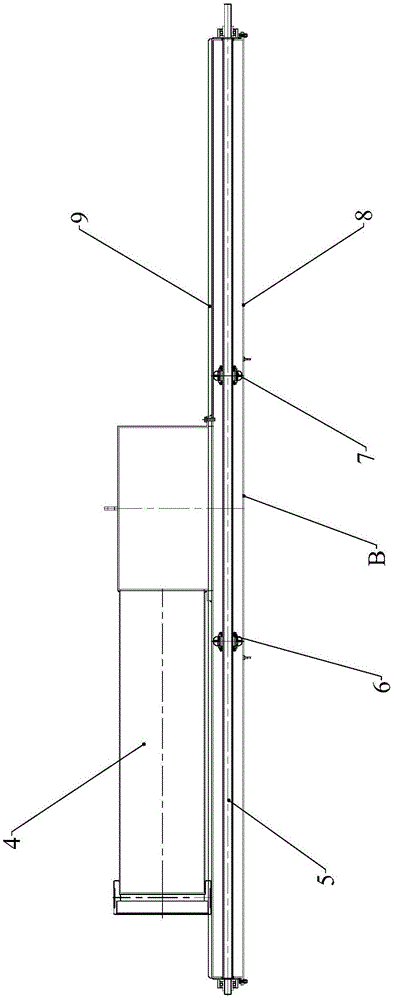

[0019] refer to Figure 1 to Figure 3 , this embodiment includes several sets of upper and lower ammonia gas heating systems arranged in a staggered arrangement along the fabric conveying direction in the drying tank 1, and the drying tank is provided with a high-temperature ammonia gas inlet 2 and an exhaust port through which the heated ammonia gas is discharged 3. Each set of ammonia heating system includes a high-temperature ammonia gas delivery channel 4, an adjustment screw 5, adjustment beams 6, 7 and a breathable plate 8, the breathable plate is made of stainless steel; the adjustment beam is set between the breathable plate and the high-temperature ammonia gas delivery Between the support covers 9 of the channel, the upper and lower sides of the adjustment beam are respectively connected with the air-permeable plate and the support cover in flexible sealing contact; the adjustment screw between each set of ammonia heating systems is synchronously driven by the synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com